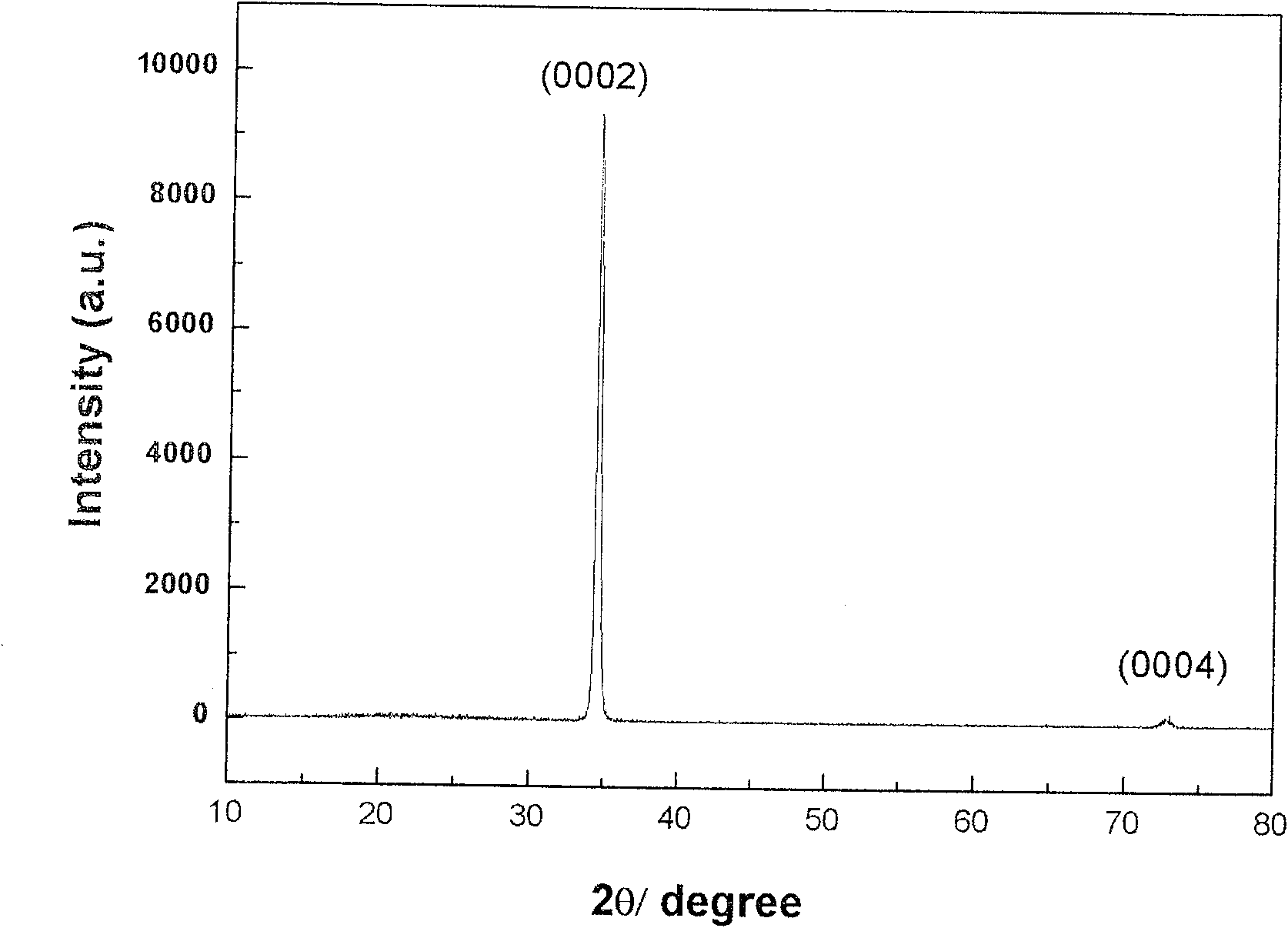

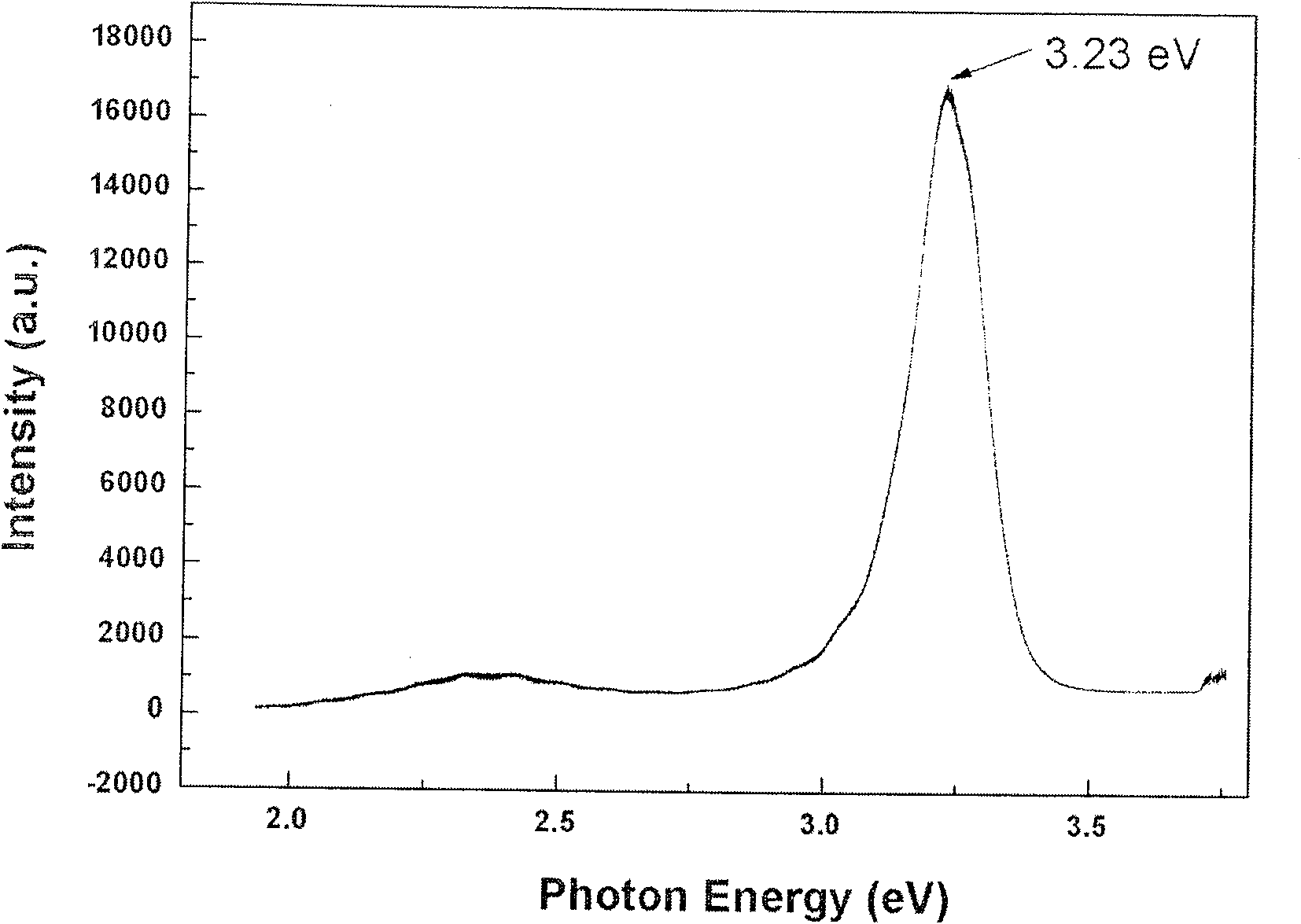

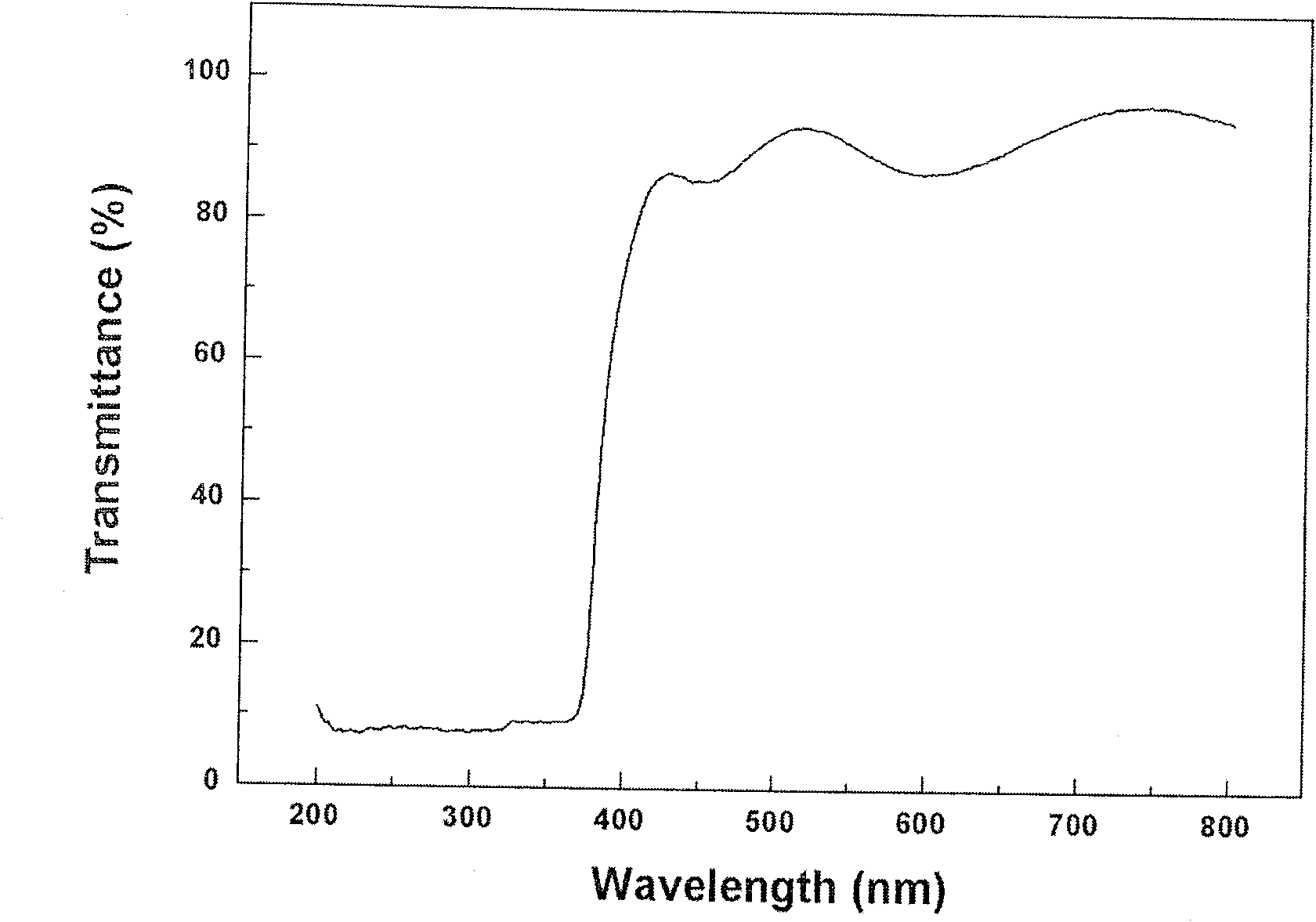

Method for growing Na doping p type ZnO crystal thin film

A crystal and thin film technology, applied in the field of growth of p-type ZnO crystal thin films, to achieve the effect of good electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1) get the zinc oxide and sodium carbonate powder that purity is 99.99%, and Na molar content is 0.5%, ZnO and Na 2 CO 3 Pour the mixed powder into an agate ball cup, put it on a ball mill and carry out ball milling, and the time of ball milling is four hours. There are two purposes of ball milling: the first is to combine ZnO, Na 2 CO 3 The powder is mixed evenly to ensure the uniformity of the prepared target. Secondly, in order to combine ZnO and Na 2 CO 3 Powder refinement for subsequent ZnO and Na 2 CO 3 Forming and sintering of mixed powders.

[0020] After ball milling, the powder was pressed into discs with a thickness of 3 mm and a diameter of 4 cm. Then pre-sintered at 800°C for 2 hours and sintered at 1250°C for 3 hours to ensure that Na 2 CO 3 decomposition.

[0021] 2) Using quartz as the substrate, clean the surface of the substrate and put it into the growth chamber of the pulsed laser deposition device. The vacuum degree of the growth chamber ...

Embodiment 2

[0027] 1) get the zinc oxide and sodium carbonate powder that the purity is 99.99%, the Na molar content is 1.0%, ZnO and Na 2 CO 3 Pour the mixed powder into an agate ball cup, put it on a ball mill and carry out ball milling, and the time of ball milling is four hours. After ball milling, the powder was pressed into discs with a thickness of 3 mm and a diameter of 4 cm. Then pre-sinter at 600°C for 2 hours and sinter at 1400°C for 3 hours.

[0028] 2) Take glass as the substrate, clean the substrate surface and put it into the growth chamber of the pulsed laser deposition device, and the vacuum degree of the growth chamber is pumped to 5×10 -3 Pa, and then heat the substrate so that the substrate temperature is 550°C to dope Na 2 The ZnO of O is used as the target, the distance between the substrate and the target is adjusted to 5cm, and the pure O 2 For the growth atmosphere, control O 2 The pressure is 30pa, the laser frequency is 3Hz, and the laser operating voltage ...

Embodiment 3

[0031] 1) get zinc oxide and sodium carbonate powder with a purity of 99.99%, the Na molar content is 0.2%, ZnO and Na 2 CO 3 Pour the mixed powder into an agate ball cup, put it on a ball mill and carry out ball milling, and the time of ball milling is four hours. After ball milling, the powder was pressed into discs with a thickness of 3 mm and a diameter of 4 cm. Then pre-sinter at 600°C for 2 hours and sinter at 1400°C for 3 hours.

[0032] 2) Take glass as the substrate, clean the substrate surface and put it into the growth chamber of the pulsed laser deposition device, and the vacuum degree of the growth chamber is pumped to 5×10 -3 Pa, and then heat the substrate so that the substrate temperature is 700°C to dope Na 2 The ZnO of O is used as the target, the distance between the substrate and the target is adjusted to 5cm, and the pure O 2 For the growth atmosphere, control O 2 The pressure is 30pa, the laser frequency is 3Hz, and the laser operating voltage is 27K...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com