A kind of preparation method of phosphorus-doped zinc oxide thin film

A technology of zinc oxide thin film and phosphorus doping, which is applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of high preparation conditions, complicated preparation process, and small number of zinc vacancies occupied by phosphorus atoms. Achieve the effect of improved structural performance, simple and easy method, and excellent consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

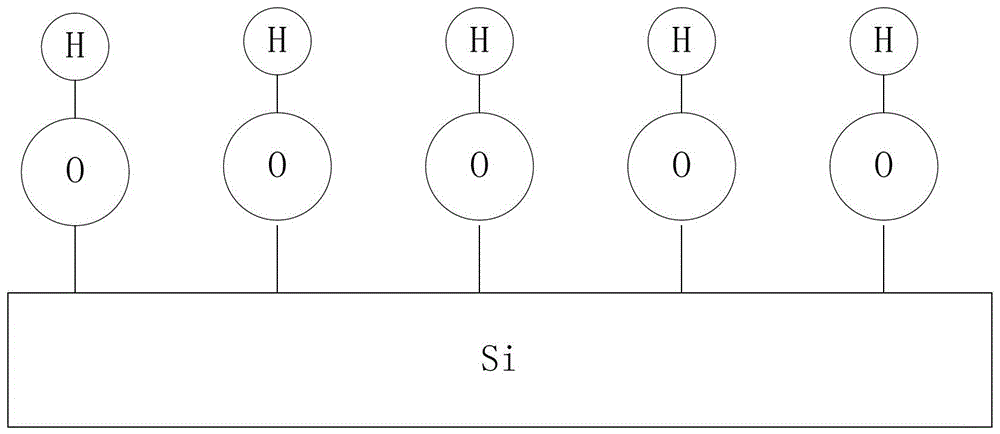

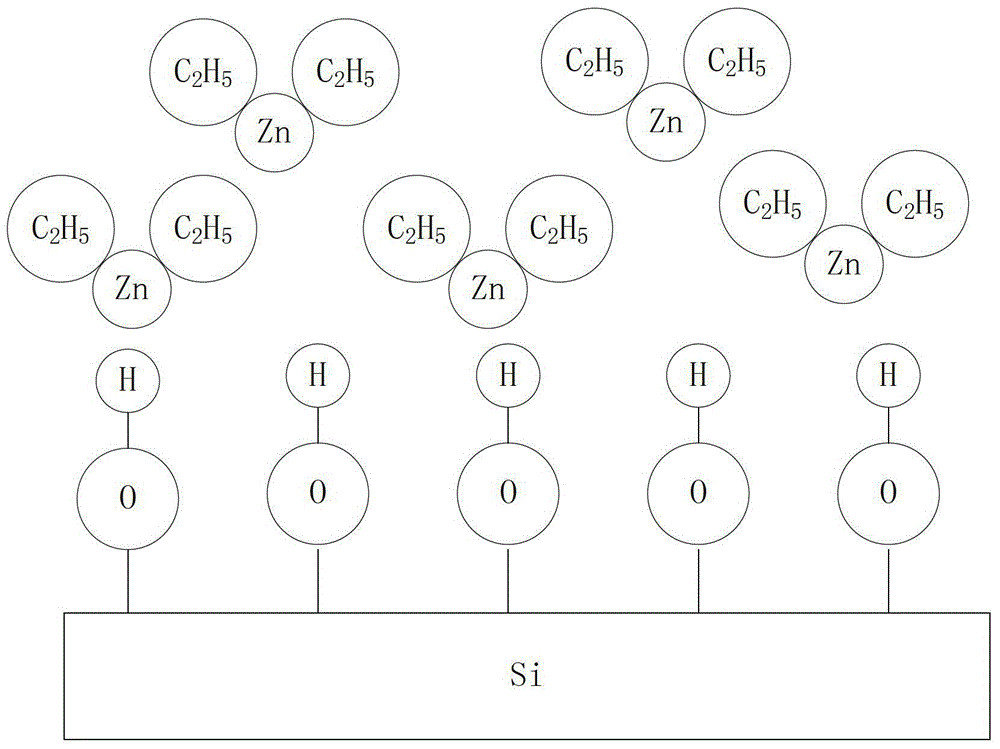

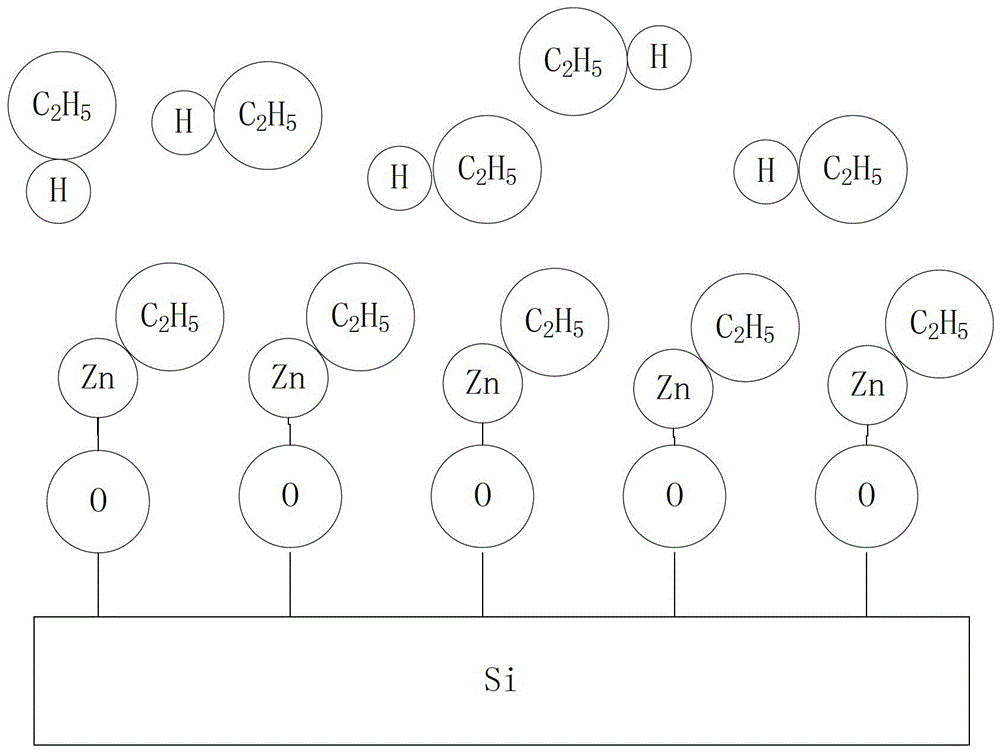

[0016] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0017] see Figure 7 , the embodiment of the present invention provides a method for preparing a phosphorus-doped zinc oxide film, which can simply realize the doping of phosphorus atoms in the zinc oxide film, the prepared film doping layer is controllable, and the uniformity of the film is relatively high. High, complete performance, including the following steps:

[0018] Step 101: Clean the surface of the silicon substrate by RCA standard cleaning method, and place the silicon substrate in the reaction chamber of the atomic layer deposition equipment after cleaning.

[0019] The RCA standard cleaning method mainly includes the following cleaning solutions: 1) SPM: composed of concentrated sulfuric acid and hydrogen peroxide, concentrated sulfuric acid: hydrogen peroxide = 4:1 (volume ratio); 2) hydrofluoric acid; 3) APM (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com