Super flexible nitride-based pyramid structure semiconductor device and preparation method thereof

A base pyramid, gallium nitride technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of device size limitation, micro-nano structure damage, difficult to achieve high flexibility devices, etc., to improve efficiency and size. Restricted, guaranteed size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of ultra-flexible GaN-based pyramid structure semiconductor device of the present invention comprises the following steps:

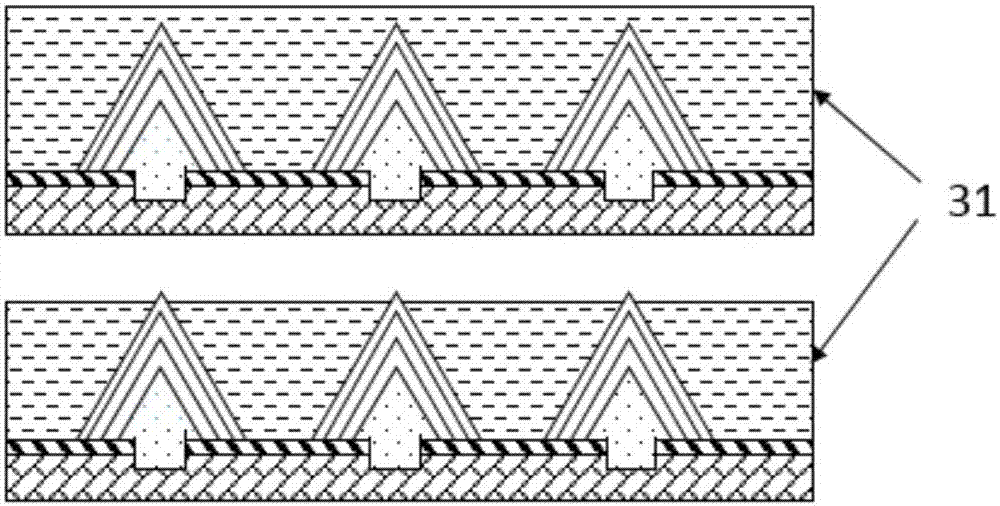

[0041] 1) SiO 2 The mask 12 is covered on the sapphire substrate 11, and then on the SiO 2 Patterning is carried out on the mask 12 and the sapphire substrate 11 to obtain a patterned substrate, then a pyramid array 2 is grown on the patterned substrate, and the gap between each pyramid in the pyramid array 2 is filled by an insulating filling material 31 , and etch to expose the top of each pyramid in the pyramid array 2;

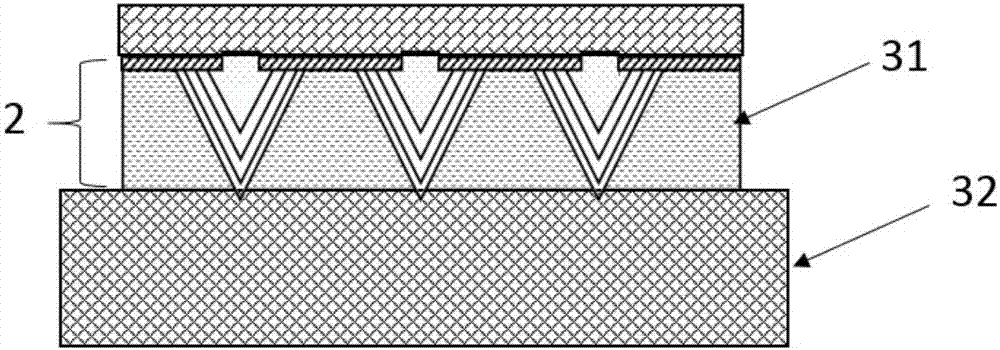

[0042] 2) transfer the pyramid array 2 to the semi-cured PDMS temporary substrate 32, wherein, the top of each pyramid in the pyramid array 2 faces down and is connected with the semi-cured PDMS temporary substrate 32, then peels off the sapphire substrate 11, Then the pyramid array 2, the semi-cured PDMS temporary substrate 32 and SiO 2 The structure that mask 12 forms rotates in vertical direction, ...

Embodiment 1

[0049] The making process of the present invention is:

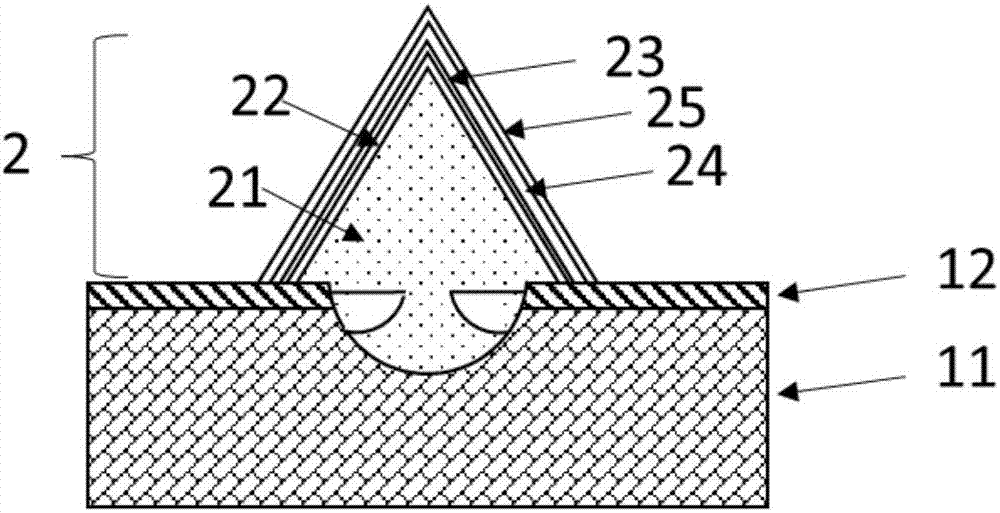

[0050] 1) Reference figure 1 , covered with SiO 2 On the sapphire substrate 11 of mask 12, carry out patterning by the mode of laser drilling, obtain patterned substrate, then grow pyramid array 2 on the substrate of described patterning, the structure of each pyramid in pyramid array 2 can be Design according to the requirements of different devices, taking light-emitting diode devices as an example, each pyramid in the pyramid array 2 includes 2um thick unintentionally doped gallium nitride 21, 1um thick n-type gallium nitride layer 22, 10 groups of quantum wells and 100nm thick p-type gallium nitride layer 24;

[0051] 2) The p-type gallium nitride layer 24 has a very high resistivity. In order to ensure the uniformity of the current distribution on the pyramid, a transparent conductive layer 25 of 100nm-200nm is deposited on the surface of the pyramid. The material of the transparent conductive layer 25 is ITO or ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com