Silicon-based LED epitaxial structure and preparation method and application thereof

An epitaxial structure, silicon-based technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of increased time and cost, long emission wavelength, low temperature, etc., to achieve simple and fast operation, improve wavelength yield, save The effect of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

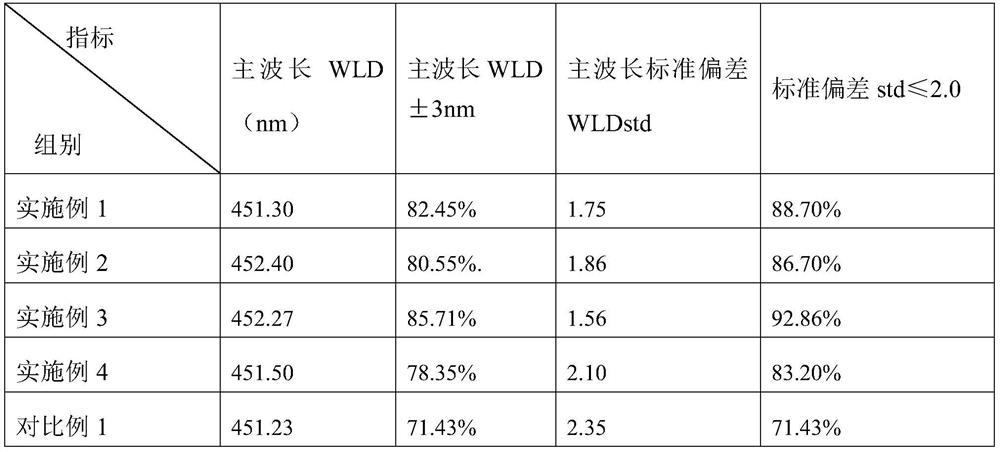

Examples

Embodiment 1

[0041] A silicon-based LED epitaxial structure, the silicon-based epitaxial structure includes a silicon-based substrate, a first buffer layer, an AlGaN1 insertion layer, a second buffer layer, an AlGaN2 insertion layer, an unintentionally doped layer, and an N-type layer from bottom to top , a quantum well light-emitting layer, a P-type electron blocking layer and a P-type AlGaN layer.

[0042] The preparation method of the silicon-based epitaxial structure comprises the following steps:

[0043] Step S1: prepare a silicon-based substrate, put the silicon-based substrate in 1000°C H 2 Baking under atmosphere for 1min;

[0044] Step S2: growing a first buffer layer on a silicon-based substrate; the growth temperature is 600° C., and the growth thickness is 20 nm;

[0045] Step S3: growing an AlGaN1 insertion layer on the first buffer layer at a growth temperature of 900°C;

[0046] Step S4: growing a second buffer layer on the AlGaN1 insertion layer at a growth temperature ...

Embodiment 2

[0054] A silicon-based LED epitaxial structure, the silicon-based epitaxial structure includes a silicon-based substrate, a first buffer layer, an AlGaN1 insertion layer, a second buffer layer, an AlGaN2 insertion layer, an unintentionally doped layer, and an N-type layer from bottom to top , a quantum well light-emitting layer, a P-type electron blocking layer and a P-type AlGaN layer.

[0055] The preparation method of the silicon-based epitaxial structure comprises the following steps:

[0056] Step S1: prepare a silicon-based substrate, put the silicon-based substrate in 1100°C H 2 Baking under the atmosphere for 2min;

[0057] Step S2: growing a first buffer layer on a silicon-based substrate; the growth temperature is 900° C., and the growth thickness is 100 nm;

[0058] Step S3: growing an AlGaN1 insertion layer on the first buffer layer at a growth temperature of 1100°C;

[0059] Step S4: growing a second buffer layer on the AlGaN1 insertion layer at a growth temper...

Embodiment 3

[0067] A silicon-based LED epitaxial structure, the silicon-based epitaxial structure includes a silicon-based substrate, a first buffer layer, an AlGaN1 insertion layer, a second buffer layer, an AlGaN2 insertion layer, an unintentionally doped layer, and an N-type layer from bottom to top , a quantum well light-emitting layer, a P-type electron blocking layer and a P-type AlGaN layer. Wherein the Al component content in the AlGaN1 insertion layer is 30%, and the Al component content in the AlGaN2 insertion layer is 15%. The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Growth thickness | aaaaa | aaaaa |

| Total thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com