LED flip chip and patterned substrate and manufacturing method of LED flip chip

A patterned substrate, flip-chip technology, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as increasing device heat transfer, device efficiency, adverse effects on performance parameters and reliability, and reducing device external quantum efficiency. , to increase the probability of exit, improve brightness and electro-optical conversion efficiency, and increase the efficiency of light extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

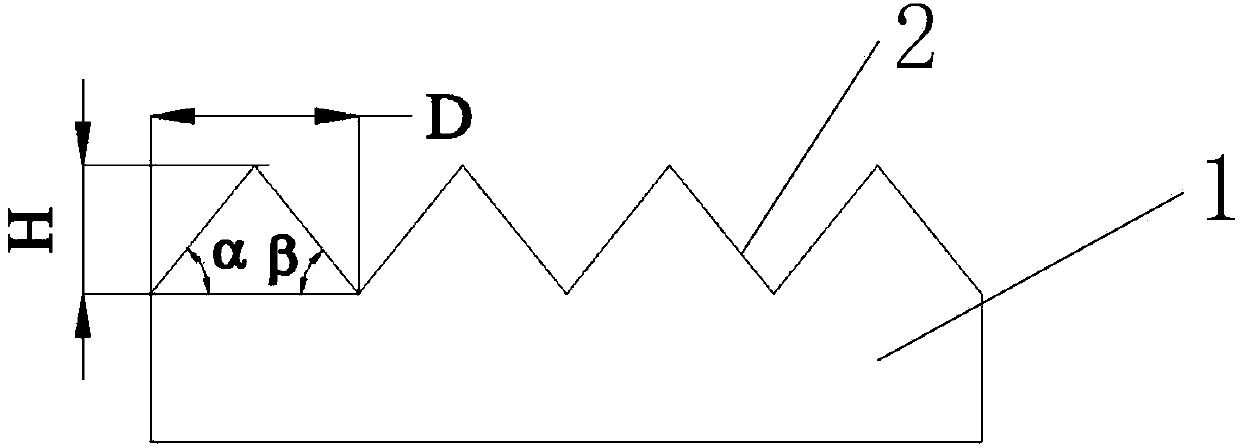

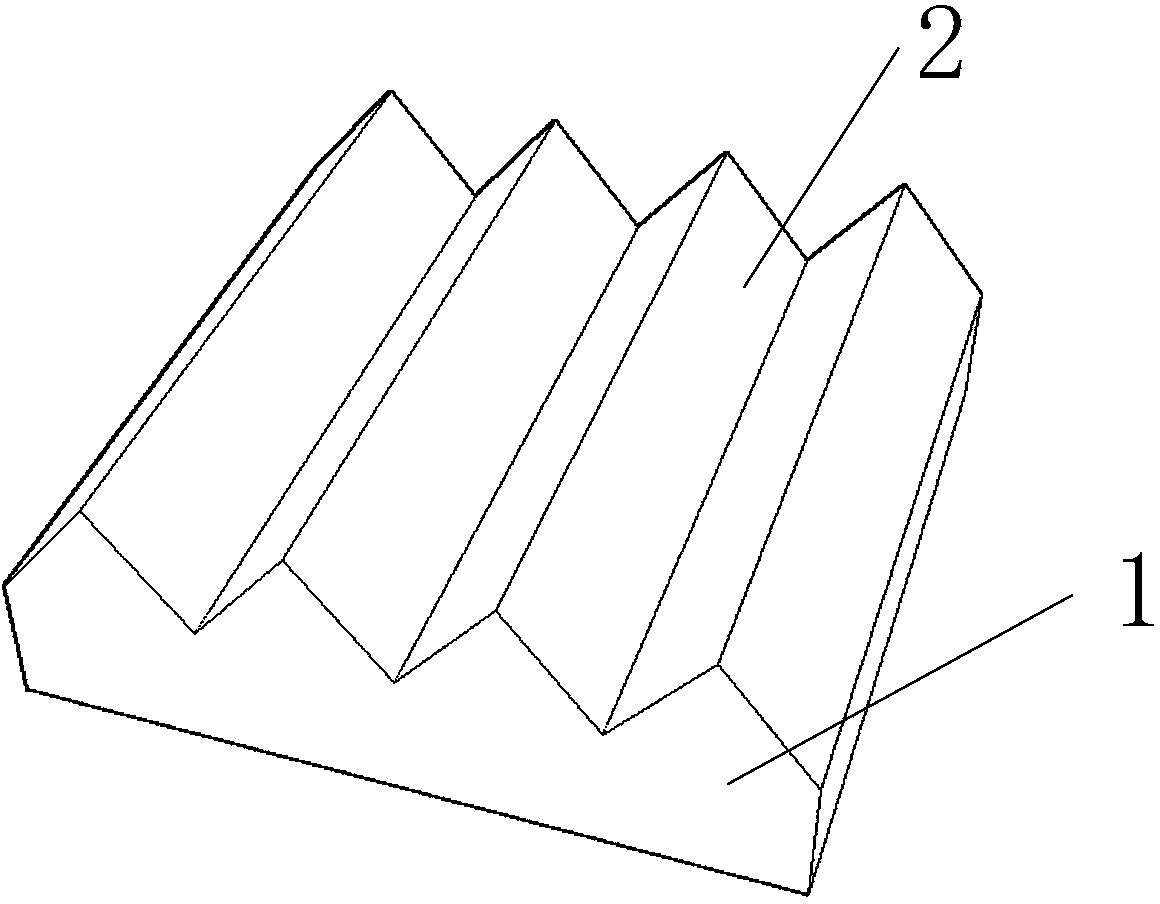

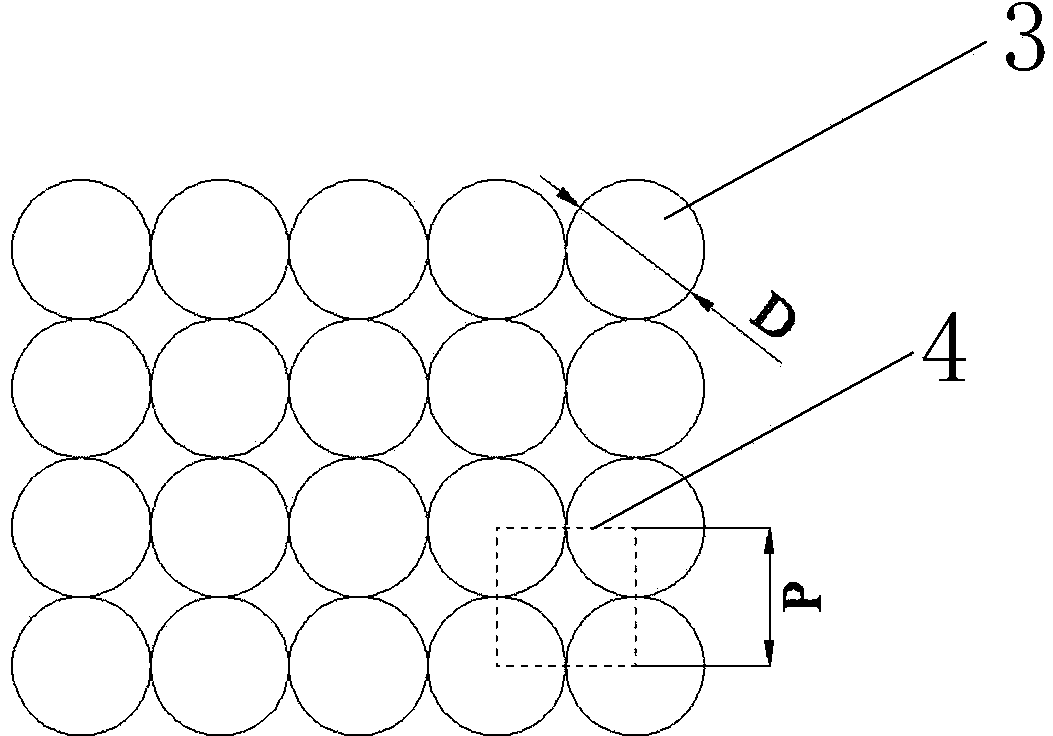

[0041] A patterned substrate for LED flip chips. The surface of the patterned substrate 1 is provided with grooves 2 with a triangular cross-section and parallel to each other, or provided with a plurality of convex structures 3 arranged in regular shapes. Graphics Array4.

[0042] The triangular cross-section is preferably an isosceles triangle, and the base angle of the triangular cross-section ranges from 10 to 80 degrees. The width of the trench 2 ranges from 10 nm to 200 μm. The graphic array 4 is arranged in a rectangular or hexagonal close-packed array, and the side length of the rectangular and hexagonal close-packed arrays ranges from 10 nm to 50 μm.

[0043] The shape of the protruding structure 3 is one or more of a cone, a cone-like body, a regular polygonal pyramid, a hemisphere, a spherical segment, a cylinder, and a regular polyhedron.

[0044] The size of the bottom of the raised structures 3 ranges from 10 nm to 50 μm; the height of each raised structure 3 ran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com