Light emitting diode crystalline grain and producing method thereof

A technology of light-emitting diodes and manufacturing methods, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as reducing the light-emitting efficiency of light-emitting diode crystal grains, and achieve the effect of improving light-emitting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

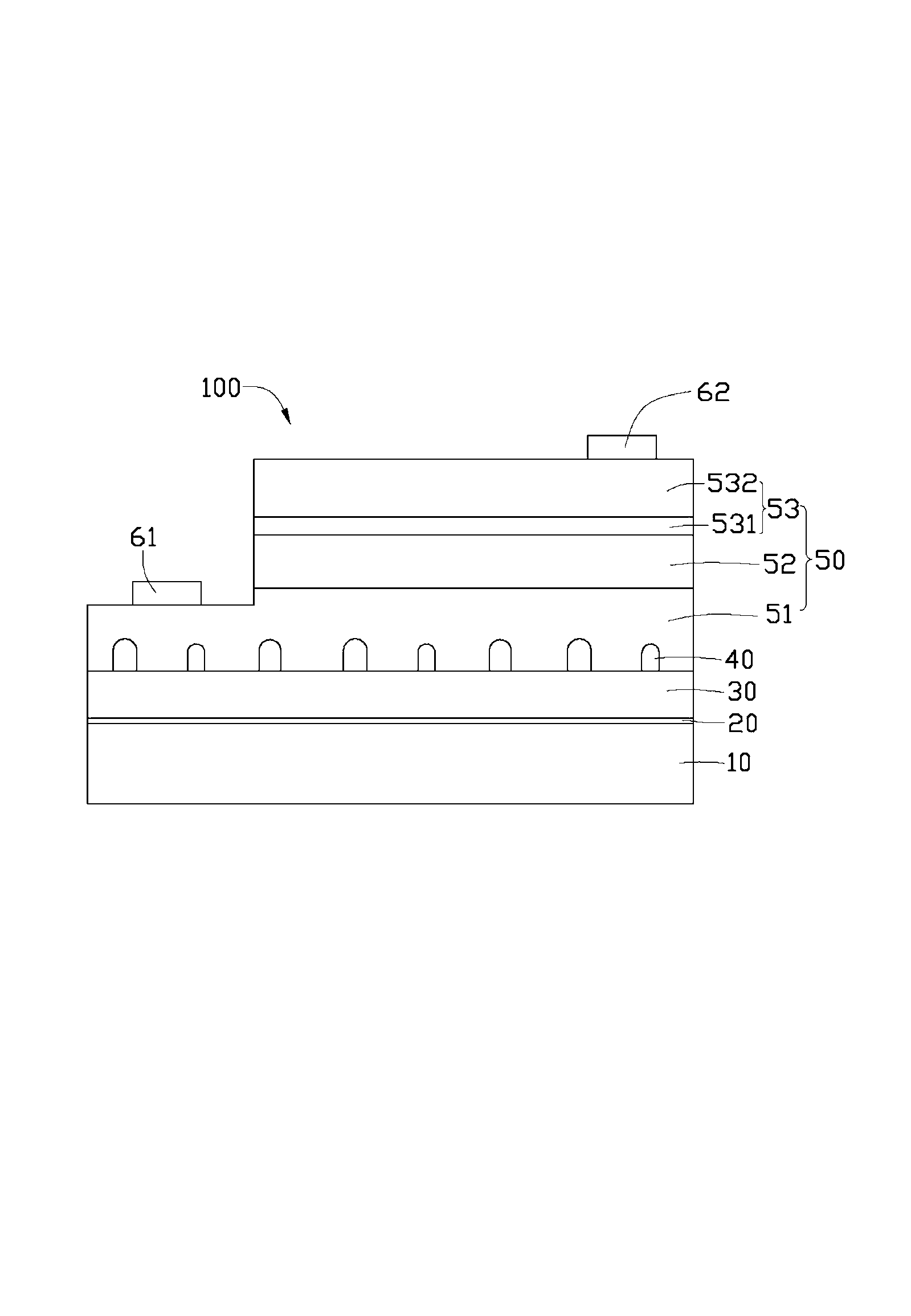

[0017] Such as figure 1 , the light emitting diode die 100 provided by the first embodiment of the present invention, which sequentially includes: a substrate 10 , a buffer layer 20 formed on the substrate 10 , a transition layer 30 formed on the buffer layer 20 , and a transition layer 30 formed on the transition layer 30 A plurality of spherical aluminum nitride 40 is formed on the transition layer 30 and covers the epitaxial layer 50 of the plurality of spherical aluminum nitride 40 .

[0018] The substrate 10 can be made of sapphire, silicon carbide (SiC), silicon (Si), gallium nitride (GaN) and other materials, preferably sapphire in this embodiment, so as to control the manufacturing cost of the light emitting chip.

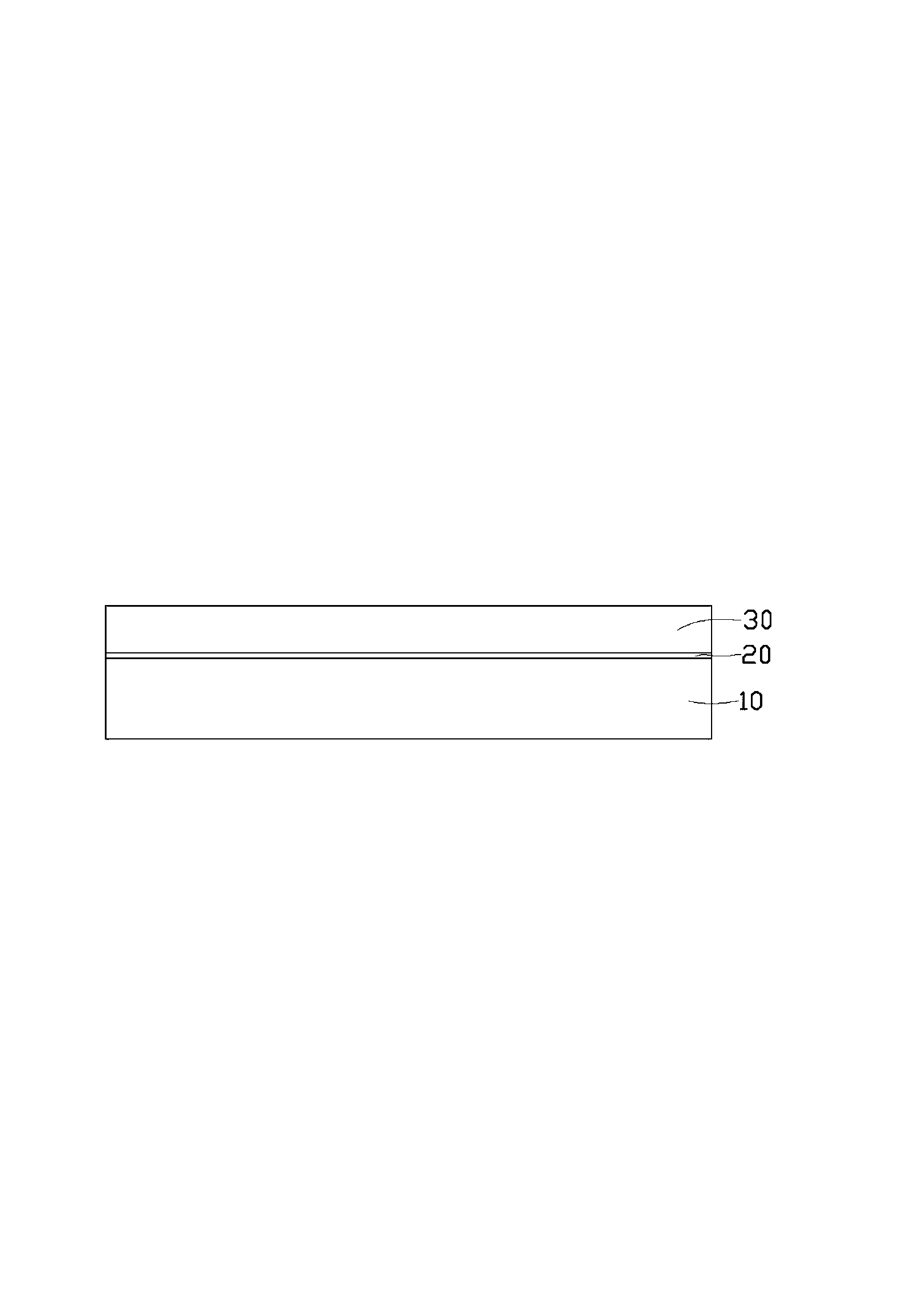

[0019] The buffer layer 20 and the transition layer 30 can be deposited by metal-organic chemical vapor deposition (Metal-Organic Chemical Vapor Deposition; MOCVD), molecular beam epitaxy (Molecular Beam Epitaxy; MBE) or halide chemical vapor phase epitaxy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com