Preparation method of GaN-based LED epitaxial wafer enhancing luminescence efficiency

A technology for LED epitaxial wafers and luminous efficiency, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as increasing process complexity, and achieve the effect of improving external quantum efficiency, simple method and reducing Stark effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

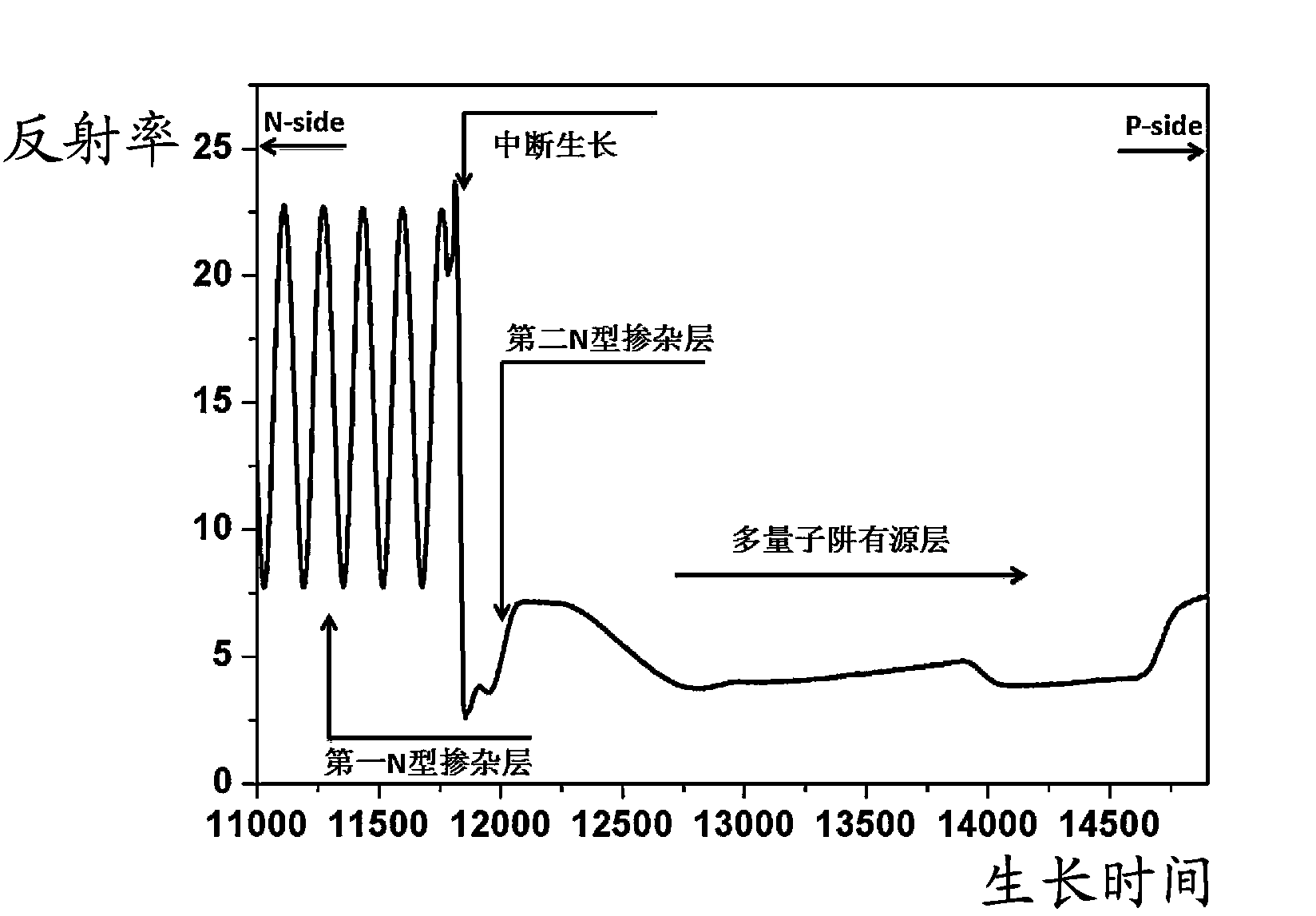

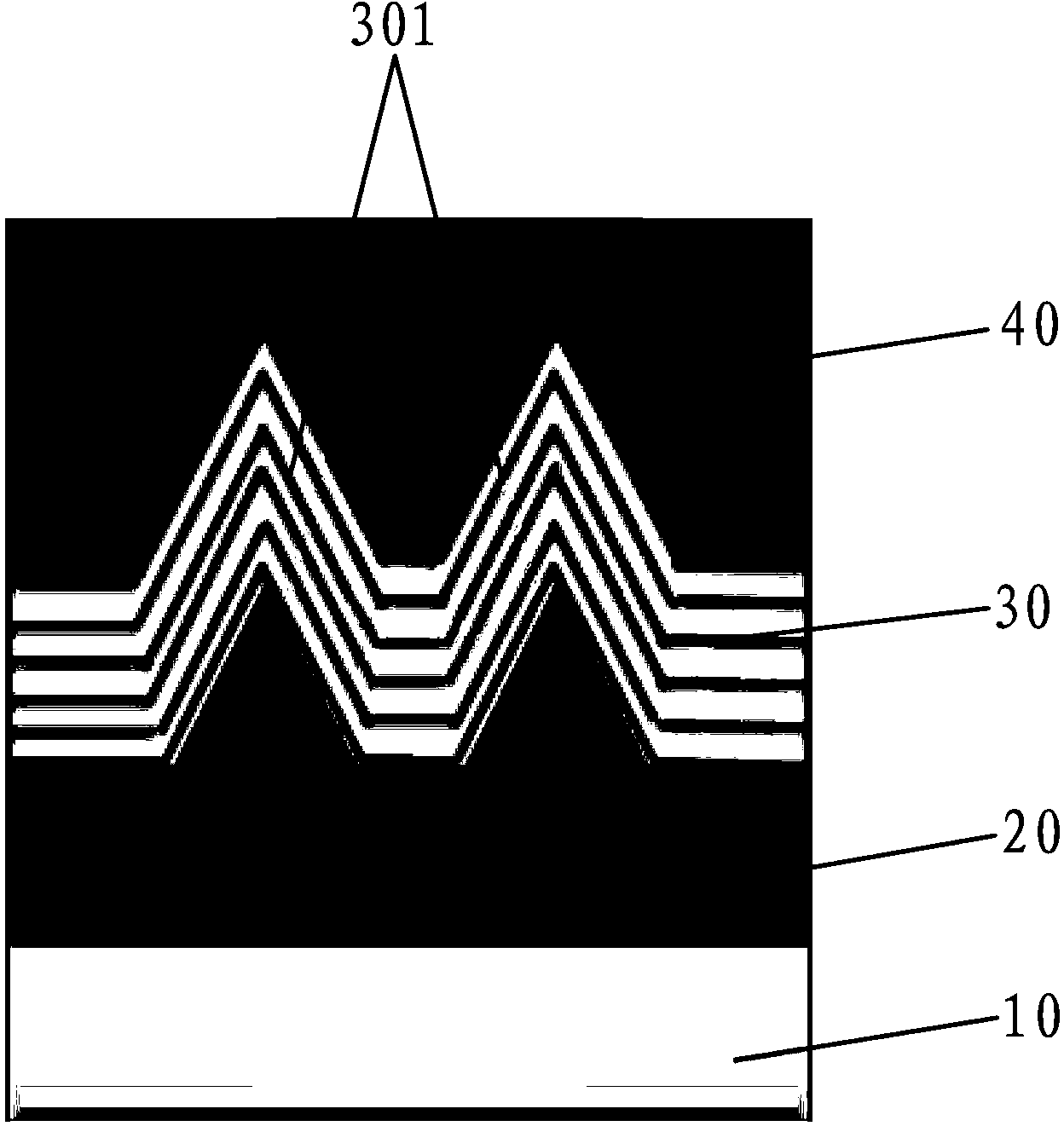

[0037] Using MOCVD equipment to grow GaN-based LEDs, using a 2-inch C-face no-clean sapphire substrate, the epitaxy steps mainly include:

[0038] 1. Raise the temperature of the reaction chamber to 1200°C, the pressure of the reaction chamber is 100mbar, in H 2 Bake the sapphire substrate under atmosphere for 300s.

[0039] 2. Reduce the temperature of the reaction chamber to 560°C and feed NH 3 , nitrided substrate 120s.

[0040] 3. Adjust the reaction chamber pressure to 600 mbar, and feed Ga source and NH 3 , The ratio of V / III is 1200, and a 25nm GaN buffer layer is grown at 560°C.

[0041] 4. Increase the temperature of the reaction chamber to 1100°C, adjust the pressure of the reaction chamber to 250mbar, and feed Ga source and NH 3 , The ratio of Ⅴ / Ⅲ is 1500, and a 2000nm non-intentionally doped GaN layer is grown.

[0042] 5. Ga source, NH 3 and silane, the ratio of V / III is 1500, and a 2500nm N-type doped GaN layer is grown, and the N-type doping concentration is...

Embodiment 2

[0052] The difference between this embodiment and the first embodiment is that in this embodiment, during the interrupted growth process, the NH 3 traffic methods such as Figure 5 Shown, specifically: keep NH within 0-15s 3 Normal flow into the reaction chamber, within 15-65s, close the NH 3 , within 65-80s, turn on NH again 3 , keep NH 3 Normal flow into the reaction chamber.

Embodiment 3

[0054] The difference between this embodiment and the first embodiment is that in this embodiment, during the interrupted growth process, the NH 3 The flow adopts pulse type, such as Figure 6 shown, specifically: pulse on NH 3 and off NH 3 The times are 5s and 15s respectively, repeating 4 cycles in total.

PUM

| Property | Measurement | Unit |

|---|---|---|

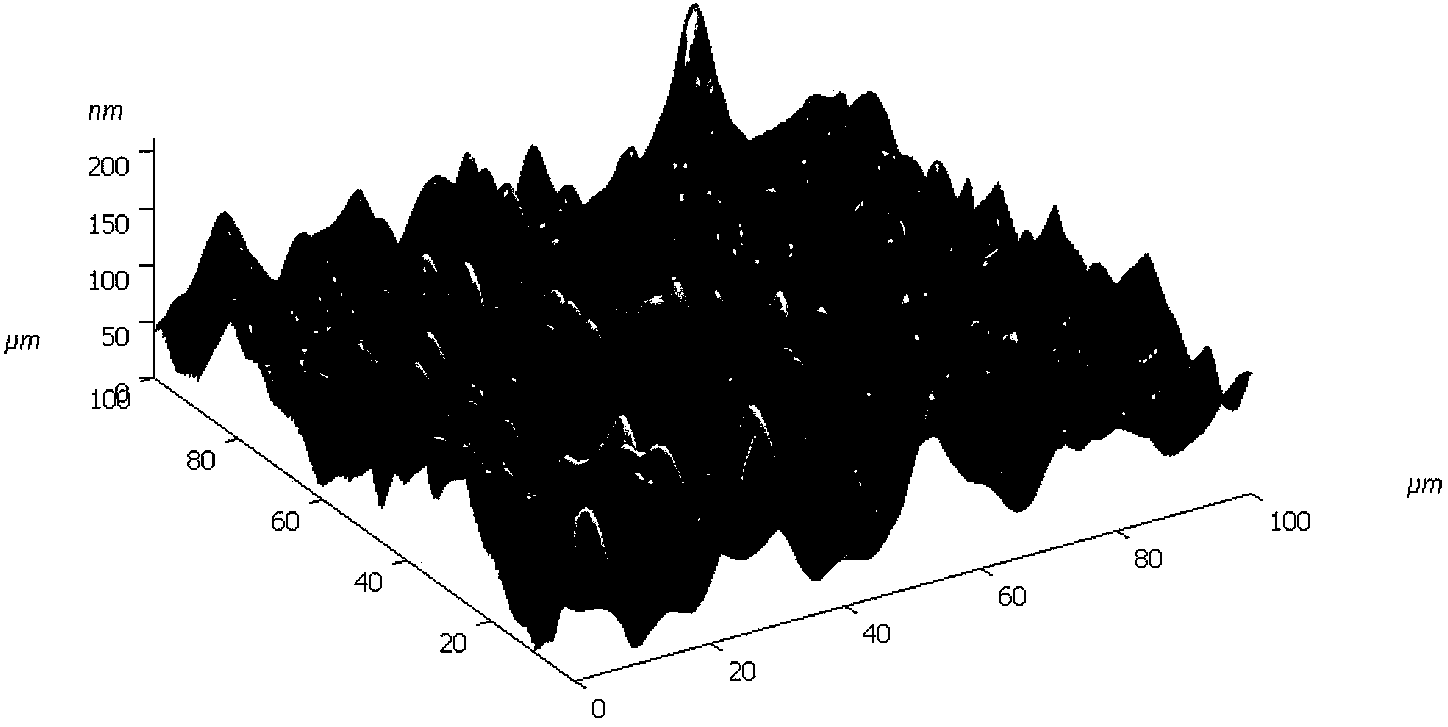

| Surface roughness | aaaaa | aaaaa |

| Average height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com