Patents

Literature

41results about How to "Increase chance of shooting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

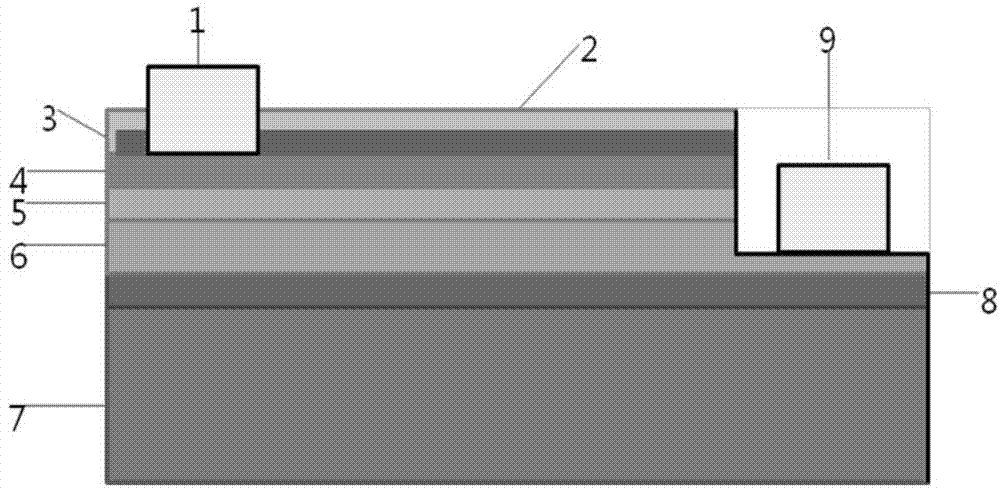

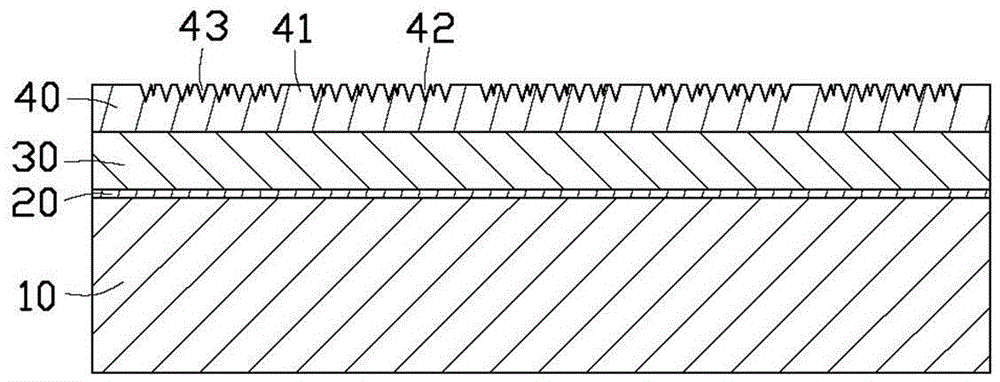

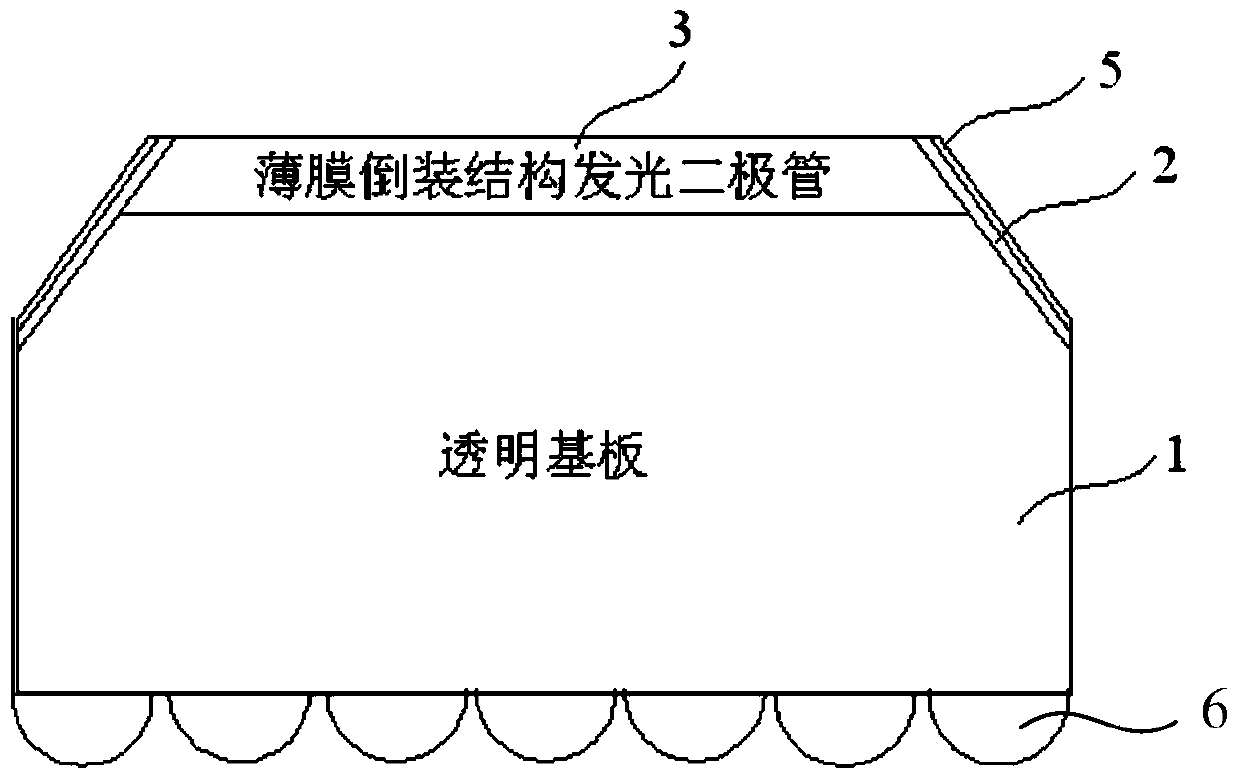

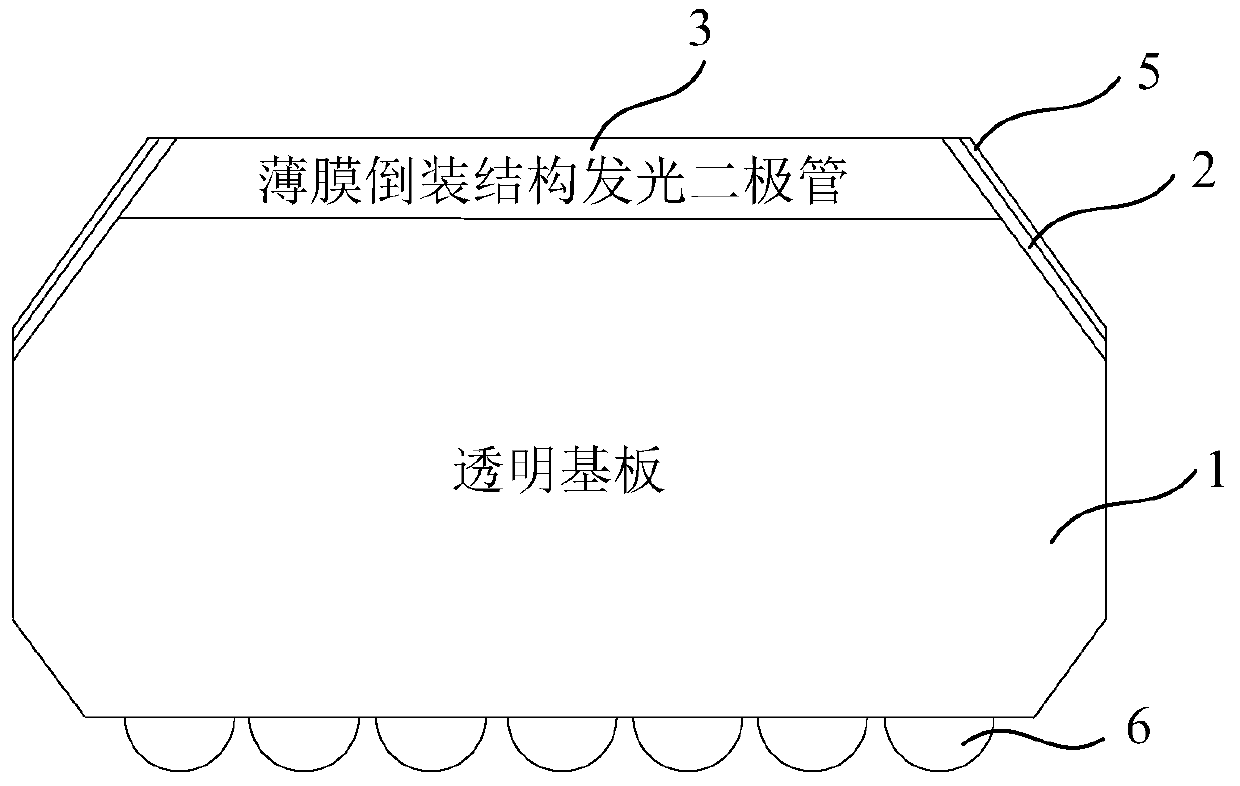

Flip-chip LED chip structure and manufacturing method thereof

InactiveCN102044608AGuaranteed compositeGuaranteed to workSemiconductor devicesContact layerMaterials science

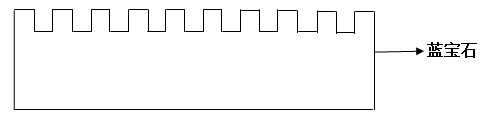

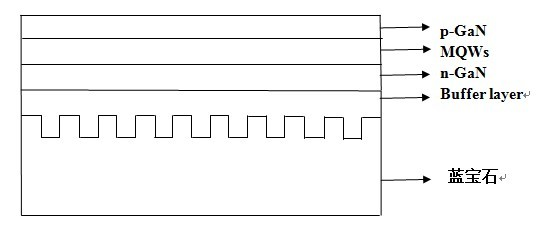

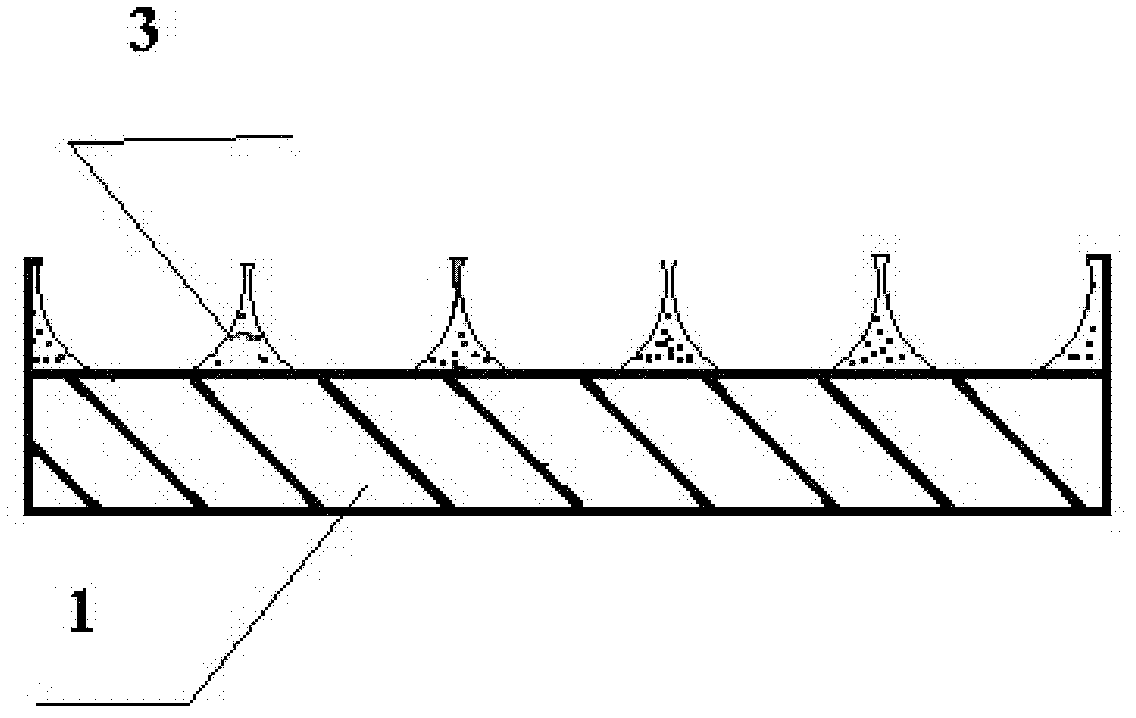

The invention discloses a flip-chip LED chip structure and a manufacturing method thereof. The LED chip comprises an epitaxial layer taking sapphire as substrate and an electrode layer taking SiO2 / Si as substrate; holes of periodical structure are etched on the front surface of the sapphire substrate, and random patterns are etched on the back surface; a growth buffer layer, an n type GaN layer (n-GaN), an MQWs (multi quantum wells) layer and a p type GaN layer (p-GaN) are successively grown on the sapphire substrate etched with holes as the epitaxial layer; one or more negative electrode grooves are etched on the p type GaN layer (p-GaN); a p type contact layer is sputtered on the p type GaN layer (p-GaN); an n type ohmic contact layer is electroplated on the n type GaN layer (n-GaN) exposed after etching; titanium (Ti), platinum (Pt) and aurum (Au) are successively deposited on the SiO2 / Si substrate as an electrode layer; the electrode distribution on the electrode layer is coincident with that on the etched epitaxial layer; and the LED chip is formed by bonding the epitaxial layer on the front surface of the sapphire substrate and the electrode layer on the SiO2 / Si substrate with Au solder. The structure has the advantages of stable performance, high utilization rate of electric energy and long service life.

Owner:CHONGQING UNIV

High-luminance chip of luminescent tube in GaN base, and preparation method

InactiveCN1874012AImprove thermal characteristicsImprovement and conductivityLaser detailsSolid-state devicesPhotonic crystal structureLead structure

The technical scheme discloses high brightness LED structure with graphic surface and microstructure. Using Nano pressing technique prepares each graphic film from organic material on luminous surface of LED so as to form microstructure on LED surface in favor of transgression of emitting light from active region, for example micrographics with structure or coarsening, and photon crystal structure. Introducing the said micrographics on surface makes interfacial area of light emergence medium increase. The increased surface presents great lot small areas unordered arranged. Emergence of light from active region and interface of medium is at random in a certain extent. The invention improves directions of emergence light, increases probability of emergence so as to raise light extraction efficiency and external quantum efficiency of LED.

Owner:PEKING UNIV

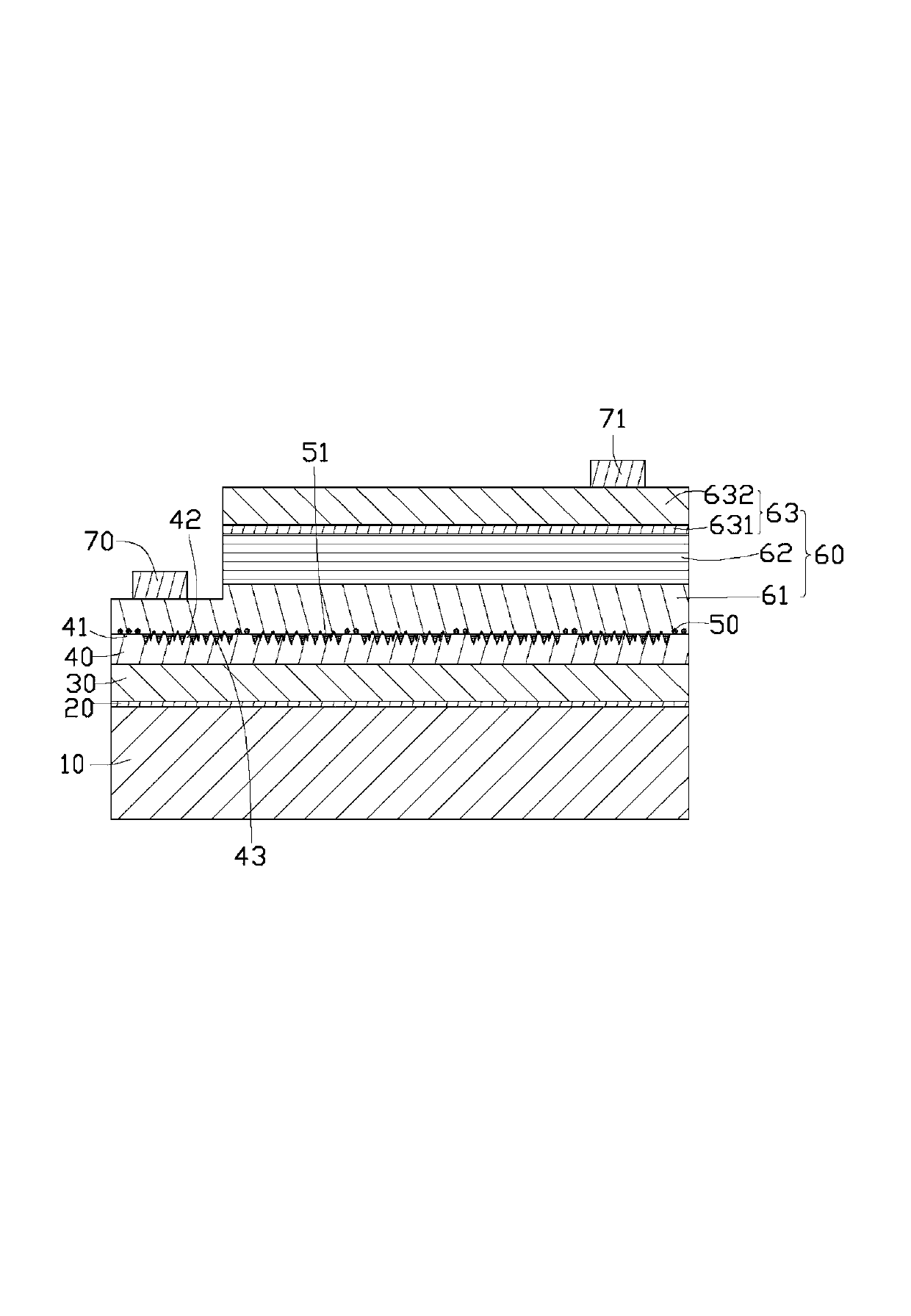

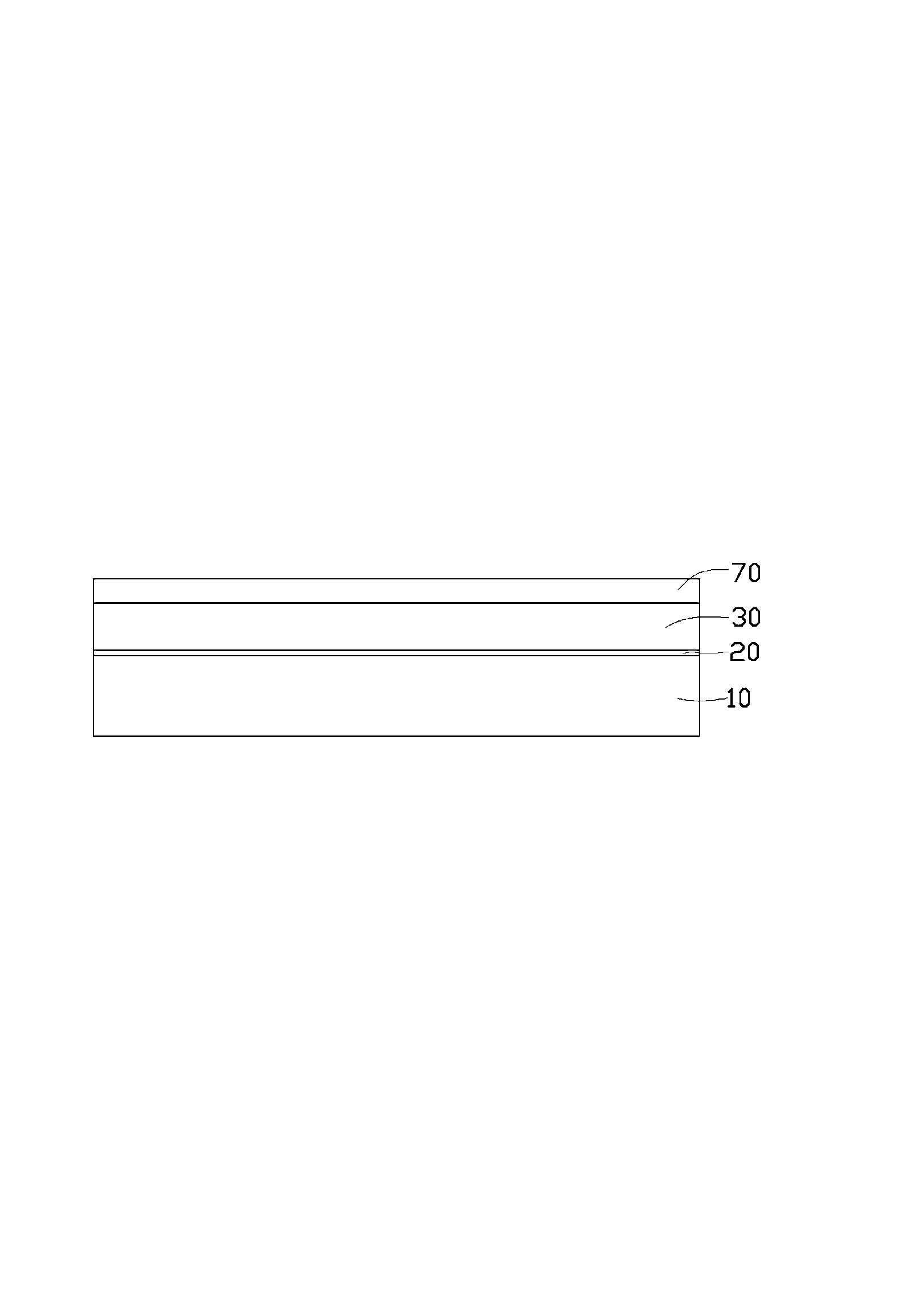

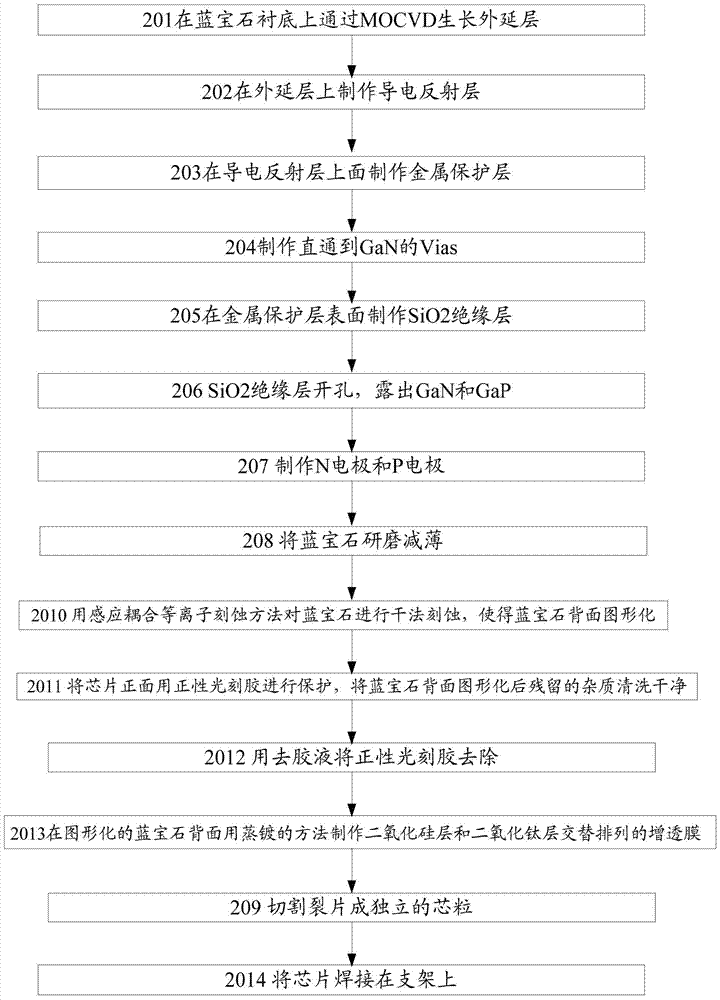

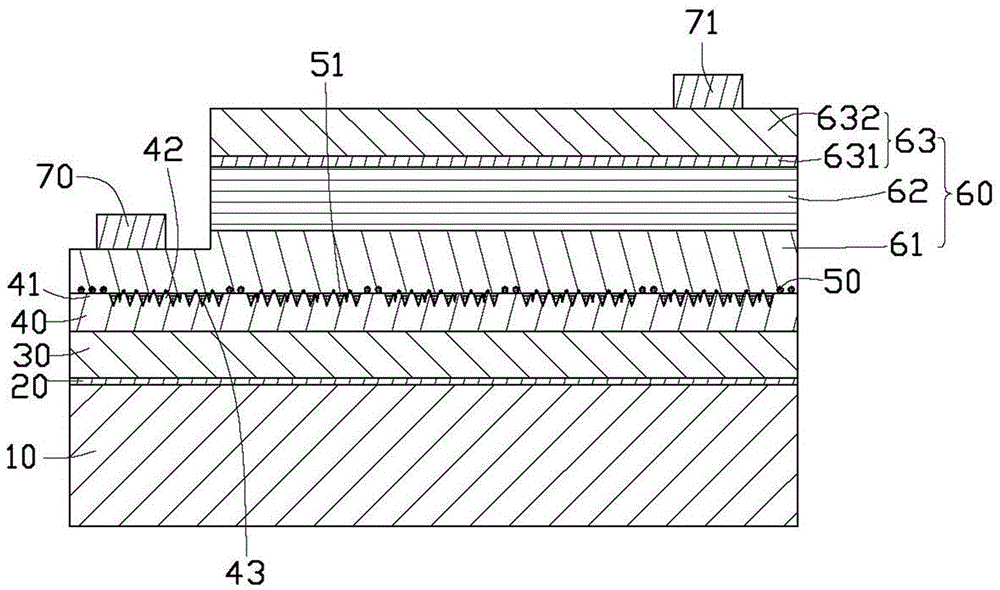

LED flip chip and manufacturing method thereof

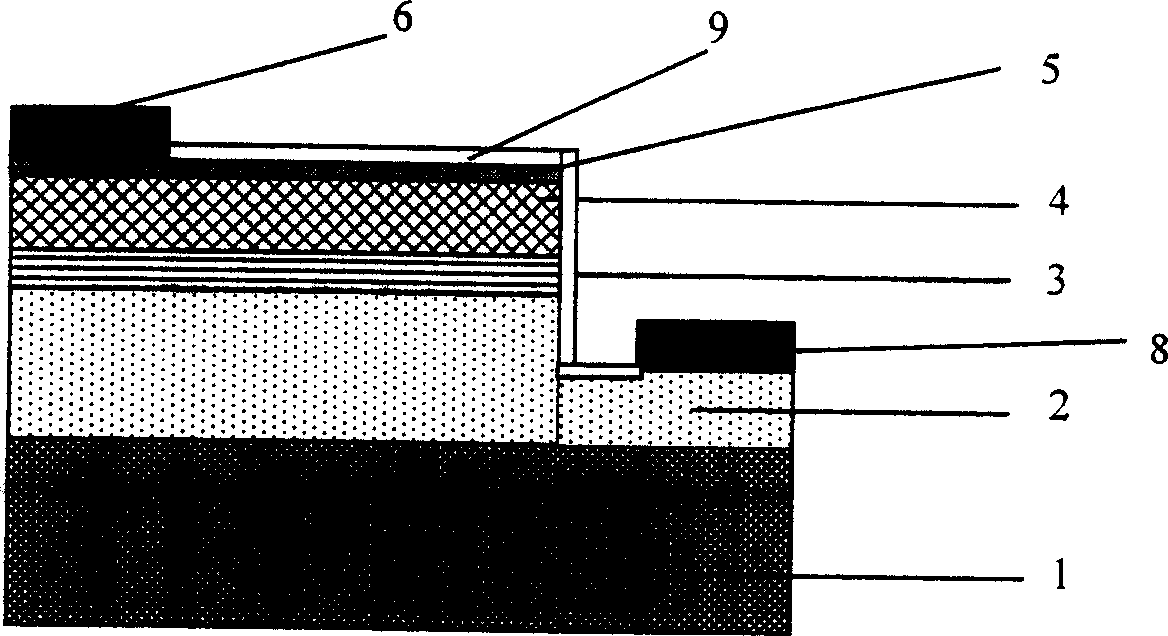

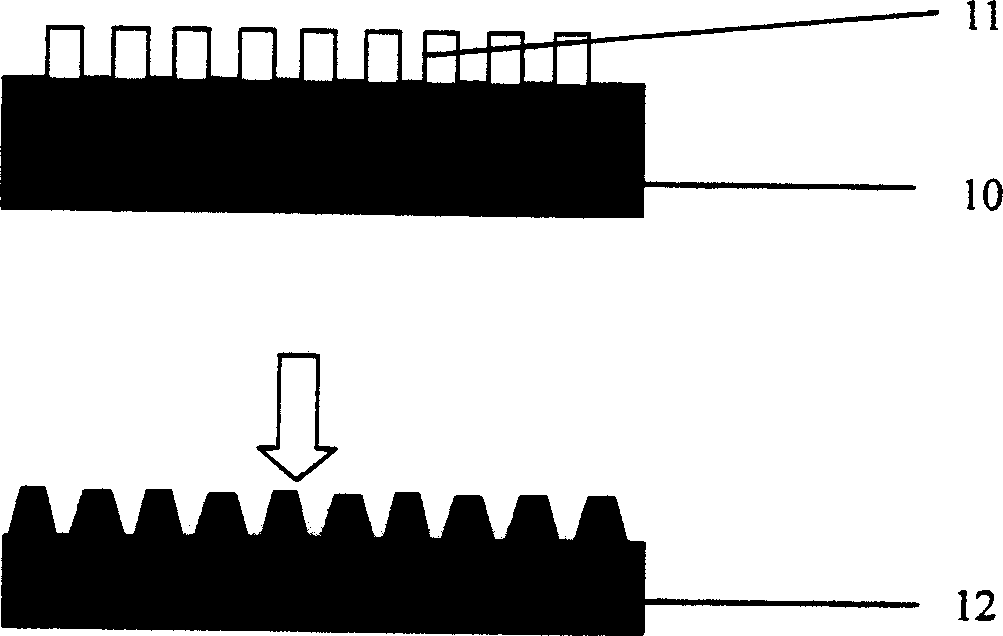

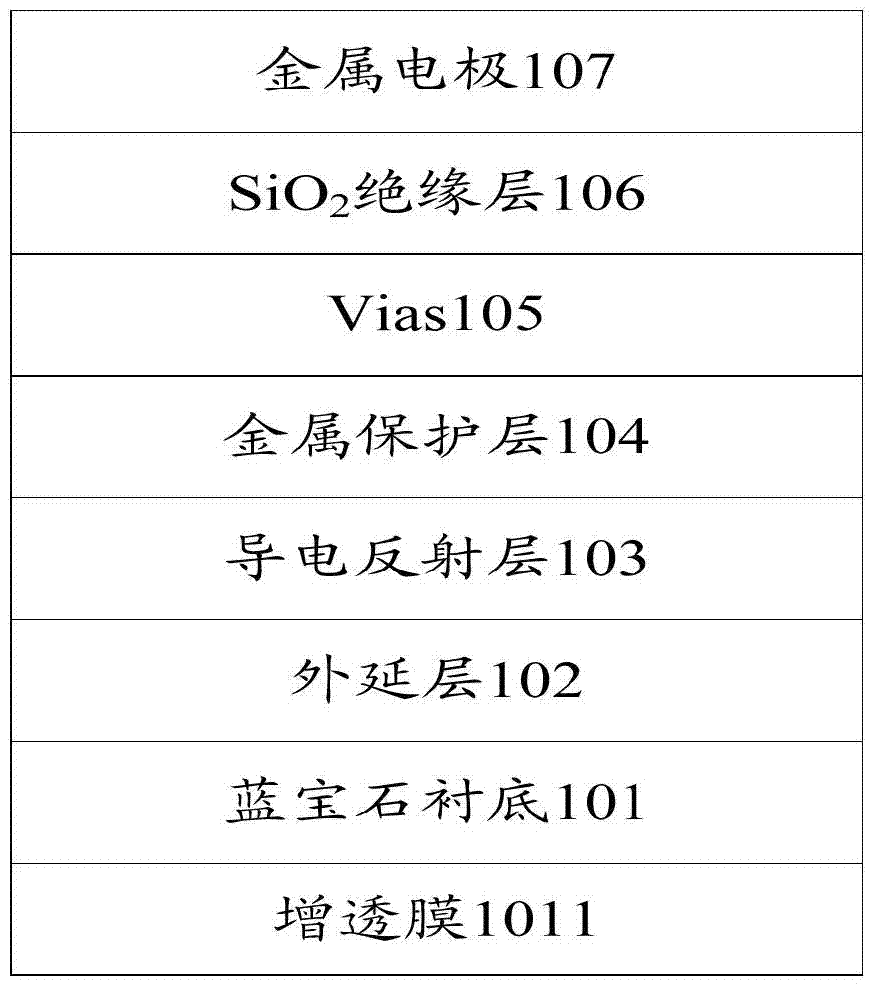

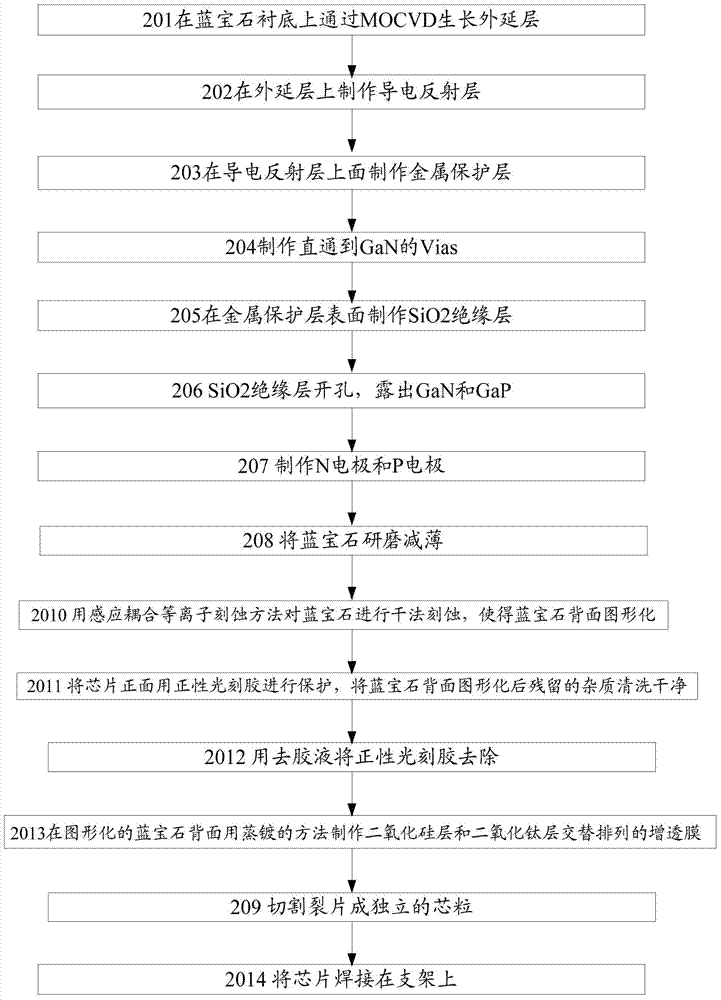

ActiveCN104269480AExtended launch angleIncrease chance of shootingSemiconductor devicesAnti-reflective coatingEvaporation

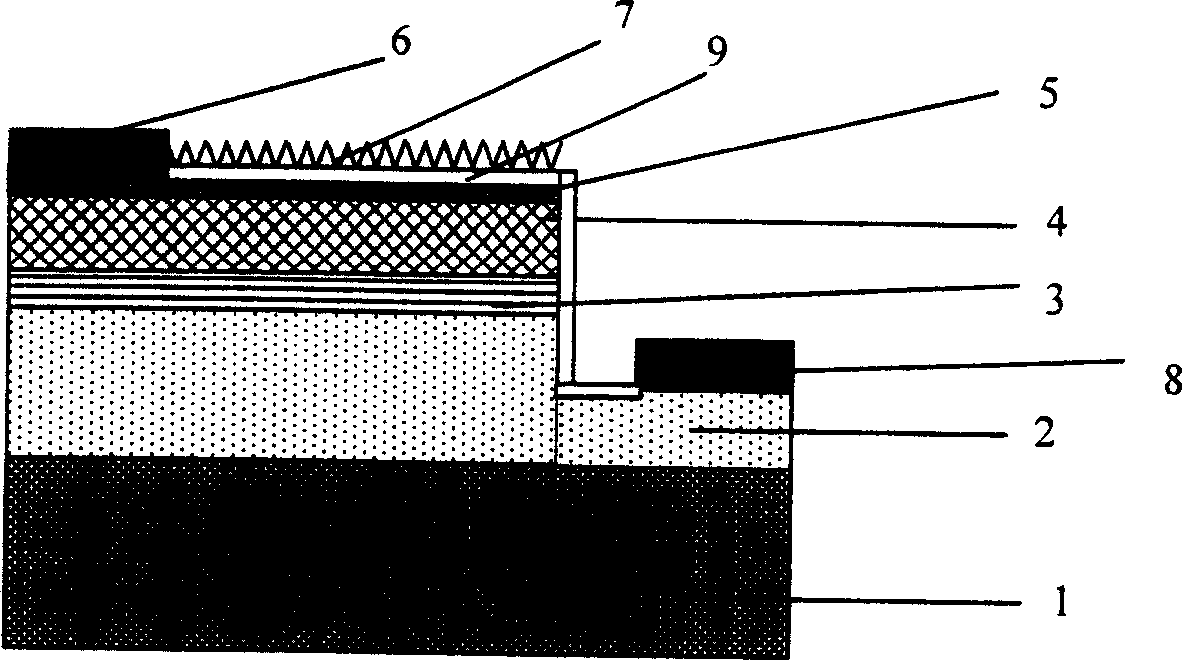

The invention discloses an LED flip chip. The LED flip chip sequentially comprises a sapphire substrate, an epitaxial layer, a conductive reflecting layer, a metal protective layer, a Vias and SiO2 insulating layer and metal electrodes from bottom to top, wherein the sapphire substrate is a sapphire substrate, obtained after inductive coupling plasma etching, with a graphical back side, an antireflection film is further arranged on the back side of the sapphire substrate, the antireflection film is an antireflection film, manufactured with an evaporation method, with silicon dioxide layers and titanium dioxide layers alternately arranged, the sum of the number of the silicon dioxide layers in the antireflection film and the number of the titanium dioxide layers in the antireflection film ranges from 6 to 15, and the thickness of the silicon dioxide layers in the antireflection film and the thickness of the titanium dioxide layers in the antireflection film range from 20 nm to 300 nm. The invention further provides a manufacturing method of the LED flip chip. The emitting angle of light at the bottom of the LED flip chip is increased through a graphical sapphire substrate technology, the light outgoing probability is increased, brightness is improved, and the brightness of white light is improved by 1% to 7%.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

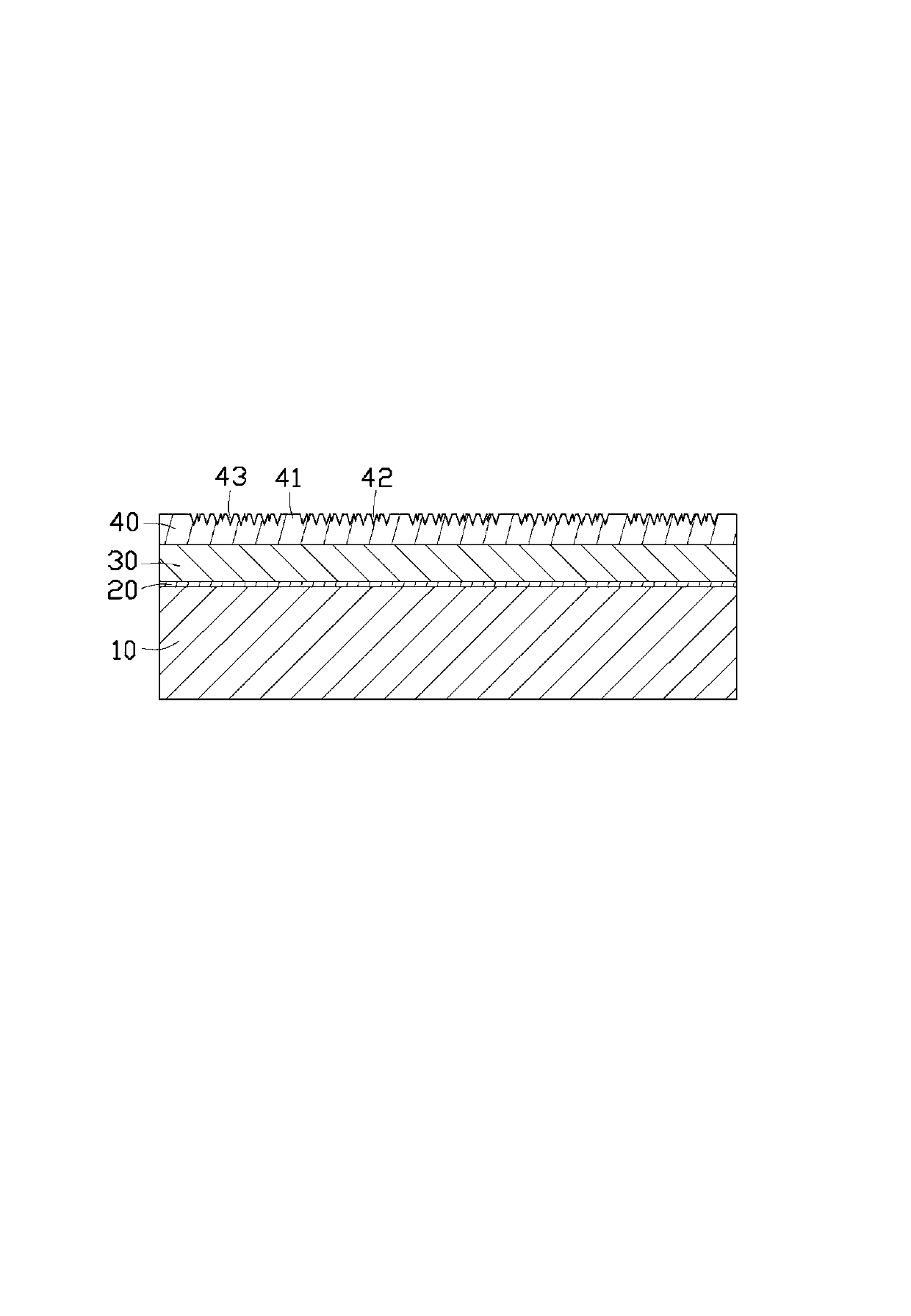

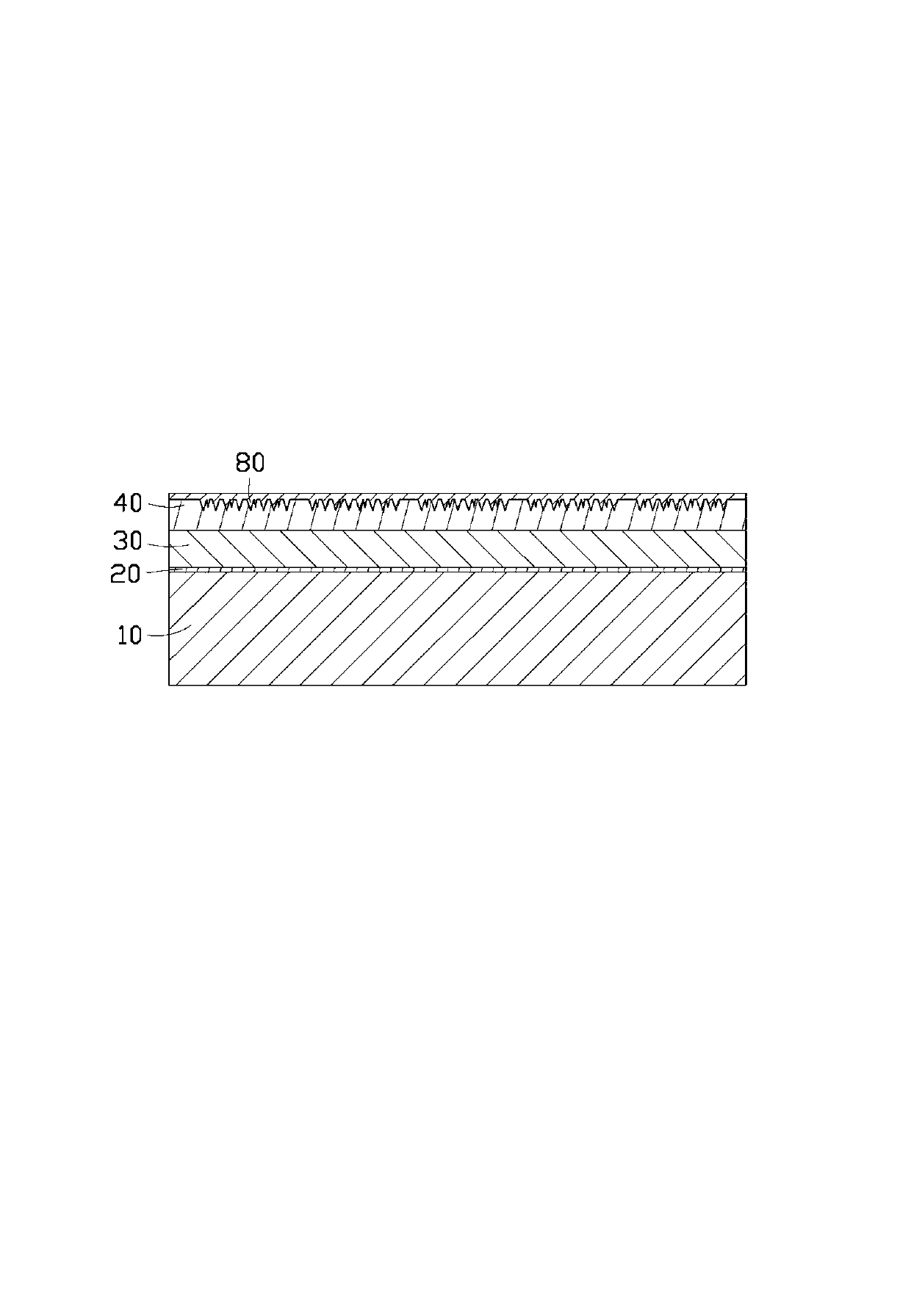

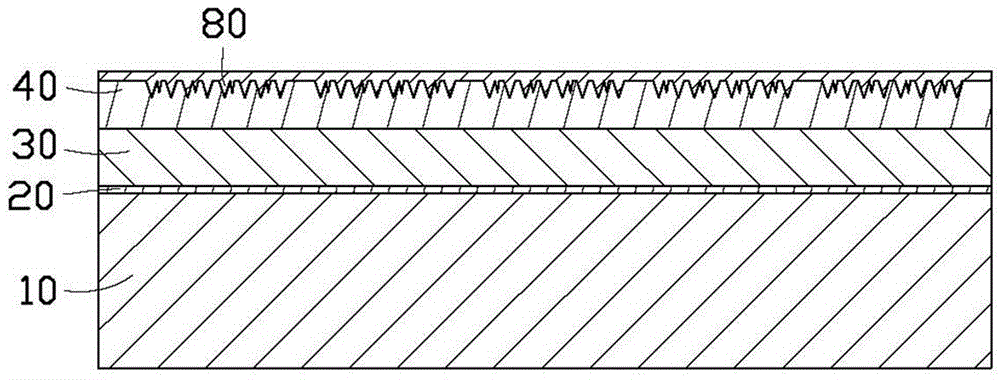

Light emitting diode grain and preparation method thereof

InactiveCN103311391AIncrease chance of shootingImprove light extraction efficiencySemiconductor devicesRough surfaceNitride

A light emitting diode grain comprises a substrate and an electrical layer formed on the substrate. A transition layer is formed between the substrate and the electrical layer and the transition layer comprises a smooth region with a smooth surface and a pattern region with a rough surface. The electrical layer is in contact with the surface of the smooth region of the transition layer, spherical aluminum nitride is clamped between the electrical layer and the transition layer, and a gap is formed between the electrical layer and the pattern region of the transition layer. According to the invention, the transition layer provided with a rough surface is first formed between the electrical layer and the substrate, the spherical aluminum nitride is then formed between the transition layer and the electrical layer, the aluminum nitride is matched with the rough surface, and a gap is formed between the aluminum nitride and the electrical layer. Thus, the probability that light emitted by a light emitting layer towards the substrate is emitted upwards through total reflection can be improved, and the light efficiency of the light emitting diode grain can be improved. The invention further relates to a method for preparing the light emitting diode grain.

Owner:ZHANJING TECH SHENZHEN +1

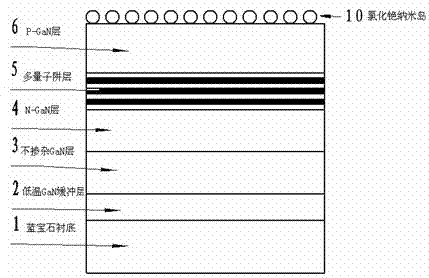

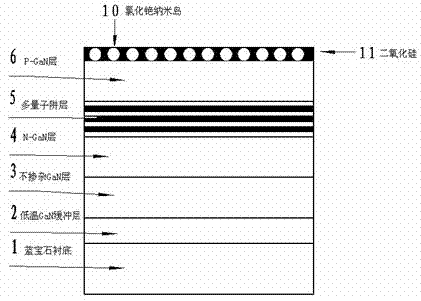

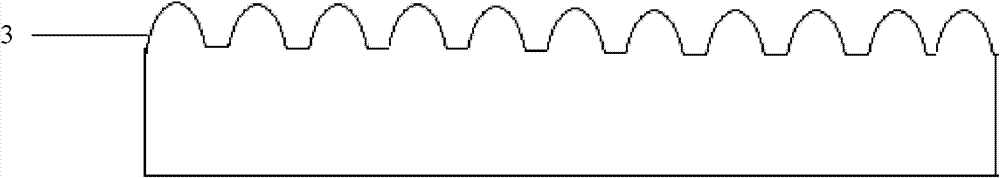

Manufacturing method for GaN-based LED (Light Emitting Diode) chip for coarsening p-GaN layer nanometer bowl-shaped surface

ActiveCN102790153AIncrease chance of shootingIncrease the exit light areaSemiconductor devicesEtchingWater vapor

The invention provides a manufacturing method for a GaN-based LED (Light Emitting Diode) chip for coarsening a p-GaN layer nanometer bowl-shaped surface and relates to the technical field of photoelectric device production. The manufacturing method comprises the following steps: firstly, evaporating a mask cesium chloride film layer for etching on the surface of a P-GaN layer of a GaN epitaxial wafer; filling water vapor into an evaporating platform chamber, thereby forming a plurality of cesium chloride nanometer islands; depositing silicon dioxide layers on the cesium chloride nanometer islands; soaking or ultrasonically treating the epitaxial wafer in deionized water, thereby forming a silicon dioxide nanometer bowl layer; taking the silicon dioxide nanometer bowl layer as an etching mask; after ending the etching, completely removing the silicon dioxide nanometer bowl layer remained on the GaN epitaxial wafer; performing ICP (Inductively Coupled Plasma) etching on one side of the GaN epitaxial wafer, thereby forming a platform; and evaporating an ITO (Indium Tin Oxide) film on the upper surface of the GaN epitaxial wafer. Compared with the conventional GaN-LED, the GaN-LED after being subjected to surface coarsening has the advantage that the luminous power is increased by above 35%.

Owner:YANGZHOU ZHONGKE SEMICON LIGHTING

Light emitting diode crystalline grain and producing method thereof

ActiveCN102916098AIncrease chance of shootingImprove light extraction efficiencySemiconductor/solid-state device manufacturingSemiconductor devicesElectrical conductorLight-emitting diode

A light emitting diode crystalline grain comprises a substrate, an epitaxial layer, and a plurality of spherical aluminum nitride, wherein the epitaxial layer is formed on the substrate and sequentially comprises a first semiconductor layer, a light emitting layer and a second semiconductor layer, the spherical aluminum nitrides are arranged at intervals between the epitaxial layer and the substrate, and the first semiconductor layer fully covers the spherical aluminum nitrides. By arranging the spherical aluminum nitrides at intervals between the epitaxial layer and the substrate, probability for light emitting towards the substrate from a light emitting layer to be totally reflected to emit upwards is increased, so that emitting efficiency of the light emitting diode crystalline grain is improved.

Owner:ZHANJING TECH SHENZHEN +1

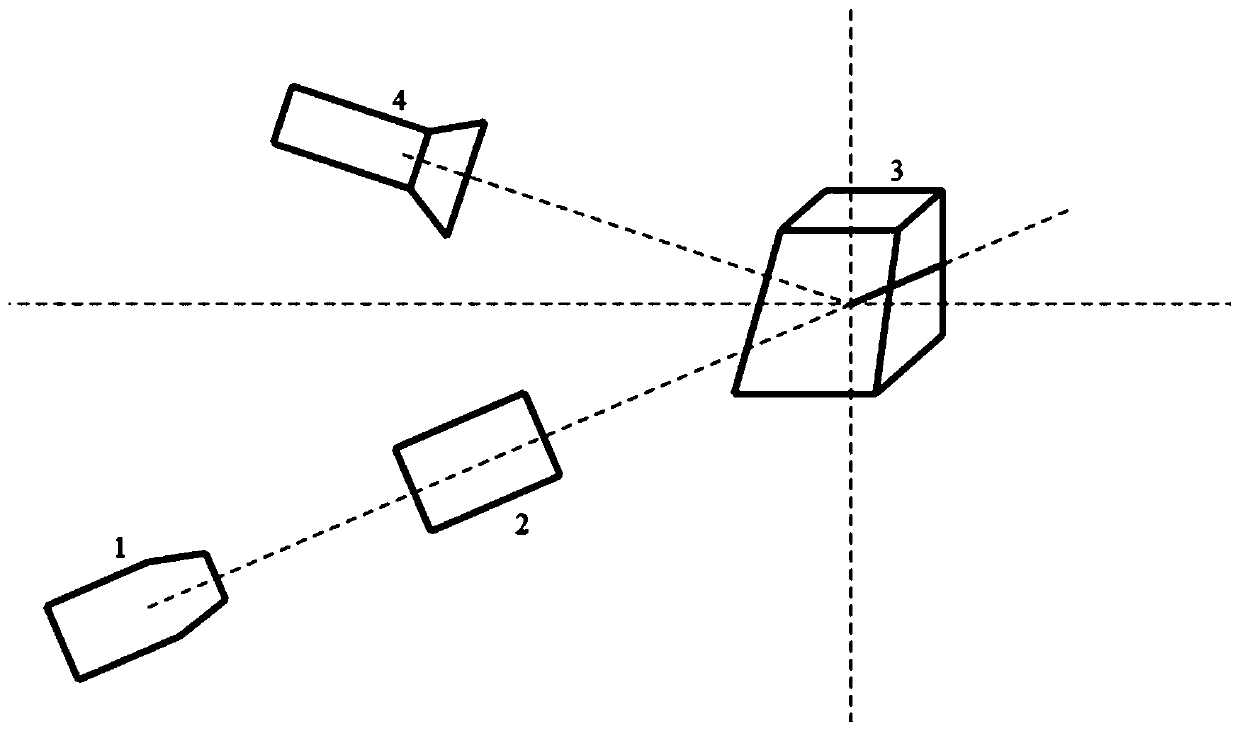

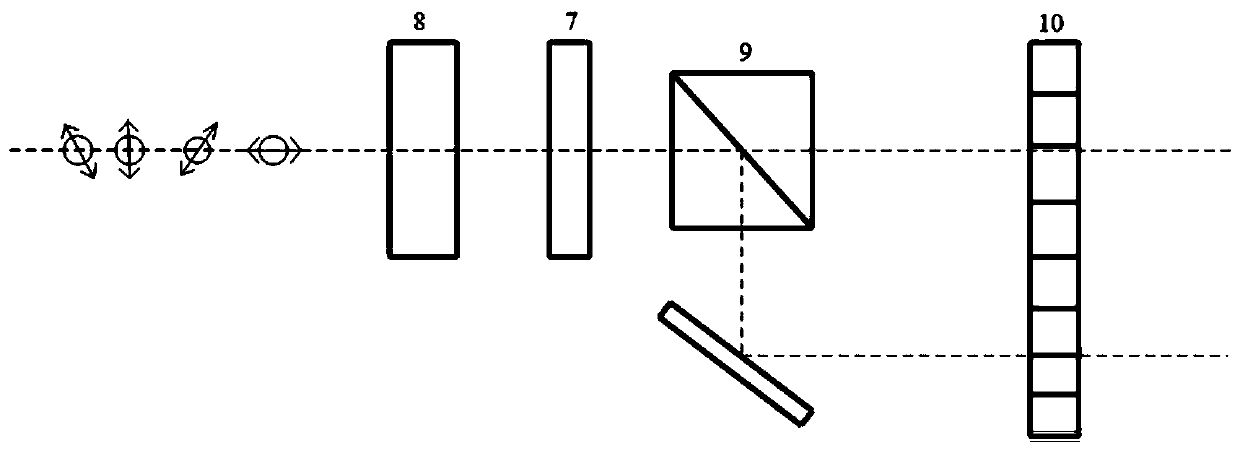

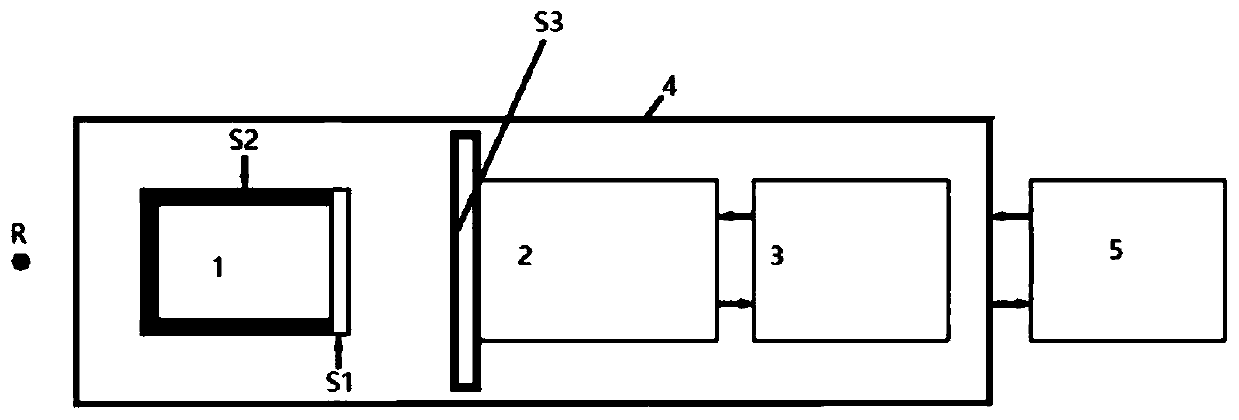

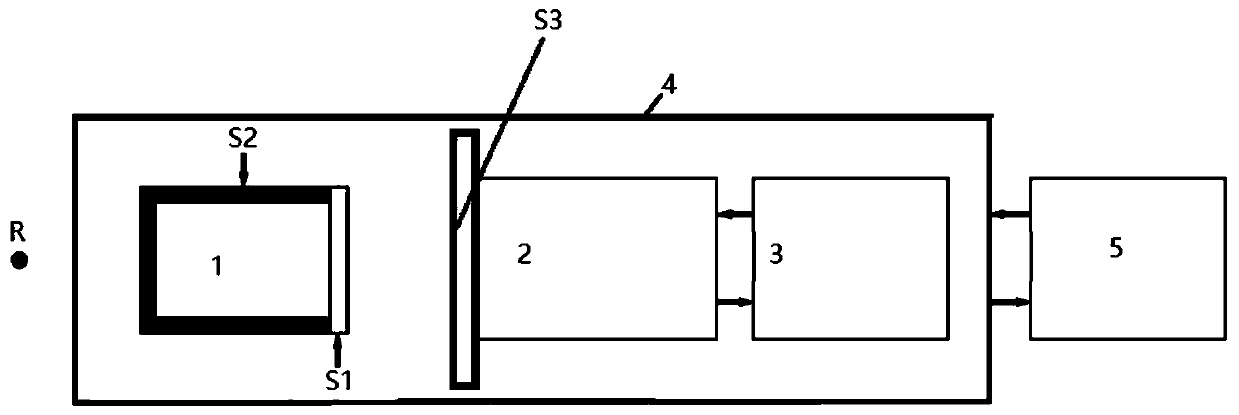

Single-photon polarization state quantum imaging system based on DMD micromirror array

InactiveCN110487427AIncrease chance of shootingLow priceInstrumentsStatistical analysisMicromirror array

The invention relates to a single-photon polarization state quantum imaging system based on a DMD micromirror array. The system comprises a laser transmitting device, a single-photon preparation system, a DMD control imaging device, and an EMCCD imaging receiving system; the laser transmitting device is a semiconductor laser and is used for emitting laser beams; the single-photon preparation system is used for converting the laser emitted by the laser transmitting device into single photon pulses in different polarization states; the MD control imaging device directly acts on the single photonpulses in different polarization states and reflects the single photon pulses to the EMCCD imaging receiving system; the EMCCD imaging receiving system images the single photons in different polarization states, performs statistical analysis on detected photon information, and also obtains an image measurement error rate and imaging reliability. The system is simple in structure, convenient to operate, accurate in measurement, high in feasibility and easy to apply.

Owner:QINGYUAN TIANZHIHENG SENSING TECH CO LTD

LED chip manufacturing method of high extraction external quantum efficiency

InactiveCN104851946AIncrease the probability of light exitImprove luminous efficiencySemiconductor devicesQuantum wellLight emission

The invention provides an LED chip manufacturing method of high extraction external quantum efficiency. The method comprises the following steps: a step (1) of growing a GaN layer, an N-GaN layer, a quantum well layer, a P-GaN layer and a deposition ITO layer on a graphical substrate at one time; a step (2) of coating a layer of photoresistive liquid on the surface of the P-GaN layer or the ITO in a suspension manner; a step (3) of performing yellow light technologies such as pattern exposure, development and baking on the photoresistive liquid or adopting a nanometer impression mode to prepare a pattern; and a step (4) of selecting an ICP or wet etching method to transfer the pattern to an epitaxial wafer or the ITO layer. According to the invention, micropores are formed in the P-GaN layer or the ITO layer, so that on one hand, phenomena that light is reflected when passing through interfaces between the P-GaN layer, ITO and SiO2 and the air are prevented, and on the other hand, light absorption of the P-GaN layer and the ITO is lowered, the probability of light emission is effectively increased, and the luminous efficiency is improved. The method provided by the invention is easy to realize, controllable in process, and convenient in industrialized production via the conventional technology.

Owner:合肥彩虹蓝光科技有限公司

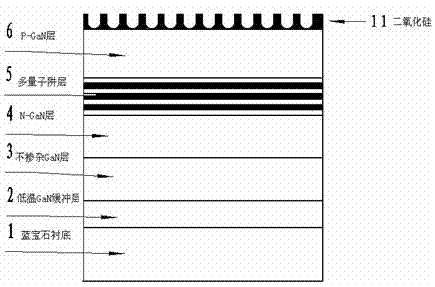

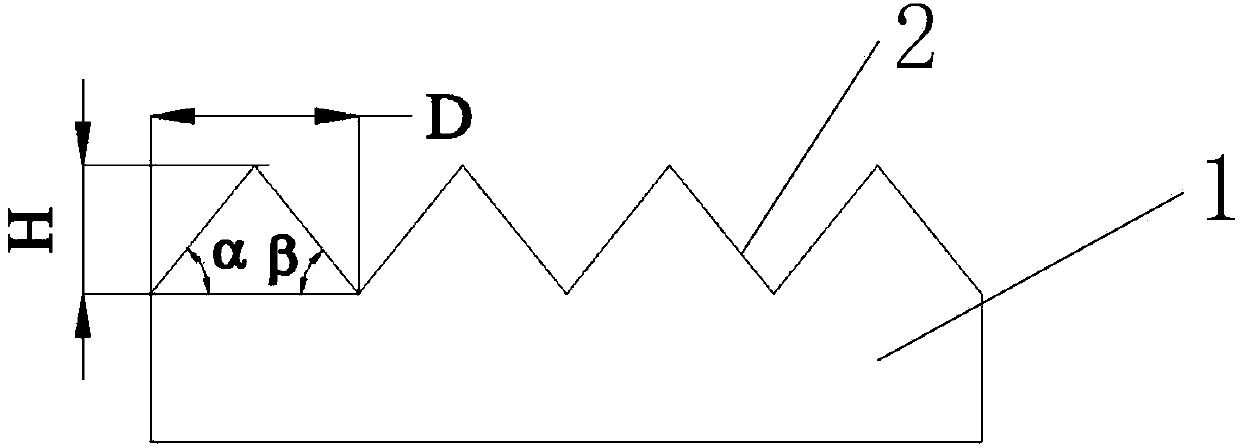

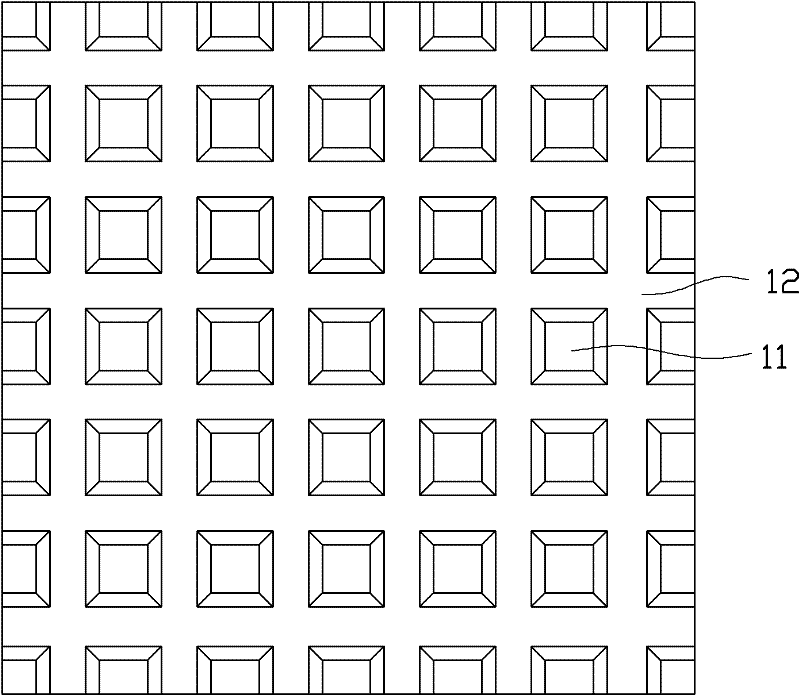

LED flip chip and patterned substrate and manufacturing method of LED flip chip

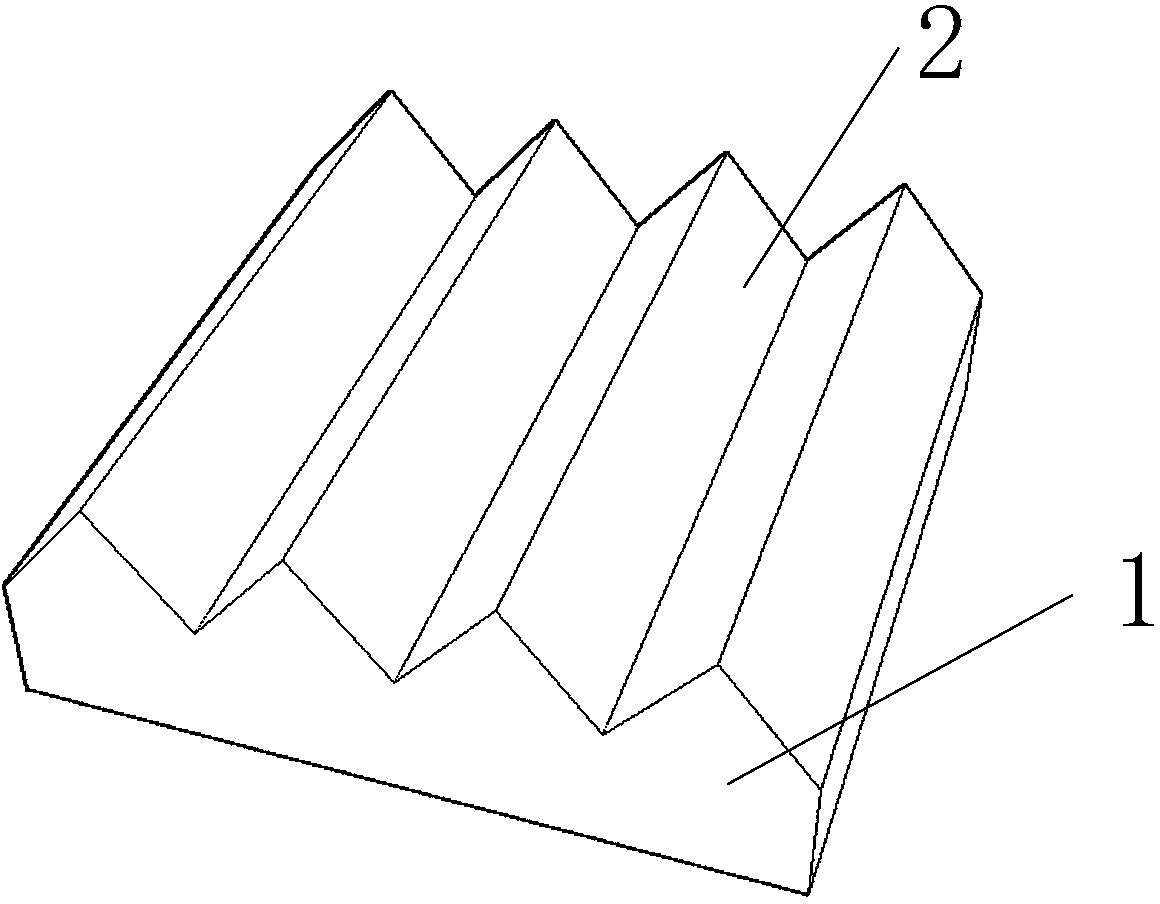

InactiveCN104183678AIncrease brightnessImprove electro-optical conversion efficiencySemiconductor devicesEngineeringPatterned substrate

The invention relates to an LED flip chip and a patterned substrate and manufacturing method of the LED flip chip. The surface of the patterned substrate is provided with grooves or a pattern array, wherein the cross sections of the grooves are triangular, the grooves are parallel to one another, and the pattern array is composed of protrusion structures which are arranged to form a regular shape. The LED flip chip comprises the patterned substrate, an epitaxial layer, P electrodes and N electrodes. The patterned substrate is arranged on the upper surface of the epitaxial layer. The P electrodes and the N electrodes are respectively arranged on the lower surface of the epitaxial layer. By means of the LED flip chip, the patterned substrate and the manufacturing method, the probability that photons are emitted out of the chip can be increased, and in other words, the light ray extraction efficiency of devices is increased so that the brightness of LEDs and the electro-optical conversion efficiency can be improved.

Owner:江苏鑫博电子科技有限公司

Light emitting diode crystal grains and manufacturing method thereof

InactiveCN102544249AIncrease chance of shootingImprove light extraction efficiencySemiconductor/solid-state device manufacturingSemiconductor devicesLight-emitting diodeSemiconductor

The invention discloses light emitting diode crystal grains and a manufacturing method thereof. The manufacturing method comprises the following steps of: forming a patterned epitaxial barrier layer on a substrate; growing an n type semiconductor layer on the patterned epitaxial barrier layer and stopping growing the n type semiconductor layer when the patterned epitaxial barrier layer is not completely covered by the n type semiconductor layer; removing the patterned epitaxial barrier layer and leaving a hole at the position of an original patterned epitaxial barrier layer; continually growing the n type semiconductor layer on the pore till a first group of pores is covered completely by the n type semiconductor layer; and forming a luminous structure on the n type semiconductor layer.

Owner:ZHANJING TECH SHENZHEN +1

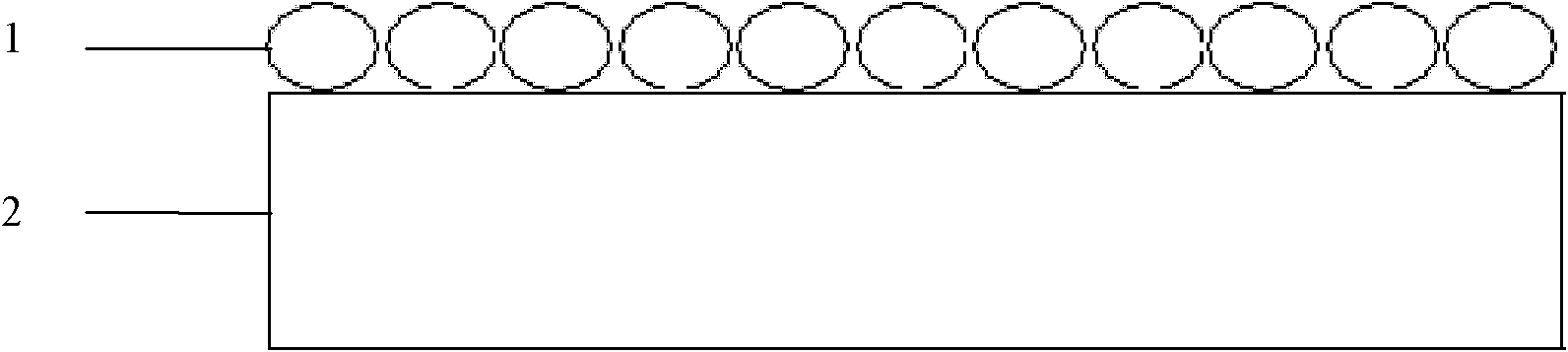

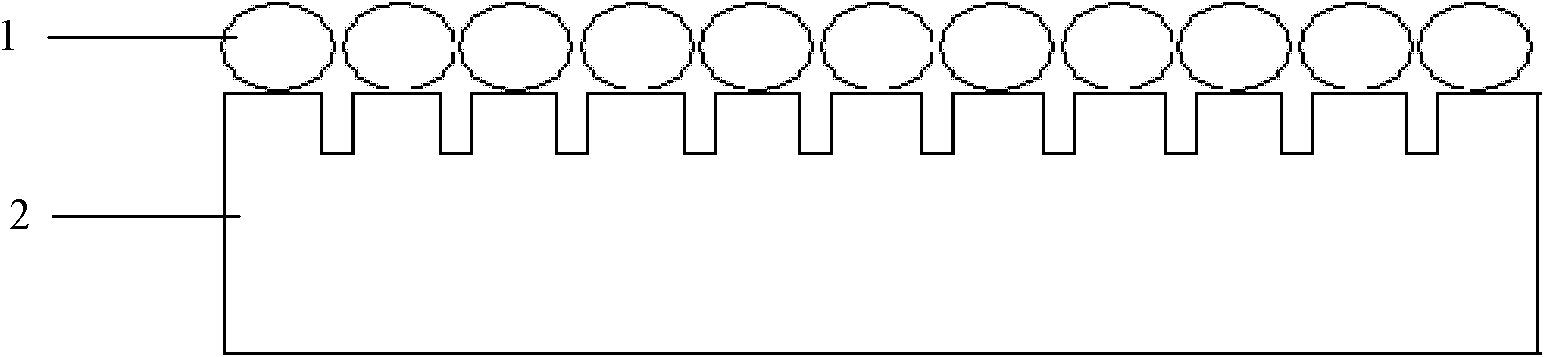

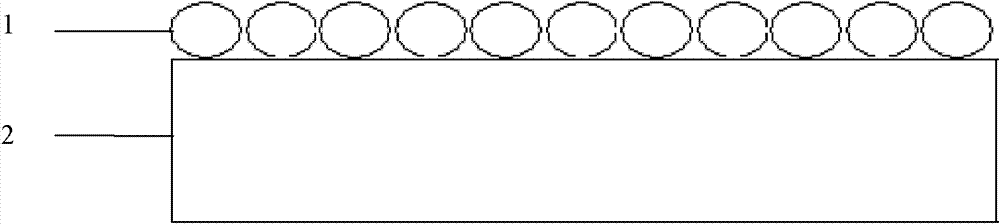

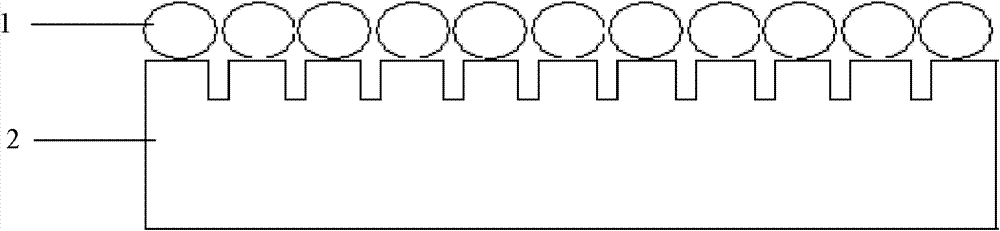

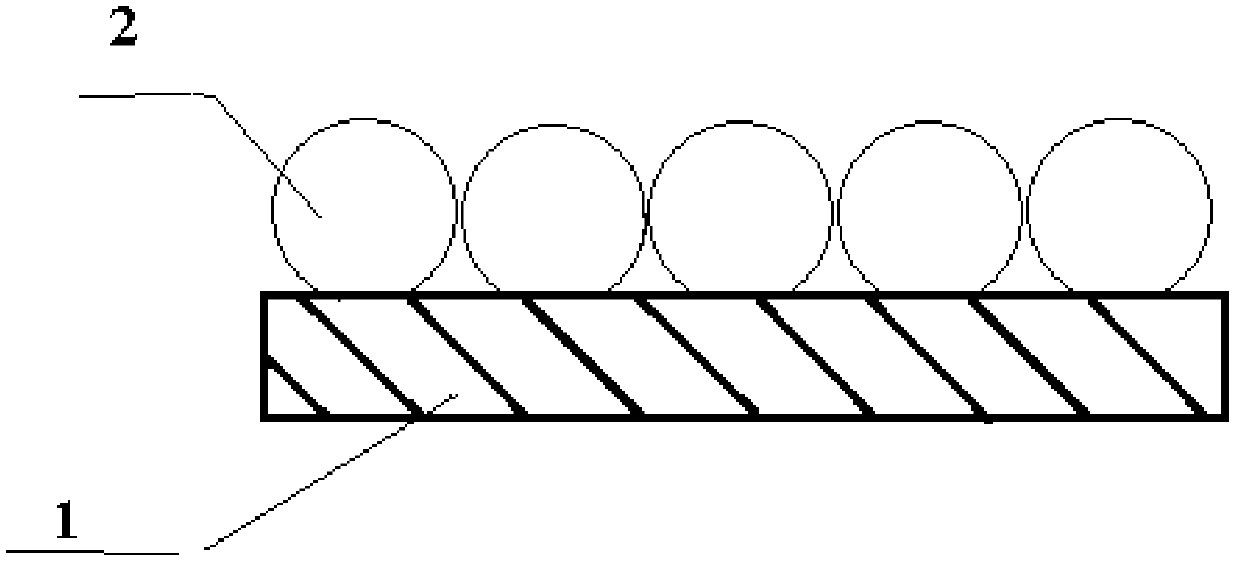

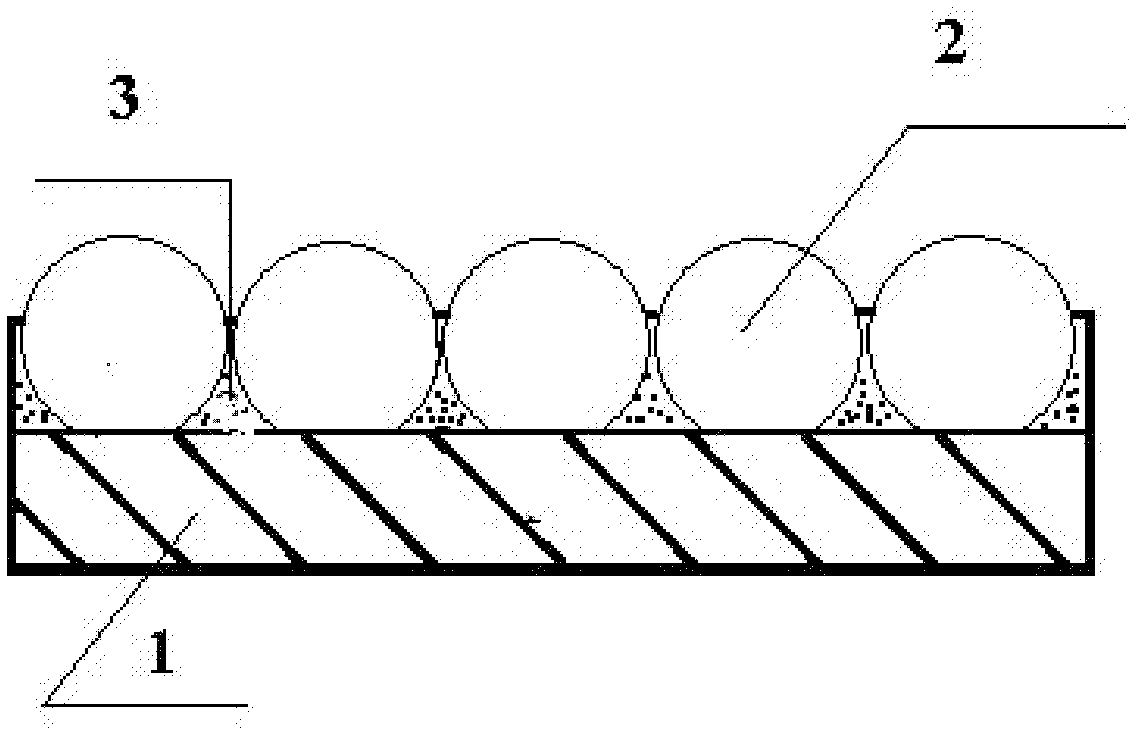

Method for preparing nanometer imaging substrate of LED (light emitting diode) chip epitaxial growth

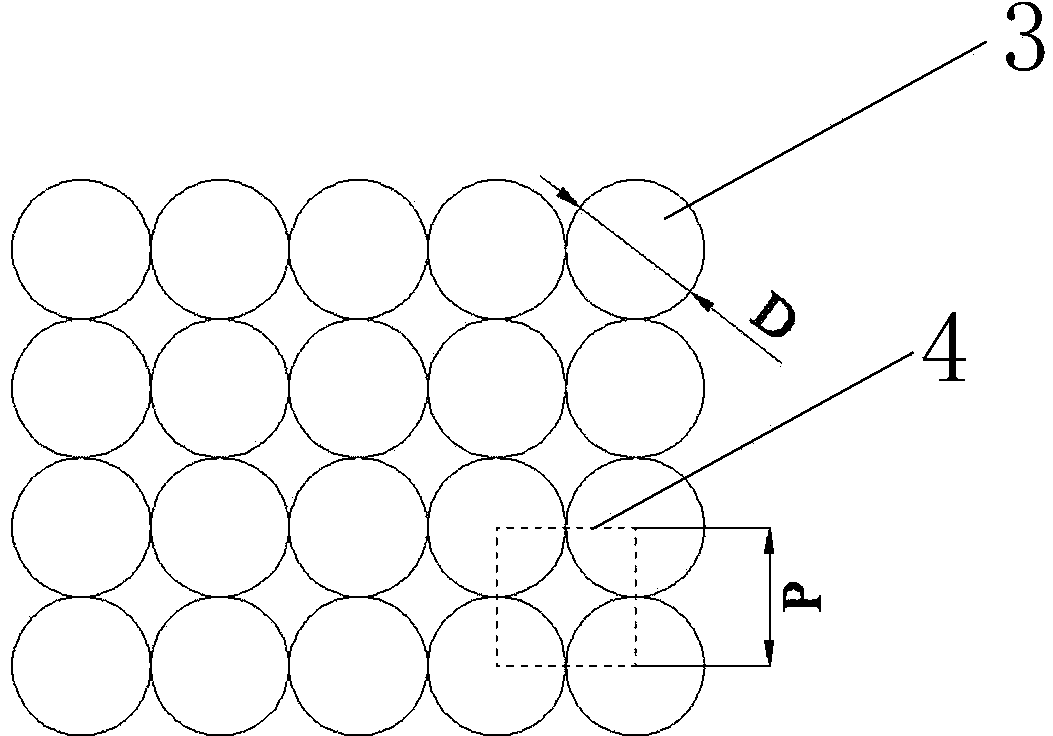

ActiveCN102214744AGood periodicityReduce dislocation densitySemiconductor devicesEtchingSilicon oxide

The invention belongs to the field of solid illumination, and in particular relates to a method for preparing a nanometer patterned substrate of LED (light emitting diode) chip epitaxial growth. The method particularly comprises the following steps: dropping silicon oxide nanometer balls which are dispersed uniformly on a sapphire substrate after cleaning treatment, and coating the silicon oxide nanometer balls on the surface of the sapphire substrate uniformly by utilizing a spin coating machine in a single layer mode; carrying out ICP (inductively coupled plasma) etching processing on the sapphire substrate which takes the silicon oxide nanometer balls as masks, and dividing the etching into two groups: firstly, etching the image depth of the nanometer patterned substrate by utilizing BC13 gas; and then etching the image width of the nanometer patterned substrate by utilizing BC13, C12, and Ar gas; and taking the sapphire substrate out after etching, and drying for use after corrosion and cleaning. According to the invention, the dislocation density in the LED chip can be reduced effectively, the occurrence of cracking can be avoided, the crystalline quality and uniformity of epitaxial materials can be improved, the probability of light emission of the light for the LED from the sapphire substrate is increased, and further the light-emitting efficiency of the LED chip can beimproved.

Owner:黄山博蓝特半导体科技有限公司

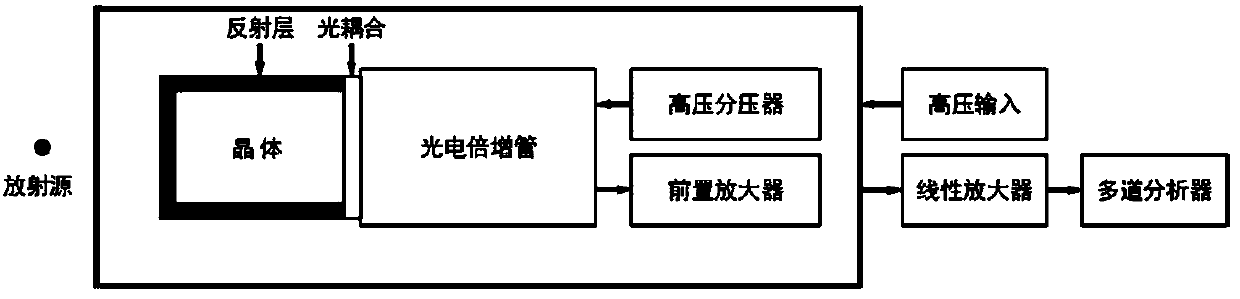

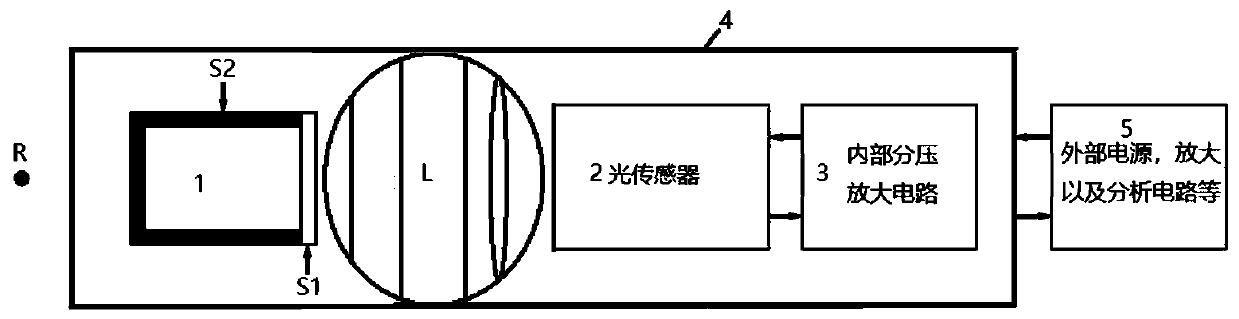

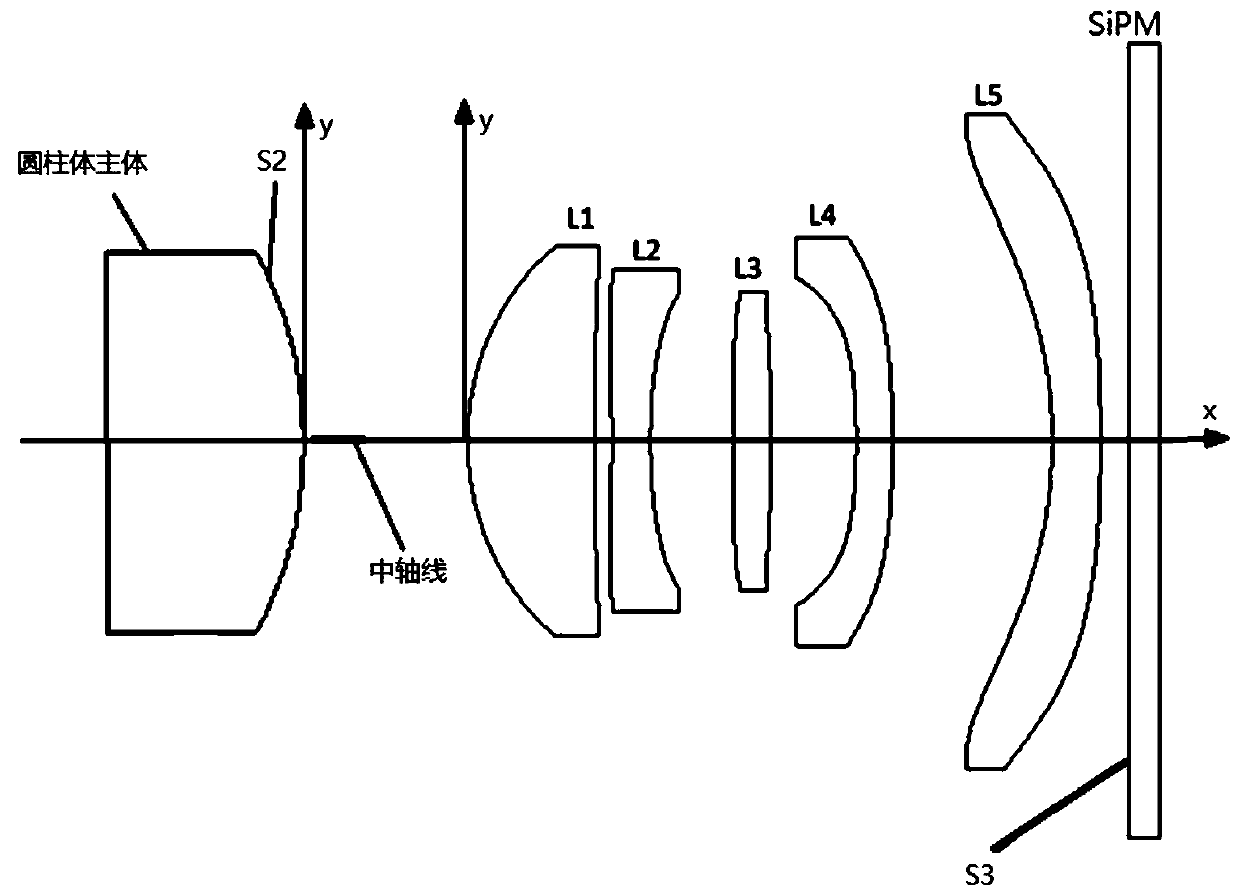

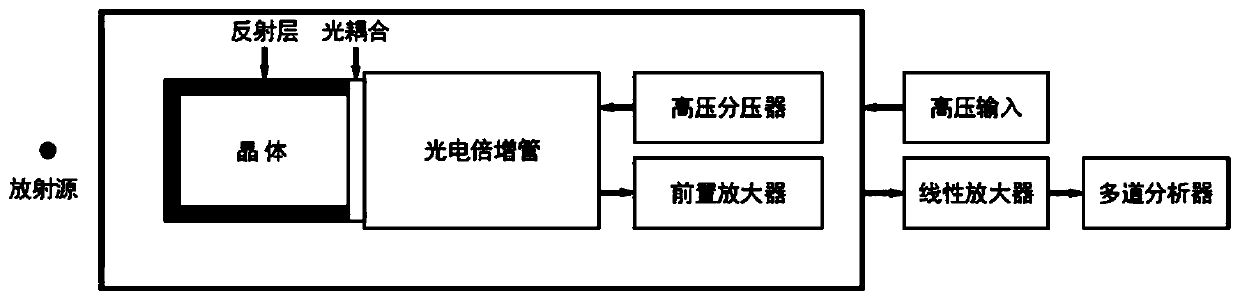

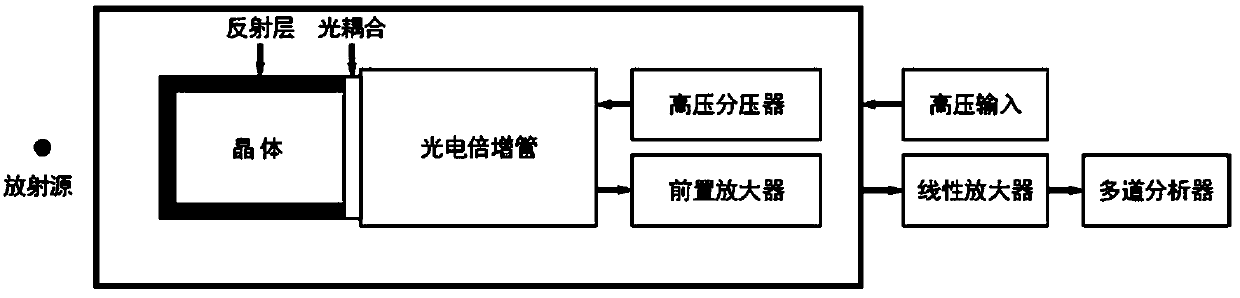

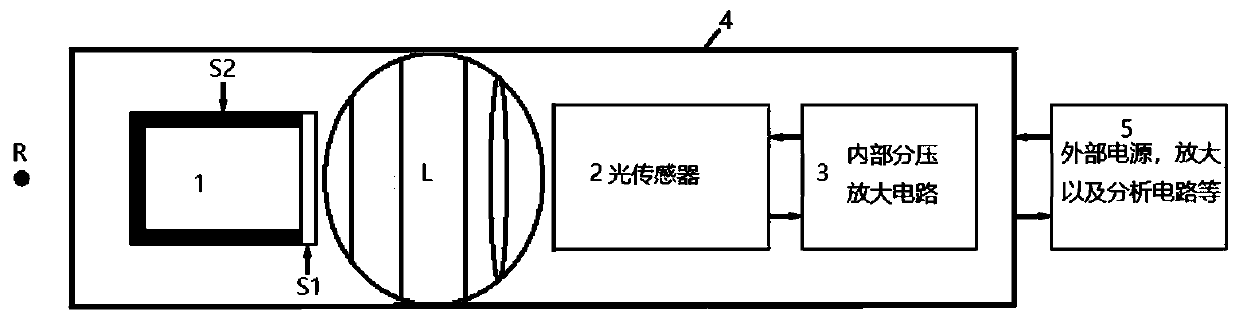

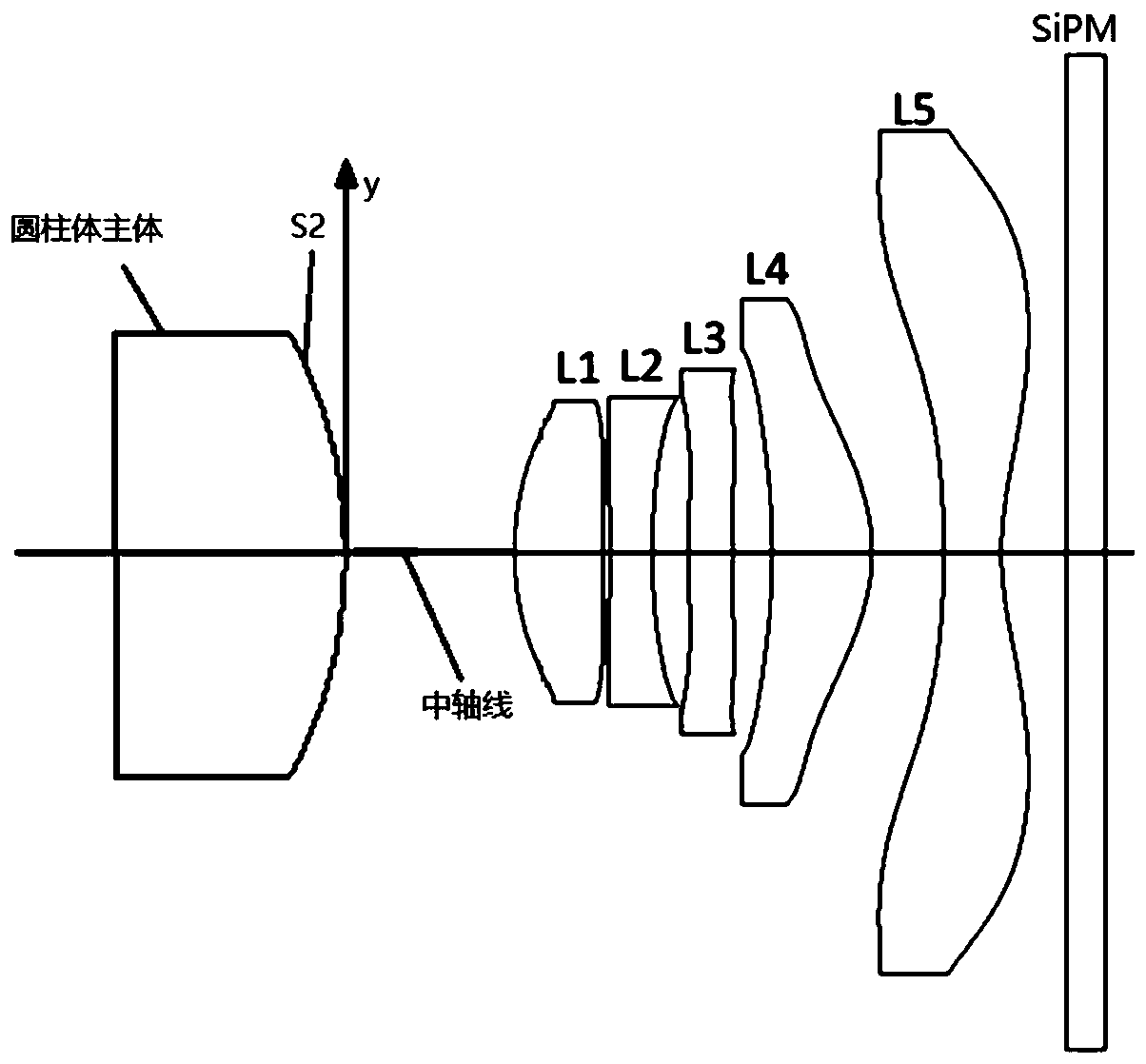

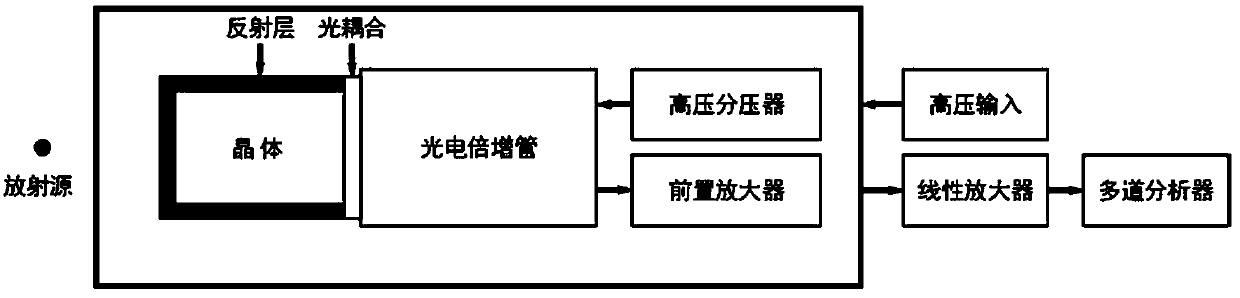

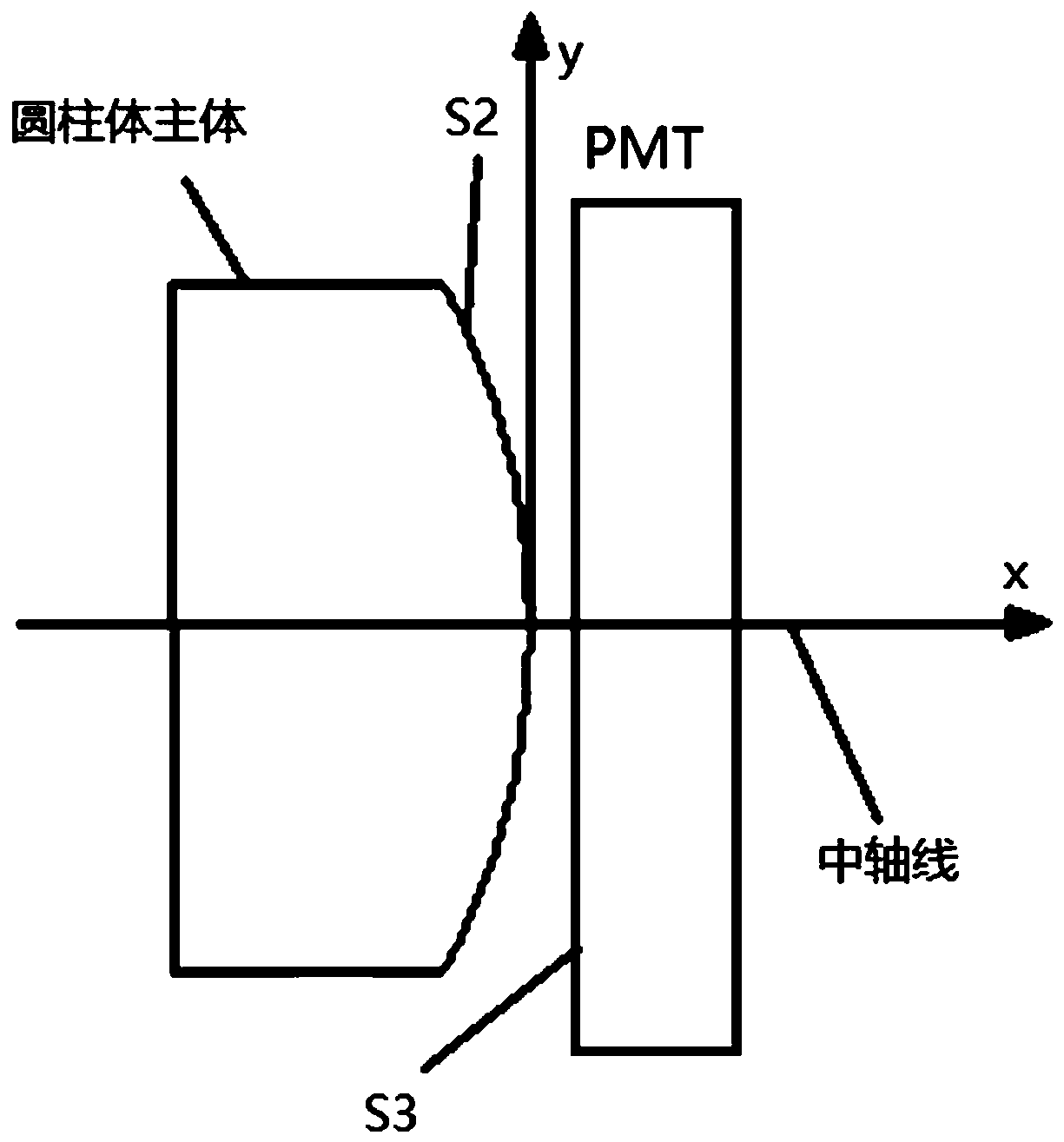

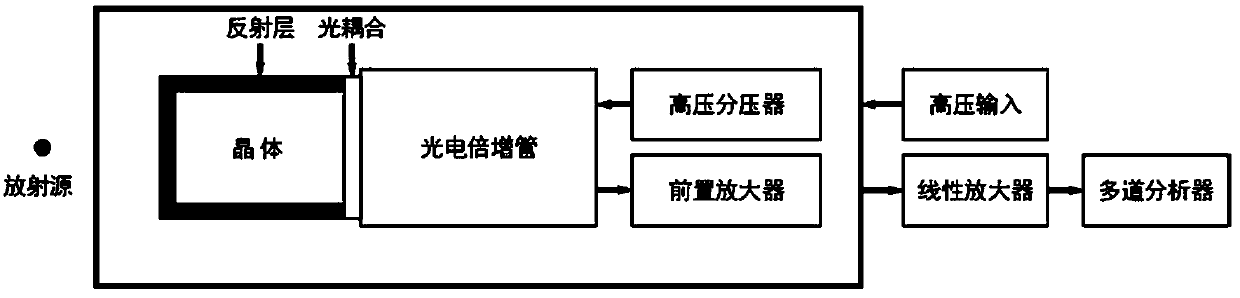

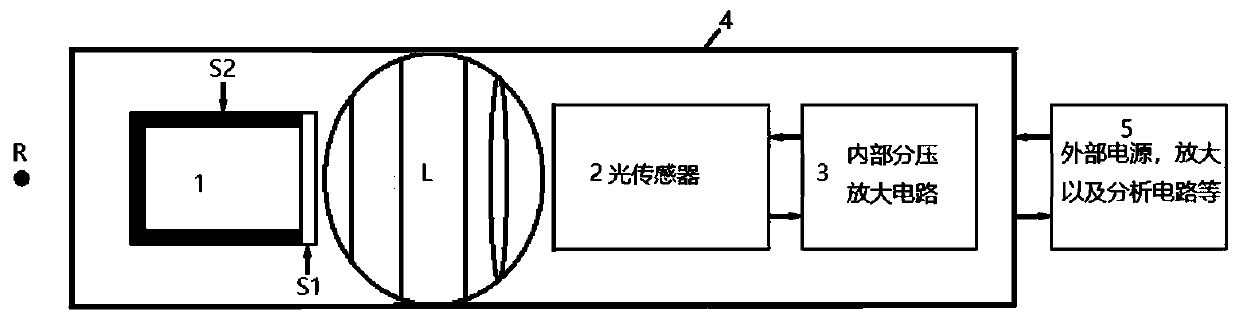

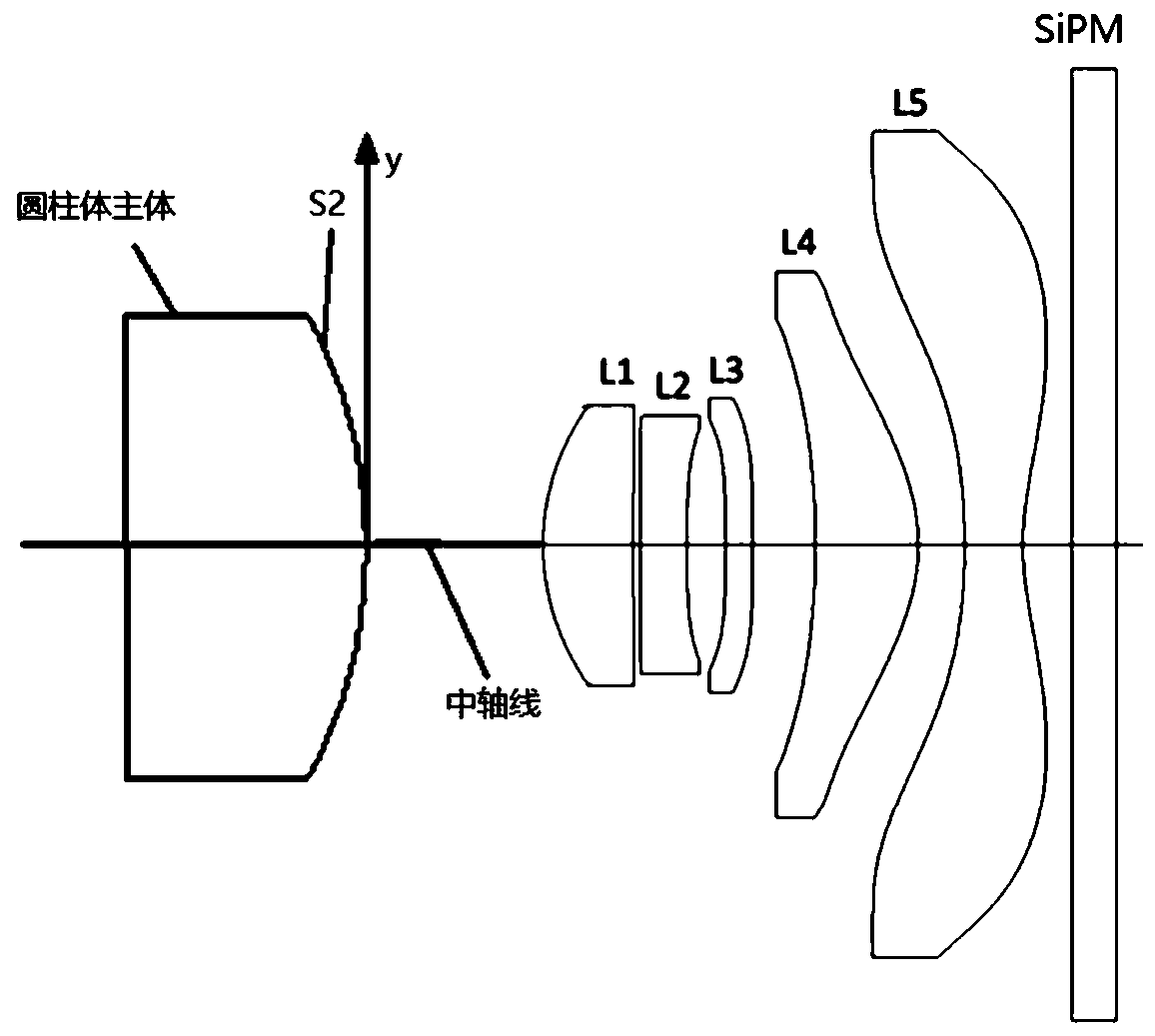

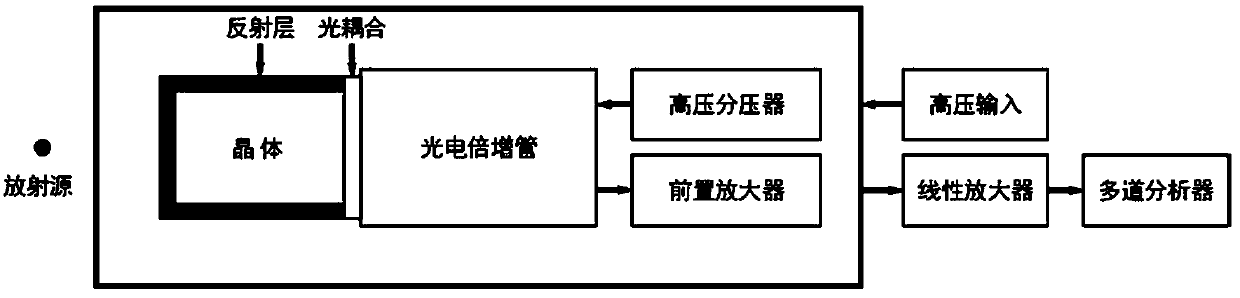

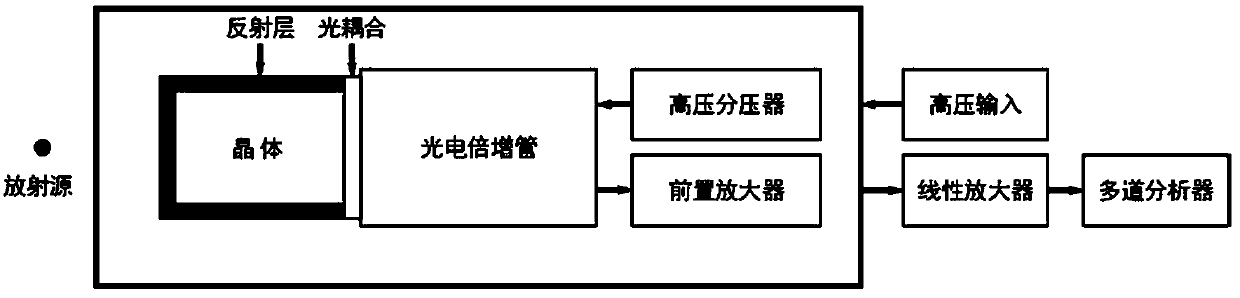

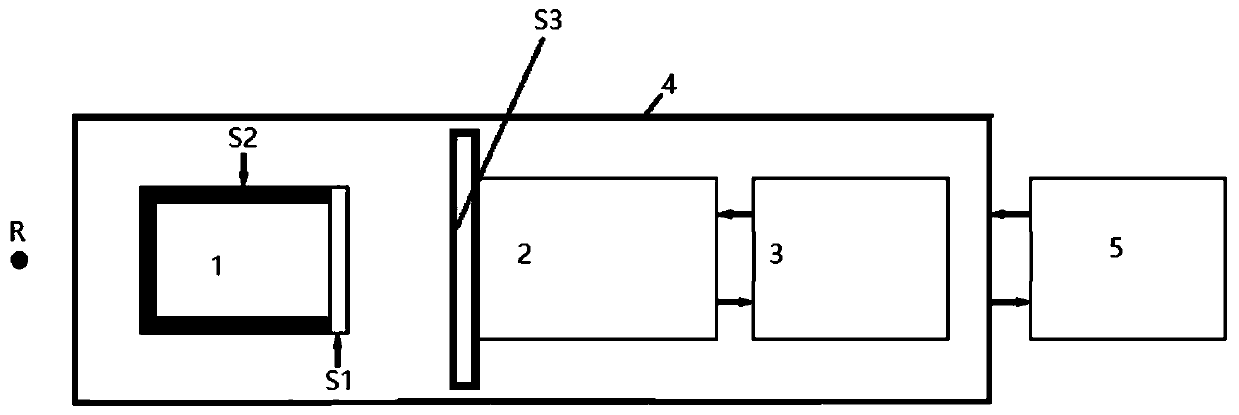

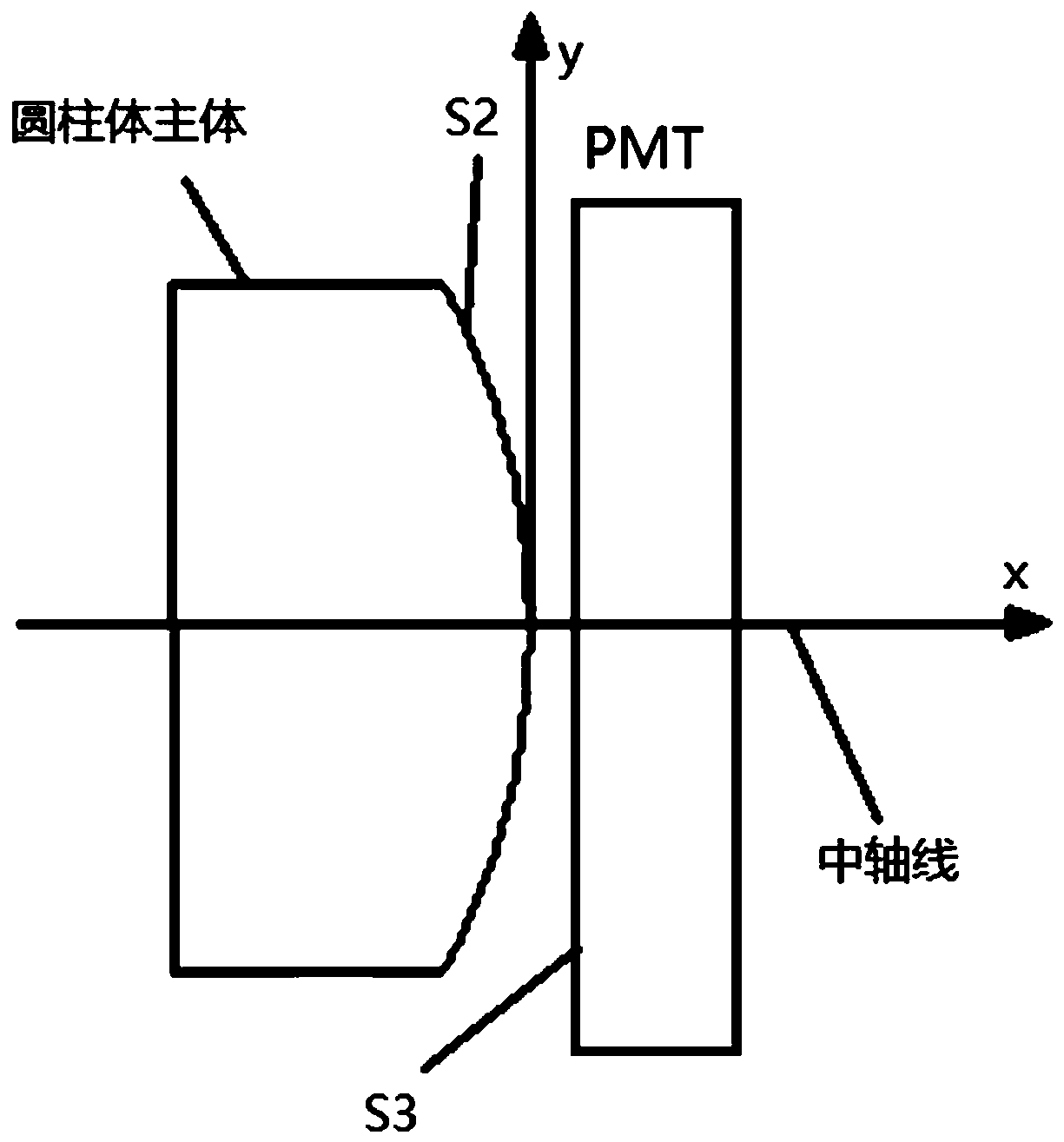

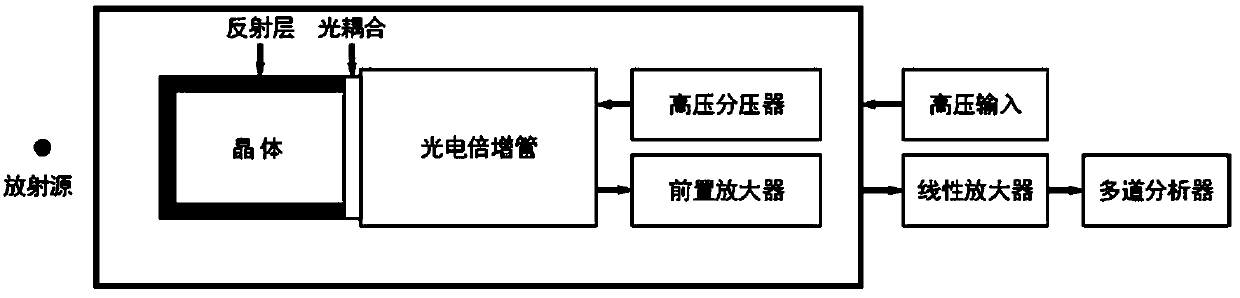

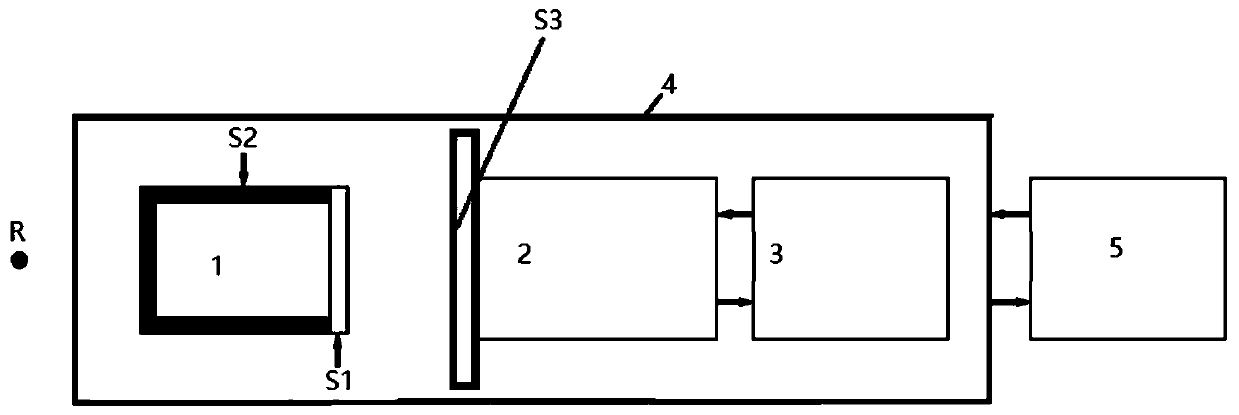

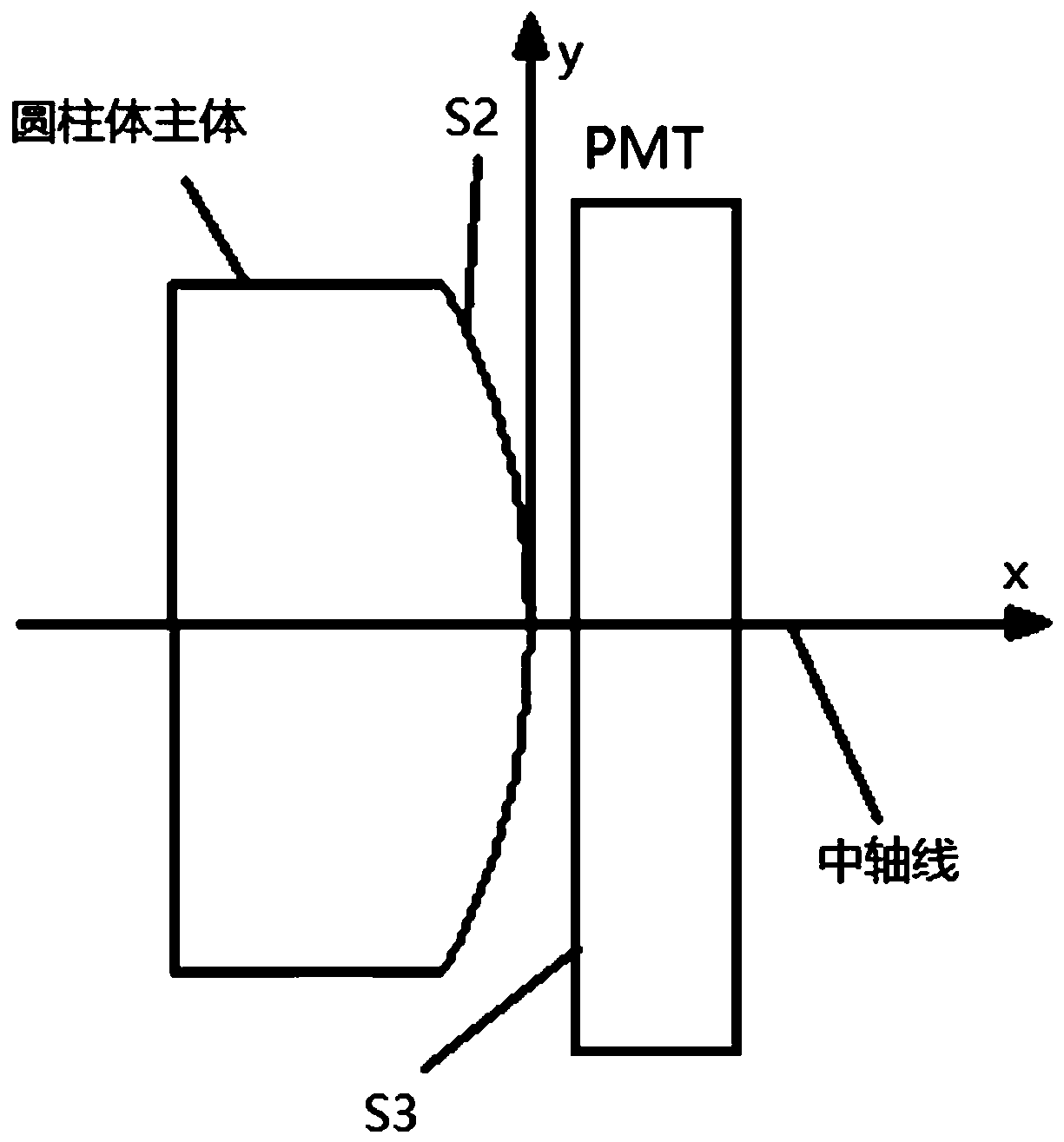

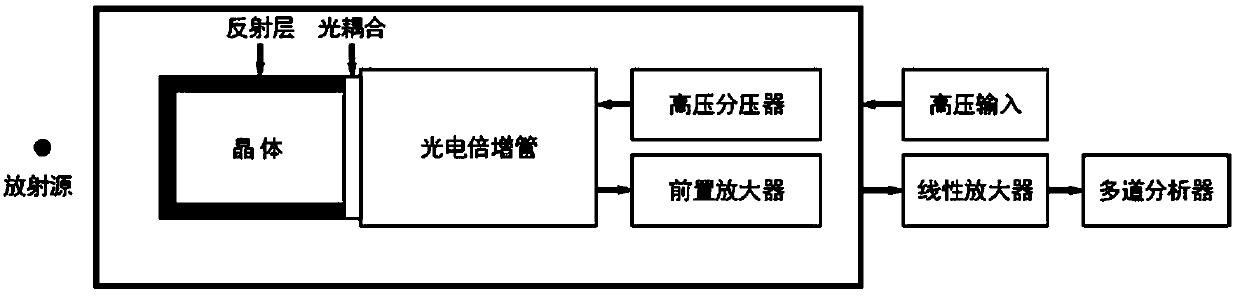

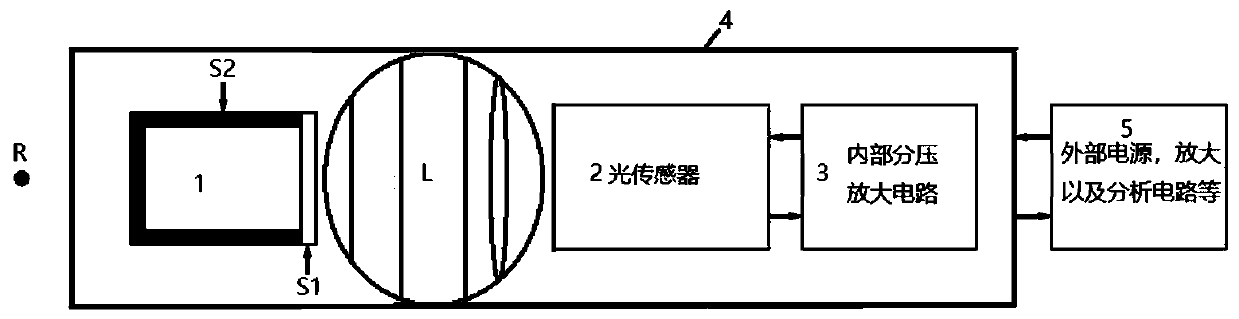

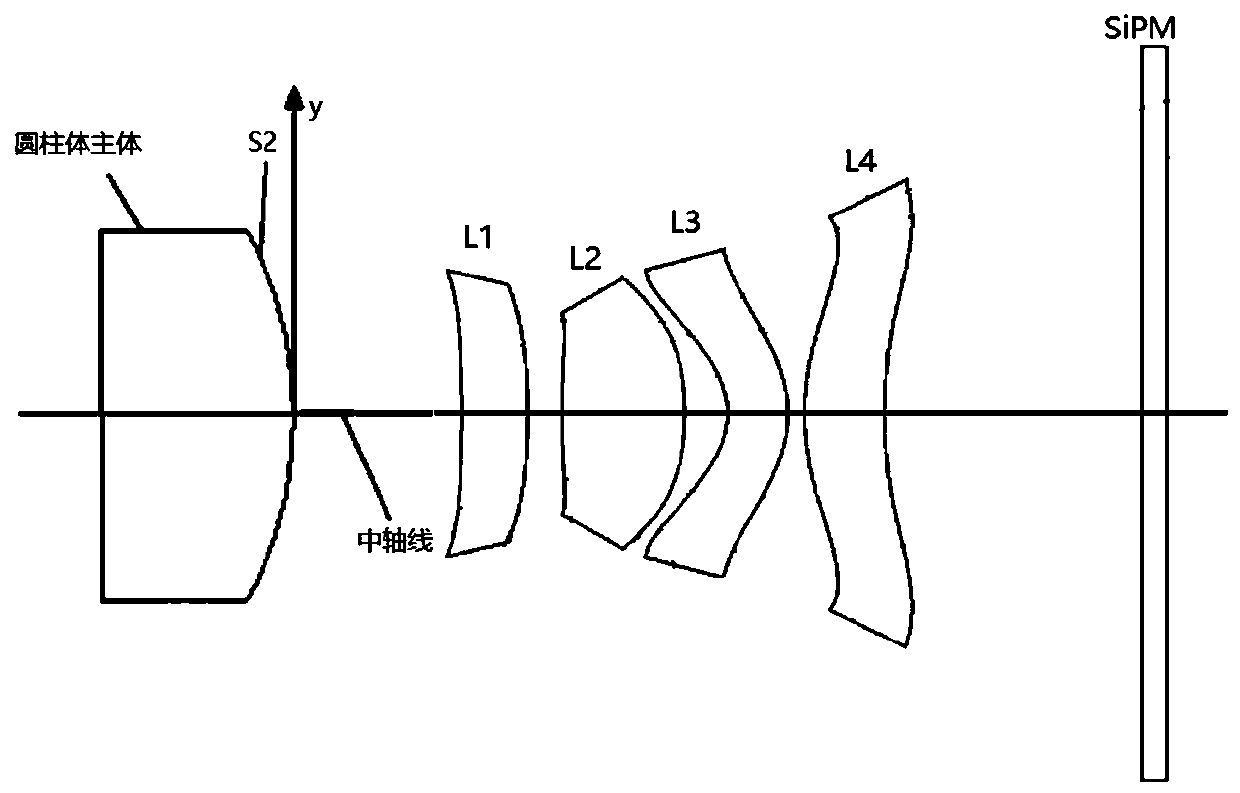

Thallium-doped sodium iodide scintillation crystal radiation detector with exit surface matched with lens group

InactiveCN110737015AOvercoming selectivityOvercome the inherent pitfalls of optimizationX/gamma/cosmic radiation measurmentImage resolutionScintillation crystals

The invention relates to a scintillation crystal radiation detector with a special light emitting surface matched with a lens group. A matched wide-angle and large-depth-of-field lens group is constructed, so the collection efficiency of the optical sensor on the scintillation light is improved and the energy resolution is improved. The specific parameter design considers the matching with the emergent wave band of the scintillation crystal, so the incident light sensor for focusing and collecting the scintillation light can be increased, the energy resolution is improved, the shape of the light emitting surface of the scintillation crystal matched with the lens group is correspondingly designed, the measurement efficiency and the measurement precision are further improved, and the detection performance can be further improved especially when a high-performance detector is developed.

Owner:左慈斌

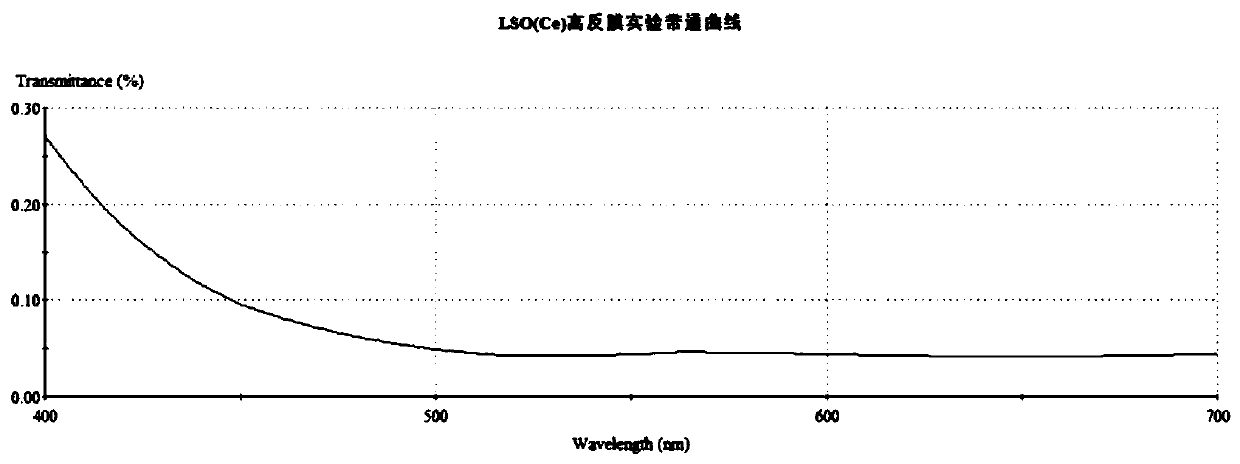

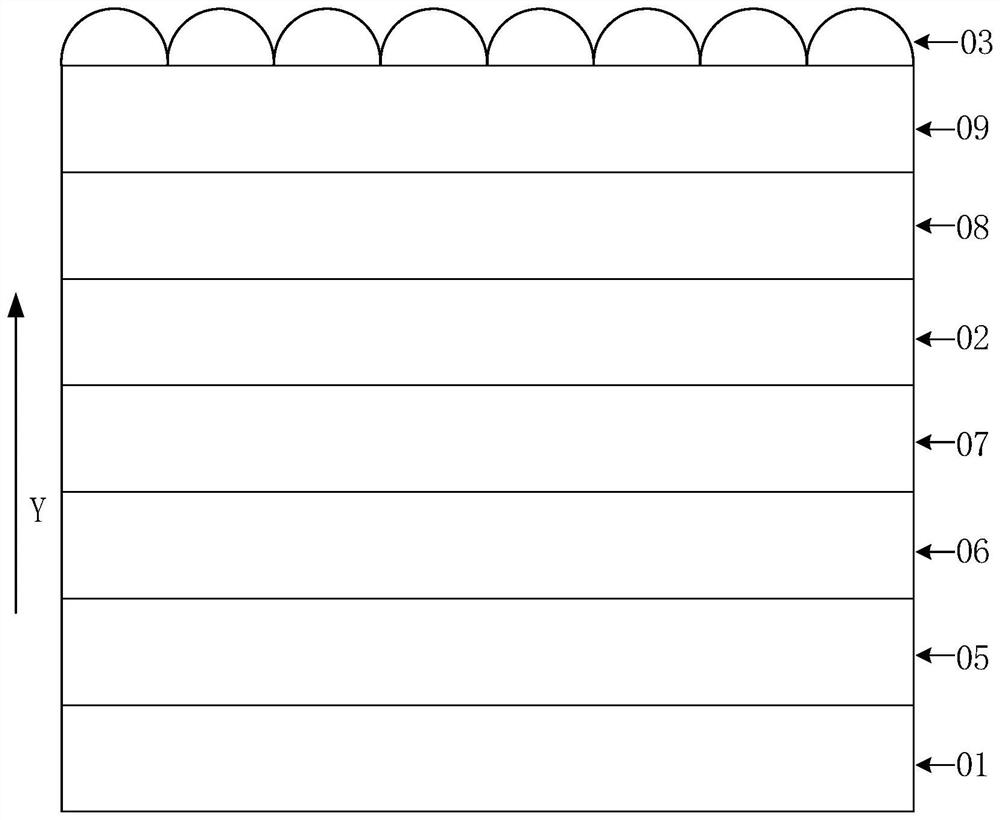

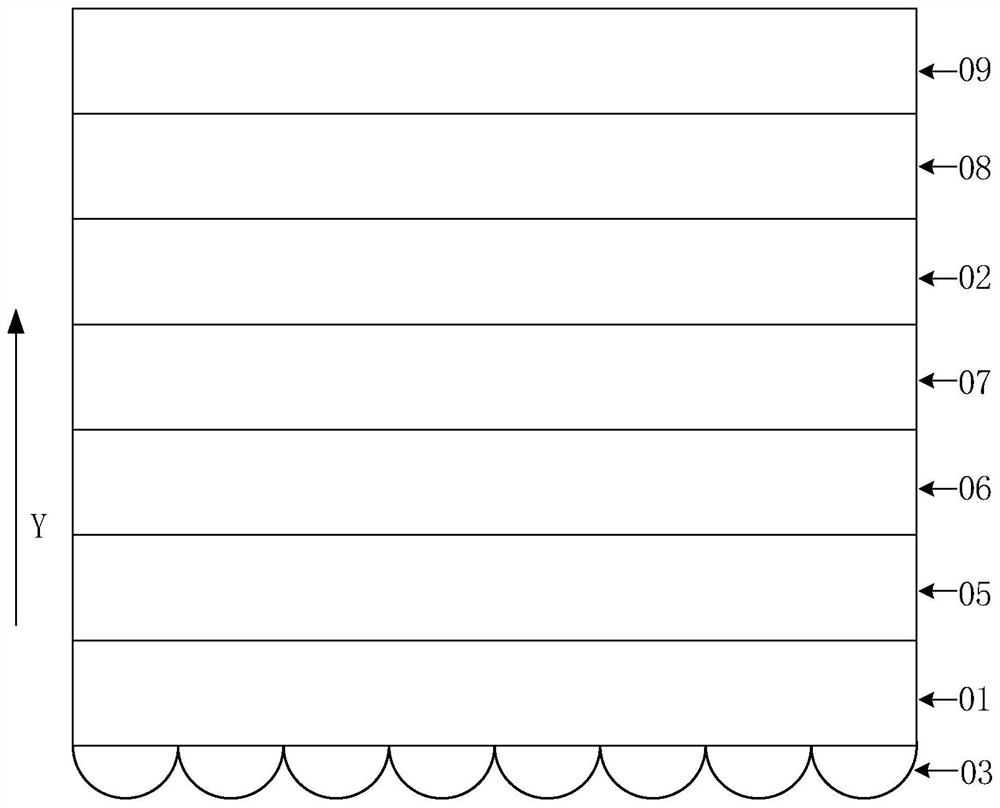

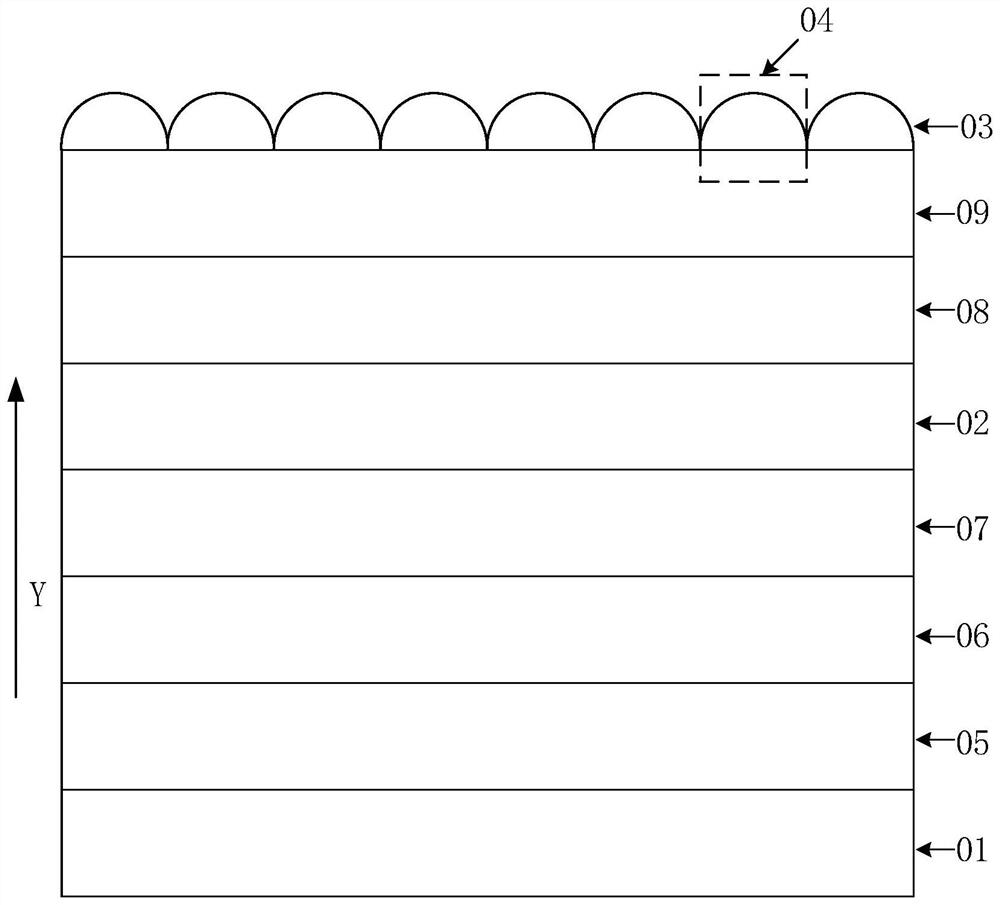

Cerium-doped lutetium silicate scintillation crystal radiation detector plated with antireflection film and special light emitting surface

InactiveCN110794446AImproved energy resolutionImprove light outputRadiation intensity measurementLutetiumPhysical chemistry

The invention relates to a scintillation crystal radiation detector plated with an antireflection film and a special light emitting surface. The conception of designing a film layer in a targeted manner is carried out aiming at a main emergent waveband of scintillation crystal, the difficulty that film research data is too large and difficult to analyze is overcome, an appropriate reflective filmlayer material is obtained, the adhesive force with crystals is good, the number of film layers is small and the implementation is easy, a special light-emitting surface design matched with a total reflection plating scheme is further provided, and the measurement efficiency and the measurement precision are correspondingly improved.

Owner:刘佳莉

A kind of LED flip chip and its manufacturing method

ActiveCN104269480BExtended launch angleIncrease chance of shootingSemiconductor devicesAnti-reflective coatingEvaporation

The invention discloses an LED flip chip. The LED flip chip sequentially comprises a sapphire substrate, an epitaxial layer, a conductive reflecting layer, a metal protective layer, a Vias and SiO2 insulating layer and metal electrodes from bottom to top, wherein the sapphire substrate is a sapphire substrate, obtained after inductive coupling plasma etching, with a graphical back side, an antireflection film is further arranged on the back side of the sapphire substrate, the antireflection film is an antireflection film, manufactured with an evaporation method, with silicon dioxide layers and titanium dioxide layers alternately arranged, the sum of the number of the silicon dioxide layers in the antireflection film and the number of the titanium dioxide layers in the antireflection film ranges from 6 to 15, and the thickness of the silicon dioxide layers in the antireflection film and the thickness of the titanium dioxide layers in the antireflection film range from 20 nm to 300 nm. The invention further provides a manufacturing method of the LED flip chip. The emitting angle of light at the bottom of the LED flip chip is increased through a graphical sapphire substrate technology, the light outgoing probability is increased, brightness is improved, and the brightness of white light is improved by 1% to 7%.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

Method for preparing nanometer imaging substrate of LED (light emitting diode) chip epitaxial growth

ActiveCN102214744BReduce dislocation densityImprove luminous efficiencySemiconductor devicesEtchingSilicon oxide

The invention belongs to the field of solid illumination, and in particular relates to a method for preparing a nanometer patterned substrate of LED (light emitting diode) chip epitaxial growth. The method particularly comprises the following steps: dropping silicon oxide nanometer balls which are dispersed uniformly on a sapphire substrate after cleaning treatment, and coating the silicon oxide nanometer balls on the surface of the sapphire substrate uniformly by utilizing a spin coating machine in a single layer mode; carrying out ICP (inductively coupled plasma) etching processing on the sapphire substrate which takes the silicon oxide nanometer balls as masks, and dividing the etching into two groups: firstly, etching the image depth of the nanometer patterned substrate by utilizing BC13 gas; and then etching the image width of the nanometer patterned substrate by utilizing BC13, C12, and Ar gas; and taking the sapphire substrate out after etching, and drying for use after corrosion and cleaning. According to the invention, the dislocation density in the LED chip can be reduced effectively, the occurrence of cracking can be avoided, the crystalline quality and uniformity of epitaxial materials can be improved, the probability of light emission of the light for the LED from the sapphire substrate is increased, and further the light-emitting efficiency of the LED chip can beimproved.

Owner:黄山博蓝特半导体科技有限公司

Cerium-doped yttrium aluminate scintillation crystal radiation detector with exit surface matched with lens group

InactiveCN111025372AOvercoming selectivityOvercome the inherent pitfalls of optimizationX/gamma/cosmic radiation measurmentImage resolutionScintillation crystals

The invention relates to a scintillation crystal radiation detector with a special exit surface matched with a lens group. A matched wide-angle and large-depth-of-field lens group is constructed; thecollection efficiency of an optical sensor on the scintillation light is improved; the energy resolution is improved; matching with the emergent wave band of the scintillation crystal is considered inspecific parameter design ; the incident light sensor for focusing and collecting the scintillation light can be increased, the energy resolution is improved, the shape of the light emitting surfaceof the scintillation crystal matched with the lens group is correspondingly designed, the measurement efficiency and the measurement precision are further improved, and the detection performance can be further improved especially when a high-performance detector is developed.

Owner:左慈斌

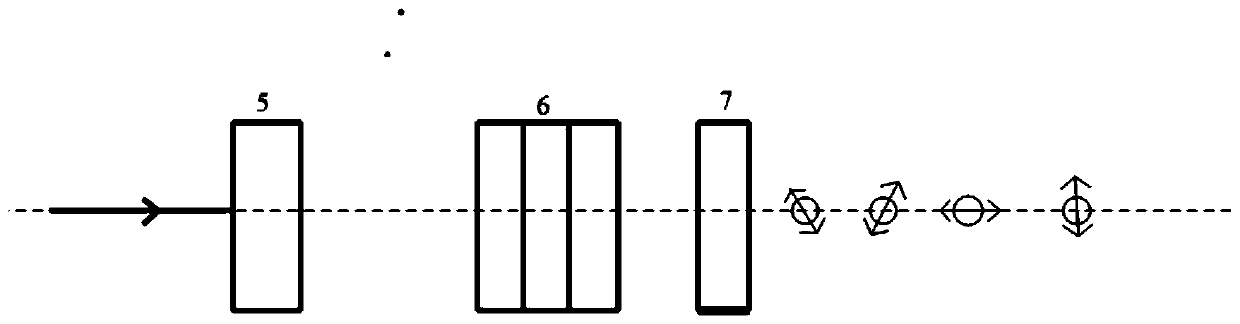

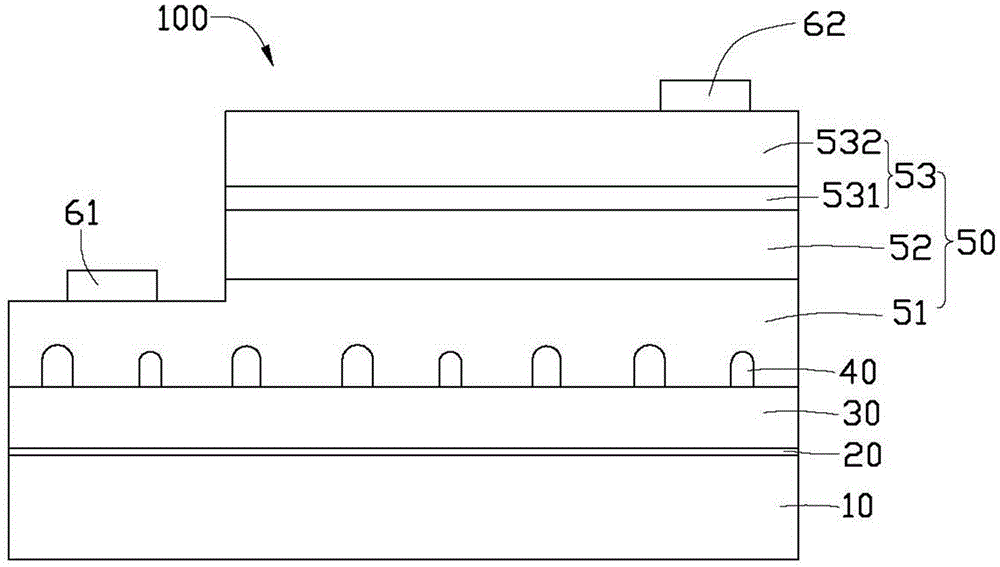

Quantum dot light emitting diode and manufacturing method

PendingCN114583087AImprove light extraction efficiencyIncrease chance of shootingSolid-state devicesSemiconductor/solid-state device manufacturingQuantum dotLight-emitting diode

The invention provides a quantum dot light-emitting diode and a manufacturing method thereof. The quantum dot light-emitting diode comprises two structures of a top-emitting quantum dot light-emitting diode and a bottom-emitting quantum dot light-emitting diode. The light path adjusting layer is additionally arranged on the light-emitting side of the top-emitting quantum dot light-emitting diode or the light path adjusting layer is additionally arranged on the light-emitting side of the bottom-emitting quantum dot light-emitting diode, and the light path adjusting layer is additionally arranged, so that the emergent section area of light emitted by the quantum dot light-emitting diode can be increased; and the light path adjusting layer can refract the light emitted by the quantum dot light emitting diode, so that light path adjustment is carried out on the light, and the light emitting probability can be improved and the light emitting uniformity of each angle of the device can be improved through light path adjustment. The light extraction efficiency of the quantum dot light emitting diode can be obviously improved by increasing the light emitting area, improving the light emitting probability and improving the light emitting uniformity of each angle of the device.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Light-emitting diode crystal grain and manufacturing method thereof

InactiveCN103311391BIncrease chance of shootingImprove light extraction efficiencySemiconductor devicesEngineering physicsLight-emitting diode

A kind of glowing diode grain, including the substrate and an electrical layer formed on the substrate, forming a transition layer between the substrate and the electrical layer, which includes the flat -scale flat area and rough pattern area of the surface.The surface of the flat area of the transition layer is contacted and the electrical layer and the transition layer are clamped with spherical aluminum nitride, and the gap between the electrical layer and the pattern area of the transition layer.The invention first forms a rough surface between the electrical layer and the substrate, and then forms a spherical aluminum nitride between the transition layer and the electrical layer.A gap between the formation can increase the probability of the light of the light from the factor plate emitted by the lighting layer through the full reflection, thereby improving the lighting efficiency of the luminous diode grain.The present invention also involves a manufacturing method of the glowing diodes.

Owner:ZHANJING TECH SHENZHEN +1

Radiator detector with cerium-doped lutetium silicate scintillation crystal with special light-emitting surface

InactiveCN110824531AIncrease chance of shootingImprove measurement efficiencyX/gamma/cosmic radiation measurmentLutetiumLight guide

The invention relates to a radiation detector with a scintillation crystal with a special light-emitting surface. A shape of a light-emitting surface of the scintillation crystal is optimized, an optical light guide structure is formed by a light-emitting end of the scintillator, the specific shape design considers the matching with the refractive index and the light-emitting wave band of the scintillation crystal, the light-emitting probability of the emergent light which is totally reflected and emitted for the first time in the prior art can be increased, the measurement efficiency and themeasurement precision are improved, and the detection performance can be further improved particularly when a high-performance detector is developed.

Owner:魏娟

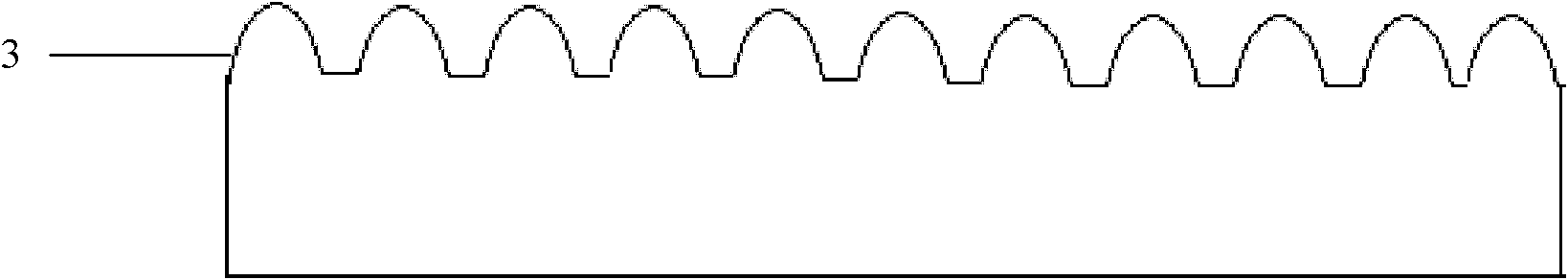

Overall wet chemical preparation method for nanoscale patterning sapphire substrate

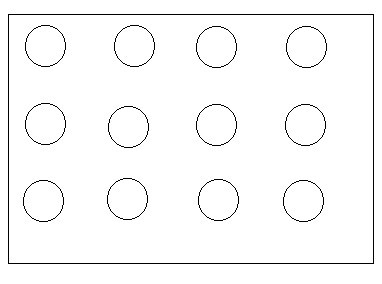

ActiveCN102646764BImprove light extraction efficiencyReduce dislocation densityAfter-treatment detailsNanotechnologyProcess equipmentMicrosphere

The invention discloses an overall wet chemical preparation method for a nanoscale patterning sapphire substrate. The method comprises the following steps that: a single-layer colloid crystal film is deposited on the sapphire substrate; after heat treatment, tetraethoxysilane sol is filled into gaps of nano microspheres, and a filling layer is formed on part of the surface of the sapphire substrate after drying; the colloid crystal film is removed; the filling layer serves as an etching mask so as to etch the sapphire substrate through a wet method, and periodicity patterns with the distribution of the nano microspheres are transferred onto the substrate; and the etching mask is removed, so as to obtain sapphire substrate with the nanoscale patterns. The overall wet chemical preparation method has the advantage that the whole process can be completed thoroughly in a common chemical laboratory without adopting any semiconductor process equipment. The nanoscale patterning sapphire substrate can reduce the dislocation density in chips effectively, improve the crystal quality of extension materials and increase the probability of light emitting from the sapphire substrate, so as to improve the light extraction efficiency of an LED (light-emitting diode).

Owner:TSINGHUA UNIV

Europium-doped calcium fluoride scintillation crystal radiation detector with exit surface matched with lens group

InactiveCN110737014AOvercoming selectivityOvercome the inherent pitfalls of optimizationX/gamma/cosmic radiation measurmentImage resolutionScintillation crystals

The invention relates to a scintillation crystal radiation detector with a special light emitting surface matched with a lens group. A matched wide-angle and large-depth-of-field lens group is constructed, so the collection efficiency of the optical sensor on the scintillation light is improved and the energy resolution is improved. The specific parameter design considers the matching with the emergent wave band of the scintillation crystal, so the incident light sensor for focusing and collecting the scintillation light can be increased, the energy resolution is improved, the shape of the light emitting surface of the scintillation crystal matched with the lens group is correspondingly designed, the measurement efficiency and the measurement precision are further improved, and the detection performance can be further improved especially when a high-performance detector is developed.

Owner:左慈斌

High light extraction efficiency Gan-based LED transparent electrode structure and preparation method

ActiveCN104659180BNo risk of injuryAvoid reflection lossSemiconductor devicesIndium tin oxideLight-emitting diode

The invention relates to a transparent electrode structure and a preparation method thereof, particularly relates to a transparent electrode structure of a GaN-based LED (Light Emitting Diode) with high light extraction efficiency and a preparation method thereof and belongs to the technical field of LED semiconductor devices. According to the technical scheme provided by the invention, the transparent electrode structure comprises a GaN substrate, wherein the GaN substrate is provided with a nano column layer and an ITO (Indium Tin Oxide) layer covering the nano column layer; the nano column layer comprises a plurality of nano columns; the ITO layer covers on the nano columns and column disconnecting holes at the two sides of the nano columns are filled with the ITO layer, so that the ITO layer and the GaN substrate are contacted. The transparent electrode structure has the advantages that the light extraction efficiency of the GaN-based positive LED can be obviously improved, the process operation is convenient, the cost is low, the application range is wide, and the safe and reliable effects are achieved.

Owner:JIANGSU XINGUANGLIAN TECH +1

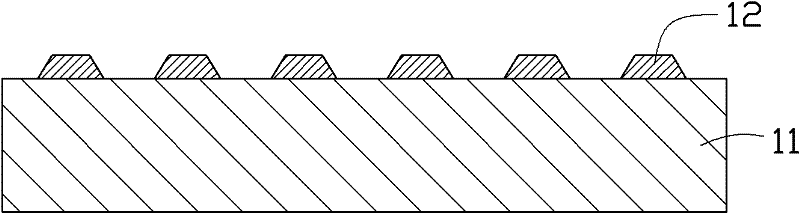

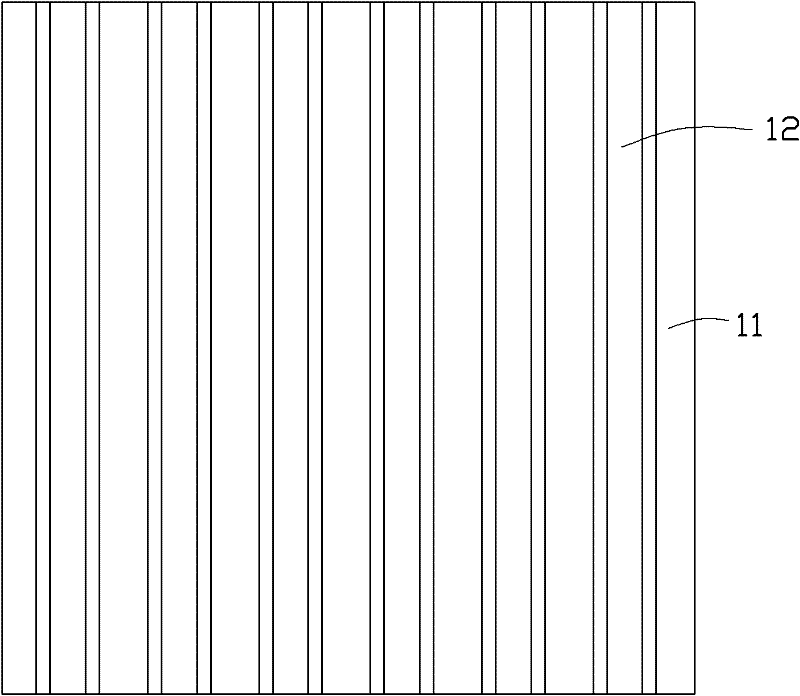

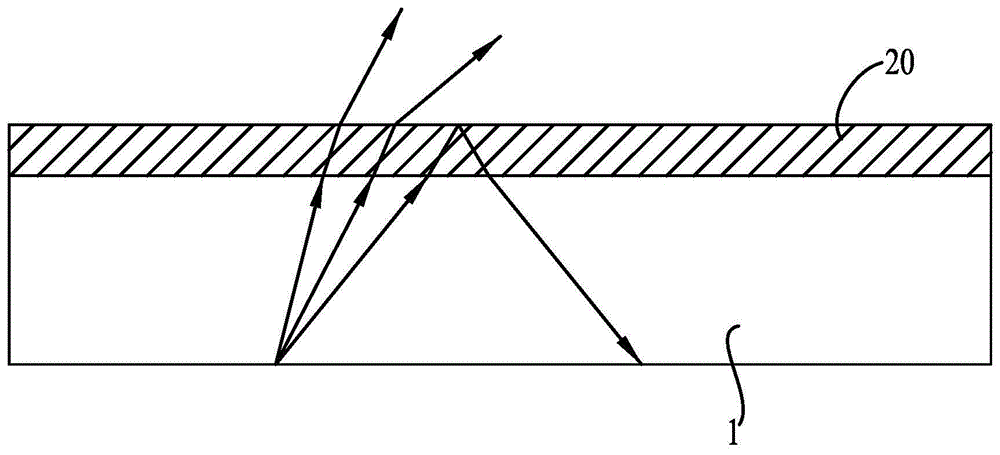

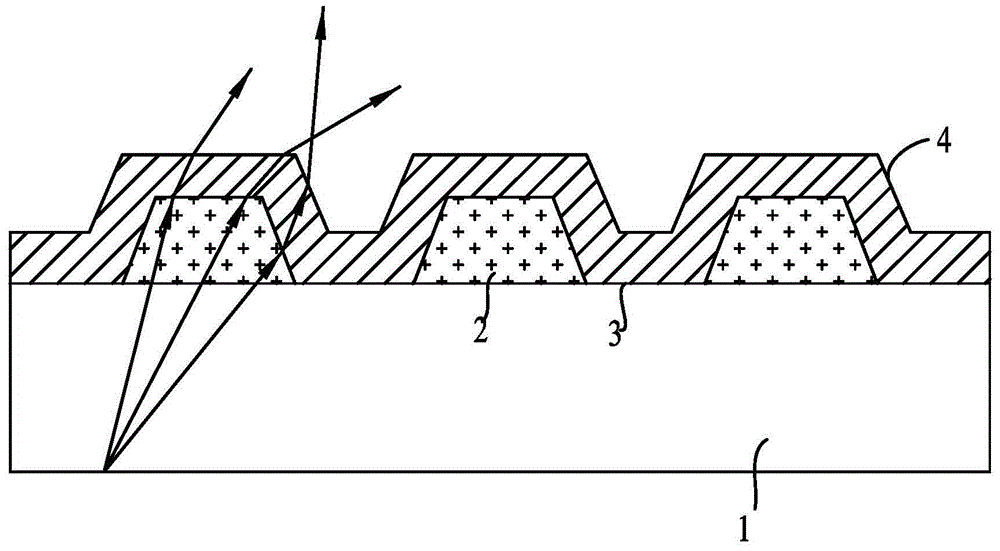

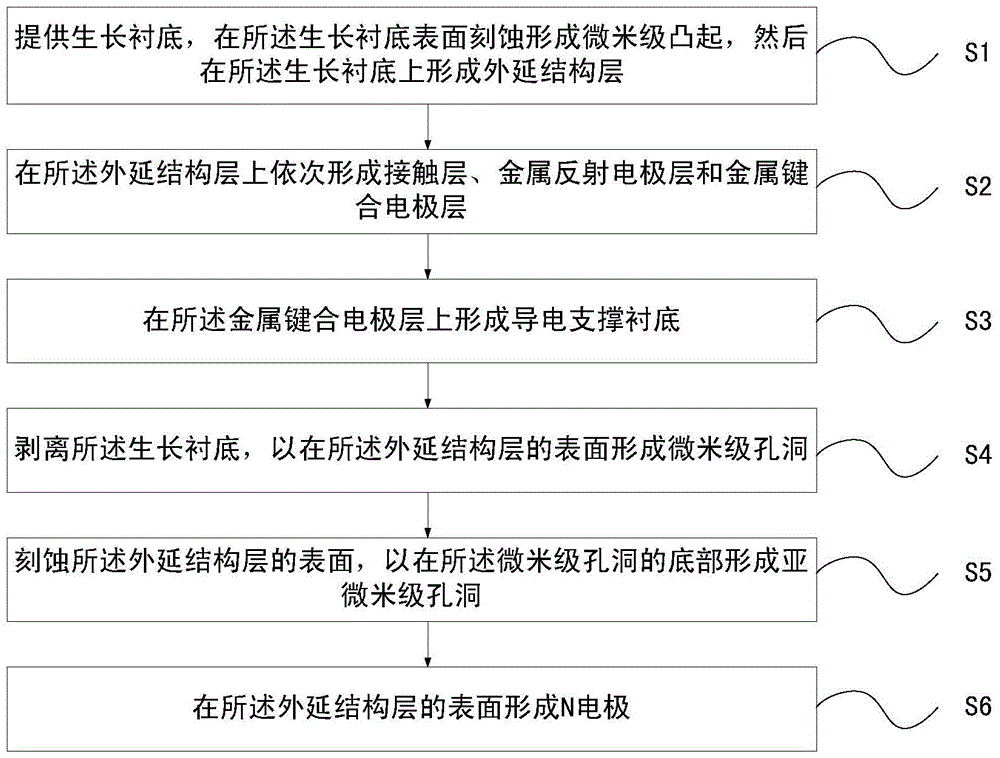

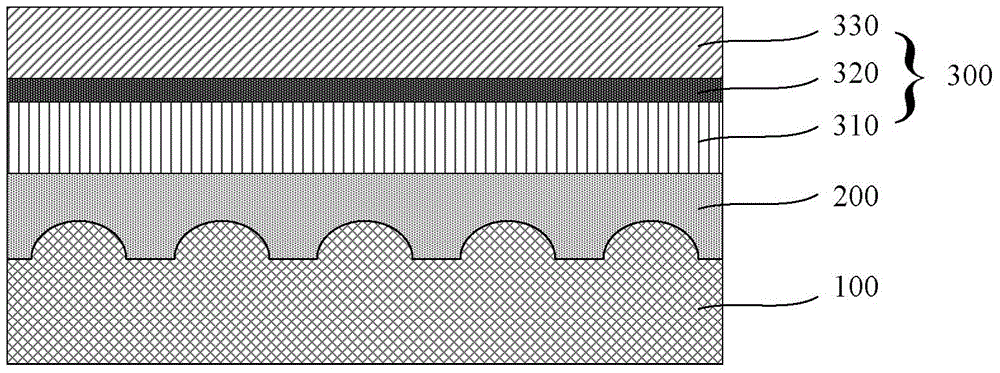

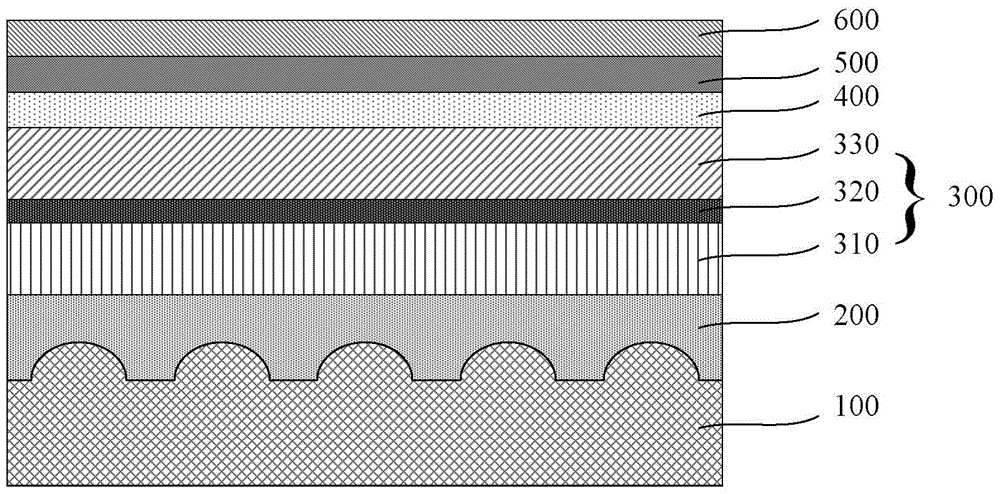

A led vertical chip structure with special roughened morphology and its preparation method

InactiveCN104218134BImprove luminous efficiencyIncrease chance of shootingSemiconductor devicesMicron scaleEngineering

A method for improving luminous efficiency of an LED in a vertical structure. First, an LED vertical chip structure with a special coarsening morphology is provided, and micron-scale holes (311) are formed in the surface of an epitaxial structure layer (300) and submicron-scale holes (312) are formed at the bottom of the micron-scale holes. The light emitting surface structure can increase the emission probability of light inside a device, and can greatly improve the light emission efficiency. Also provided is a preparation method for the chip structure. Micron-scale holes (311) are formed in an epitaxial structure layer (300) by stripping a growth substrate (100) with micron-scale bumps, and submicron-scale holes (312) are formed at the bottom of the micron-scale holes (311) by means of etching. The method is simple in process, can be applied to large-scale industrial production, and can greatly improve the luminous efficiency of the LED in the vertical structure.

Owner:ENRAYTEK OPTOELECTRONICS

Light-emitting diode crystal grain and manufacturing method thereof

ActiveCN102916098BIncrease chance of shootingImprove light extraction efficiencySemiconductor/solid-state device manufacturingSemiconductor devicesElectrical conductorLight-emitting diode

A light emitting diode (LED) comprises a substrate, an epitaxial layer and an aluminum nitride (AlN) layer sequentially disposed on the substrate. The AlN layer comprises a plurality of stacks separated from each other, wherein the epitaxial layer entirely covers the plurality of stacks of the AlN layer. The AlN layer with a plurality of stacks reflects upwardly light generated by the epitaxial layer and downwardly toward the substrate to an outside of LED through a top plan of the LED. A method for forming the LED is also disclosed.

Owner:ZHANJING TECH SHENZHEN +1

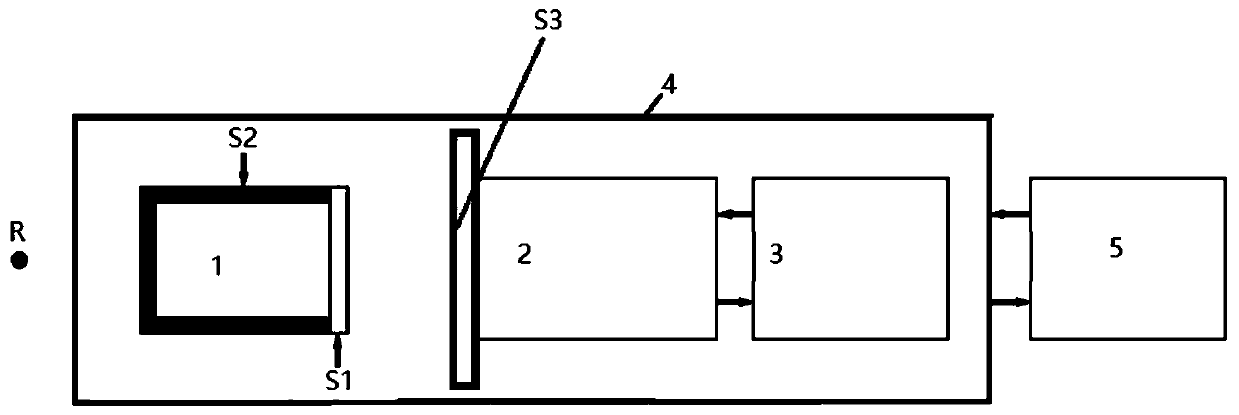

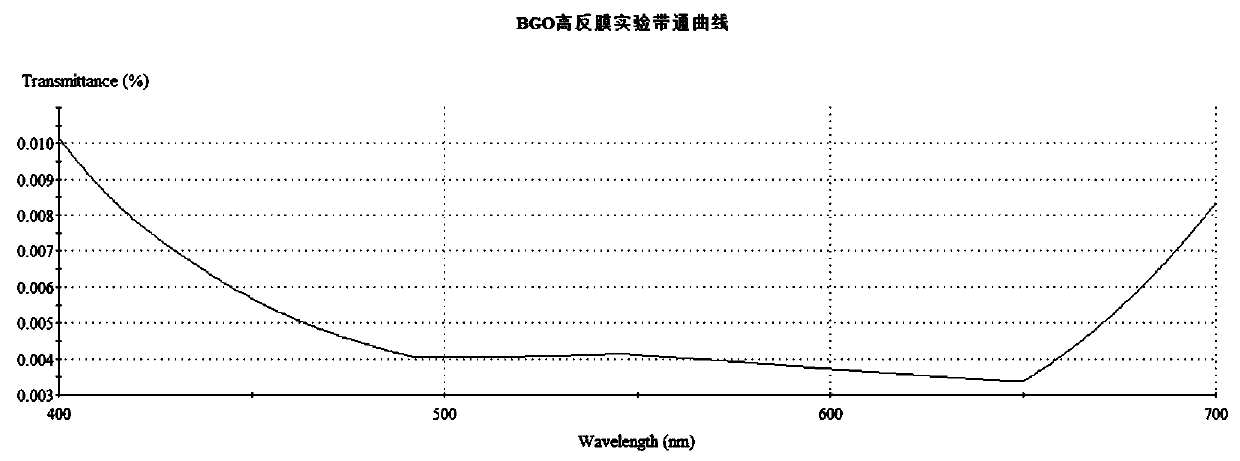

Bismuth germanate scintillating crystal radiation detector plated with high reflecting film and special light-out surface

InactiveCN110727014AImproved energy resolutionImprove light outputRadiation intensity measurementScintillation crystalsThin membrane

The invention relates to a scintillating crystal radiation detector plated with a high reflecting film and a special light-out surface. According to the detector, the conception of performing pertinent film design according to a main transmitting waveband of a scintillating crystal itself is adopted, and the difficulties that the data volume is excessively large and analysis is not easy in thin film research are overcome; an appropriate reflecting film material is obtained, the material has adhesive force as good as the crystal, and film layers are small in quantity and easy to realize; and special light-out surface design matched with a total-reflection film plating scheme is further provided, and measurement efficiency and measurement precision are improved accordingly.

Owner:刘佳莉

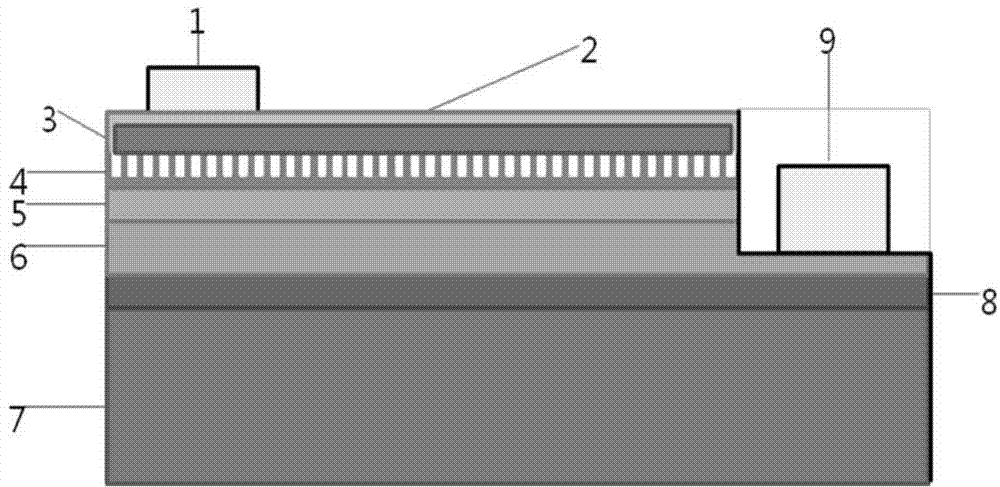

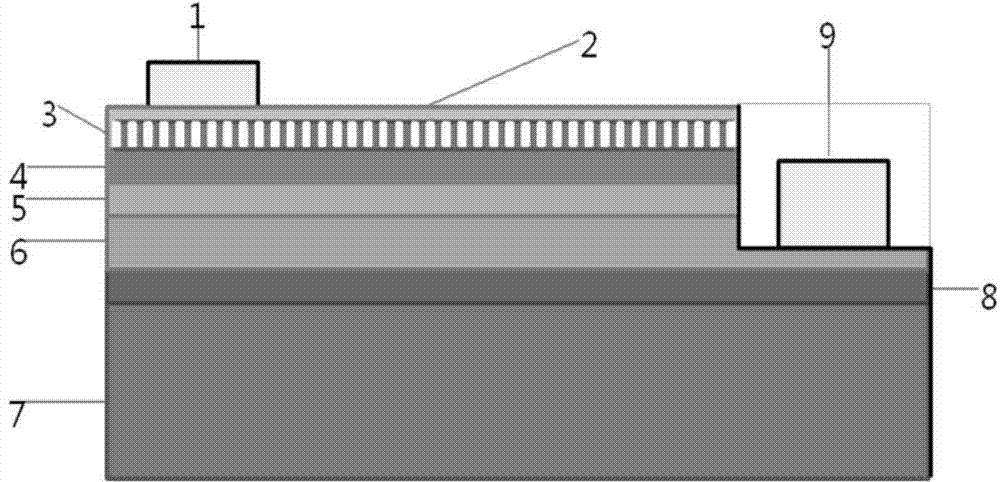

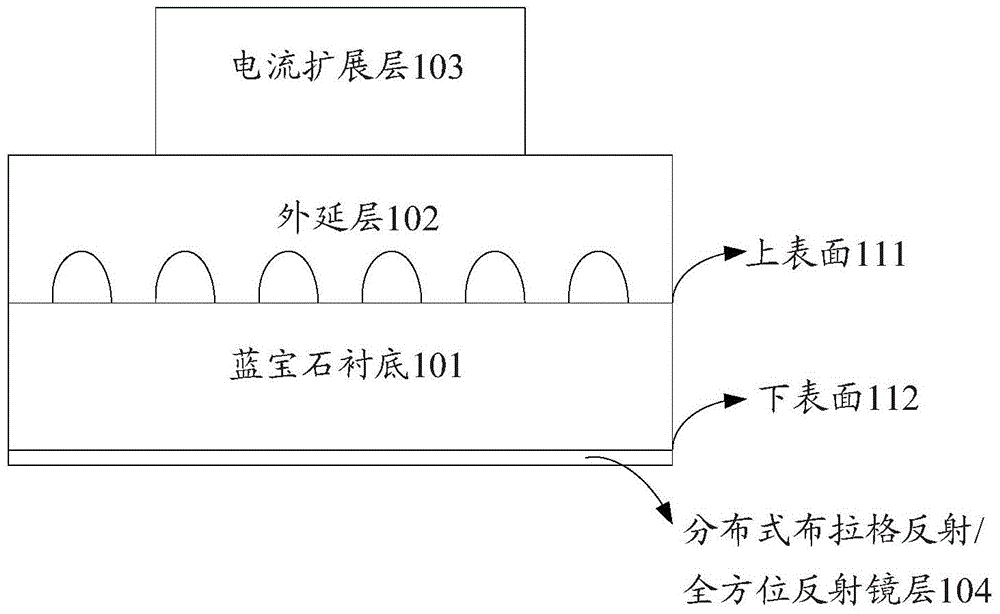

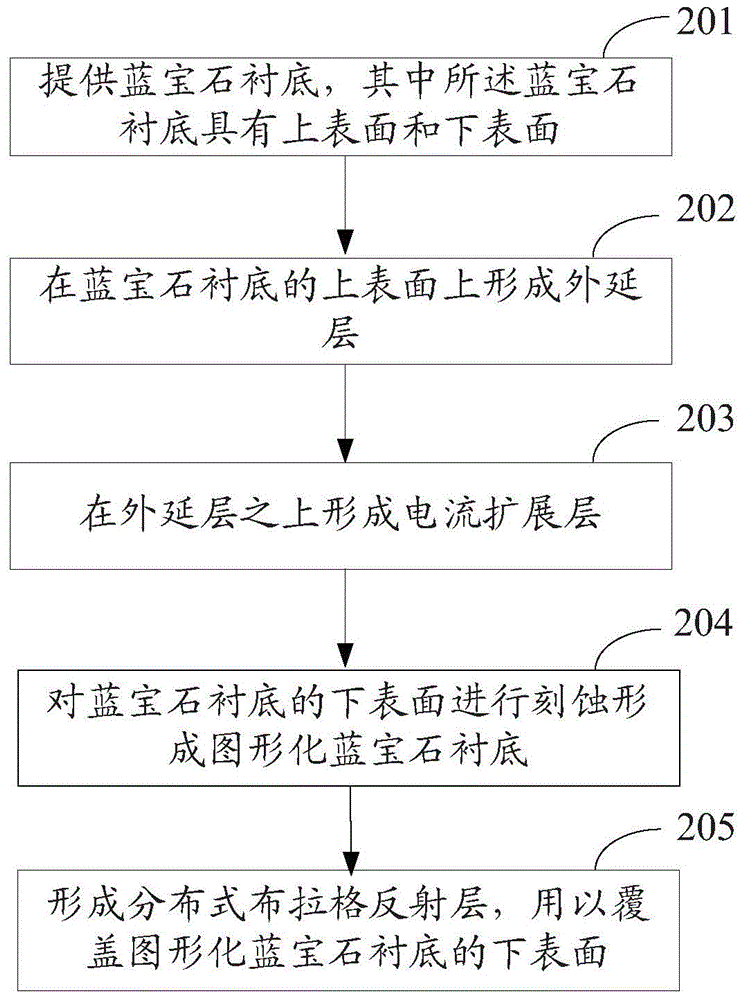

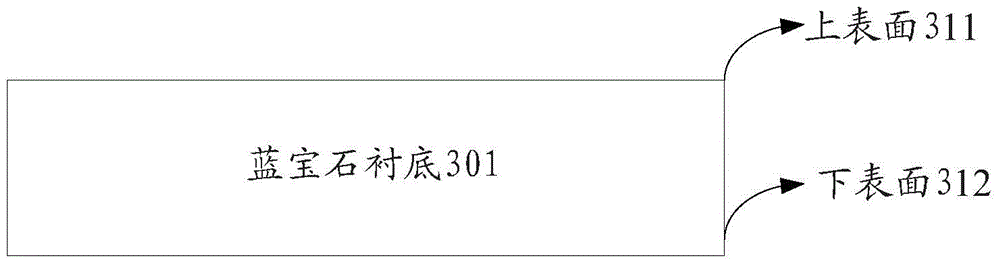

Light-emitting diode chip and method of making the same

ActiveCN104091869BReduce the chance of total reflectionIncrease chance of shootingSemiconductor devicesPower flowReflective layer

The invention discloses a light emitting diode chip. The light emitting diode chip is characterized by comprising a current expanding layer, an epitaxial layer, a graphical sapphire substrate and a distributed Bragg reflecting layer, wherein the epitaxial layer is arranged below the current expanding layer; the graphical sapphire substrate is arranged below the epitaxial layer and is provided with an upper surface and a lower surface, and the upper surface is close to the epitaxial layer; the distributed Bragg reflecting layer is used for covering the lower surface of the graphical sapphire substrate. The light emitting diode chip is manufactured by combining a graphical sapphire substrate technology with a distributed Bragg reflection technology, the light emission angle of the bottom of the light emitting diode chip is increased, the probability of total reflection of light of the distributed Bragg reflection technology is reduced and the light emergent probability is increased.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

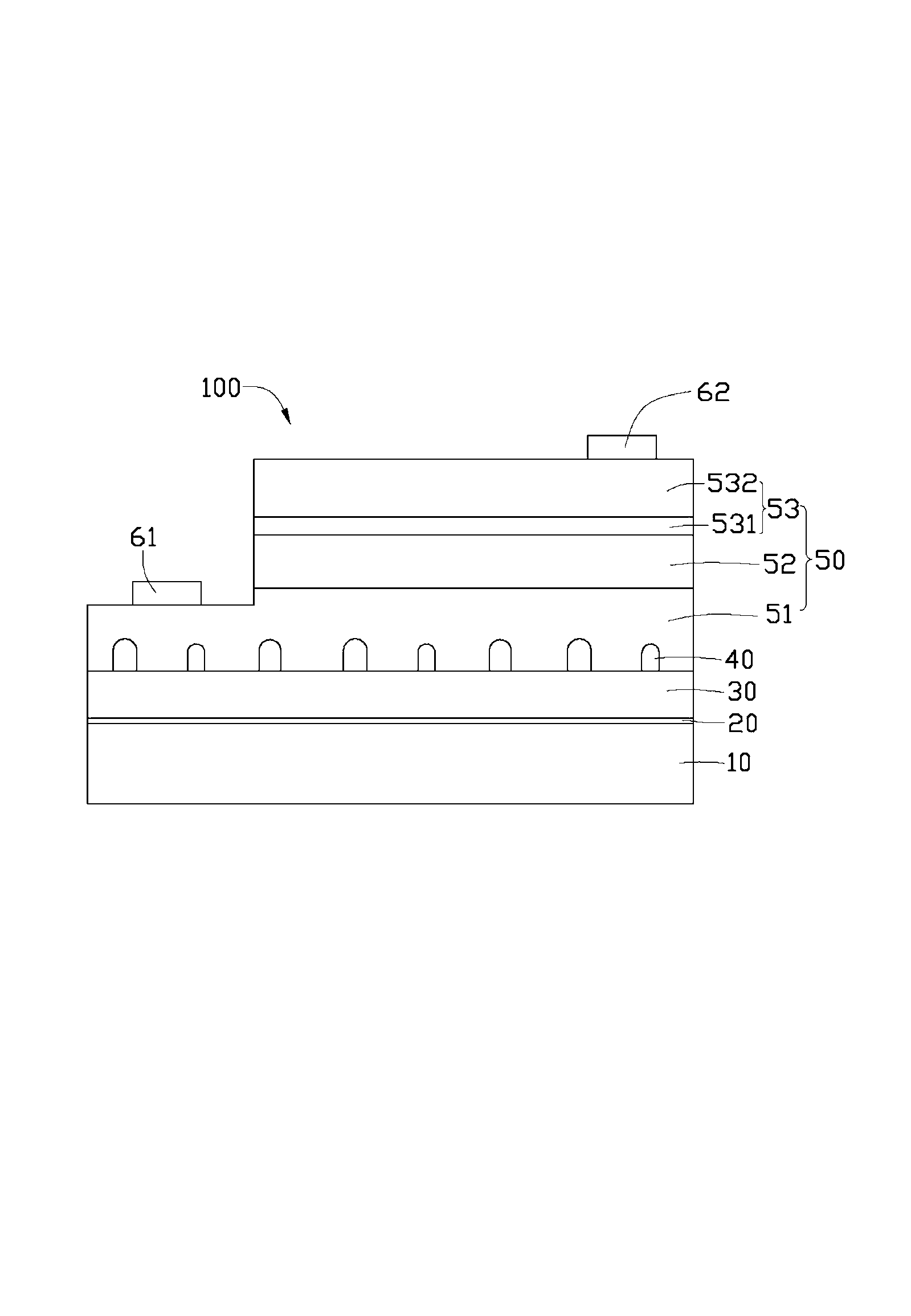

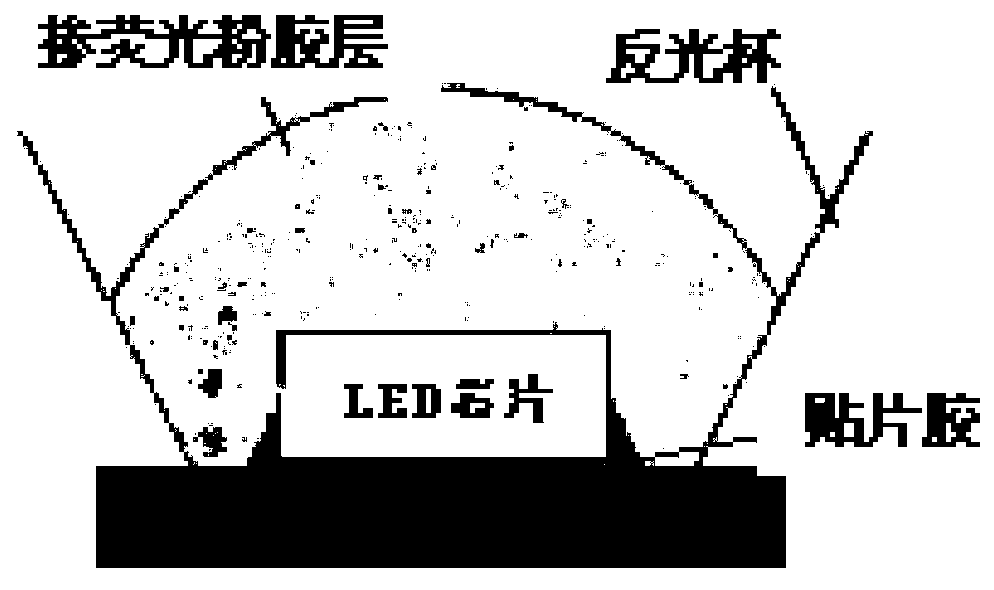

A device structure suitable for monochromatic LED wafer level packaging

ActiveCN107123713BIncrease contact areaSpread evenlySemiconductor devicesRefractive indexGallium nitride

Owner:SHANGHAI XINYUANJI SEMICON TECH

Radiation detector with special light-exiting surface thallium doped cesium iodide scintillation crystal

InactiveCN110824535AIncrease chance of shootingImprove measurement efficiencyX/gamma/cosmic radiation measurmentScintillation crystalsRefractive index

The invention relates to a radiation detector with a special light exit surface scintillation crystal. A shape of a light exit surface of the scintillation crystal is optimized; an exit end of a scintillant forms an optical guide structure; matching with a refractive index and an exit wave band of the scintillation crystal are taken into consideration during particular shape design of the radiation detector; the exit probability of total reflection exit light during first exit in the prior art can be increased; the measurement efficiency and measurement accuracy are improved; and particularly,the detection performance can be further improved when the high-performance detector is developed.

Owner:魏娟

Radiation detector with europium-doped calcium fluoride scintillation crystal with special light-emitting surface

InactiveCN110824532AIncrease chance of shootingImprove measurement efficiencyX/gamma/cosmic radiation measurmentLight guideScintillation crystals

The invention relates to a radiation detector with a scintillation crystal with a special light-emitting surface. A shape of the light-emitting surface of the scintillation crystal is optimized, an optical light guide structure is formed by a light-emitting end of a scintillator, the specific shape design considers the matching between the refractive index and the light-emitting wave band of the scintillation crystal, the light-emitting probability of the emergent light which is totally reflected and emitted for the first time in the prior art can be increased, the measurement efficiency and the measurement precision are improved, and the detection performance can be further improved particularly when a high-performance detector is developed.

Owner:魏娟

Cerium-doped lutetium silicate scintillation crystal radiation detector with exit surface cooperated with lens group

InactiveCN110658546AOvercoming selectivityOvercome the inherent pitfalls of optimizationX/gamma/cosmic radiation measurmentLutetiumImage resolution

The invention relates to a scintillation crystal radiation detector with a special exit surface cooperated with a lens group. A matched wide-angle and large-depth-of-field lens group is constructed; the scintillation light collecting efficiency of a light sensor is improved; the energy resolution is improved; matching with the emergent waveband of the scintillation crystal itself is considered inspecific parameter design; more scintillation light is focused and collected and then input to the light sensor; the shape of the exit surface of the scintillation crystal cooperated with the lens group is designed correspondingly to further improve the measuring efficiency and precision; and in particular, the detection performance for researching and developing a high-performance detector can befurther improved.

Owner:左慈斌

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com