Patents

Literature

46 results about "Unintentional doping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

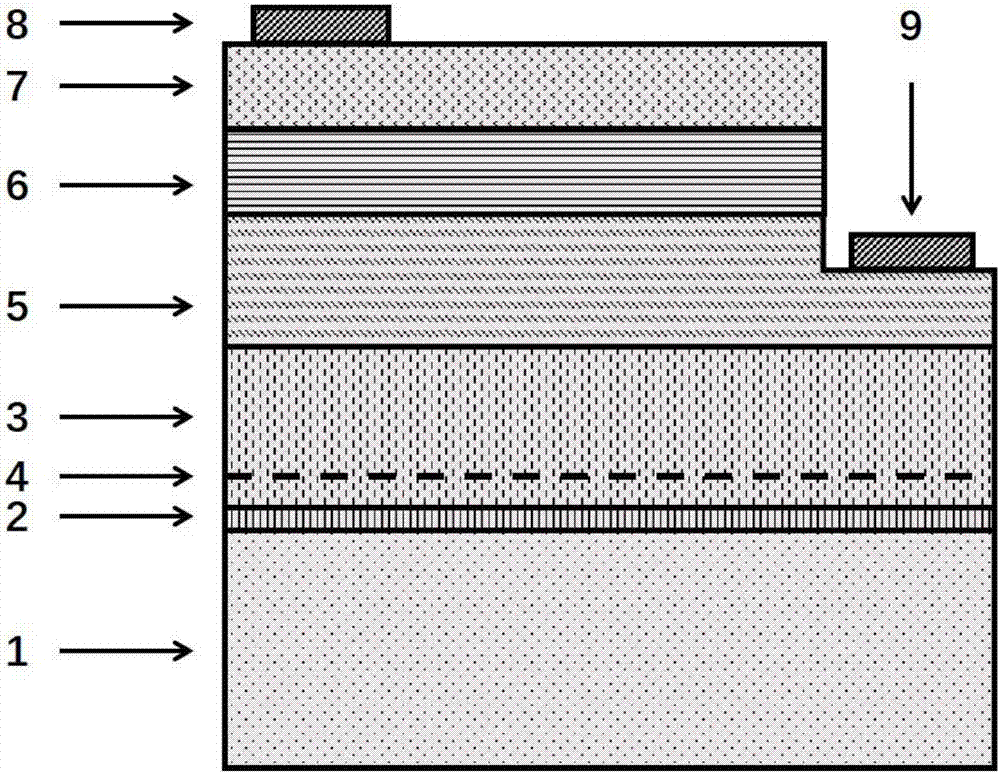

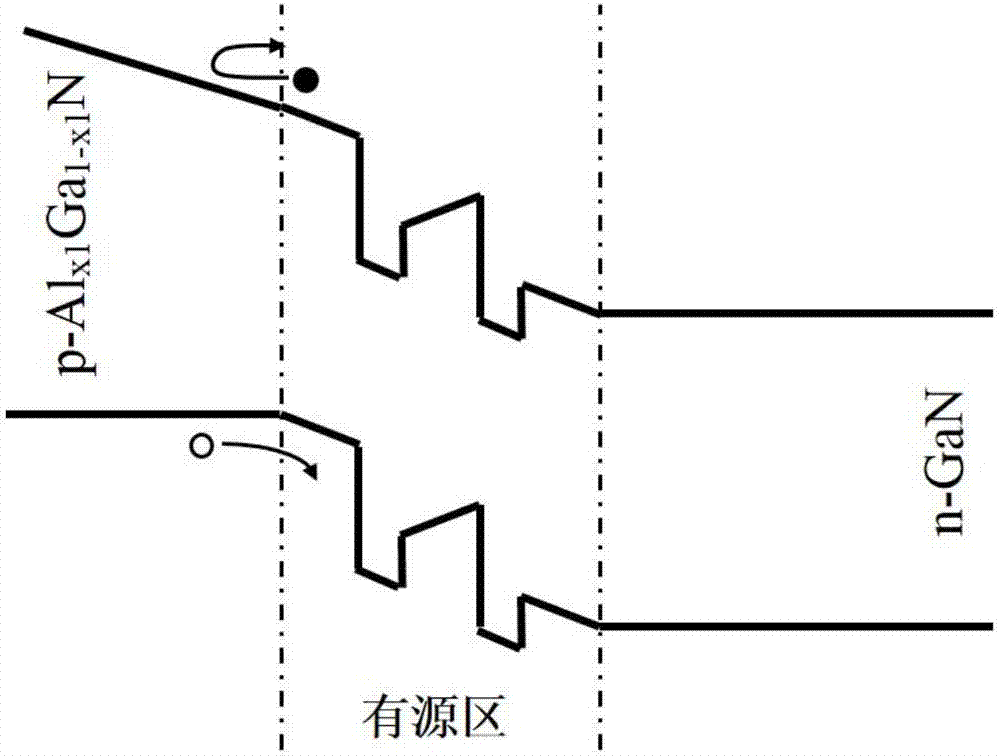

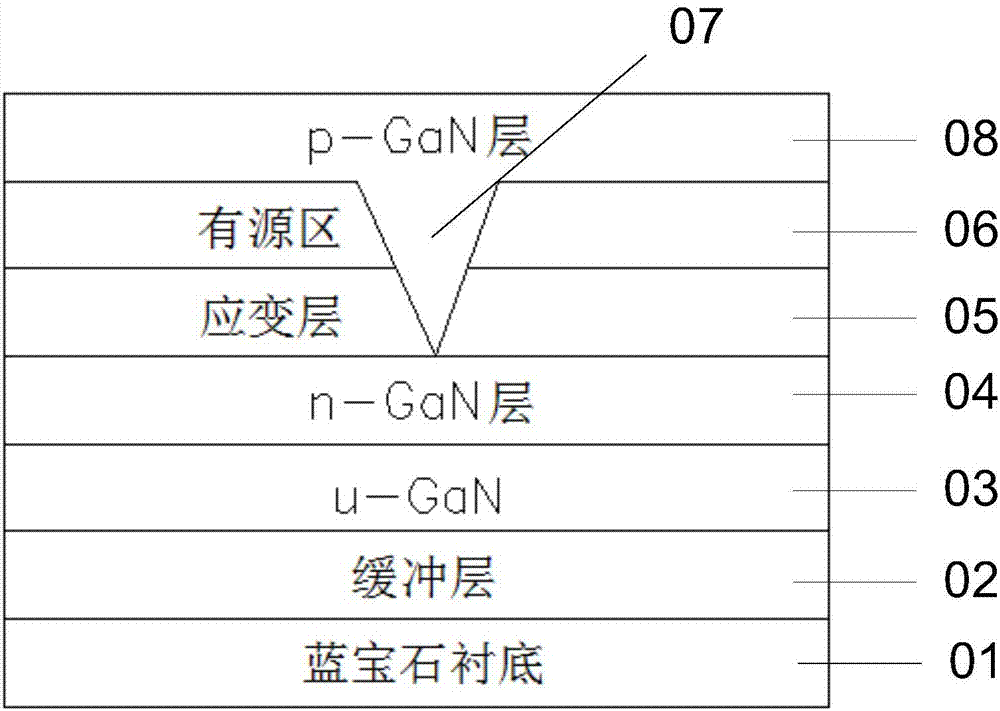

Nitrogen-containing polar blue-violet LED chip with polarization-induced p-type doping layer and preparation method

ActiveCN107978661AReduce dislocation densityReduce concentrationSemiconductor devicesDislocationElectron

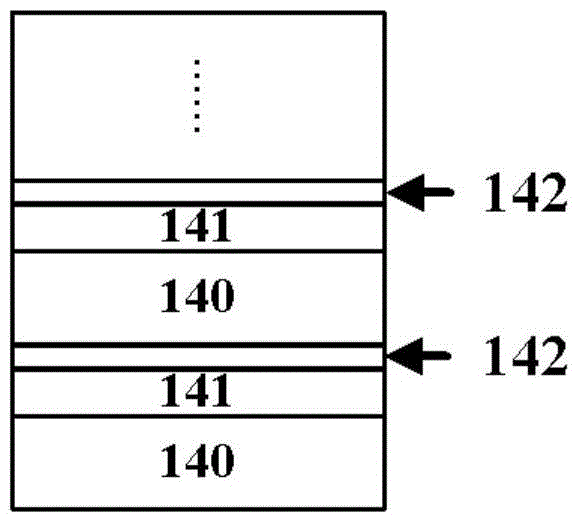

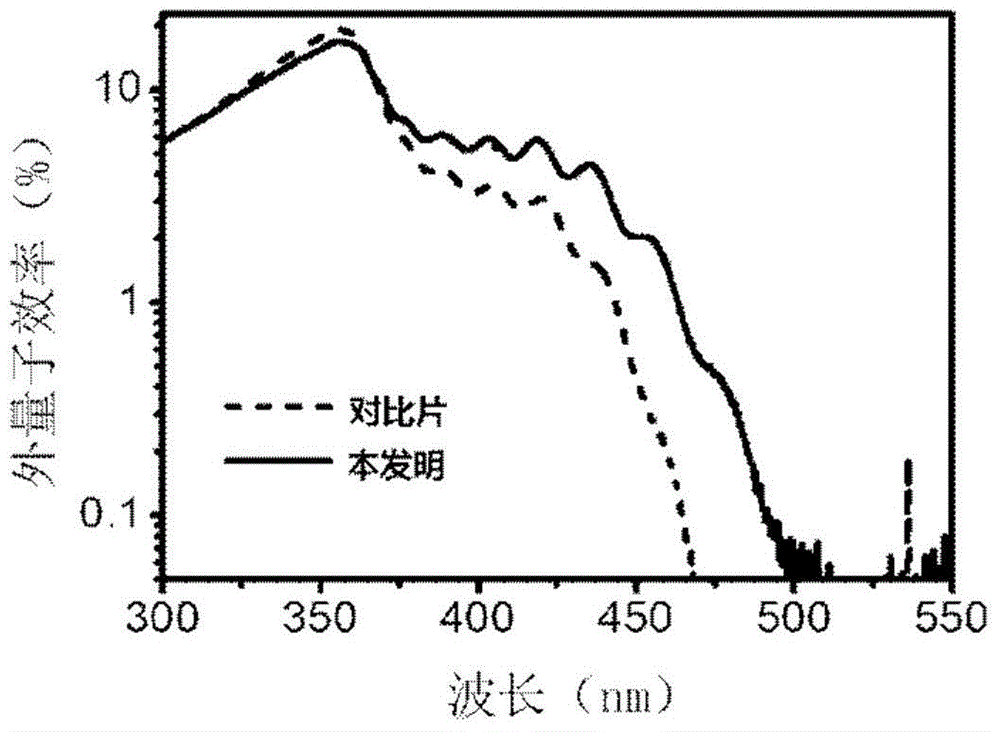

The invention relates to a nitrogen-containing polar blue-violet LED chip with a polarization-induced p-type doping layer and a preparation method, and belongs to the technical field of semiconductorlight emitting devices. The nitrogen-containing polar blue-violet LED chip is composed of a (0001) surface sapphire substrate, a low-temperature GaN buffer layer, a nitrogen-containing polar GaN template layer, an n-GaN electron injecting layer, a multi-quantum well active layer and a polarization-induced p-type doping hole injecting layer, the nitrogen-containing polar GaN template layer is inside provided with a SiNx mask layer, the polarization-induced p-type doping hole injecting layer is provided with a p electrode, and the n-GaN electron injecting layer has a bare bench, and an n electrode is arranged on the bare bench. According to the invention, the beveled sapphire substrate is improved, and the crystal quality and the surface evenness of an epitaxial wafer are improved; the SiNxmask layer is inserted into the nitrogen-containing polar GaN template layer in an in-situ manner, dislocation is effectively blocked, the concentration of unintentional doping is reduced, and the internal quantum efficiency is improved; Mg-doped AlGaN of which the Al component is linearly increased is employed to make the polarization-induced p-type doping hole injecting layer, the hole concentration is increased, the electron injecting efficiency is improved.

Owner:上海镓旦电子信息有限公司

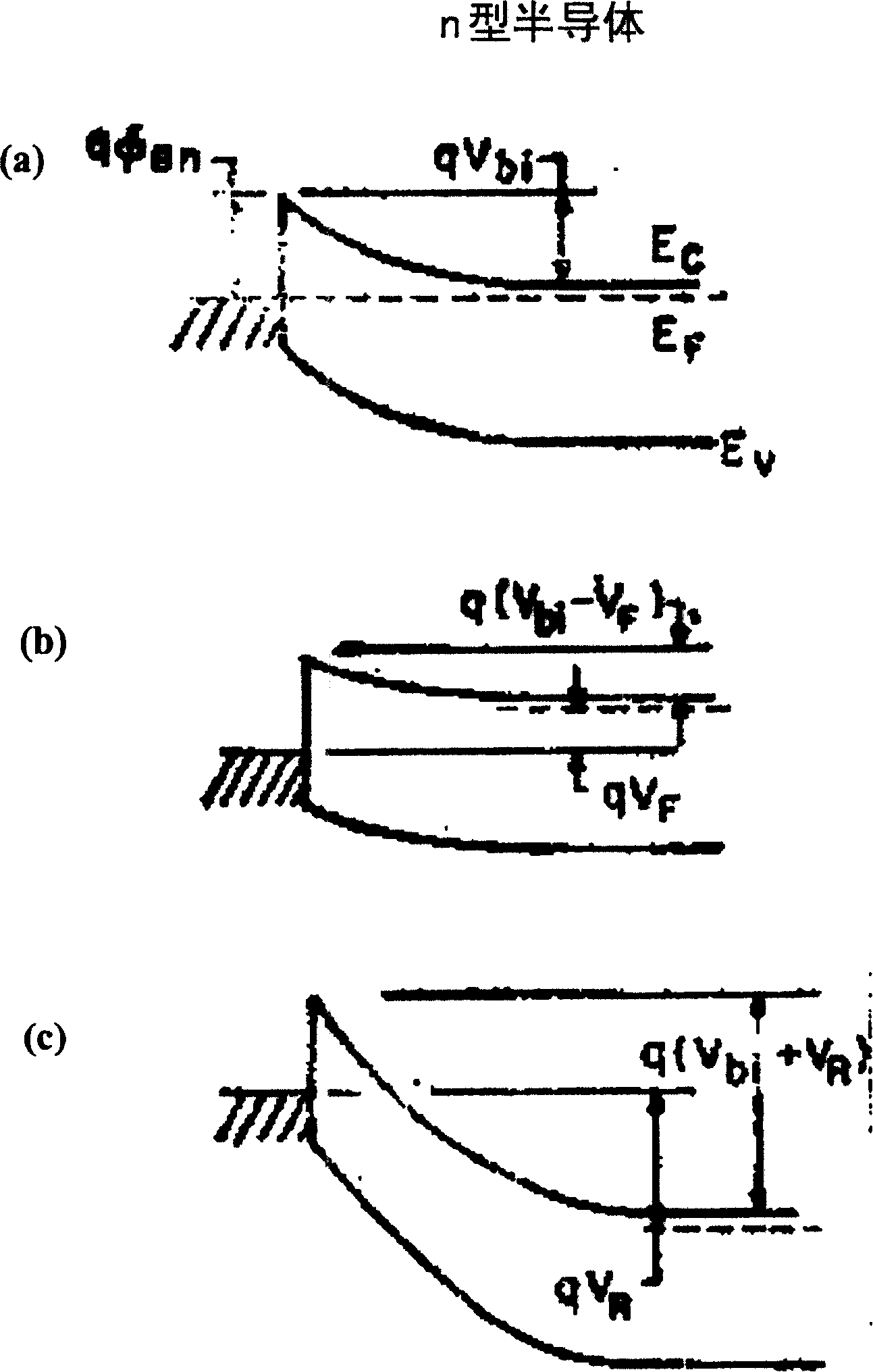

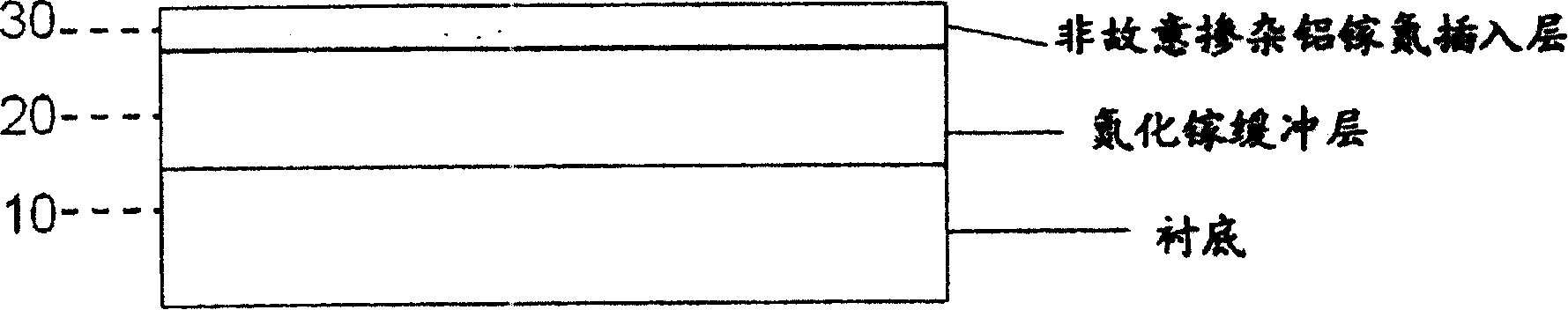

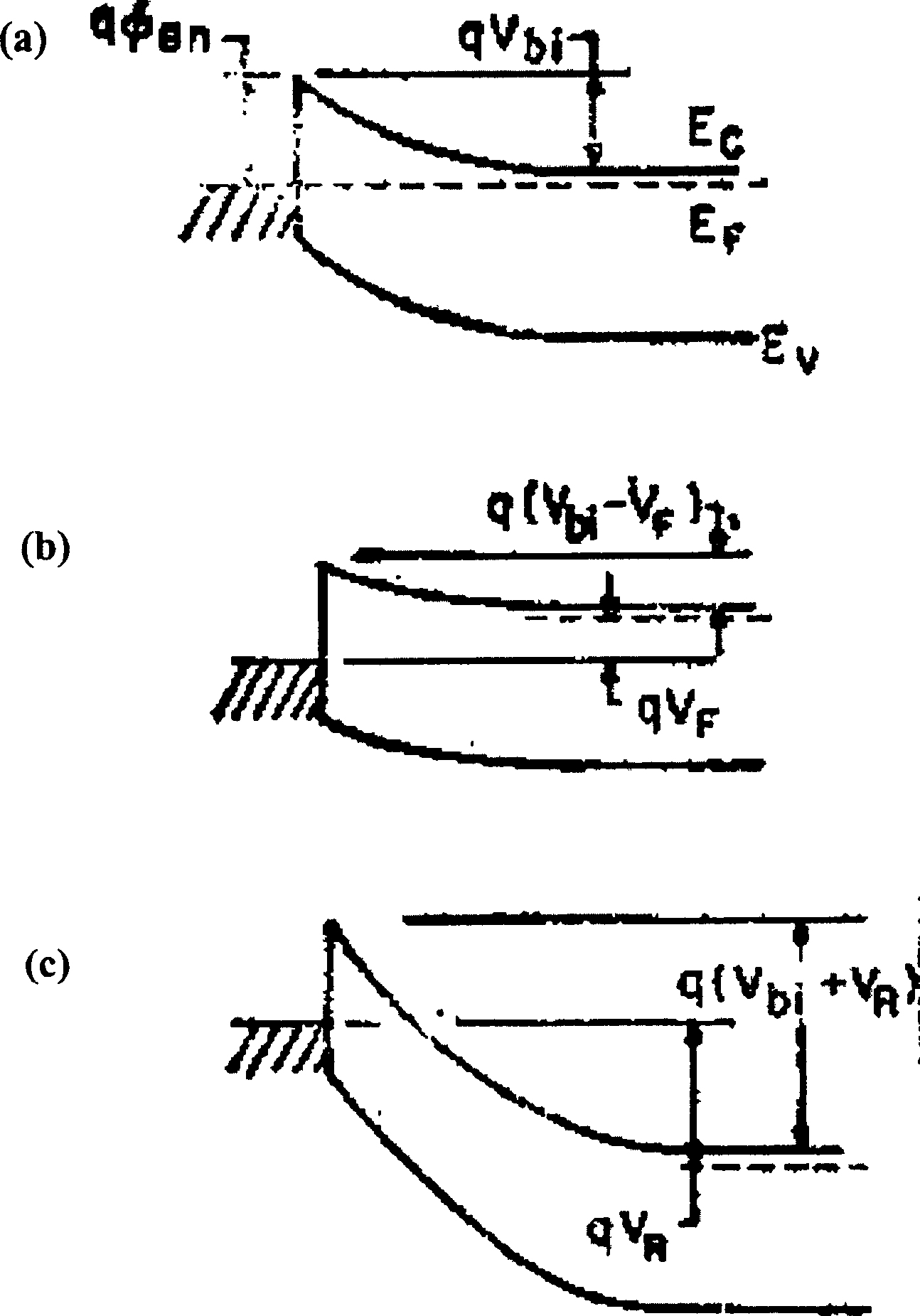

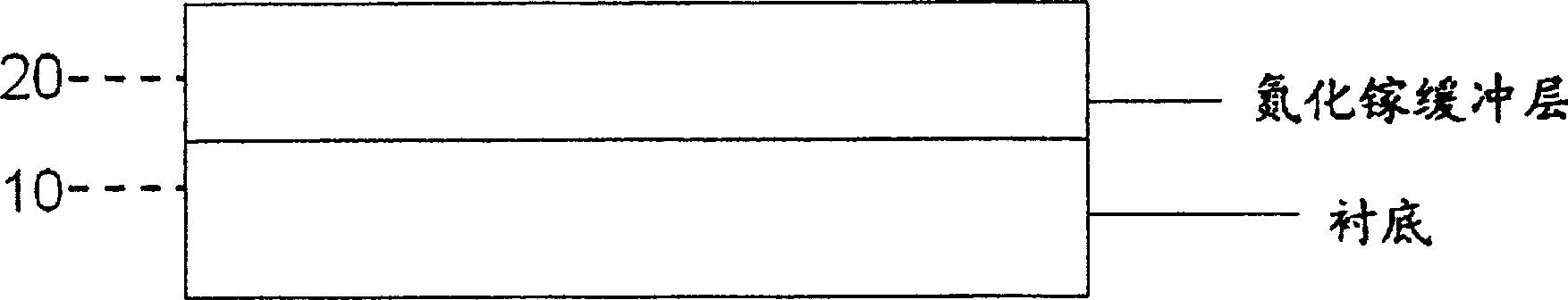

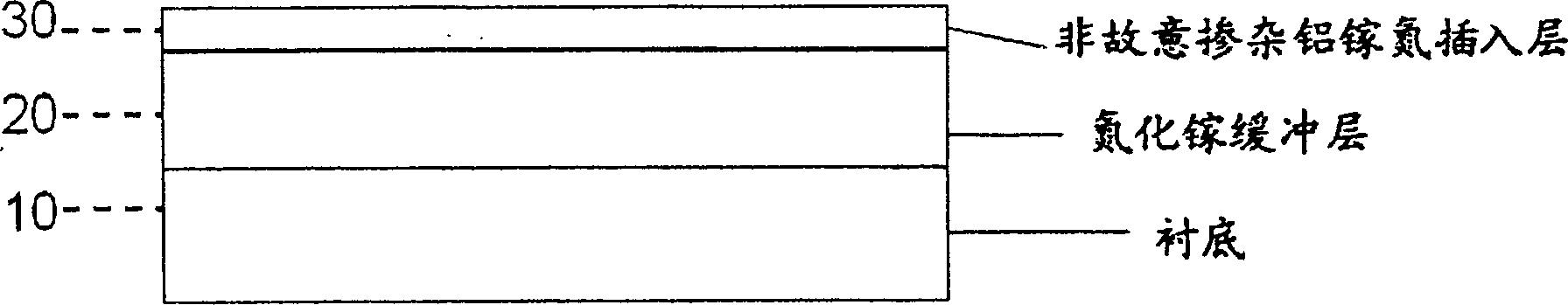

Structure for improving Schottky performance of grid electrode of gallium nitride based transistor in high electron mobility

InactiveCN1797787AReduce leakageIncreased output current capabilitySemiconductor/solid-state device manufacturingSemiconductor devicesGallium nitrideResistor

The structure is as following: a sapphire substrate or silicon carbide substrate or silicon substrate; buffer layer of gallium nitride in high-ohmic resistor prepared on substrate; an interposed layer of unintentional doping aluminum ¿C gallium - nitrogen in thin layer prepared on buffer layer of gallium nitride in high-ohmic resistor; a channel layer of gallium nitride in high mobility prepared on the interposed layer of unintentional doping aluminum ¿C gallium ¿C nitrogen; a spatial isolation layer of unintentional doping aluminum ¿C gallium ¿C nitrogen prepared on the channel layer of gallium nitride in high mobility; n type supply layer of aluminum ¿C gallium ¿C nitrogen carrier prepared on the spatial isolation layer of unintentional doping aluminum ¿C gallium ¿C nitrogen; an unintentional doping aluminum ¿C gallium ¿C nitrogen covering cap layer prepared on n type supply layer of aluminum ¿C gallium ¿C nitrogen carrier.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

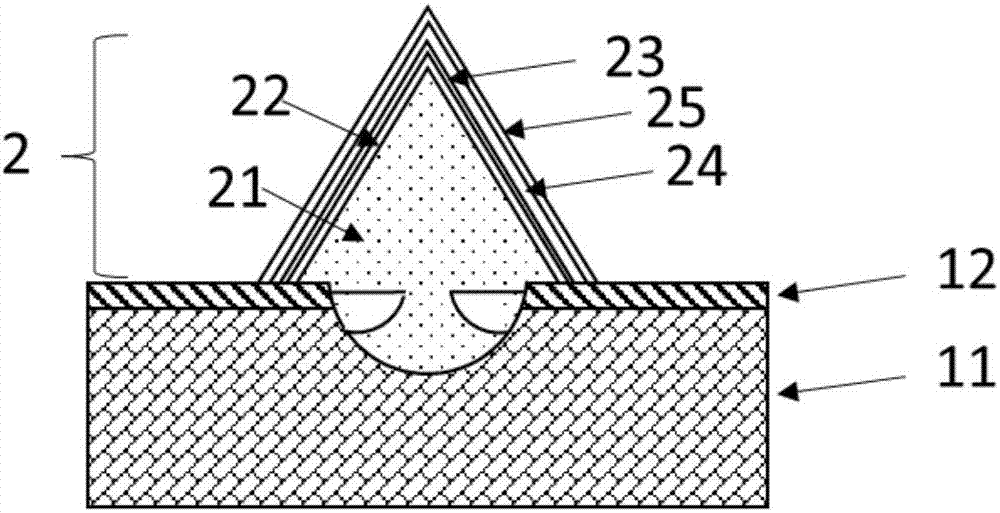

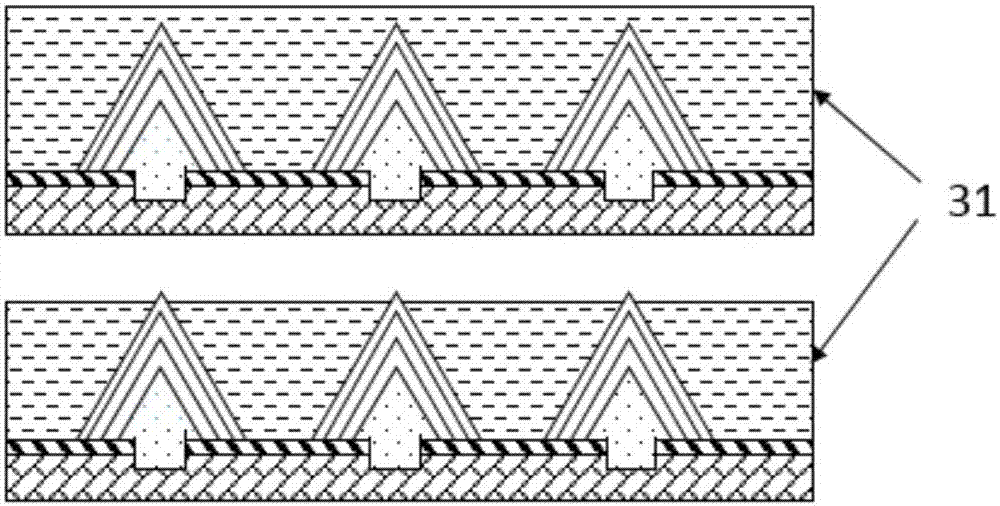

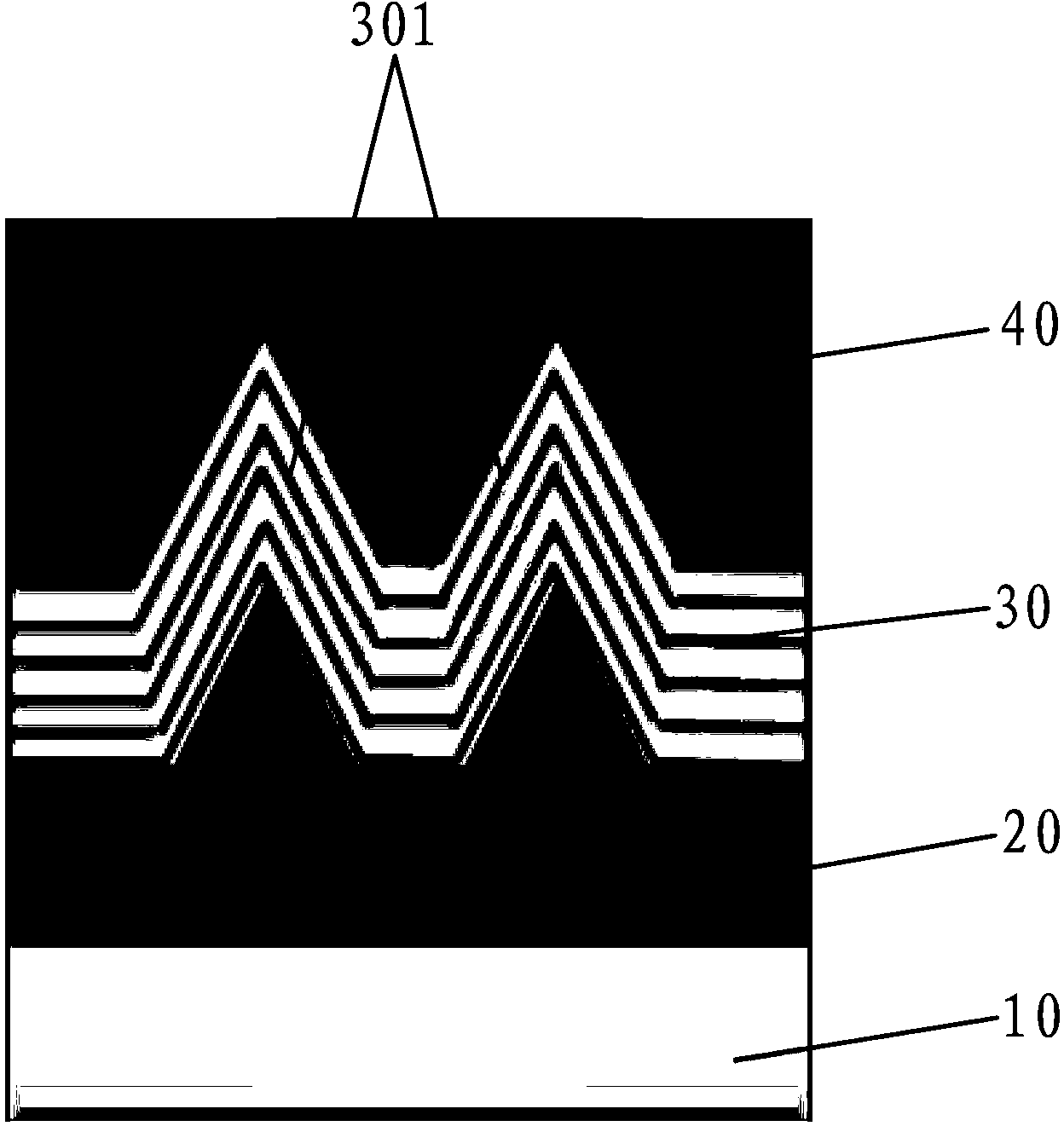

Super flexible nitride-based pyramid structure semiconductor device and preparation method thereof

InactiveCN107482088AImprove efficiencyUnlimited sizeSemiconductor devicesQuantum wellDevice material

The invention discloses a super flexible nitride-based pyramid structure semiconductor device and a preparation method thereof; the semiconductor device comprises a flexible substrate, a conductive bonding layer, a SiO2 mask layer, a pyramid array and a P-surface transparent electrode arranged in order from bottom to top; an insulation filler is filled between pyramids in the pyramid array; each pyramid in the array comprises a pyramid structure unintentional doping gallium nitride, and a n-type gallium nitride layer, a quantum well layer, a p-type gallium nitride layer and a transparent conductive layer covering the unintentional doping gallium nitride in order; the bottom of the unintentional doping gallium nitride penetrates the SiO2 mask layer and is connected with the conductive bonding layer; the top of the transparent conductive layer is connected with the P-surface transparent electrode; the semiconductor device is not limited in size, high in flexibility, and the preparation method is simple, convenient and easy to realize.

Owner:XI AN JIAOTONG UNIV

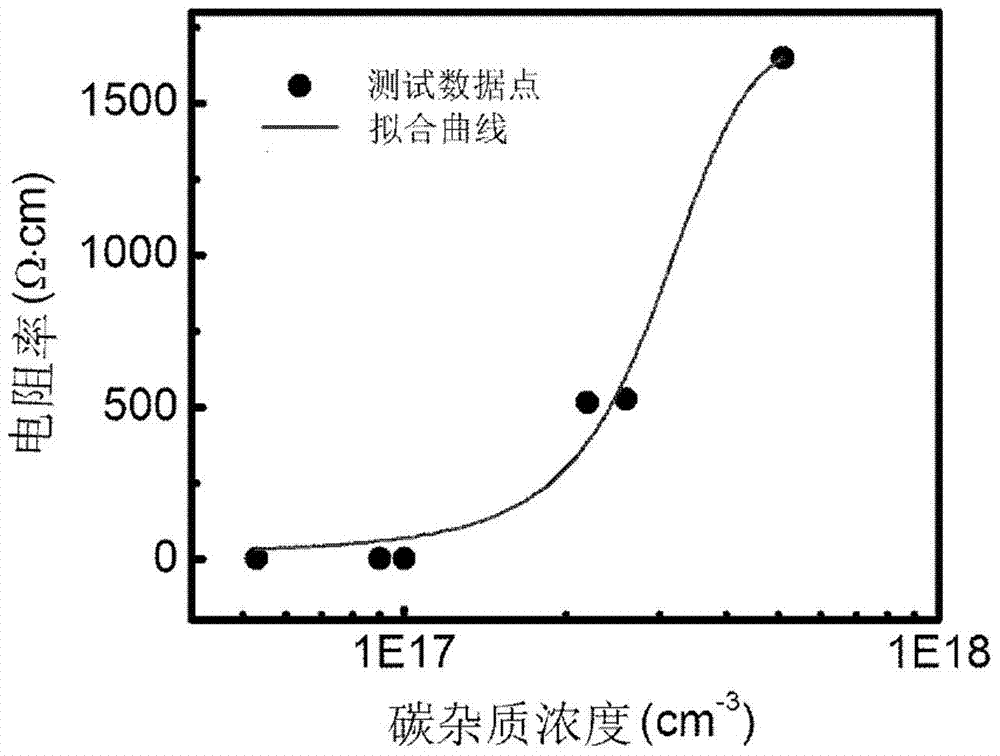

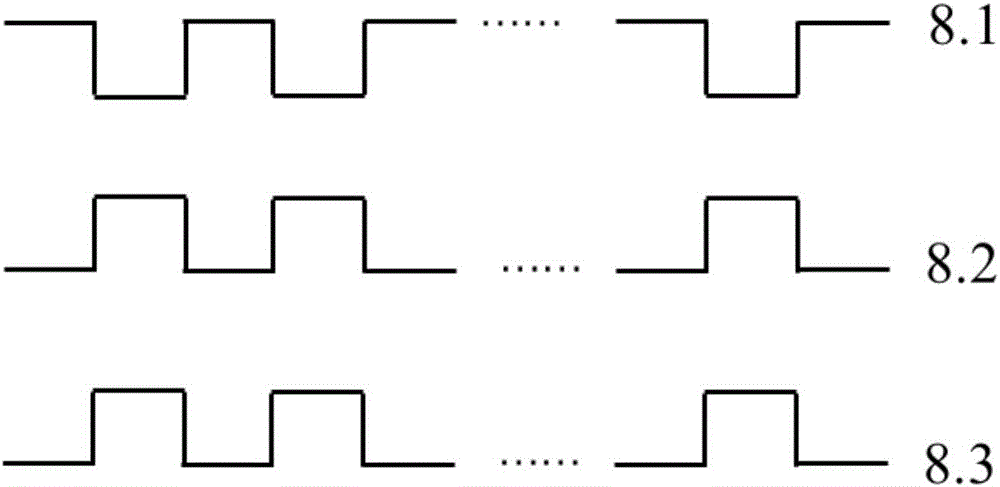

HEMT structure with modulated carbon-doped gallium nitride high-resistance layer and preparation method of structure

PendingCN106653839AExtend your lifeImprove reliabilitySemiconductor/solid-state device manufacturingSemiconductor devicesHeterojunctionHigh resistance

The invention discloses an HEMT structure with a modulated carbon-doped gallium nitride high-resistance layer and a preparation method of the structure. The HEMT structure comprises a substrate, a GaN nucleating layer, a GaN buffer layer, a GaN:C / GaN superlattice high-resistance layer and an AlGaN barrier layer from bottom to top successively, the high-resistance layer is formed by connecting GaN:C intentional doping layers and unintentional doping GaN layers alternatively, the thickness of the single GaN:C intentional doping layer is 5-500nm, and the thickness of the single unintentional doping GaN layer is 5-500nm. GaN:C / GaN superlattices can improve the resistance of a gallium nitride material but not reduce the crystal quality, and the high voltage withstanding characteristic, reliability and service life of a GaN / AlGaN heterojunction HEMT device can be improved.

Owner:SOUTH CHINA UNIV OF TECH

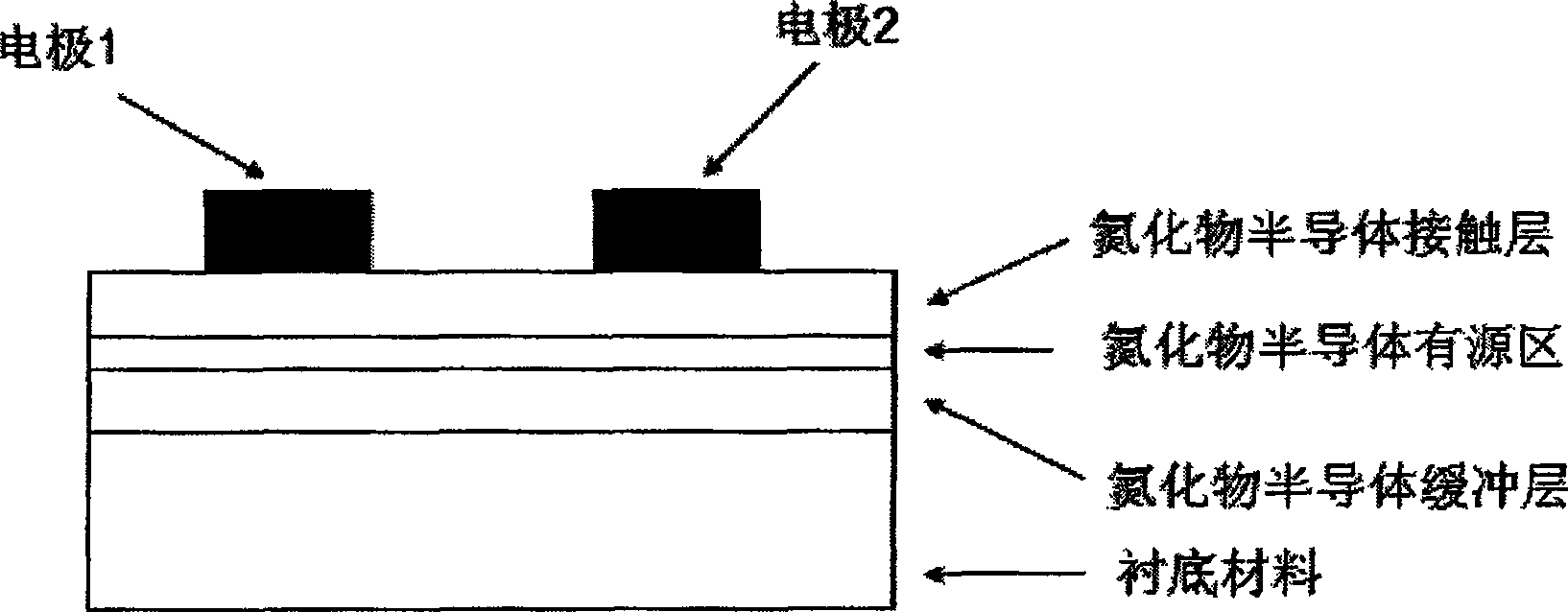

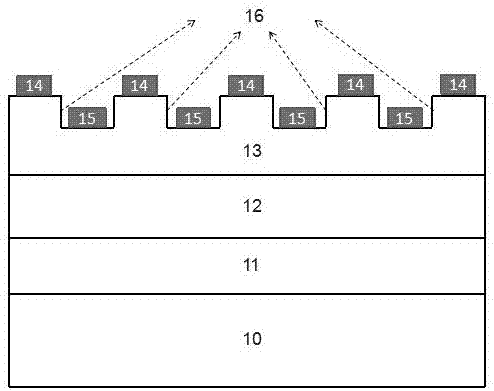

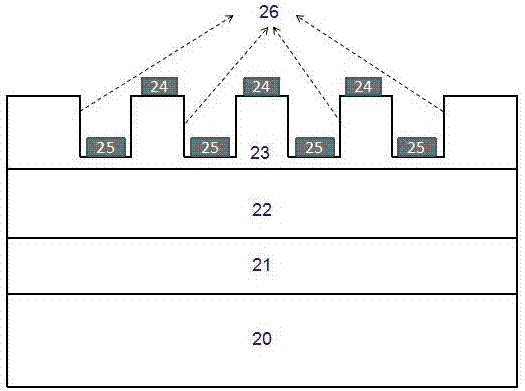

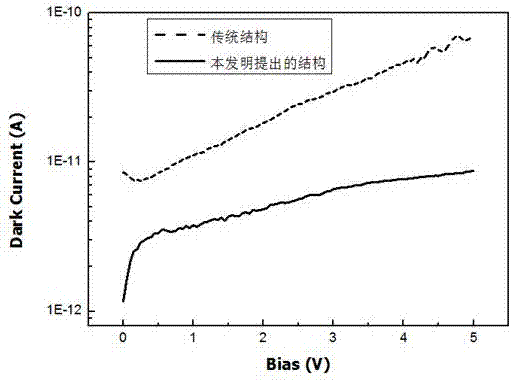

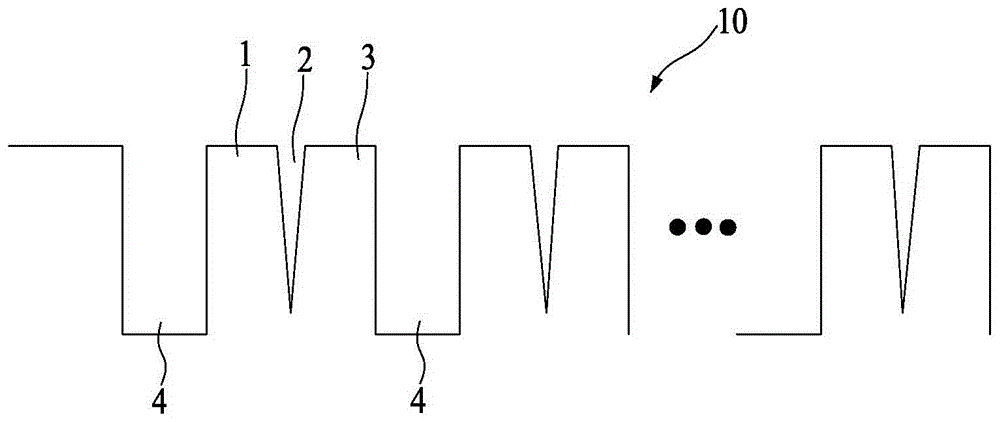

InGaN-based MSM visible light photoelectric detector with groove-type electrode structure

ActiveCN107482070AReduce dark currentImprove electric field distributionSemiconductor devicesPhotovoltaic detectorsOptoelectronics

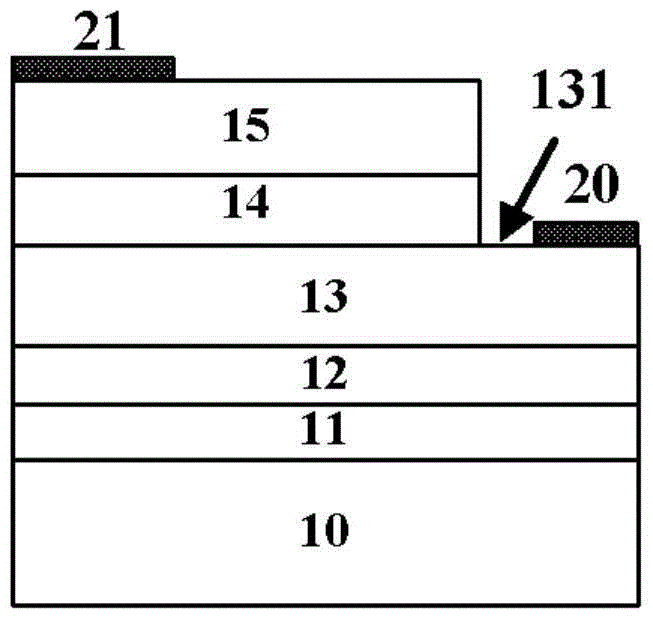

The invention discloses an InGaN-based MSM visible light photoelectric detector with a groove-type electrode structure. The device structure comprises a substrate (10) and an epitaxial layer growing on the substrate (10), wherein the epitaxial layer includes, sequentially from bottom to top, a buffer layer (11), a transition layer (12), an unintentional doping InxGa1-xN active layer (13), and an inserting-finger-shaped electrode (14) and an inserting-finger-shaped electrode (15), which have a schottky metal-semiconductor-metal (MSM) device structure and are coated on an InxGa1-xN active layer (13), wherein the electrode (14) is deposited on the surface of a primordial InxGa1-xN(13), and the electrode (15) is deposited in an inserting-finger-shaped groove (16). The groove (16) is formed on the active layer (13) through etching by a dry method or wet method. Compared with a conventional planar MSM structure, An InGaN-based MSM visible light photoelectric detector with a groove-type electrode structure uses groove sidewall to block leakage current of carriers due to range transition of InGaN original surface, thereby substantially reducing the dark current of the detector. The groove electrode improves the field distribution between electrodes, thereby effectively improving photoelectric current.

Owner:SUN YAT SEN UNIV

Broadband efficient GaN-based LED chip based on surface plasma effect and preparation method thereof

ActiveCN106784221AIncrease current densityEnough thicknessNanotechnologySemiconductor devicesQuantum wellCoupling

The invention discloses a broadband efficient GaN-based LED chip based on surface plasma effect and a preparation method thereof. The broadband efficient GaN-based LED chip is an inversion structure, and successively comprises a substrate, a buffer layer, an unintentional doping GaN layer, a n-GaN layer, a quantum well layer, an electronic barrier layer, a p-GaN layer, a metal reflector layer, a passivation layer, a p-electrode layer, a n-electrode layer, a p-electrode hole and a n-electrode hole from bottom to top. The bottom face, connected with the surface of the p-GaN layer, of the metal reflector layer is provided with a micron-nano compound metal structure. The micron metal structure comprises alternately installed bulge part and groove part. The bulge part is extended to the adjacent place of the quantum well, and the efficient SP-MQW coupling is realized. The p-GaN surface is covered by the groove part, so the p-GaN layer has enough thickness for injecting the hole. The nano-metal structure is distributed on the division surface of the micron-metal structure and the p-GaN.

Owner:SOUTH CHINA UNIV OF TECH

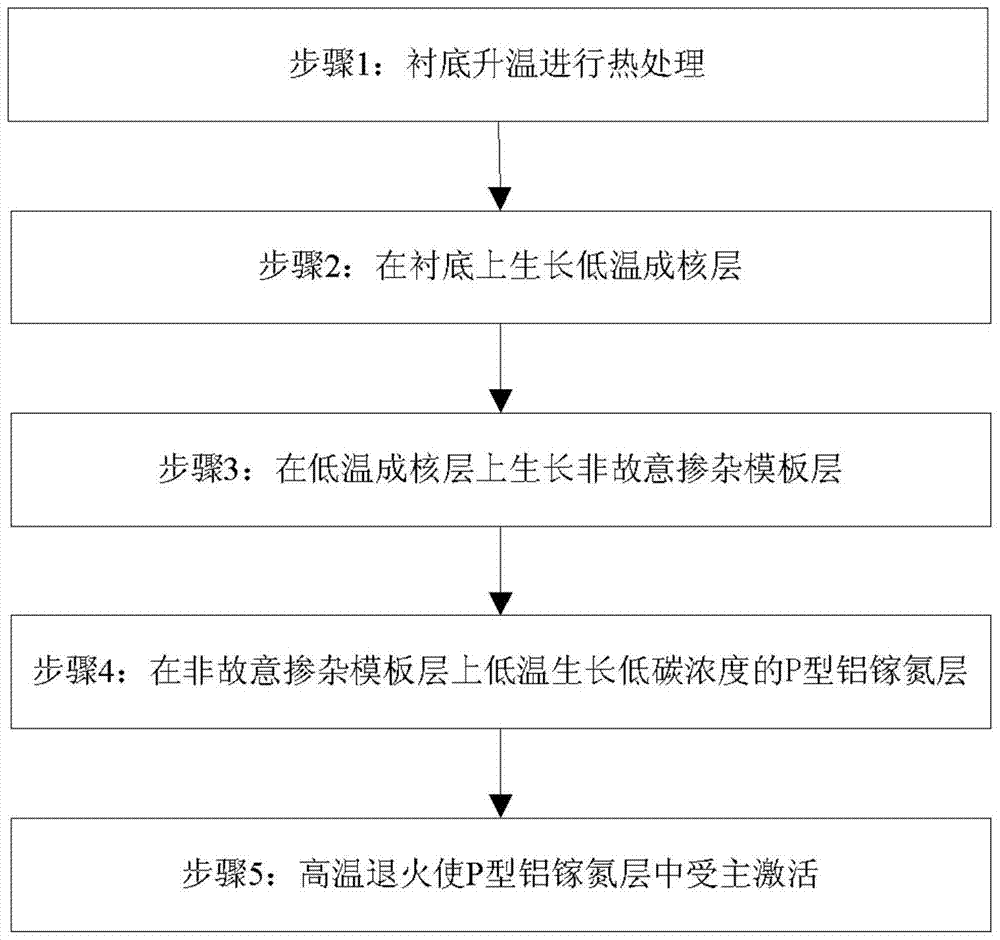

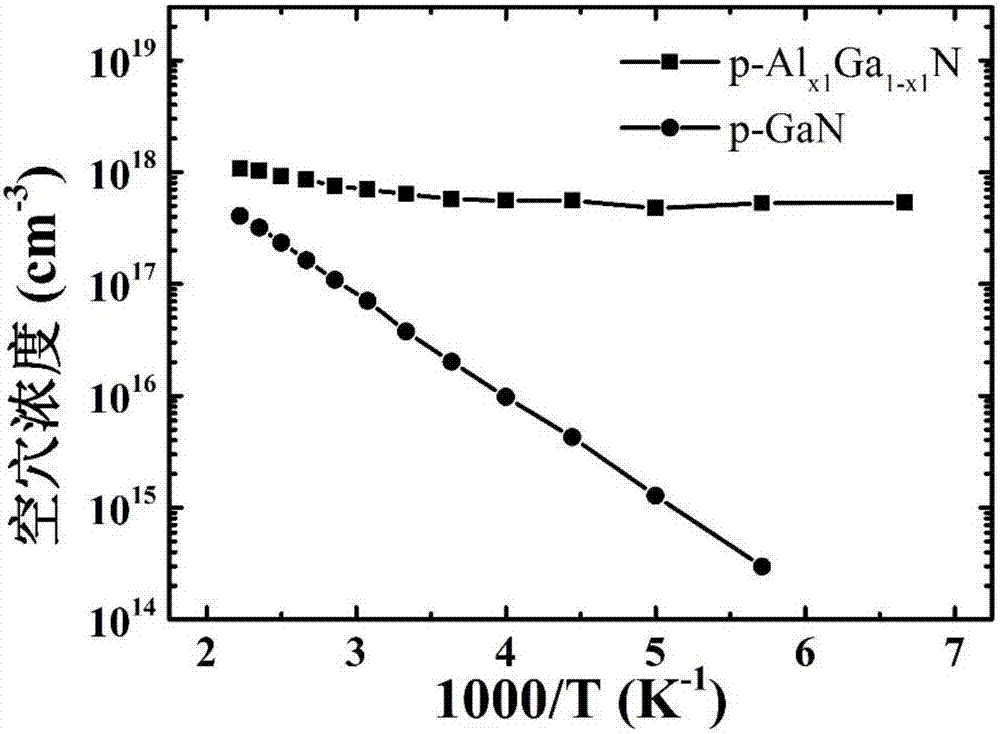

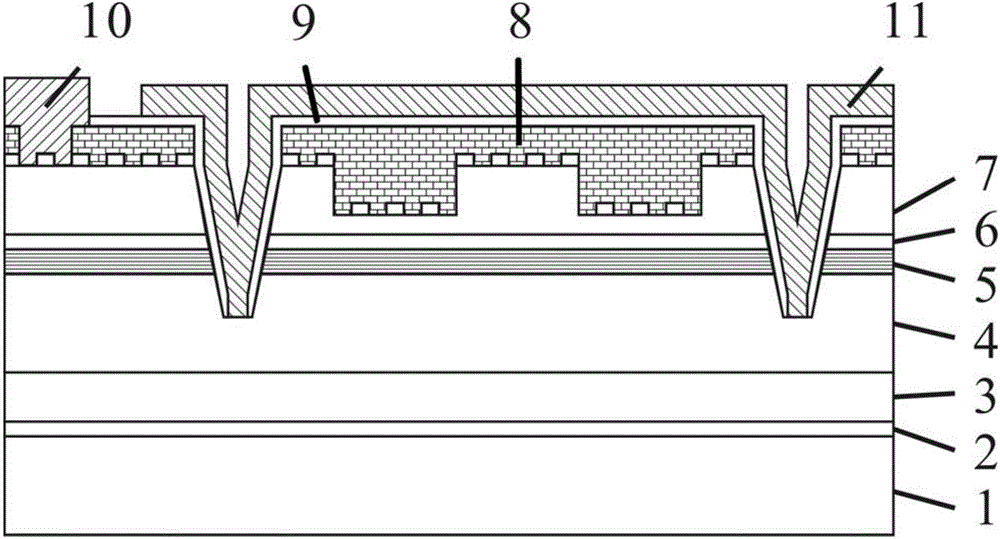

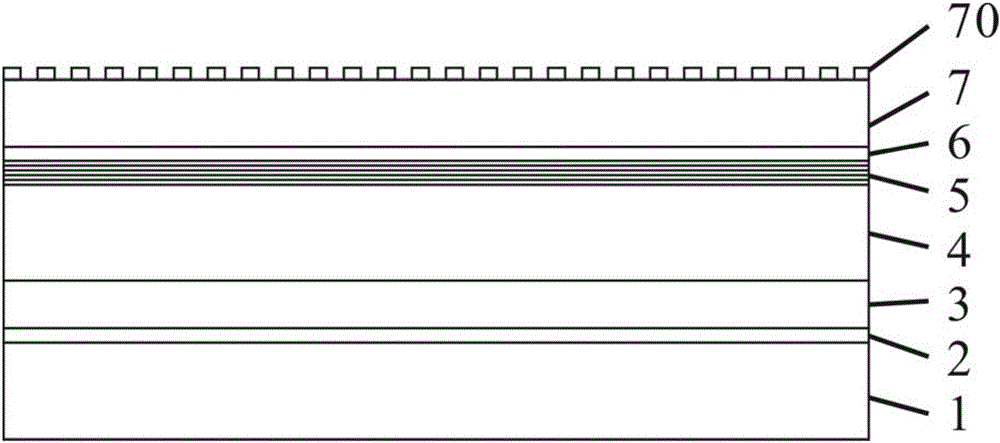

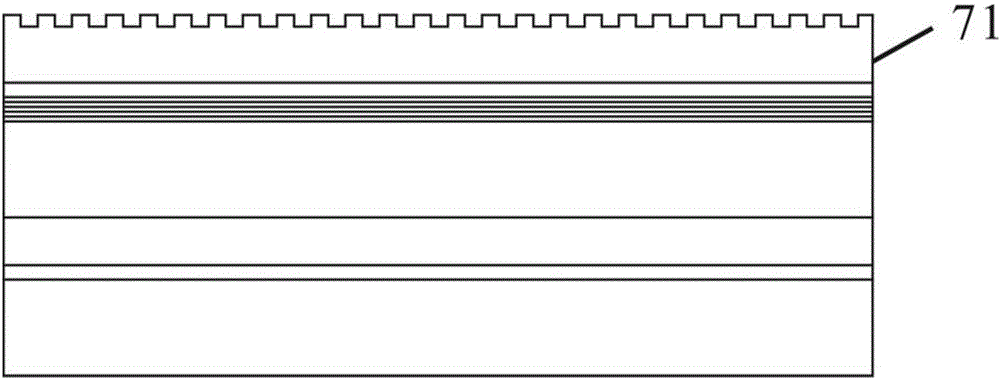

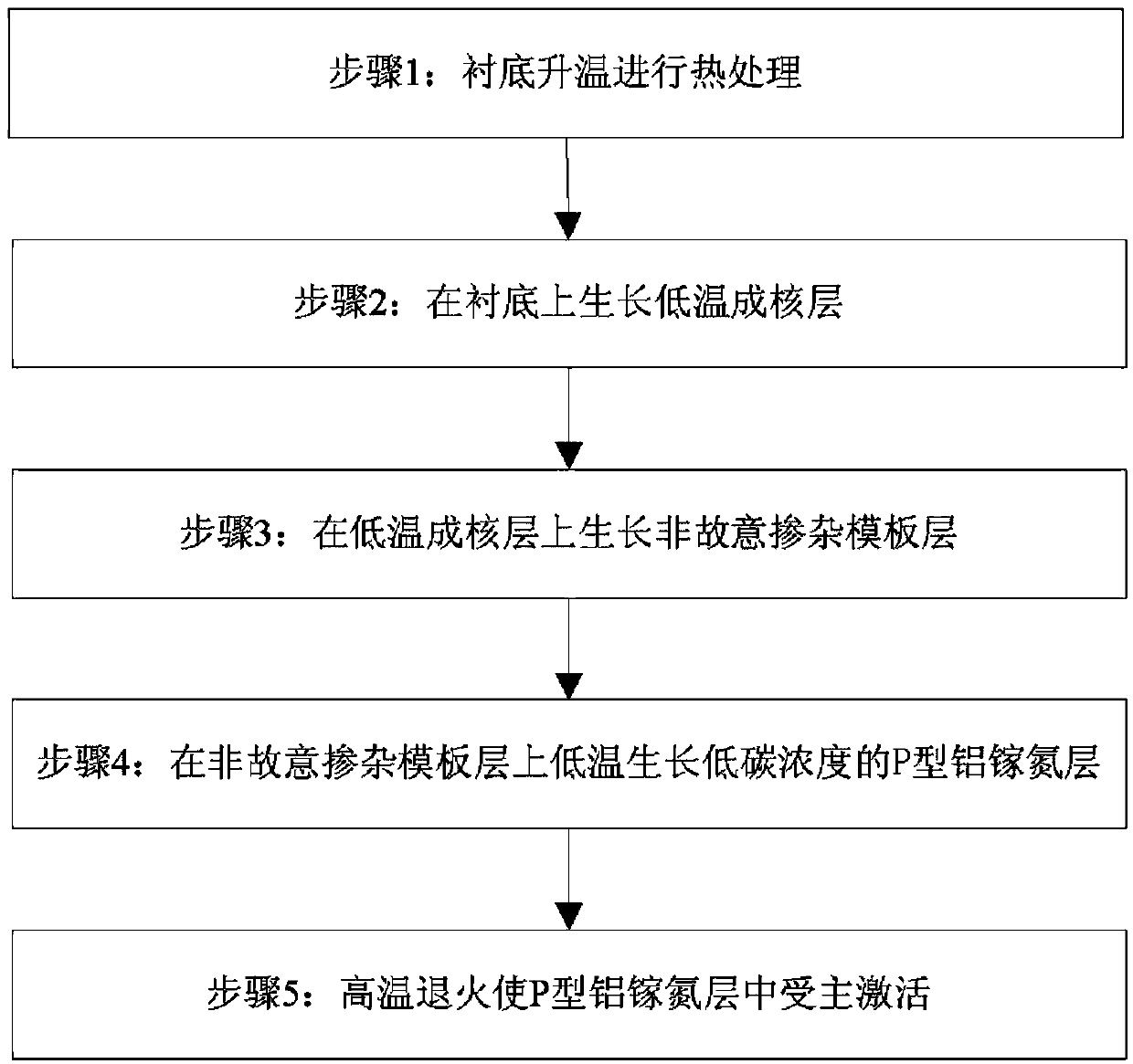

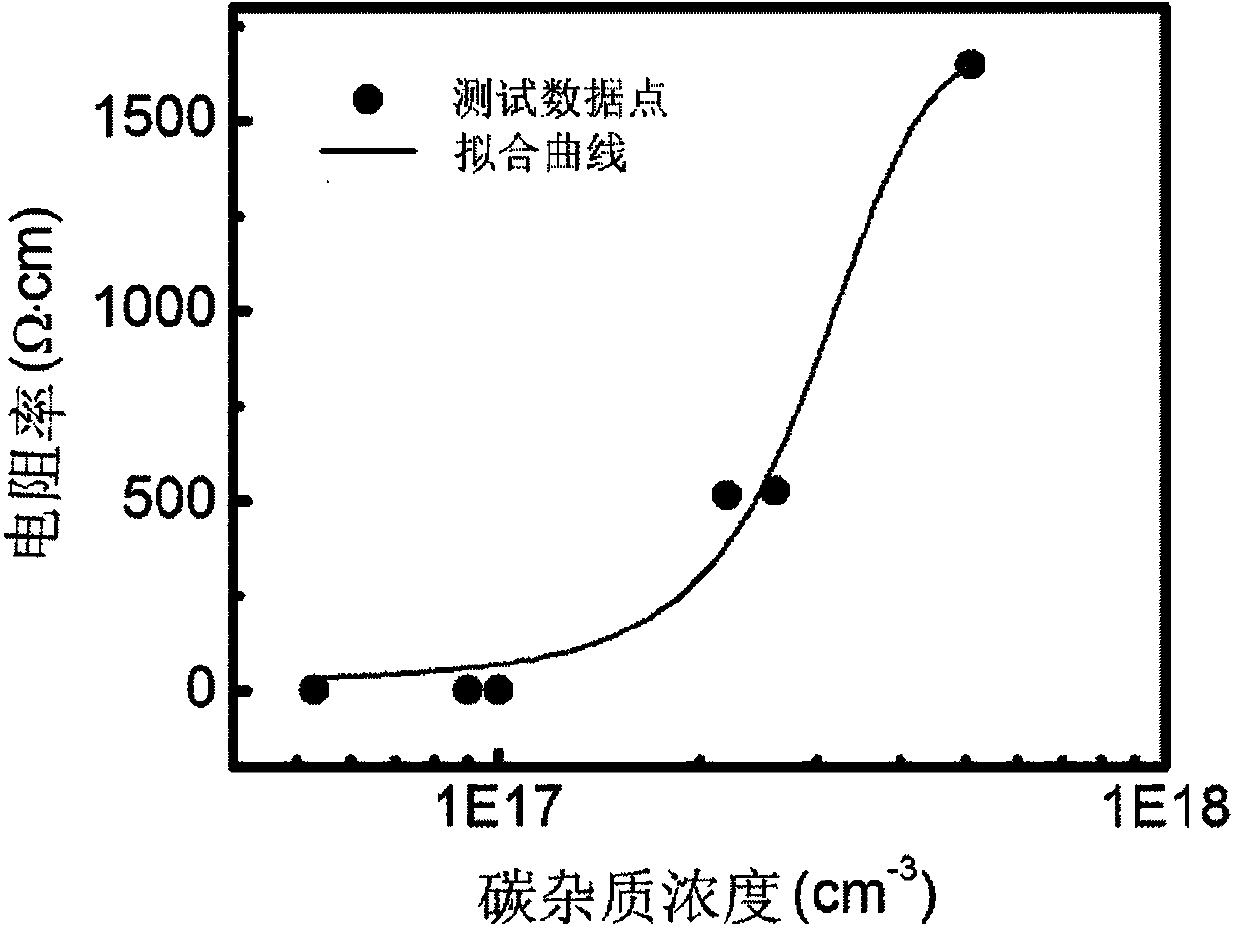

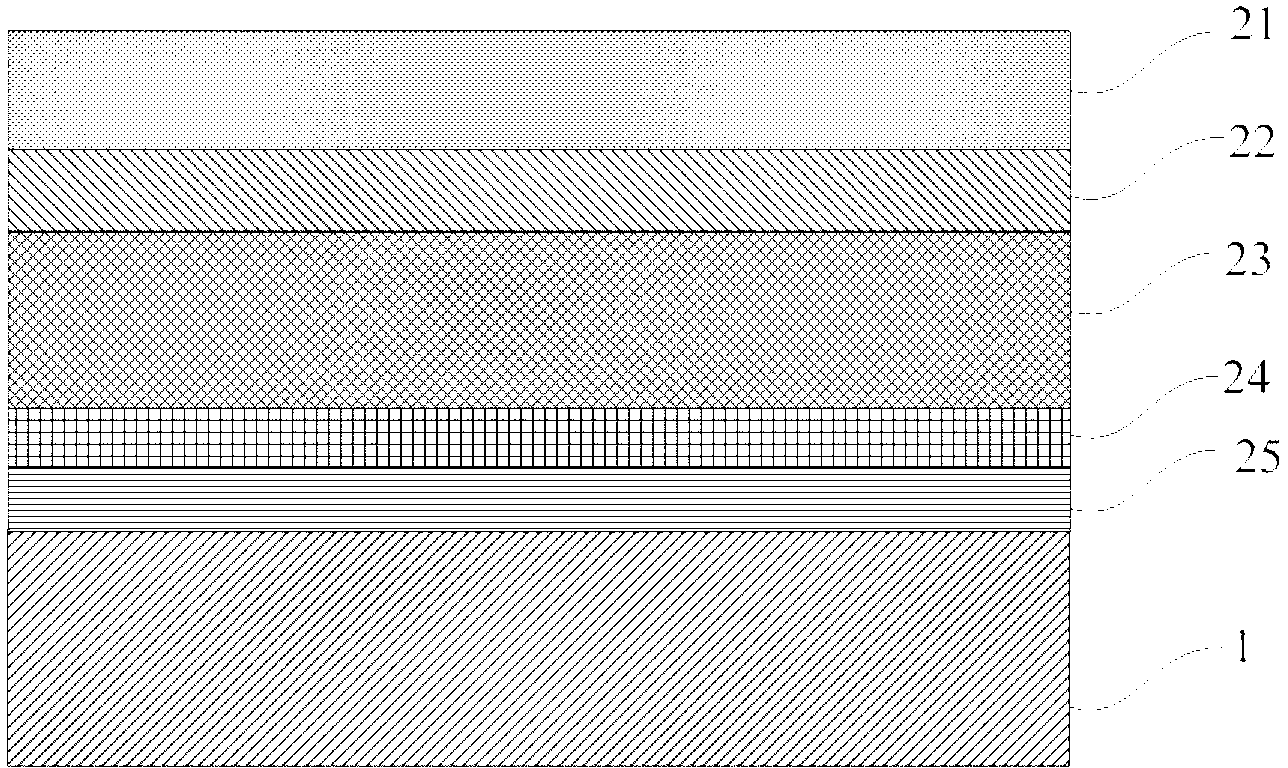

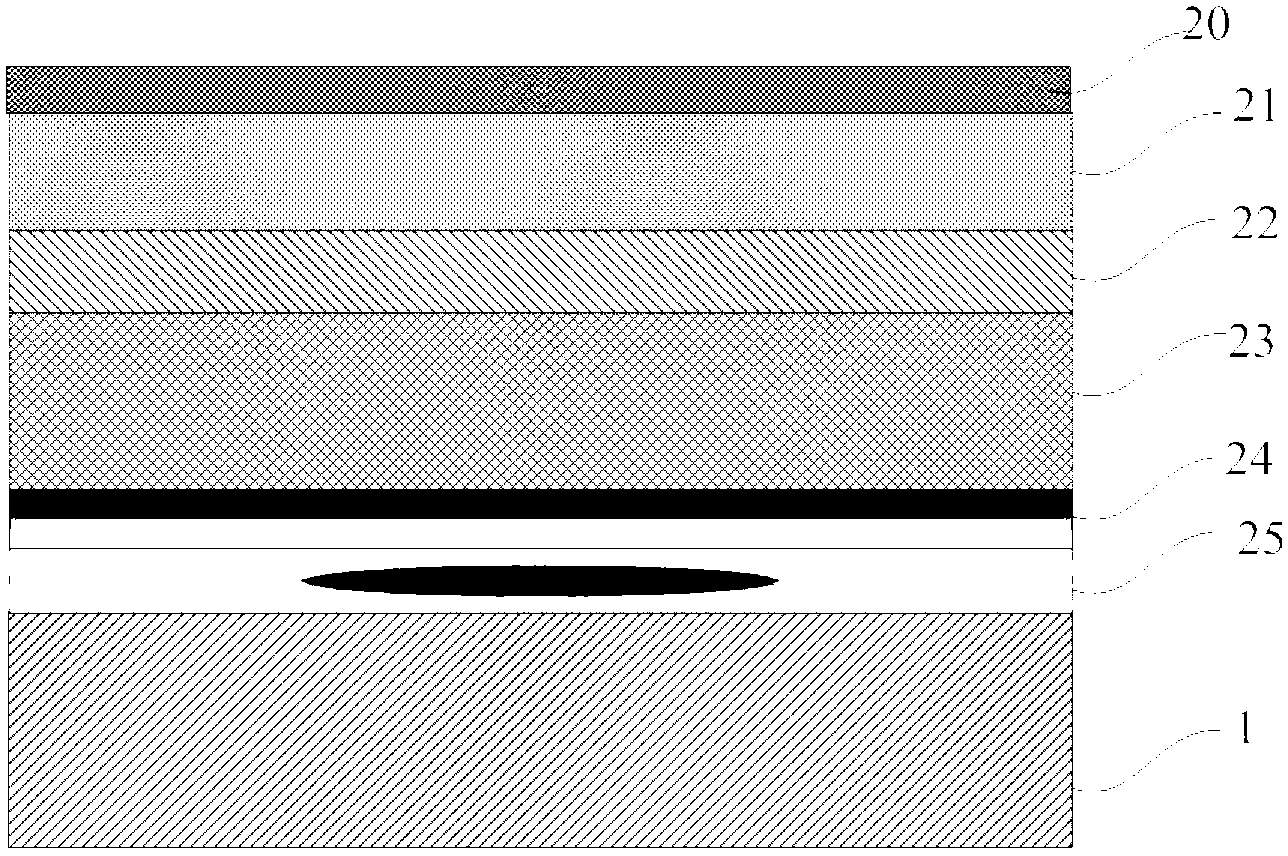

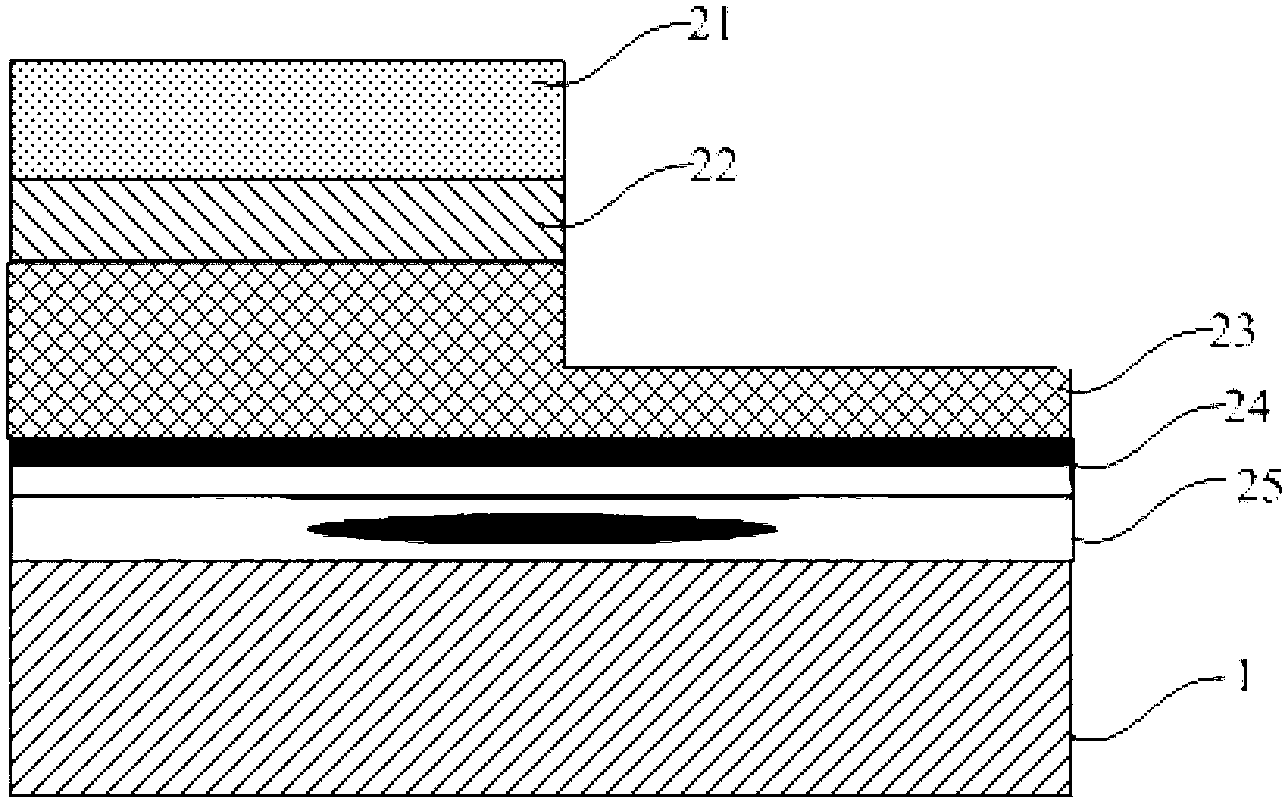

Preparation method for low-resistivity low-temperature P type aluminum gallium nitride materials

ActiveCN104201256ALow resistivityReduced series resistanceSemiconductor devicesHydrogenCarbon impurities

A preparation method for low-resistivity low-temperature P type aluminum gallium nitride materials comprises the following steps of step 1, warming a substrate and performing thermal treatment under the hydrogen material environment; step 2, enabling a layer of low-temperature nucleating layer to grow on the substrate and providing a nucleation center for follow-up epitaxial growth; step 3, enabling a layer of unintentional doping template layer to grow on the low-temperature nucleating layer; step 4, enabling a layer of P type aluminum gallium nitride layer with low carbon impurity concentration to grow on the unintentional doping template layer in a epitaxial mode under low temperature to form into an epitaxial wafer; step 5, annealing the epitaxial wafer with high temperature under nitrogen environment to enable an acceptor in the P type aluminum gallium nitride layer to be active and obtain the P type aluminum gallium nitride layer materials with low resistivity. The preparation method for the low-resistivity low-temperature P type aluminum gallium nitride materials can reduce the concentration of unintentional doping carbon impurities in the low-temperature developed P type aluminum gallium nitride materials, accordingly relieving the acceptor compensation function and achieving the purpose of reducing the P type material resistivity.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Semiconductor light-emitting device and manufacturing method thereof

InactiveCN103311409AImprove cooling effectImprove light extraction efficiencySemiconductor devicesEngineeringGallium nitride

The invention provides a semiconductor light-emitting device and a manufacturing method thereof. The manufacturing method at least includes the following steps: providing a substrate; growing an epitaxial layer on the substrate; forming an air interlayer in zonal distribution and a corresponding coarsened structure interface between the substrate and the unintentional doping GaN layer; continuing subsequent chip processing; adopting an inverted packaging process to package the device, wherein the epitaxial layer comprises the GaN buffering layer, the unintentional doping GaN layer, an N-type gallium nitride layer, a light-emitting layer and a P-type gallium nitride layer sequentially front bottom to top. Heat dissipation capacity of a chip is effectively improved, and luminous efficiency is improved.

Owner:EPILIGHT TECH

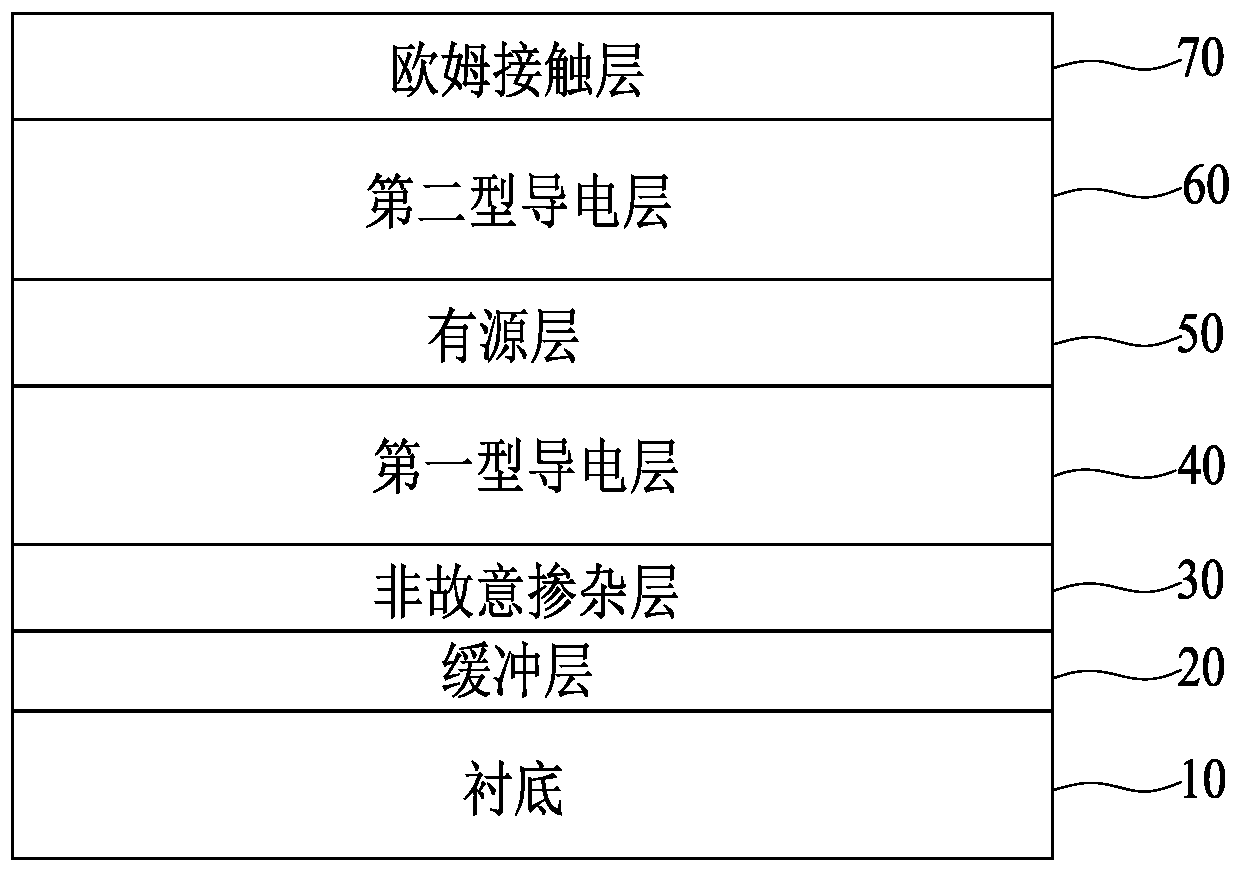

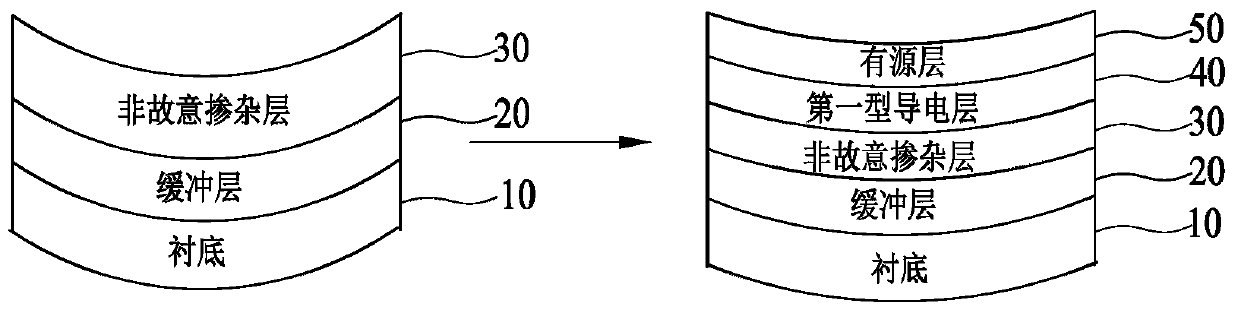

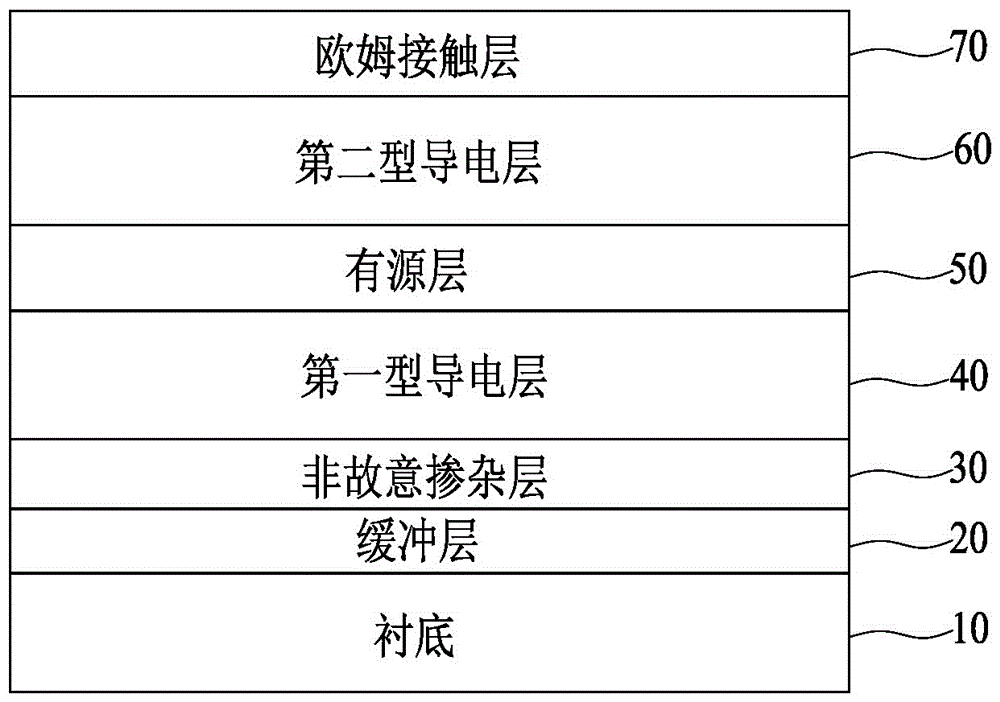

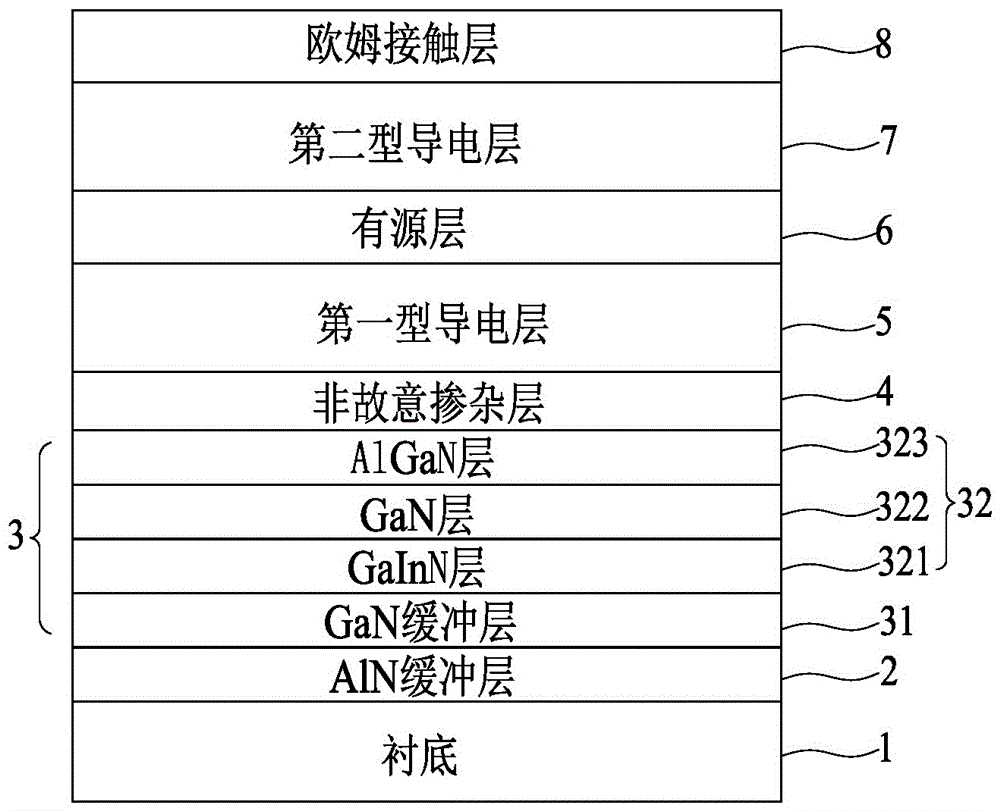

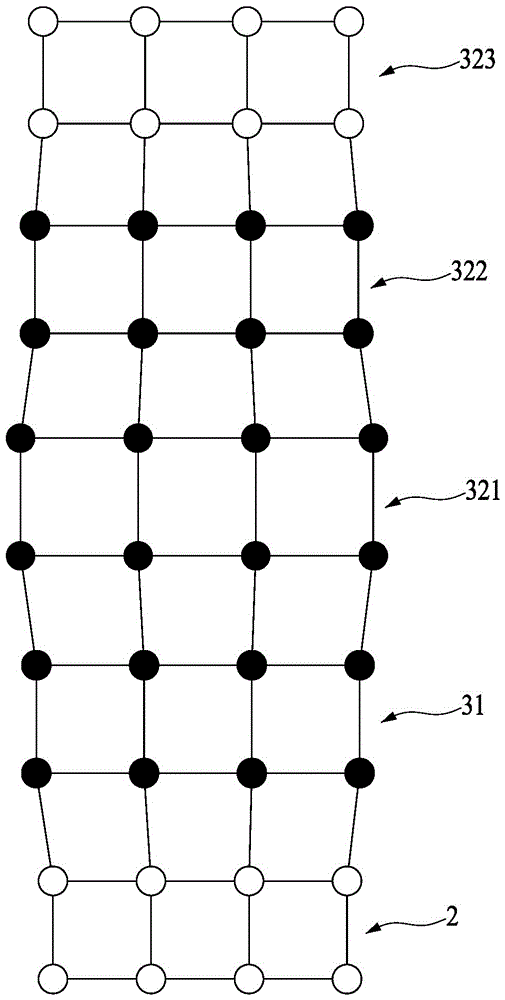

Manufacturing method of no-easy-warpage large-dimension light emitting diode epitaxial wafer

ActiveCN105789396AQuality improvementImprove uniformitySemiconductor devicesOhmic contactReaction temperature

The invention discloses a manufacturing method of a no-easy-warpage large-dimension light emitting diode epitaxial wafer. The manufacturing method comprises the steps of performing vapor plating of an AlN buffer layer on the upper surface of a substrate; performing epitaxial growth of a GaN buffer layer on the AlN buffer layer; performing epitaxial growth of a composite buffer layer on the GaN buffer layer at a reaction temperature of about 1000 DEG C, wherein the composite buffer layer is composed of a GaN buffer layer and multiple buffer layers; after growth of the composite buffer layer, increasing the epitaxial growth temperature to above 1050 DEG C for realizing successive epitaxial growth of an unintentional doping layer and a first type conductive layer; reducing the epitaxial growth temperature to lower than 800 DEG C and performing epitaxial growth of an active layer on the first type conductive layer; and increasing the temperature to above 900 DEG C and successively growing a second type conductive layer and an ohmic contact layer on the active layer. The manufacturing method settles problems of epitaxial surface abnormity and electrical performance abnormity because of large warpage caused by temperature change in epitaxial wafer growth process in which the large-dimension substrate is utilized.

Owner:XIAMEN CHANGELIGHT CO LTD

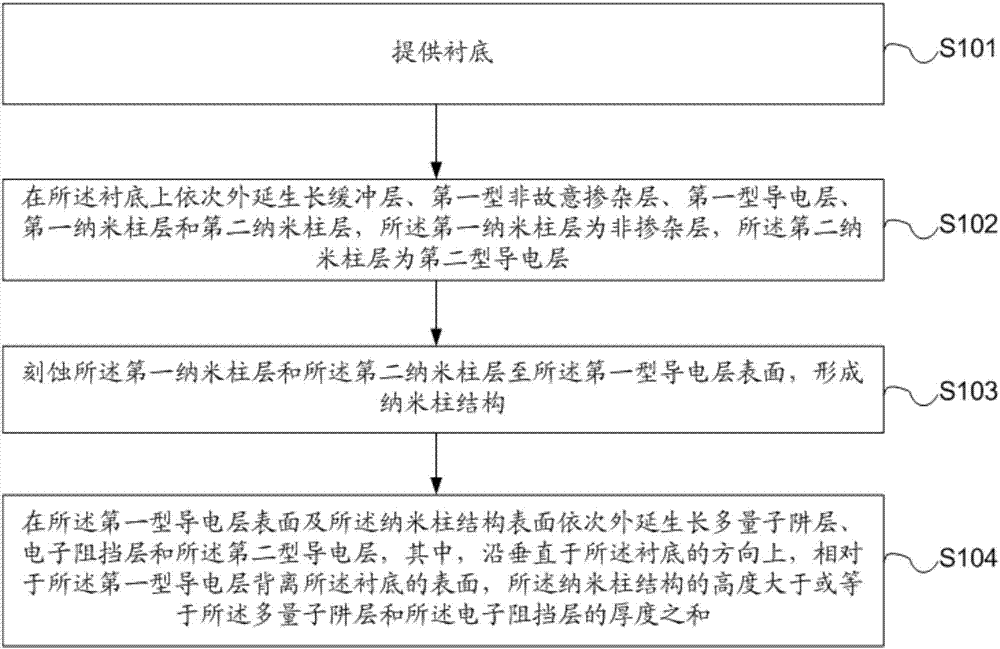

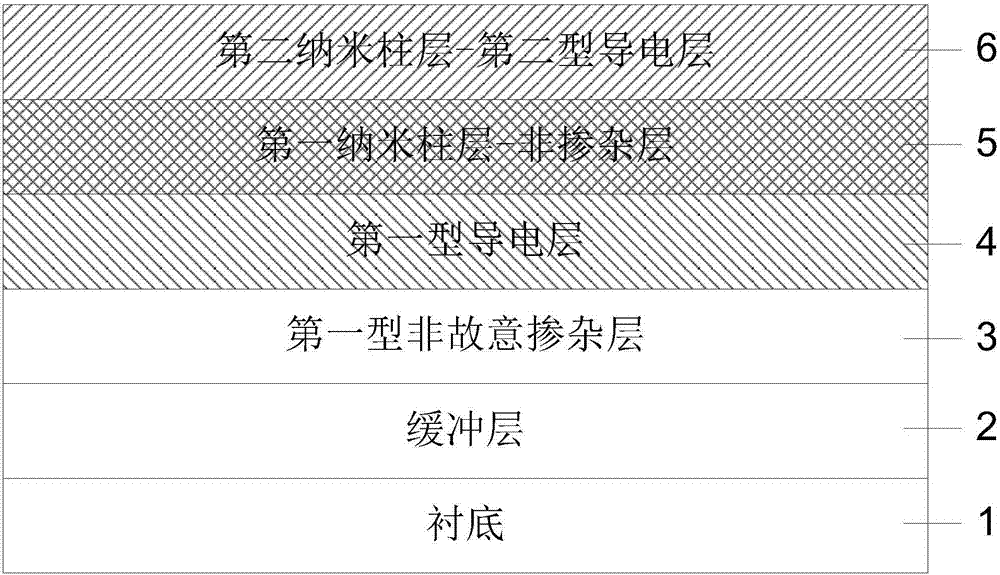

Light-emitting diode (LED) epitaxial structure, manufacturing method thereof, and LED

The application provides a light-emitting diode (LED) epitaxial structure, a manufacturing method thereof, and an LED. The manufacturing method of the LED epitaxial structure includes: providing a substrate; successively and epitaxially growing a buffer layer, a first type of unintentional doping Layer, a first type of conductive layer, an non-doped layer and a second type of conductive layer on the substrate; etching the non-doped layer and the second type of conductive layer to form a nano-pillar structure; and re-epitaxially growing a multi-quantum well layer, an electron blocking layer, and a second type of conductive layer. The nano-pillar structure replaces a conventional V-pits structure. Because the nano-pillar structure has good crystal quality and the first type of conductive layer can be isolated from the second type of conductive layer, device failure caused by electric leakage of the V-pits structure can be solved.

Owner:厦门未来显示技术研究院有限公司

Panchromatic Micro/Nano LED array direct epitaxy method and structure

InactiveCN112331747ASolve process bottlenecksHigh LED DensitySolid-state devicesSemiconductor devicesLed arrayPhysical chemistry

The invention discloses a panchromatic Micro / Nano LED array direct epitaxy method and structure. The panchromatic Micro / Nano LED array direct epitaxy method comprises the following steps: 1) epitaxially growing a buffer layer, an unintentional doping layer and an n-type layer on a substrate; 2) depositing a first dielectric layer on the n-type layer, manufacturing a first group of micro or nano-pore arrays on the first dielectric layer, and epitaxially growing a first light-emitting unit in the manufactured first group of micron or nano-pore arrays; 3) manufacturing a second dielectric layer,manufacturing a second group of micro or nano-pore arrays on the second dielectric layer, and epitaxially growing a second light-emitting unit in the manufactured second group of micro or nano-pore arrays; 4) manufacturing a third dielectric layer, manufacturing a third group of micro or nano-pore arrays on the third dielectric layer, and epitaxially growing a third light-emitting unit in the manufactured third group of micro or nano-pore arrays; and 5) removing the corrosion of the dielectric layer by using a chemical solution to expose the light-emitting unit. The problem of huge transfer issolved, the panchromatic Micro / Nano LED array can be directly grown in an epitaxial mode, and the method and the structure have huge application potential.

Owner:XIAMEN UNIV

Light emitting diode and manufacturing method thereof

ActiveCN107546307AImprove current blocking abilityImproved ohmic contact performanceSemiconductor devicesPower flowOhmic contact

The invention discloses a light emitting diode (LED) and a manufacturing method thereof. The LED comprises a substrate, a buffer layer, an unintentional doping layer, a first doping layer, a first heavy doping layer, a first ohmic contact layer, a first high doping layer, a first isolation layer, a second doping layer, a first current blocking layer, an active region, a second current blocking layer, a third doping layer, a second ohmic contact layer, a transparent conductive layer, a first electrode, a second electrode and a third electrode, wherein the second doping layer comprises a first platform, the first high doping layer comprises a second platform, the first ohmic contact layer comprises a third platform, the first platform, the second platform and the third platform are differentin surface roughness, the first electrode directly contacts with the first platform, the second platform and the third platform, and the first electrode and the second electrode realize electrical isolation through a second protection layer. The LED is advantaged in that the manufacturing process is simple, manufacturing cost of chips is reduced, and a current congestion problem of the LED is effectively solved.

Owner:XIAMEN CHANGELIGHT CO LTD

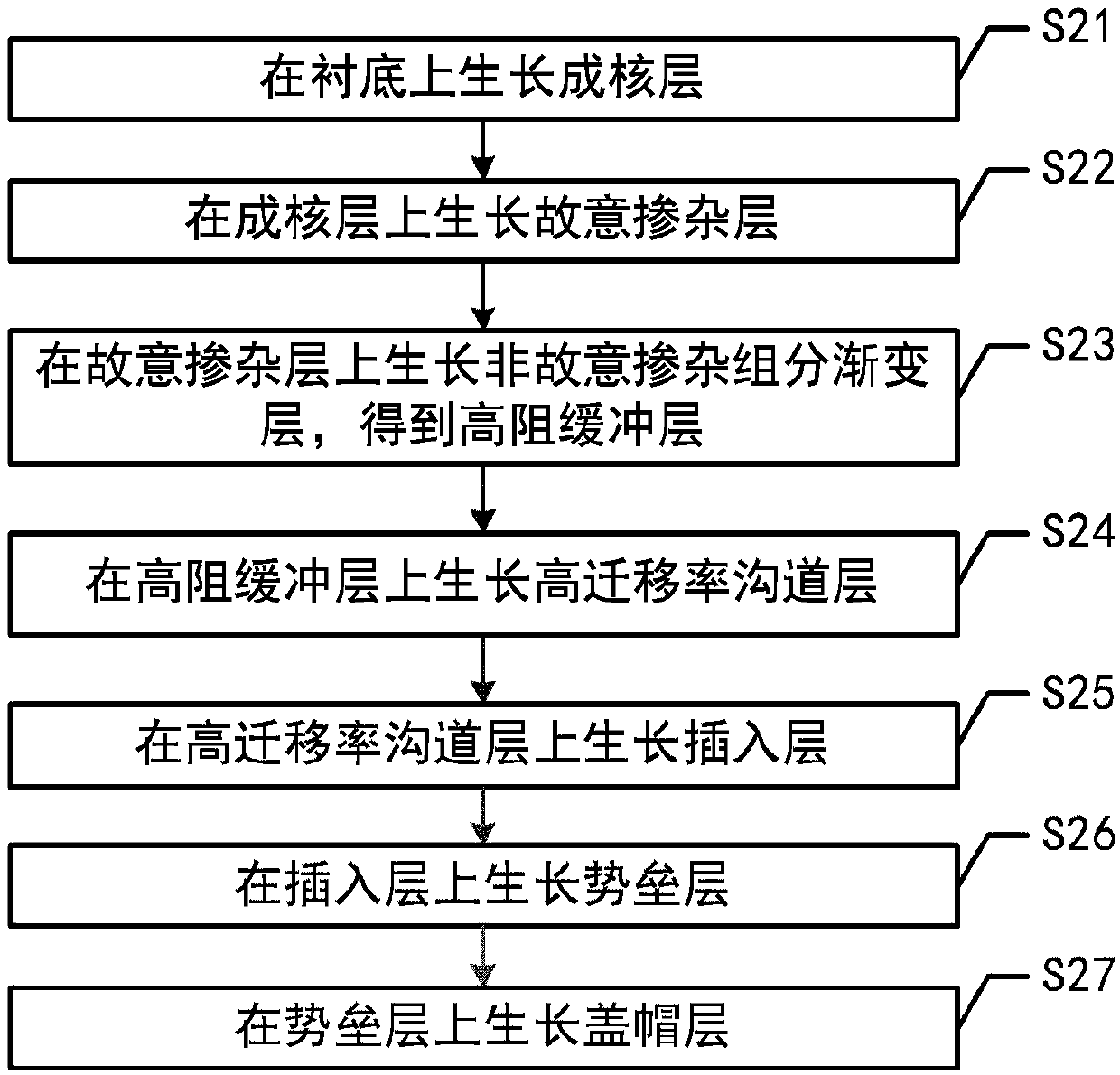

Double-heterojunction HEMT containing component gradual-changing high resistance buffer layer and manufacturing method thereof

InactiveCN109638066AReduce leakageImprove mobilitySemiconductor/solid-state device manufacturingSemiconductor devicesHigh resistanceNitrogen

The invention discloses a double-heterojunction HEMT containing a component gradual-changing high resistance buffer layer and a manufacturing method thereof. The double-heterojunction HEMT comprises asubstrate, a nucleating layer located on the substrate, the high resistance buffer layer located on thenucleating layer, a high mobility channel layer located on thehigh resistance buffer layer, a barrier layer located on thehigh mobility channel layer and a capping layer located on the barrier layer, wherein the high resistance buffer layer comprises an intentional doping layer and an unintentional doping component gradual-changing layer located on the intentional doping layer, and components of the unintentional doping component gradual-changing layerare gradually reduced in the direction of epitaxial growth of the double-heterojunction HEMT. According to the double-heterojunction HEMT, on the one hand, channel electron mobility is increased, limiting ability to two-dimensional electrongasis improved, electric leakage of the buffer layer of the double-heterojunction HEMT is reduced, breakdown voltage is increased, and regulatory capacity of a gate is improved; on the other hand, component gradual-changing of aluminumof aluminum-gallium-nitrogen in the high resistance buffer layer is used, latticestrain is lowered, piezoelectric polarization is reduced, and working stability andreliability of the double-heterojunction HEMTis integrally improved.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI +1

Epitaxial growth method of light-emitting diode with well region doping

InactiveCN106098862AImprove the blocking effectImprove luminous efficiencySemiconductor devicesQuantum wellOhmic contact

The invention discloses a light emitting diode epitaxial growth method with well region doping, which provides a substrate, on which a buffer layer, an unintentional doping layer and a first-type conductive layer are sequentially epitaxially grown from bottom to top; The pre-quantum barrier is grown on the layer; the V-type quantum well is then epitaxial on the pre-quantum barrier; the post-quantum barrier is continued to be epitaxial on the V-type quantum well; The active region is formed by epitaxial growth; the electron blocking layer, the second-type conductive layer and the ohmic contact layer are then epitaxially grown on the active region from bottom to top. The invention can reduce the resistance value of the whole active area, reduce the working voltage and improve the luminous efficiency.

Owner:XIAMEN CHANGELIGHT CO LTD

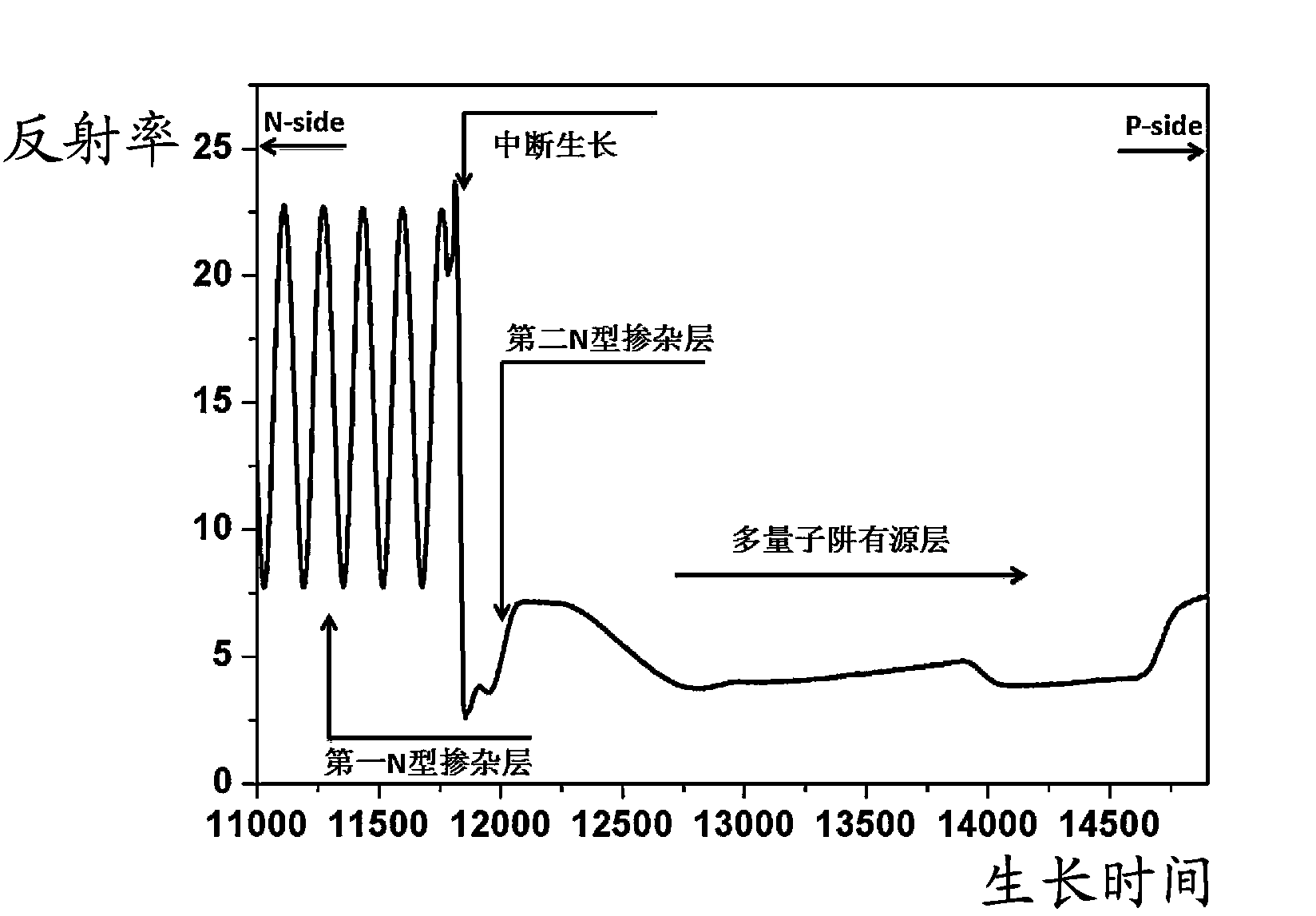

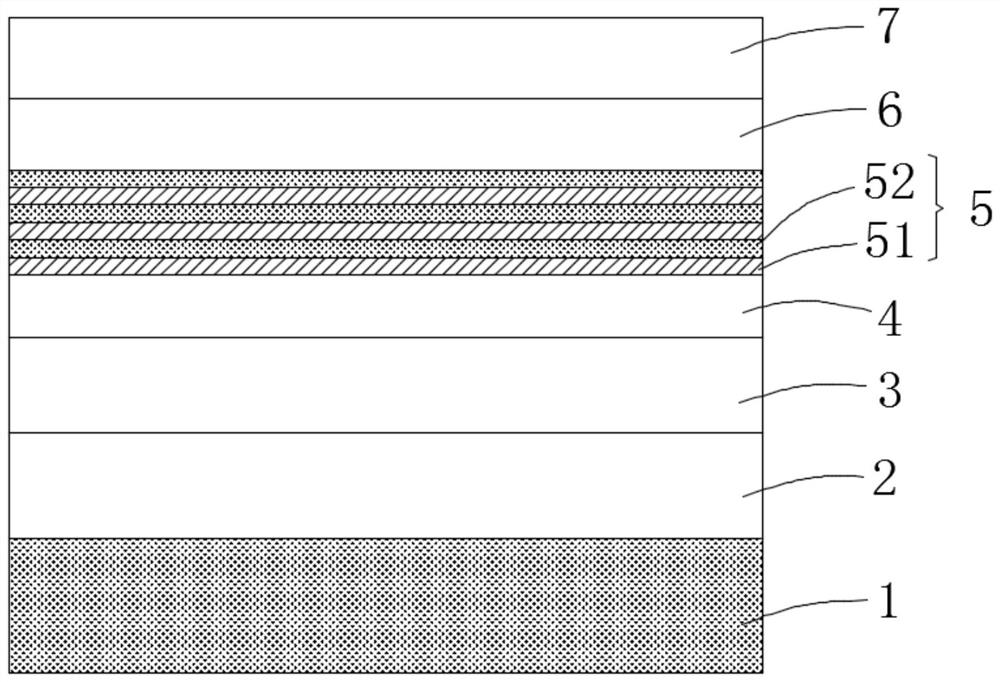

Preparation method of GaN-based LED epitaxial wafer enhancing luminescence efficiency

ActiveCN104393136ASimple methodNo need to increase production costsSemiconductor devicesContact layerLuminescence

The invention discloses a preparation method of a GaN-based LED epitaxial wafer enhancing luminescence efficiency. The preparation method comprises the following steps that a buffer layer, an unintentional doping layer, a first N-type doping layer, a second N-type doping layer, a InGaN / GaN multi-quantum well active layer, an electron blocking layer, a P-type doping layer and a contact layer are grown on a substrate in turn; after the first N-type doping layer is grown completely, an organic source is closed, piping of NH3 into a reaction chamber is reduced or stopped and growing is stopped for 10-200s under the atmosphere of H2 or N2 so that the first N-type doping layer with a rough surface is acquired. LED internal quantum efficiency and external quantum efficiency can be enhanced simultaneously. Besides, the preparation method is simple and preparation cost is relatively low.

Owner:XIAMEN CHANGELIGHT CO LTD

Ultraviolet LED epitaxial structure and growth method thereof

PendingCN114725260AImprove crystal qualityIncrease chance of compoundingSemiconductor devicesQuantum efficiencyElectron hole

The invention discloses an ultraviolet LED epitaxial structure and a growth method thereof, and relates to the technical field of semiconductor materials. Comprising a buffer layer, an unintentional doping layer, an n-type doping layer, a multi-quantum well light-emitting layer, an EBL layer and a p-type AlGaN layer which are sequentially grown on a substrate, the buffer layer comprises an AlN layer, an AlGaN layer and an AlInGaN layer which grow in sequence, and the growth temperature of the buffer layer is 700-1100 DEG C. According to the invention, the crystal quality of the LED epitaxial wafer can be improved, non-radiative recombination caused by defects is reduced, the recombination probability of electrons and holes is improved, the internal quantum efficiency is improved, and the luminous efficiency is greatly improved.

Owner:广州市众拓光电科技有限公司

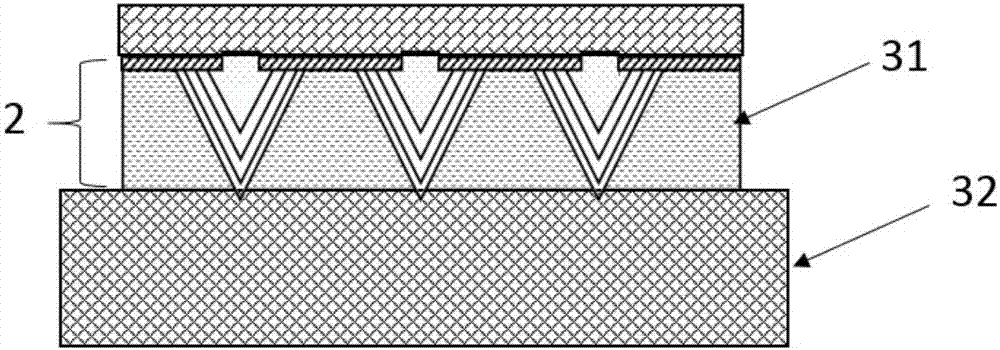

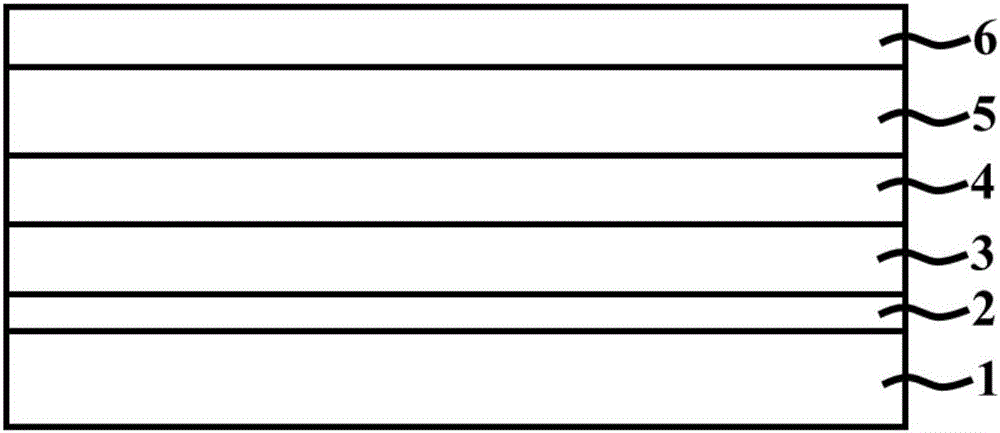

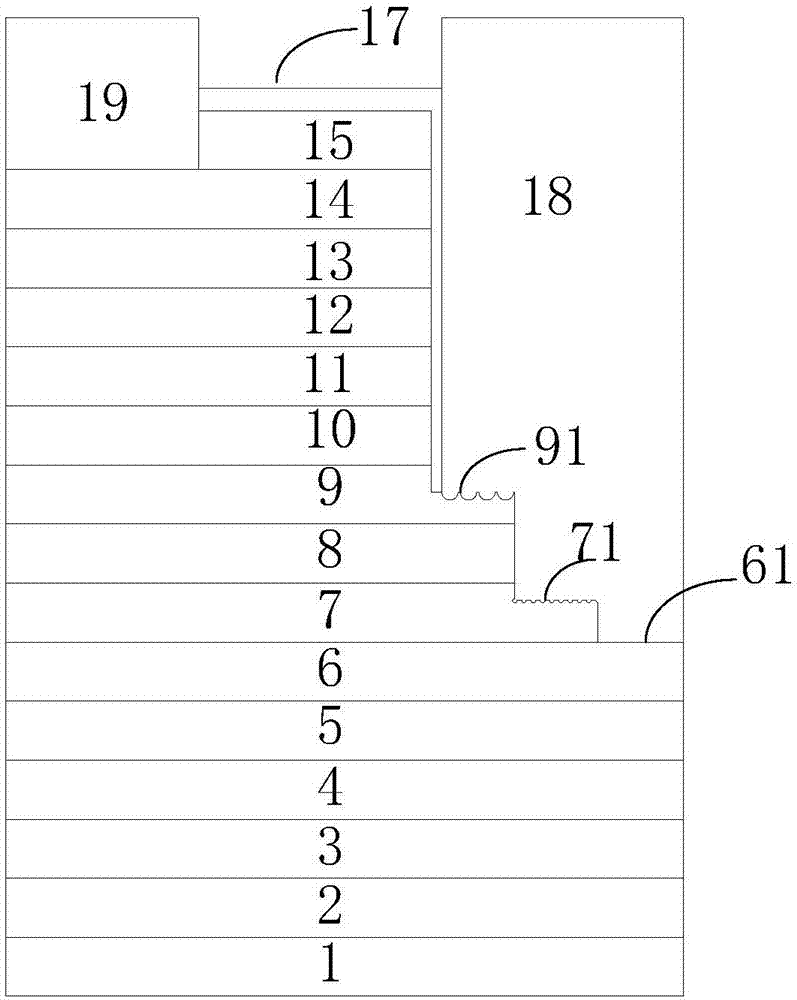

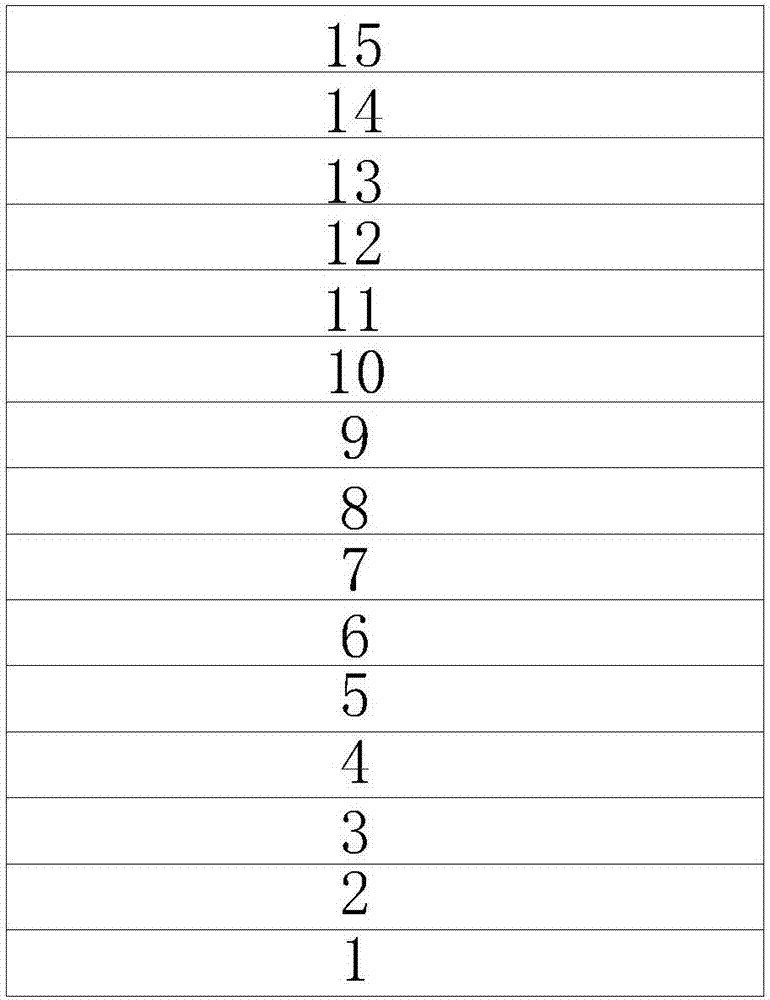

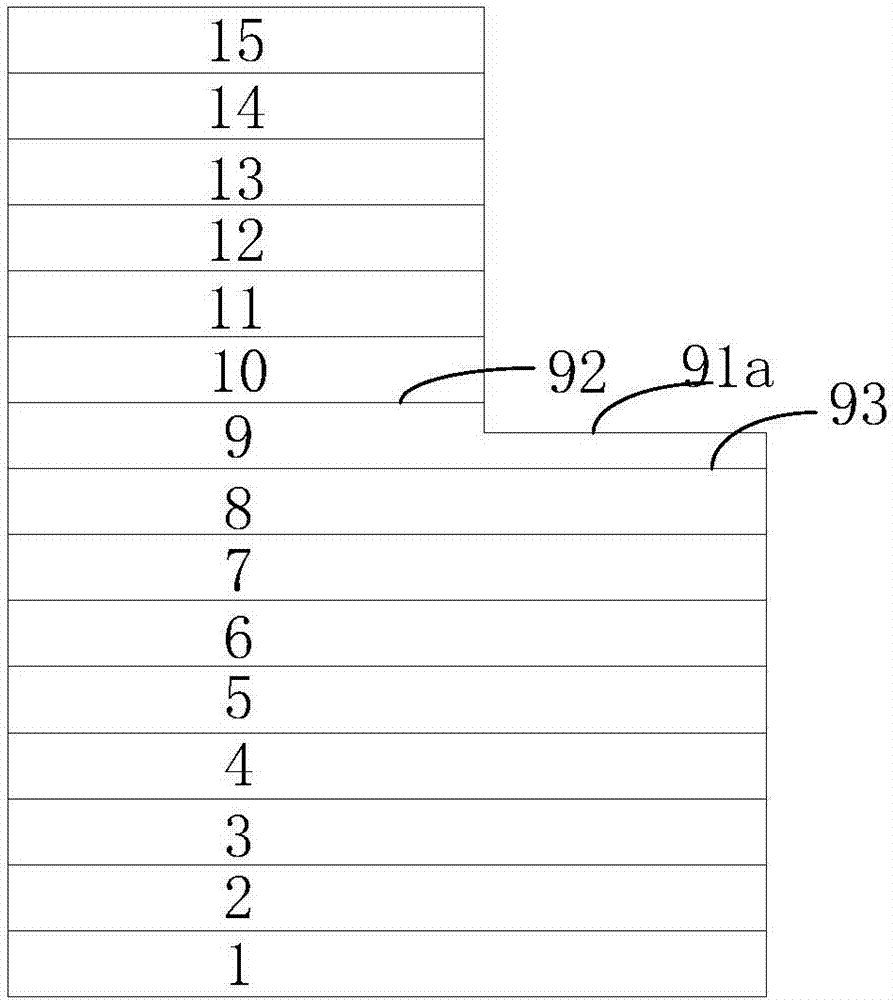

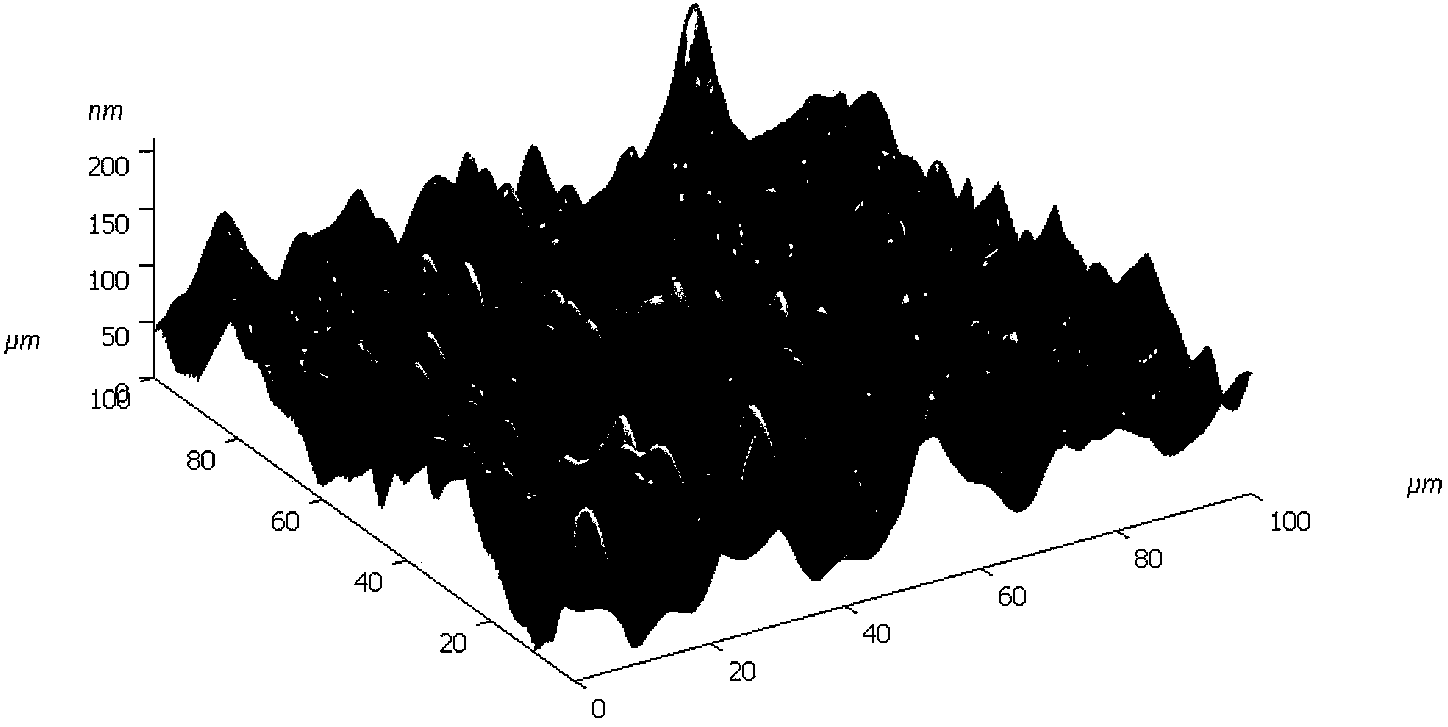

Epitaxy method of vertical [beta]-gallium oxide nanowire array

PendingCN112210768AAvoid Unintentional Adulteration ContaminationDoping Flexible ControlNanotechnologyChemical vapor deposition coatingPtru catalystAutocatalysis

The invention discloses an epitaxy method of a vertical [beta]-gallium oxide nanowire array. The epitaxy method of the vertical [beta]-gallium oxide nanowire array comprises the following steps: introducing a Ga source and an O source; and epitaxially growing the nanowire array on the surface of a substrate by using a Ga catalyst autocatalysis method, wherein the epitaxial growth temperature is 400-550 DEG C. According to the invention, the preparation of the high-crystalline-quality nanowire array perpendicular to the surface of the substrate is realized by utilizing a Ga liquid drop autocatalysis technology, and the unintentional doping pollution of other catalysts to the epitaxial material is avoided. According to the invention, the epitaxial preparation of the [beta]-Ga<2>O<3> nanowirecan be realized at a low-temperature section below 500 DEG C, and the energy consumption can be effectively saved.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Light-emitting diode and method of making the same

ActiveCN107546307BReduce current crowdingImprove current blocking abilitySemiconductor devicesPower flowOhmic contact

The invention discloses a light emitting diode (LED) and a manufacturing method thereof. The LED comprises a substrate, a buffer layer, an unintentional doping layer, a first doping layer, a first heavy doping layer, a first ohmic contact layer, a first high doping layer, a first isolation layer, a second doping layer, a first current blocking layer, an active region, a second current blocking layer, a third doping layer, a second ohmic contact layer, a transparent conductive layer, a first electrode, a second electrode and a third electrode, wherein the second doping layer comprises a first platform, the first high doping layer comprises a second platform, the first ohmic contact layer comprises a third platform, the first platform, the second platform and the third platform are differentin surface roughness, the first electrode directly contacts with the first platform, the second platform and the third platform, and the first electrode and the second electrode realize electrical isolation through a second protection layer. The LED is advantaged in that the manufacturing process is simple, manufacturing cost of chips is reduced, and a current congestion problem of the LED is effectively solved.

Owner:XIAMEN CHANGELIGHT CO LTD

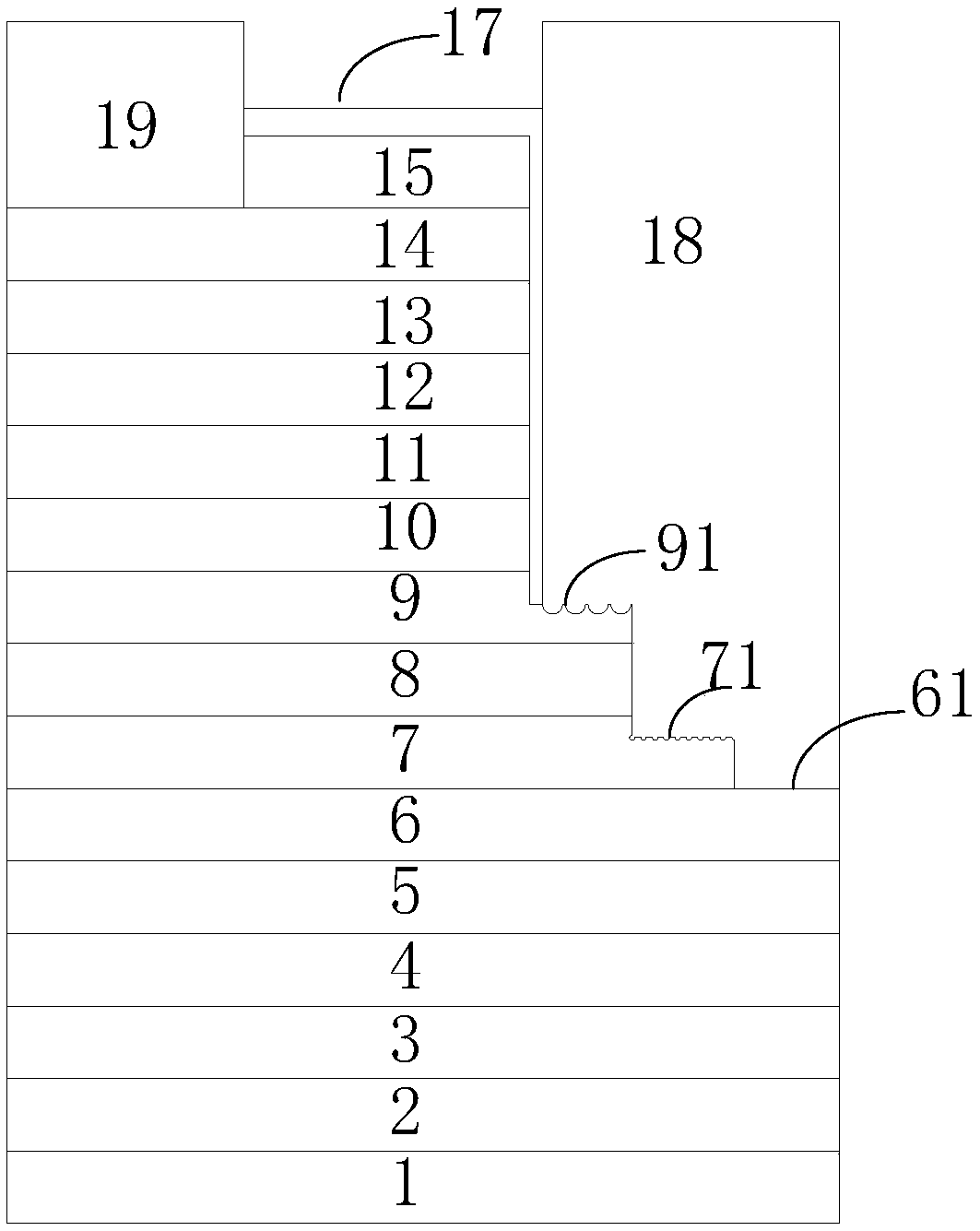

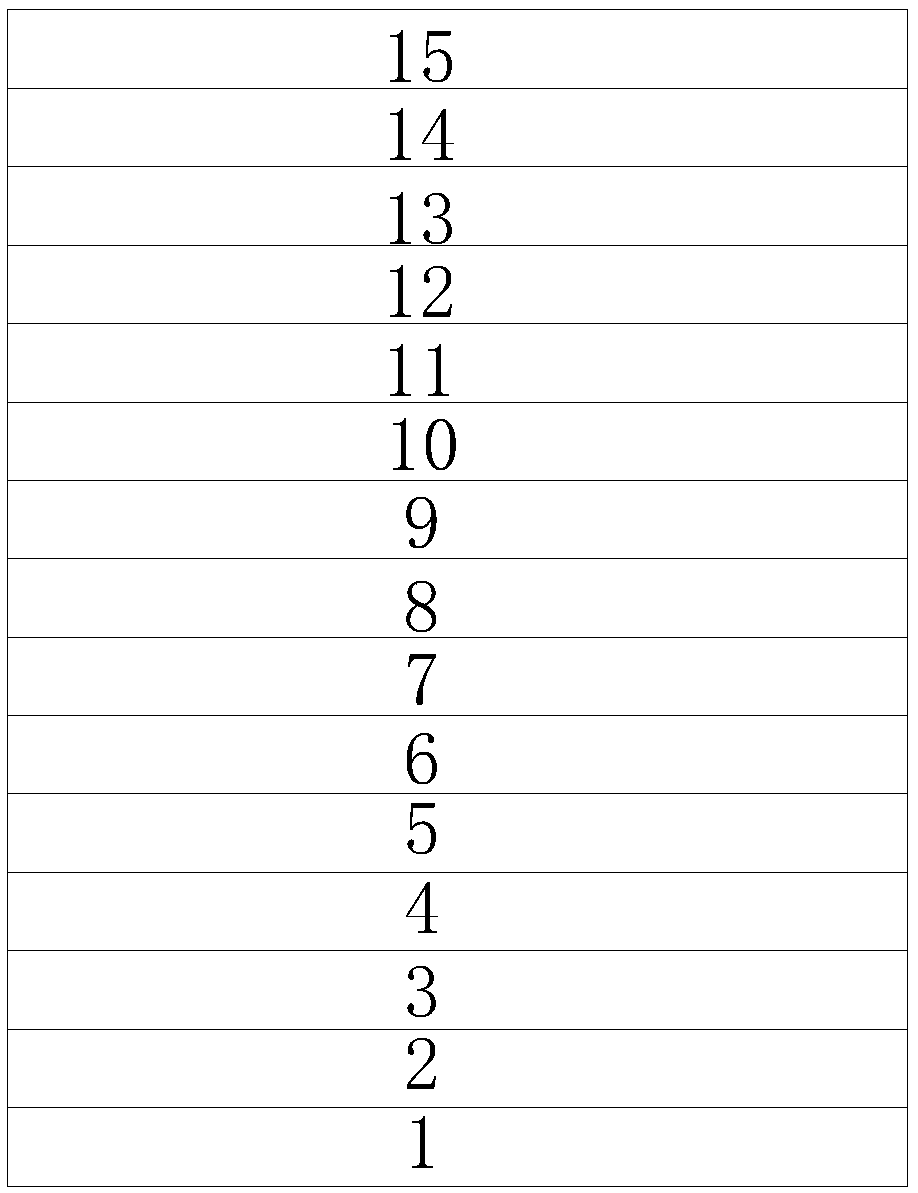

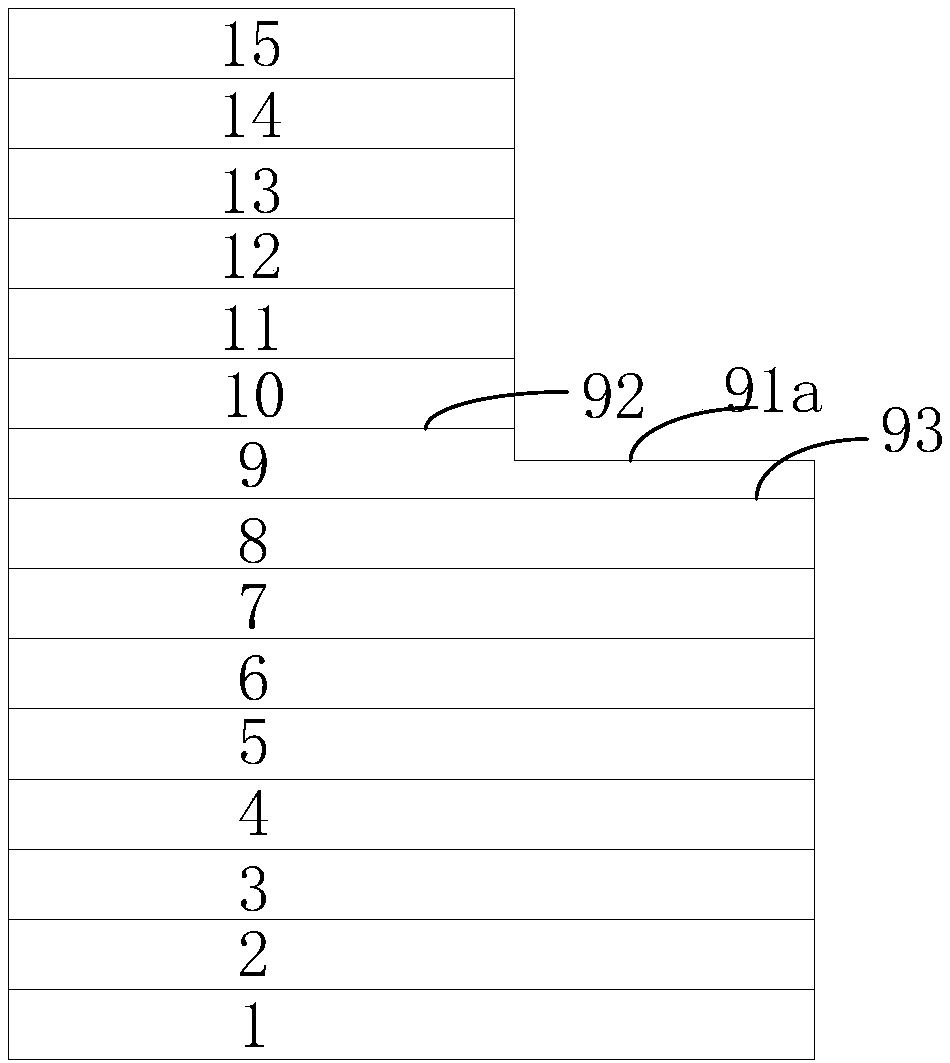

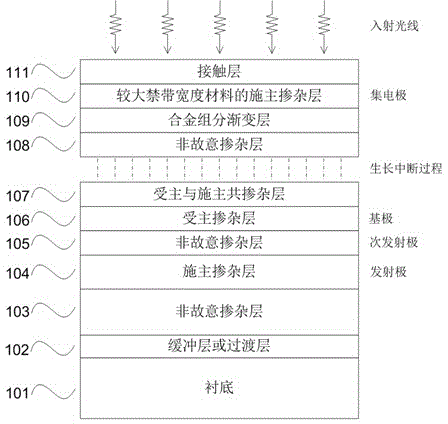

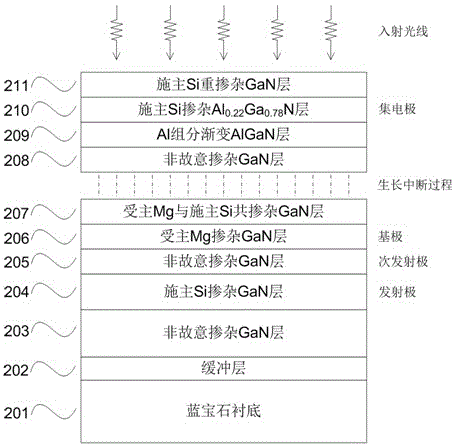

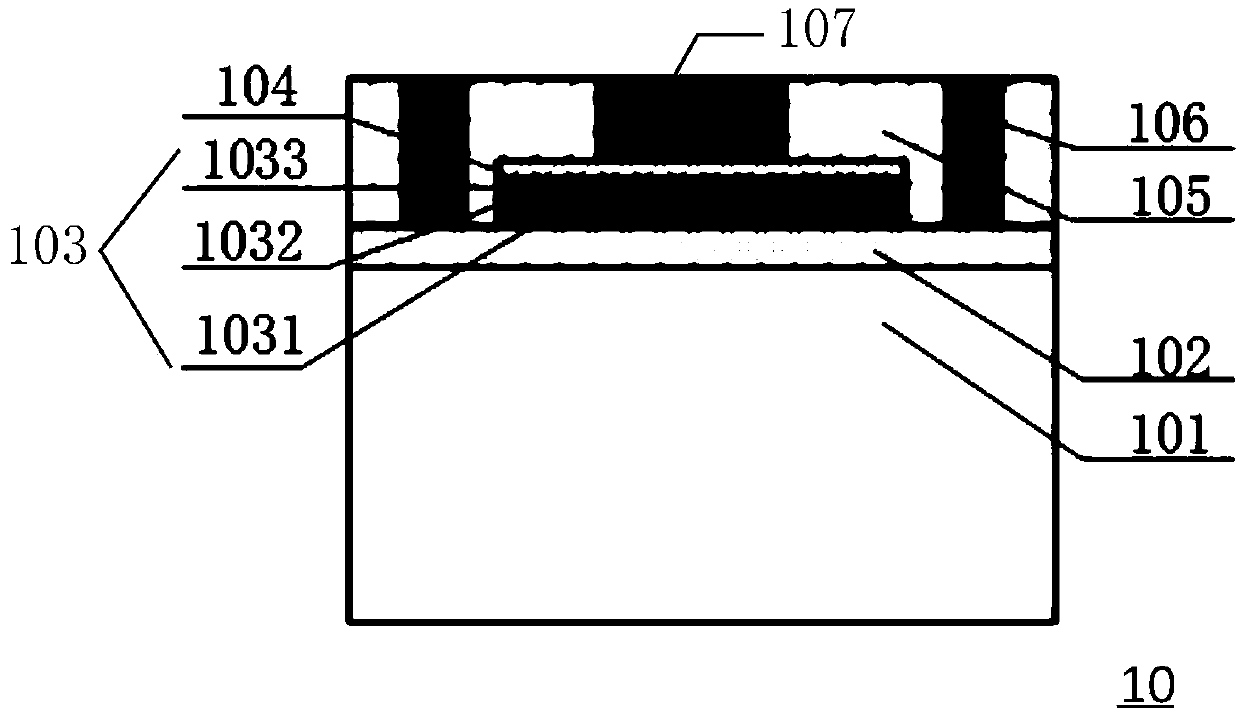

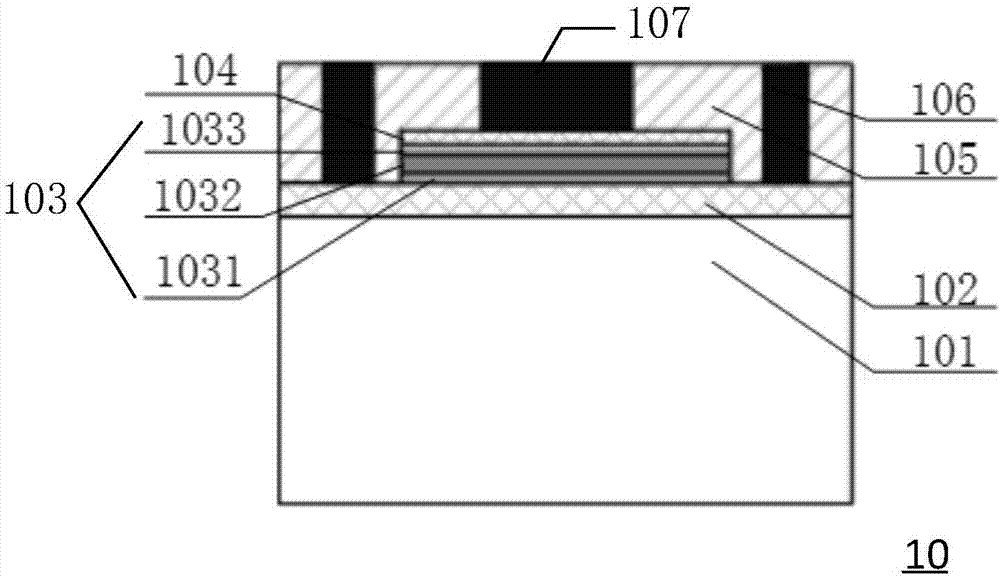

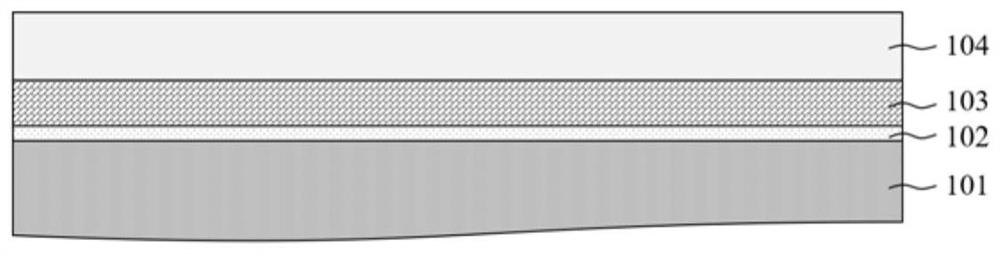

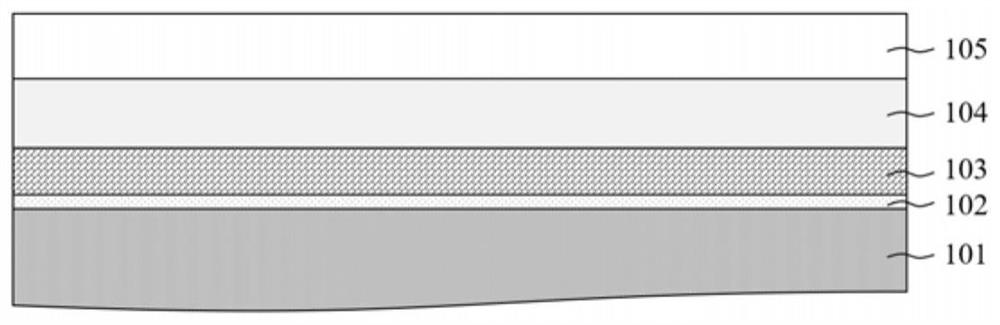

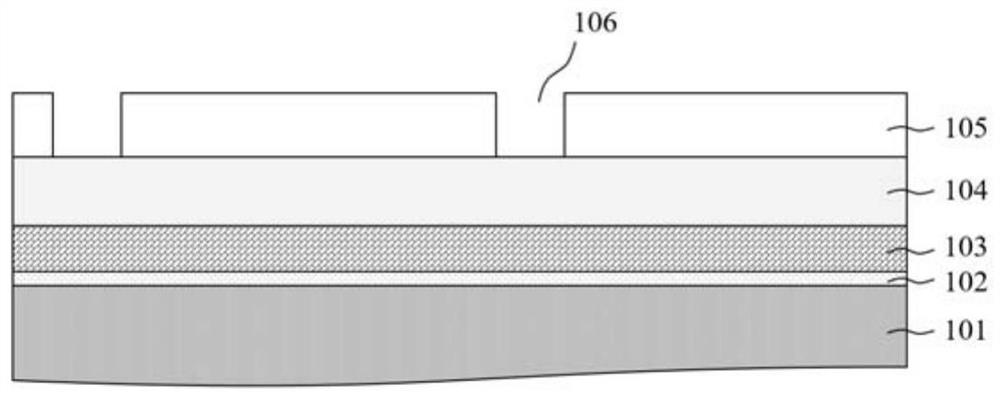

Three-family nitride-based phototransistor detector and manufacturing method thereof

InactiveCN102820368BHigh gainPromote absorptionFinal product manufactureSemiconductor devicesEngineeringContact layer

The invention discloses a three-family nitride-based phototransistor detector and a manufacturing method thereof. The phototransistor detector comprises a substrate (101), a buffering layer or transition layer (102), an unintentional doping layer (103), a donor doping layer (104), a secondary unintentional doping layer (105), an acceptor doping layer (106), an acceptor and donor co-doping layer (107), a third unintentional doping layer (108), an alloy component gradient layer (109), a donor doping layer made of a material with a larger forbidden bandwidth, and a contact layer (111) in sequence from bottom to top. The three-family nitride-based phototransistor detector provided by the invention has the advantages of low defect density, low working voltage, high grain, low dark current, high probing sensitivity and the like.

Owner:SUN YAT SEN UNIV

A light-emitting diode epitaxial growth method with adjustable warpage during growth

ActiveCN105977352BAdjust warpageImprove photoelectric performanceSemiconductor devicesOhmic contactElectron blocking layer

The invention discloses an epitaxial growth method for a light-emitting diode capable of adjusting wrapping in the growth process. The epitaxial growth method comprises the following steps of enabling a buffer layer to be grown on the upper surface of the substrate; enabling an unintentional doping layer to be grown on the buffer layer; enabling each layer structure of a composite adjusting layer to be grown on the unintentional doping layer; enabling a first type conductive layer to be grown on the composite adjusting layer; enabling an active layer to be grown on the first type conductive layer; and enabling an electron barrier layer, a second type conductive layer and an ohmic contact layer to be grown on the active layer in sequence. By adoption of the epitaxial growth method, the problem of epitaxial wafer bending caused by temperature changes and internal stresses when the epitaxial layers of different functions are grown on the substrate in the epitaxial growth process can be solved; and meanwhile, the problems of abnormal epitaxial surface and abnormal electrical property caused by enlarged bending of the epitaxial wafer are solved as well.

Owner:XIAMEN CHANGELIGHT CO LTD

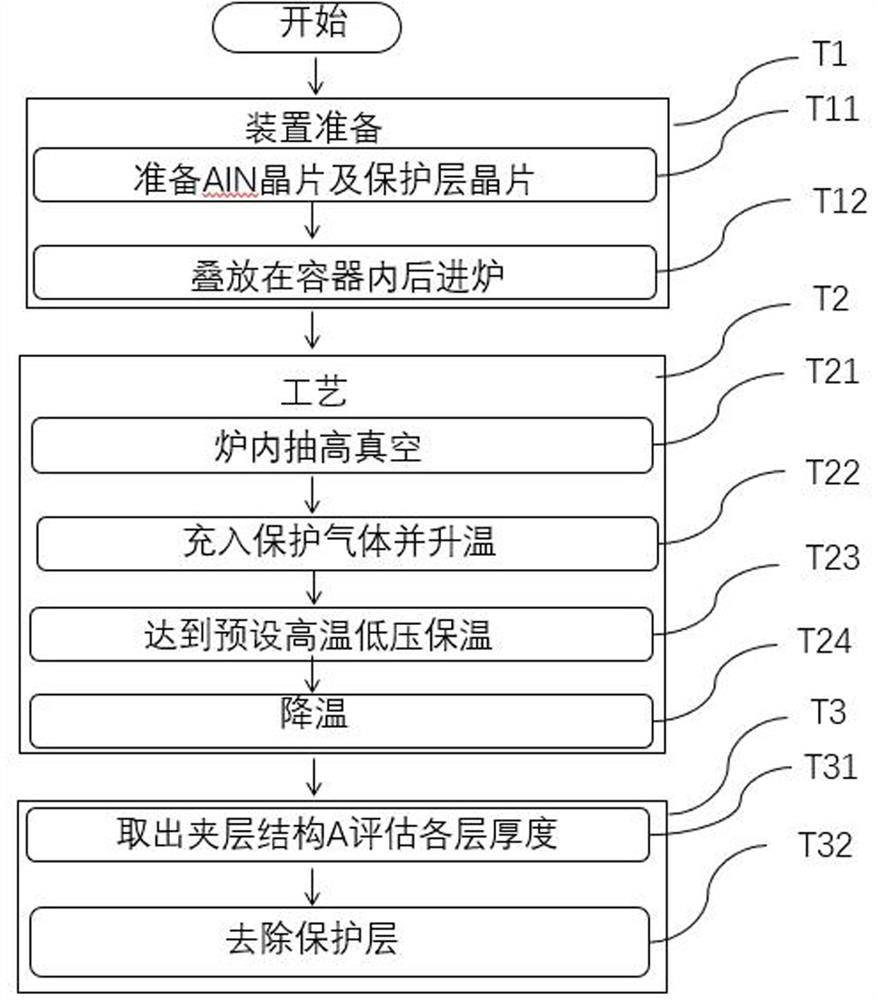

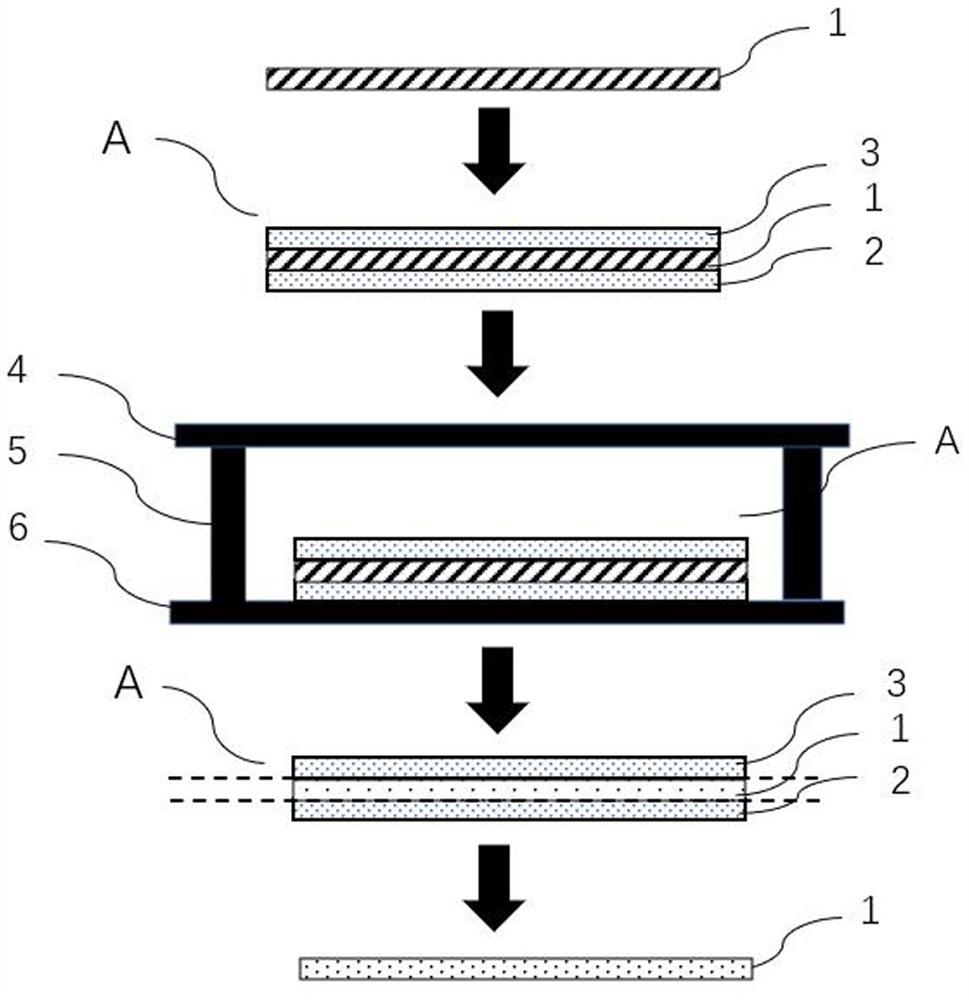

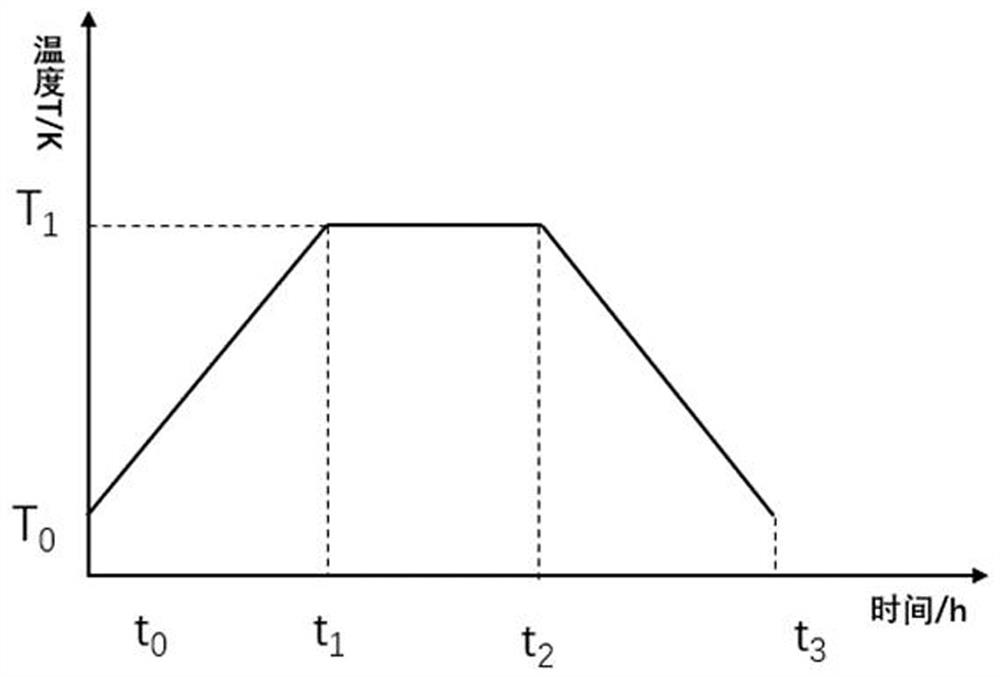

Method for improving ultraviolet transmittance of aluminum nitride wafer

ActiveCN113668061AImprove UV transmittanceImprove color uniformityPolycrystalline material growthAfter-treatment detailsWaferingUltraviolet lights

The invention provides a method for improving the ultraviolet transmittance of an aluminum nitride wafer, which comprises the steps of covering at least one layer of protective material on the upper surface and the lower surface of the aluminum nitride wafer to be treated to form an interlayer composite structure; assembling the interlayer composite structure into a container, and placing the container in a high-temperature furnace; vacuumizing the high-temperature furnace, inflating protective gas after the temperature is raised, and conducting heat preservation for preset time after the preset heat preservation temperature and the low-pressure environment are reached; and cooling to room temperature, taking out the container from the high-temperature furnace, removing the protective material in the interlayer composite structure, and taking out the aluminum nitride wafer. According to the method disclosed by the invention, the ultraviolet light transmittance of the AlN wafer is improved by adopting a high-temperature and low-pressure heat treatment mode, and the uniformity of the color and optical performance of the wafer caused by unintentional doping is improved.

Owner:ULTRATREND TECH INC

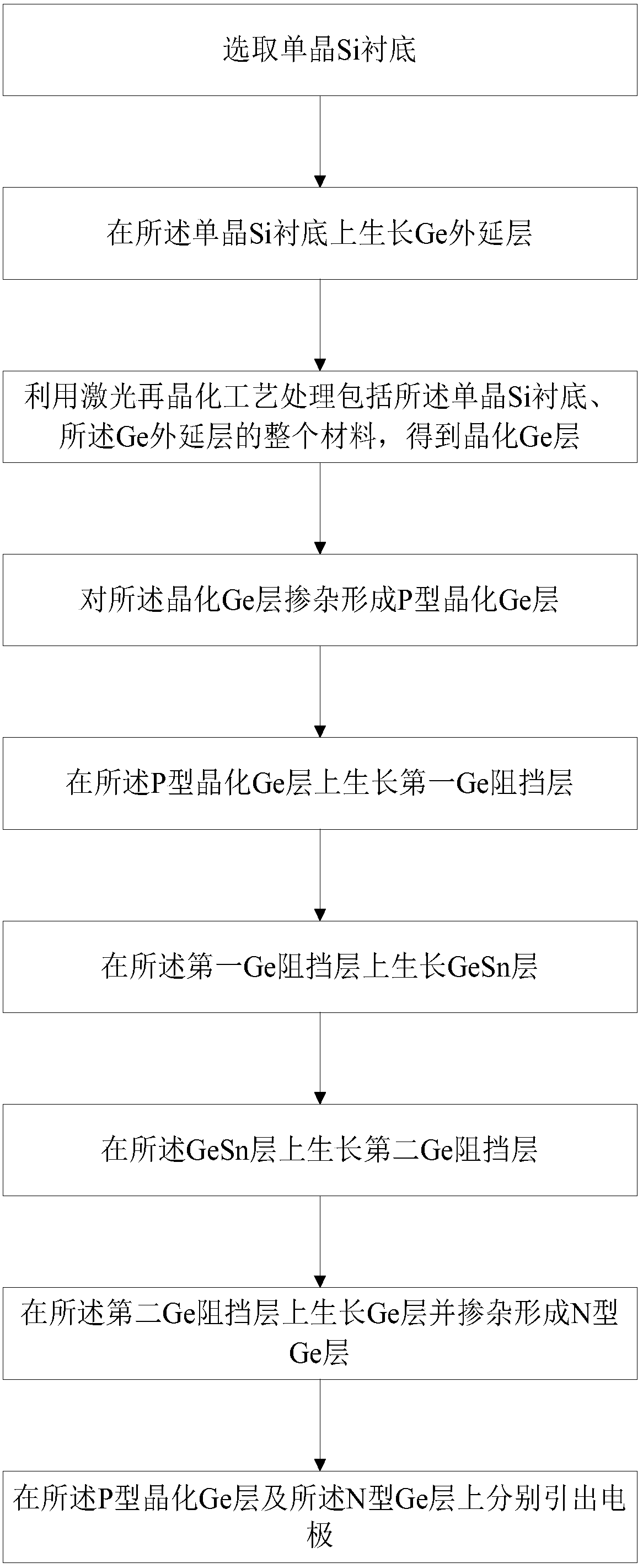

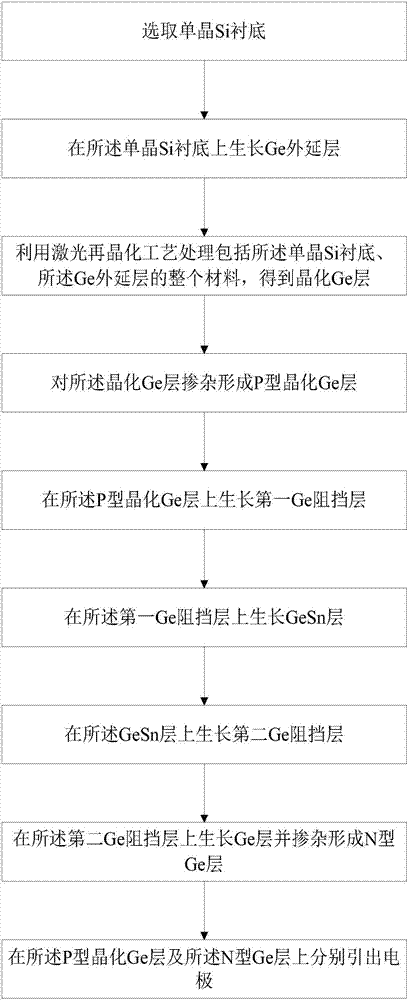

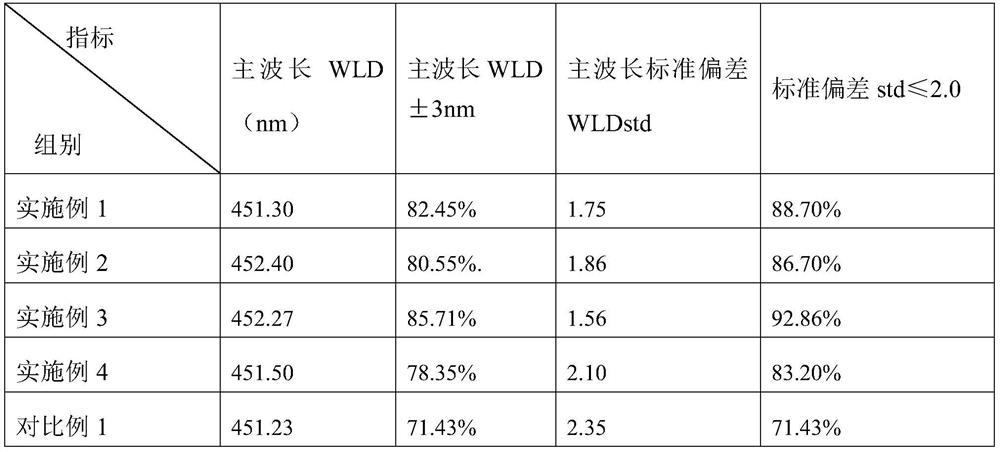

leds based on gesn materials

ActiveCN107248541BAvoid unintentional adulterationImprove performanceSemiconductor/solid-state device manufacturingSemiconductor devicesIntrinsicsCrystallization

The invention relates to a GeSn material-based LED. The LED comprises a monocrystal Si substrate, a P type crystallization Ge layer, an intrinsic Ge layer and a SiO<2> passivation layer, wherein the monocrystal Si substrate, the P type crystallization Ge layer, the intrinsic Ge layer and the SiO<2> passivation layer are arranged in a stacked manner in sequence. According to the GeSn material-based LED provided by the embodiment, GeSn is adopted to replace Ge to be used as the light source in a photoelectric integrated circuit, so that luminous efficiency is improved and defect expansion can be suppressed effectively so as to obtain the high-quality Ge / Si virtual substrate; and in addition, a Ge barrier layer structure is introduced between the Ge doping layer and the GeSn intrinsic layer, so that unintentional doping to the GeSn by the doping source of the Ge layer can be avoided, thereby improving the performance of the device.

Owner:道县晶维电子有限公司

InGaN/GaN multiple quantum well solar cells with low temperature insertion layer

ActiveCN104201220BEffective protectionInhibition formationPhotovoltaic energy generationSemiconductor devicesNucleationSolar cell

An indium gallium nitride or gallium nitride multi-quantum-well solar cell comprising a low-temperature insert layer comprises a substrate, a low-temperature nucleating layer which is manufactured on the substrate, an unintentional doping gallium nitride buffering layer which is manufactured on the low-temperature nucleating layer, an n type doping gallium nitride layer which is manufactured on the unintentional doping gallium nitride buffering layer, an unintentional doping multi-quantum-well layer which is manufactured on one side above the n type doping gallium nitride layer, a p type doping gallium nitride layer which is manufactured on the unintentional doping multi-quantum-well layer, an N type ohmic electrode which is manufactured on a platform surface of the n type doping gallium nitride layer and a P type ohmic electrode which is manufactured on the p type doping gallium nitride layer; the low-temperature nucleating layer provides a nucleation center for later growth of the gallium nitride materials; the platform surface is formed above the other side of the n type doping gallium nitride layer; the unintentional doping multi-quantum-well layer is an absorption layer of a indium gallium nitride solar cell. The indium gallium nitride or gallium nitride multi-quantum-well solar cell has the advantages of increasing absorption of incident light and improving the separating efficiency of carriers.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Ultraviolet LED epitaxial structure and preparation method and application thereof

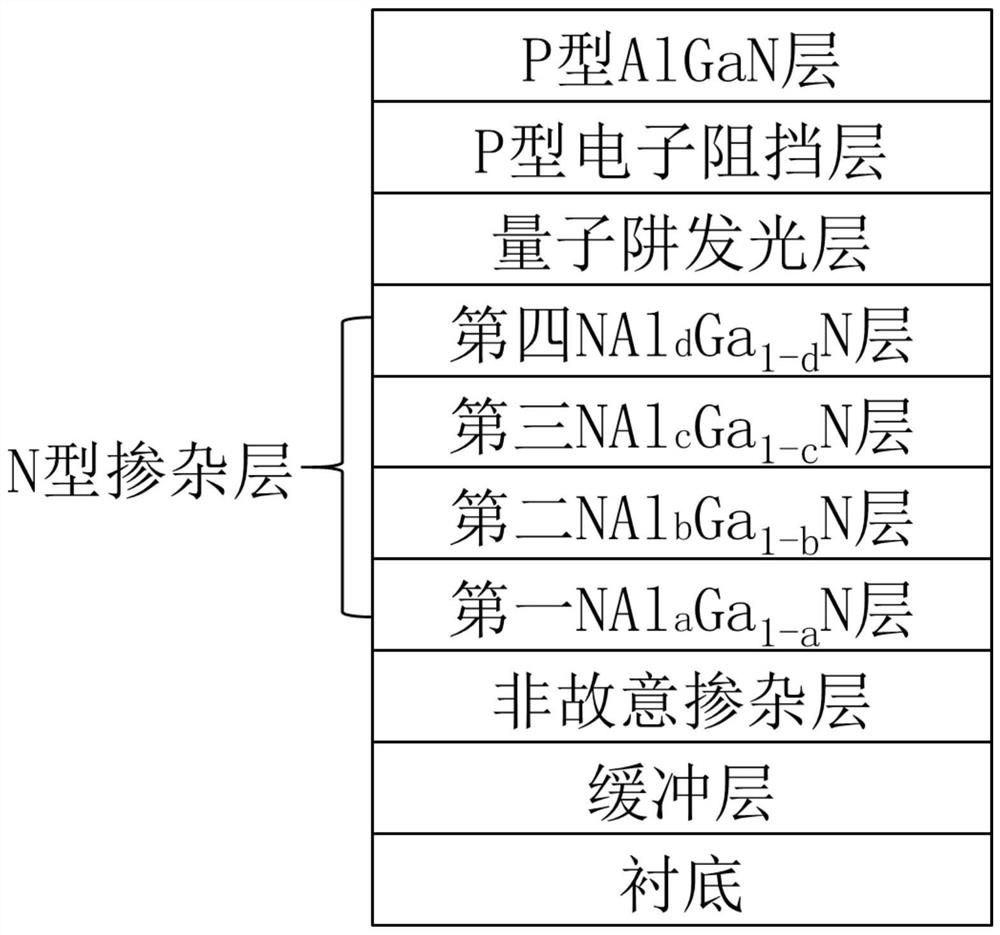

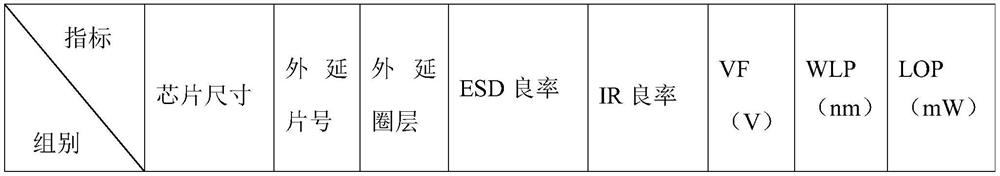

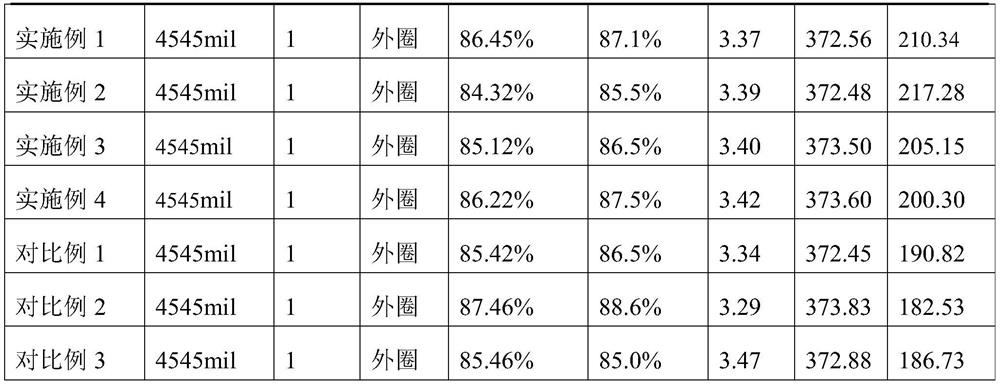

PendingCN113725332ARegulation of migration efficiencyImprove uniformitySemiconductor devicesQuantum efficiencyElectron hole

The invention relates to the technical field of light emitting diodes, in particular to an ultraviolet LED epitaxial structure and a preparation method and application thereof. The ultraviolet LED epitaxial structure sequentially comprises a substrate, a buffer layer, an unintentional doping layer, an N-type doping layer, a quantum well light-emitting layer, a P-type electron blocking layer and a P-type AlGaN layer from bottom to top, wherein the N-type doped layer sequentially comprises a first NAlaGa<1-a>N layer, a second NAlbGa<1-b>N layer, a third NAlcGa<1-c>N layer and a fourth NAldGa<1-d> N layer from bottom to top. The invention provides a novel N-type doping layer structure which can effectively adjust the migration efficiency of electrons, improve the distribution balance of the electrons and holes in an MQW region, effectively improve the recombination probability of the electrons and the holes, remarkably improve the internal quantum efficiency and greatly improve the luminous efficiency.

Owner:广州市众拓光电科技有限公司

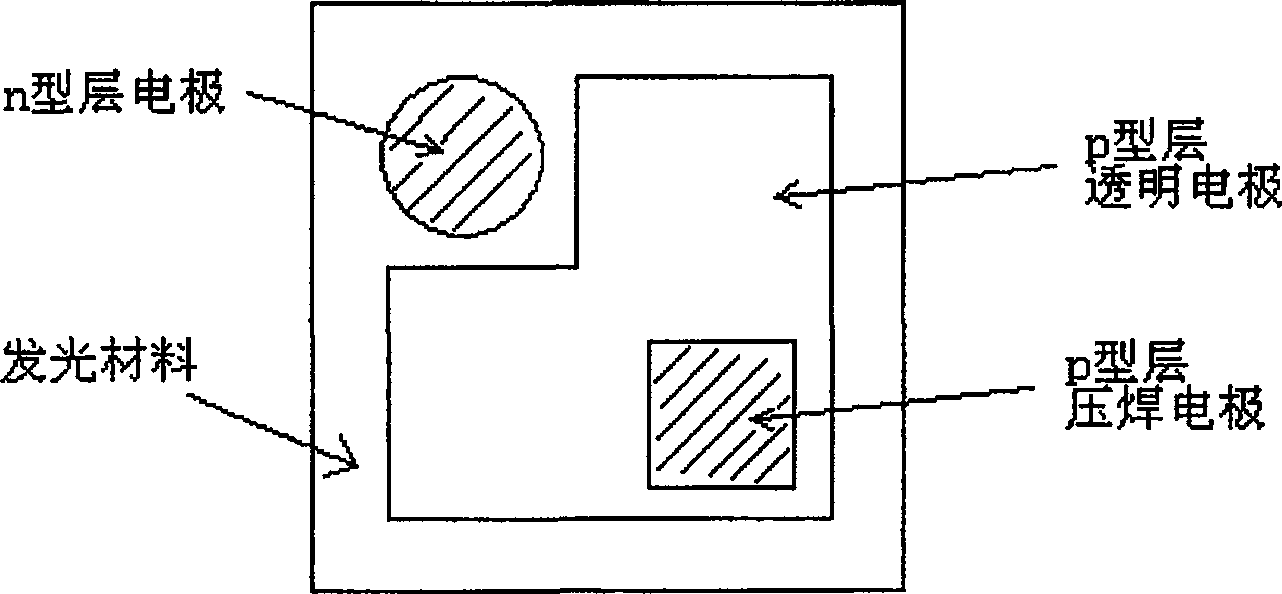

III group nitride semiconductor LED based on plane structure and its preparing process

Owner:NANJING UNIV

Preparation method of low-resistivity low-temperature p-type aluminum gallium nitride material

ActiveCN104201256BLow resistivityReduced series resistanceSemiconductor devicesHydrogenCarbon impurities

A preparation method for low-resistivity low-temperature P type aluminum gallium nitride materials comprises the following steps of step 1, warming a substrate and performing thermal treatment under the hydrogen material environment; step 2, enabling a layer of low-temperature nucleating layer to grow on the substrate and providing a nucleation center for follow-up epitaxial growth; step 3, enabling a layer of unintentional doping template layer to grow on the low-temperature nucleating layer; step 4, enabling a layer of P type aluminum gallium nitride layer with low carbon impurity concentration to grow on the unintentional doping template layer in a epitaxial mode under low temperature to form into an epitaxial wafer; step 5, annealing the epitaxial wafer with high temperature under nitrogen environment to enable an acceptor in the P type aluminum gallium nitride layer to be active and obtain the P type aluminum gallium nitride layer materials with low resistivity. The preparation method for the low-resistivity low-temperature P type aluminum gallium nitride materials can reduce the concentration of unintentional doping carbon impurities in the low-temperature developed P type aluminum gallium nitride materials, accordingly relieving the acceptor compensation function and achieving the purpose of reducing the P type material resistivity.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

GeSn material-based LED

ActiveCN107248541AAvoid unintentional adulterationImprove performanceSemiconductor/solid-state device manufacturingSemiconductor devicesIntrinsicsCrystallization

The invention relates to a GeSn material-based LED. The LED comprises a monocrystal Si substrate, a P type crystallization Ge layer, an intrinsic Ge layer and a SiO<2> passivation layer, wherein the monocrystal Si substrate, the P type crystallization Ge layer, the intrinsic Ge layer and the SiO<2> passivation layer are arranged in a stacked manner in sequence. According to the GeSn material-based LED provided by the embodiment, GeSn is adopted to replace Ge to be used as the light source in a photoelectric integrated circuit, so that luminous efficiency is improved and defect expansion can be suppressed effectively so as to obtain the high-quality Ge / Si virtual substrate; and in addition, a Ge barrier layer structure is introduced between the Ge doping layer and the GeSn intrinsic layer, so that unintentional doping to the GeSn by the doping source of the Ge layer can be avoided, thereby improving the performance of the device.

Owner:道县晶维电子有限公司

Silicon-based LED epitaxial structure and preparation method and application thereof

The invention relates to the technical field of light emitting diodes, in particular to a silicon-based LED epitaxial structure and a preparation method and application thereof. The silicon-based epitaxial structure comprises a silicon-based substrate, a first buffer layer, an AlGaN1 insertion layer, a second buffer layer, an AlGaN2 insertion layer, an unintentional doping layer, an N-type layer, a quantum well light-emitting layer, a P-type electron blocking layer and a P-type AlGaN layer from bottom to top. By arranging the AlGaN1 insertion layer and the AlGaN2 insertion layer, the phenomenon that the LED epitaxial wafer warps due to stress generated by lattice mismatch and thermal deformation difference between the silicon-based substrate and GaN is avoided, warping of the silicon-based epitaxial structure is controlled, and then the wavelength yield is increased.

Owner:广州市众拓光电科技有限公司

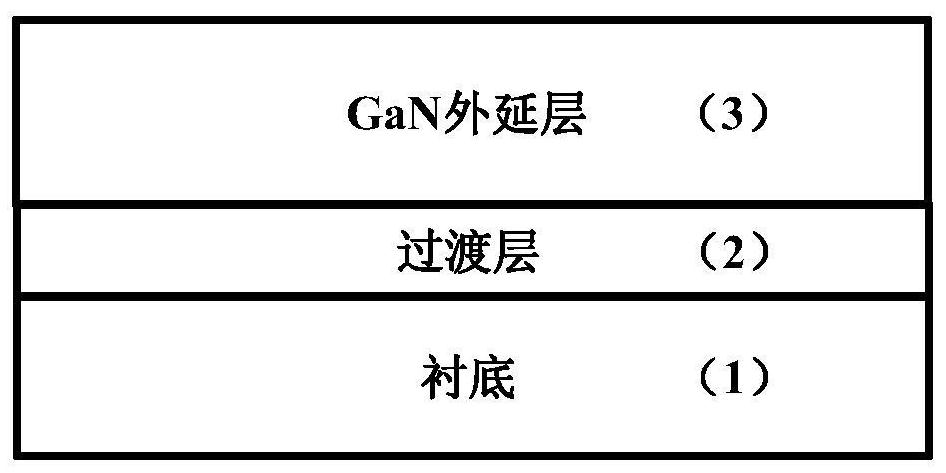

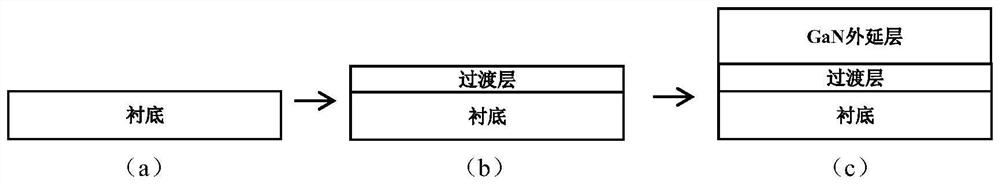

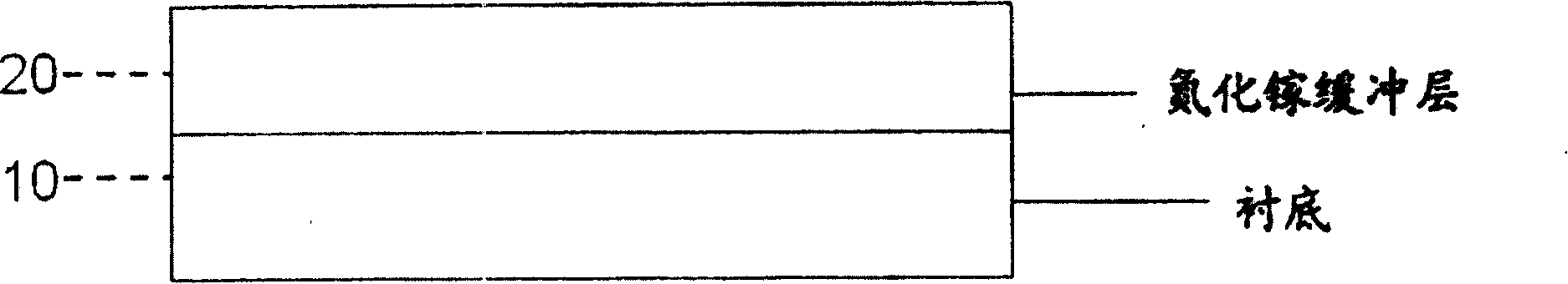

Nitrogen polar surface GaN material and homoepitaxial growth method

PendingCN112750691AReduce dislocation densityImprove adsorption capacitySemiconductor/solid-state device manufacturingSemiconductor devicesRectifier diodesSingle crystal

The invention discloses a nitrogen polar surface GaN material and a manufacturing method thereof, and solves the problems that an existing nitrogen polar surface GaN material is high in dislocation density, poor in surface appearance, high in unintentional doping background carrier concentration and large in growth process control difficulty are mainly solved. The nitrogen polar surface GaN material structure comprises a substrate (1), a transition layer (2) and a GaN epitaxial layer (3) from bottom to top, wherein the transition layer adopts InAlN or ScAlN or YAlN, and the substrate is made of non-diagonal plane nitrogen polar surface gallium nitride single crystal. The manufacturing method comprises the following steps of: growing the transition layer with the thickness of 1-10 nm on the substrate by using a molecular beam epitaxy method; and growing the GaN epitaxial layer on the transition layer by using the molecular beam epitaxy method. The nitrogen polar surface GaN material is high in crystallization quality, smooth in surface appearance, low in background carrier concentration, simple in growth process and high in process repeatability and consistency, and can be used for manufacturing high-electron-mobility transistors and high-speed microwave rectifier diodes.

Owner:XIDIAN UNIV

Structure for improving Schottky performance of grid electrode of gallium nitride based transistor in high electron mobility

InactiveCN100383980CReduce leakageIncreased output current capabilitySemiconductor/solid-state device manufacturingSemiconductor devicesGallium nitrideResistor

The structure is as following: a sapphire substrate or silicon carbide substrate or silicon substrate; buffer layer of gallium nitride in high-ohmic resistor prepared on substrate; an interposed layer of unintentional doping aluminum-gallium - nitrogen in thin layer prepared on buffer layer of gallium nitride in high-ohmic resistor; a channel layer of gallium nitride in high mobility prepared on the interposed layer of unintentional doping aluminum-gallium-nitrogen; a spatial isolation layer of unintentional doping aluminum-gallium-nitrogen prepared on the channel layer of gallium nitride in high mobility; n type supply layer of aluminum-gallium-nitrogen carrier prepared on the spatial isolation layer of unintentional doping aluminum-gallium-nitrogen; an unintentional doping aluminum-gallium-nitrogen covering cap layer prepared on n type supply layer of aluminum-gallium-nitrogen carrier.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Epitaxy method of vertical [beta]-gallium oxide nanowire array Epitaxy method of vertical [beta]-gallium oxide nanowire array](https://images-eureka.patsnap.com/patent_img/ac7911cb-ae18-480f-b644-d27c05c1fa1b/HDA0002128196150000011.png)

![Epitaxy method of vertical [beta]-gallium oxide nanowire array Epitaxy method of vertical [beta]-gallium oxide nanowire array](https://images-eureka.patsnap.com/patent_img/ac7911cb-ae18-480f-b644-d27c05c1fa1b/HDA0002128196150000012.png)

![Epitaxy method of vertical [beta]-gallium oxide nanowire array Epitaxy method of vertical [beta]-gallium oxide nanowire array](https://images-eureka.patsnap.com/patent_img/ac7911cb-ae18-480f-b644-d27c05c1fa1b/HDA0002128196150000021.png)