Patents

Literature

51results about How to "Reduce the chance of total reflection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

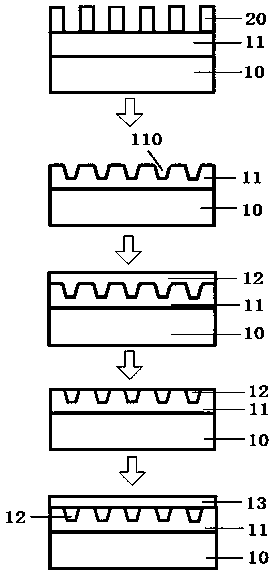

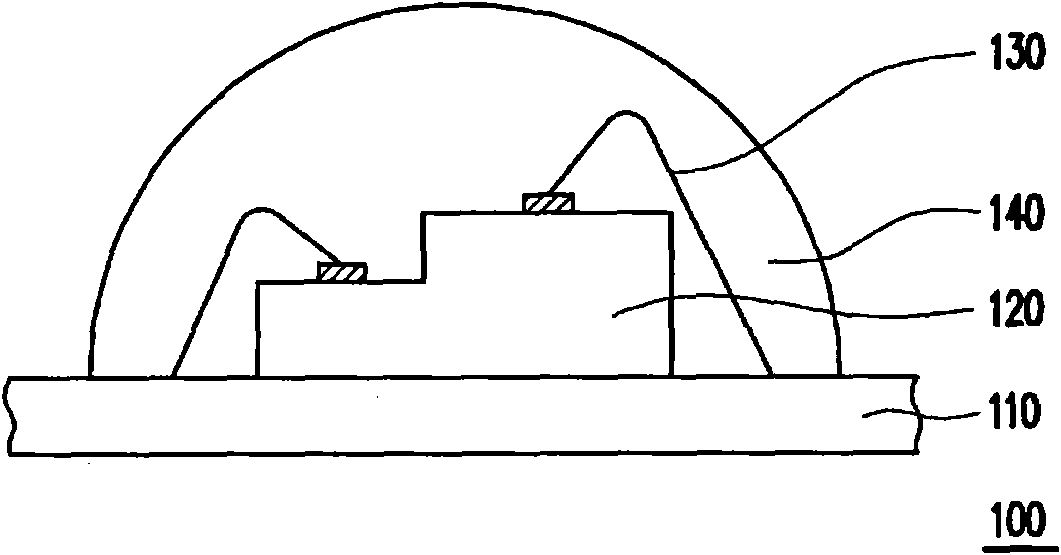

Large-angle lens and large-angle light-emergent LED (Light Emitting Diode) light source module

ActiveCN102818216AIncrease the light output angleGuaranteed efficiencyPoint-like light sourceElectric lightingLight beamEngineering

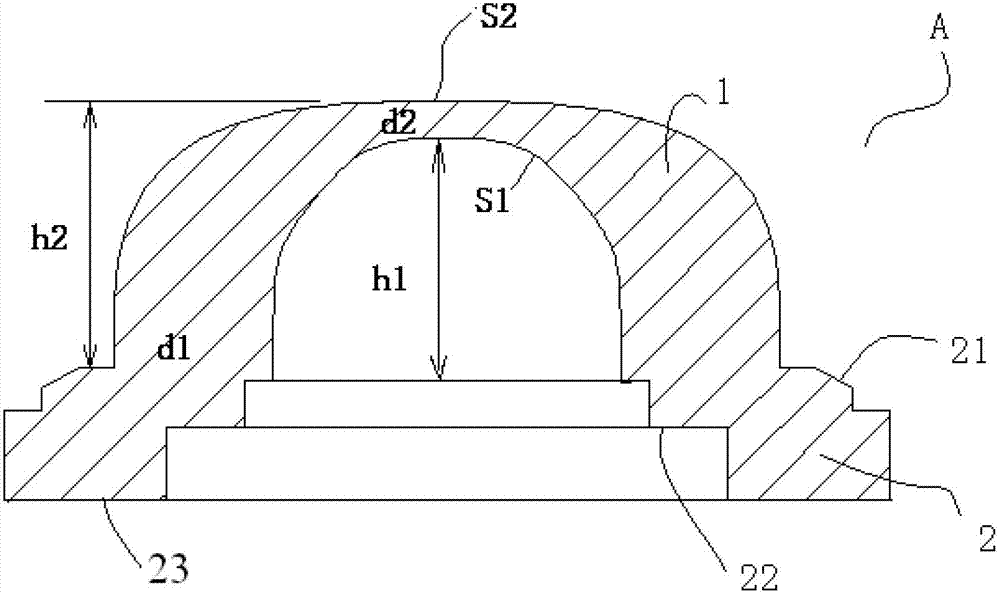

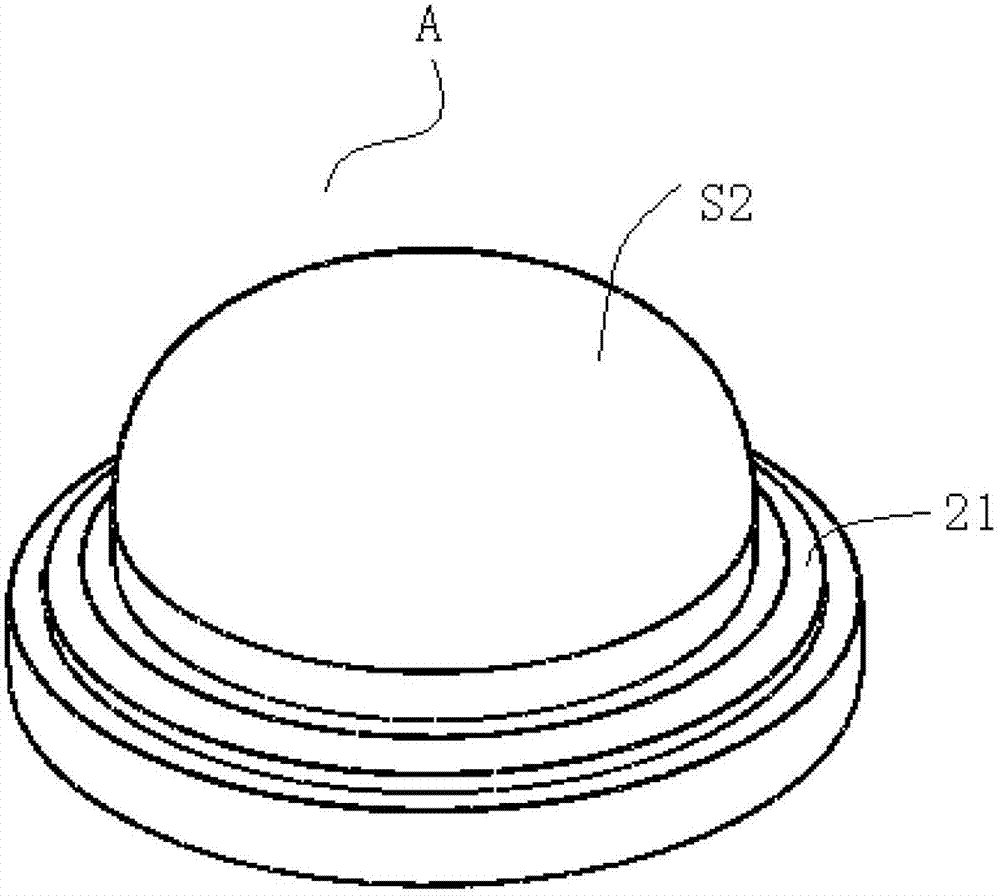

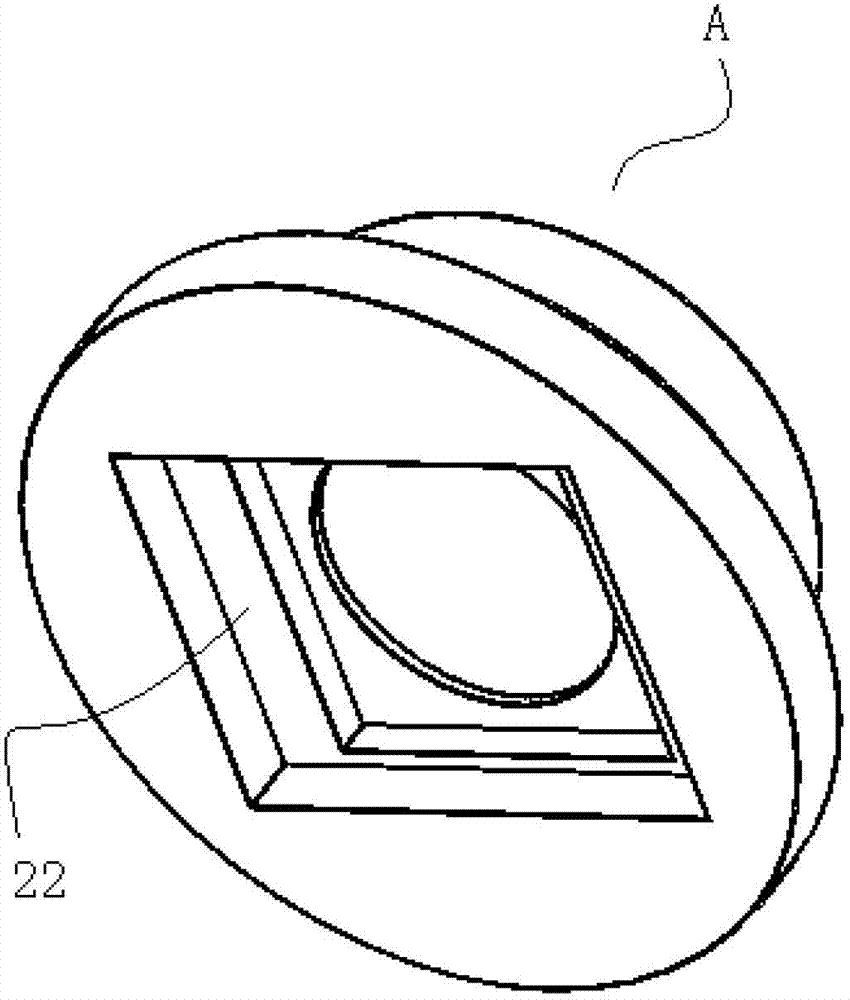

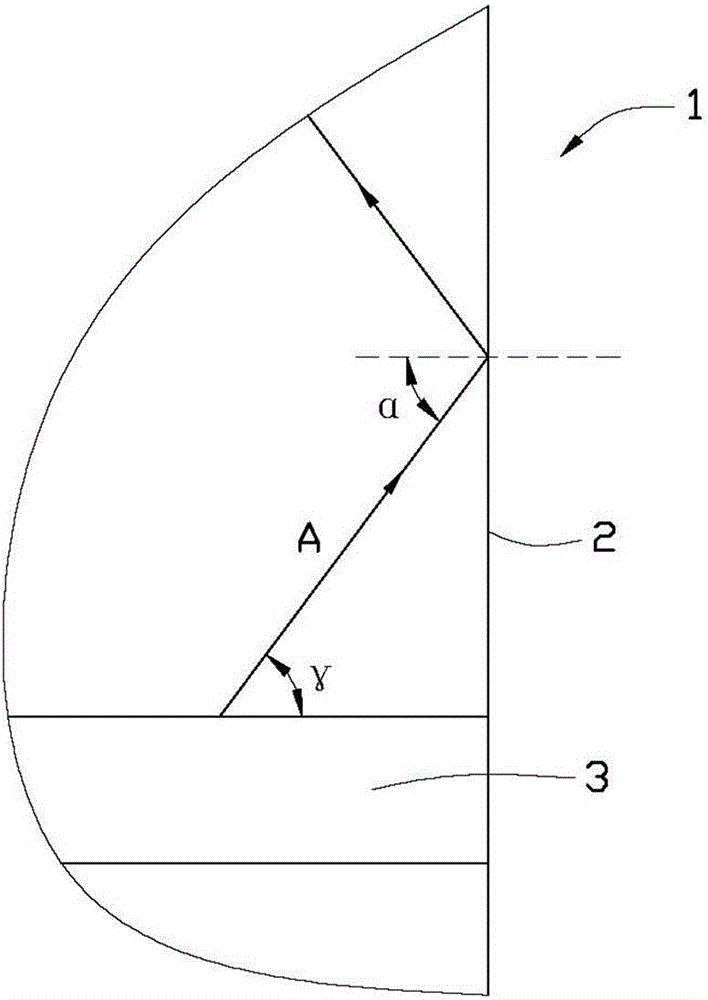

The invention discloses a large-angle LED (Light Emitting Diode) lens, comprising a main body, wherein the lower end of the main body is provided with an opening, the main body is shell-shaped and is provided with light-incident surfaces and light-emergent surfaces; the light-incident surfaces are symmetrically arranged around the central axis of the main body, and are positioned at the inner sides of the main body; the light-emergent surfaces are arranged at the outer side of the main body; the light-incident surfaces are light-transmitting concave surfaces; the light-emergent surfaces are light-transmitting convex surfaces; the maximum thickness d1 of the lower part of the main body and the minimum thickness d2 of the top part of the main body meet the condition that d1 / d2 is more than 4 and less than 6; the concave depth h1 of each light-transmitting concave surface and the minimum thickness d2 of the top part of the main body meet the relation: h1 is more than 4*d2; and the convex height h2 of the light-transmitting convex surface and the minimum thickness d2 of the top part of the main body meet the relation: h2 is more than 5*d2. The large-angle LED lens disclosed by the invention has the advantages that the light beam angle of the large-angle lens is converted to be larger than 130 degrees so as to realize large-angle illumination and simultaneously improve the illumination uniformity; and due to the design with the light-transmitting concave surfaces and the light-transmitting convex surfaces, the total reflection probability of light is reduced to be lowest, so that the enlarging of the light-emergent angle is ensured, simultaneously, the efficiency of the lens is also enabled to be 90%, and the light utilization rate is furthest increased. The invention also discloses a large-angle light-emergent LED light source module.

Owner:FOSHAN NATIONSTAR OPTOELECTRONICS CO LTD

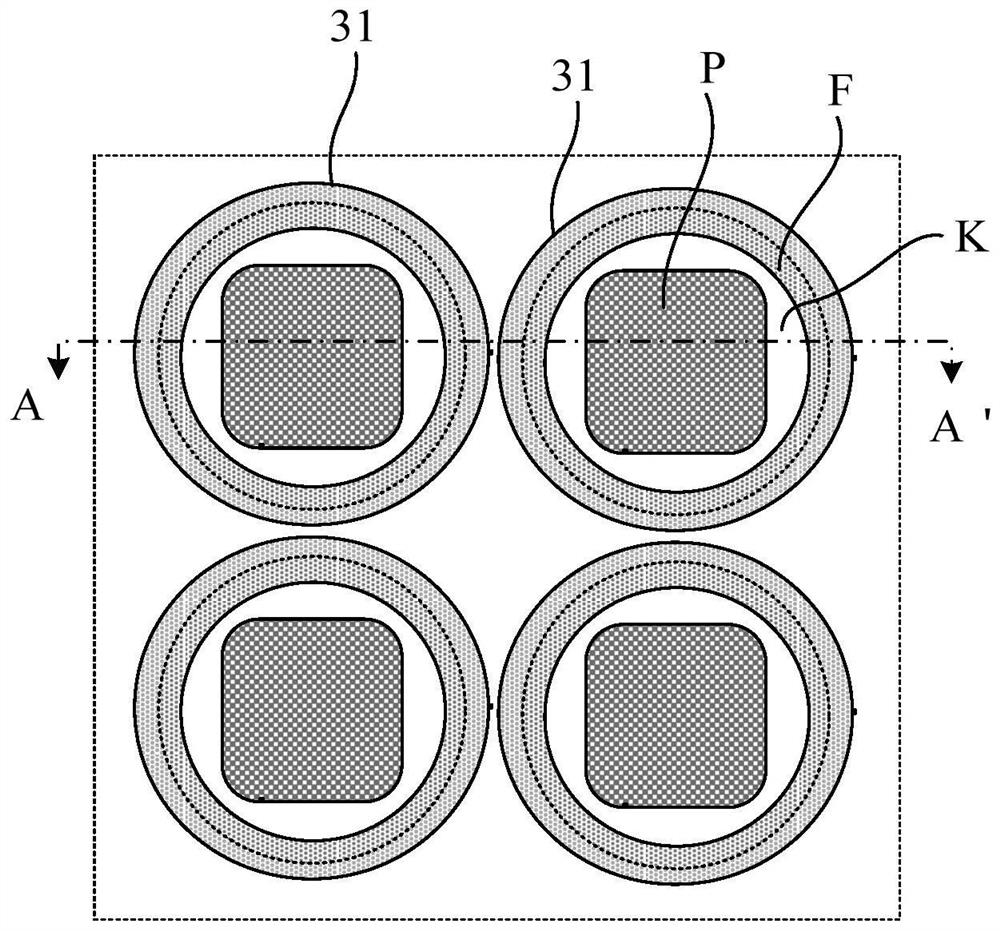

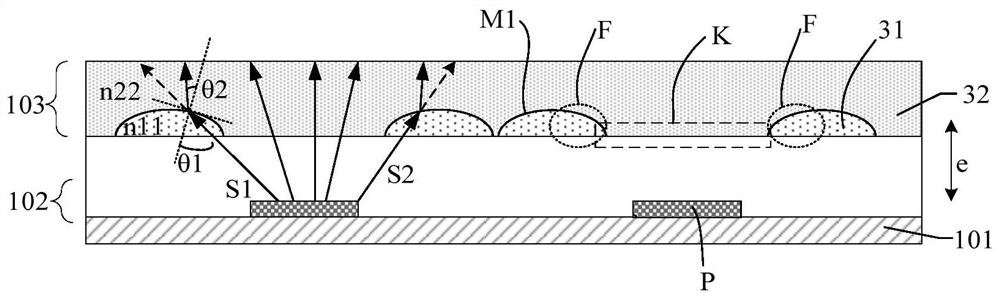

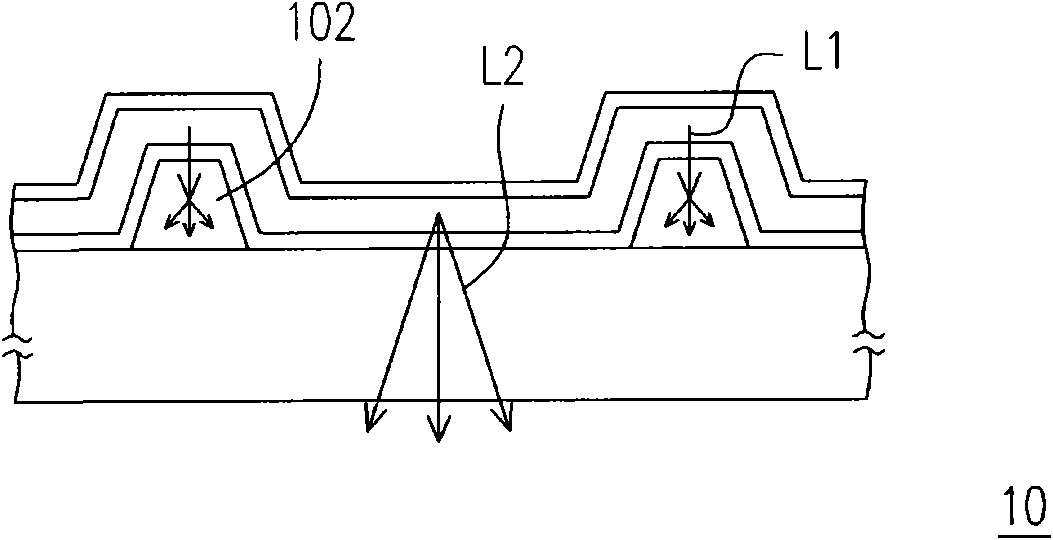

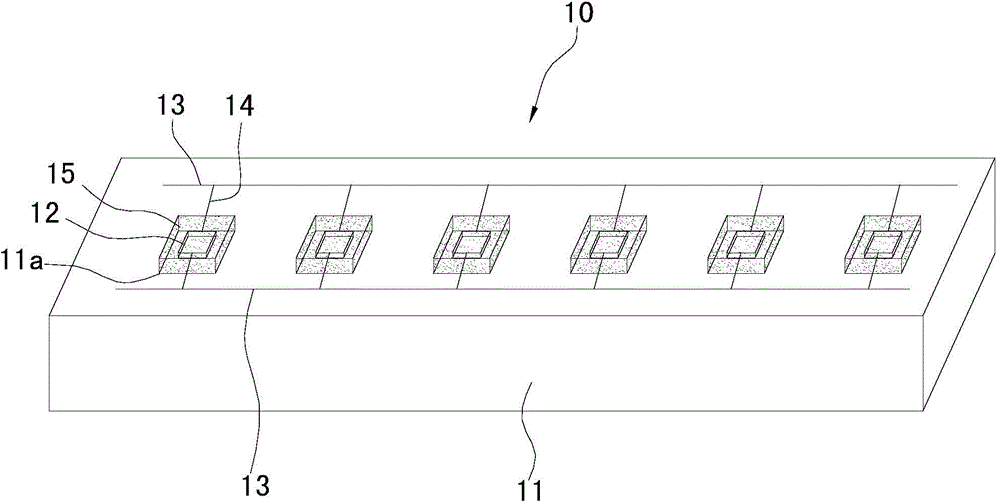

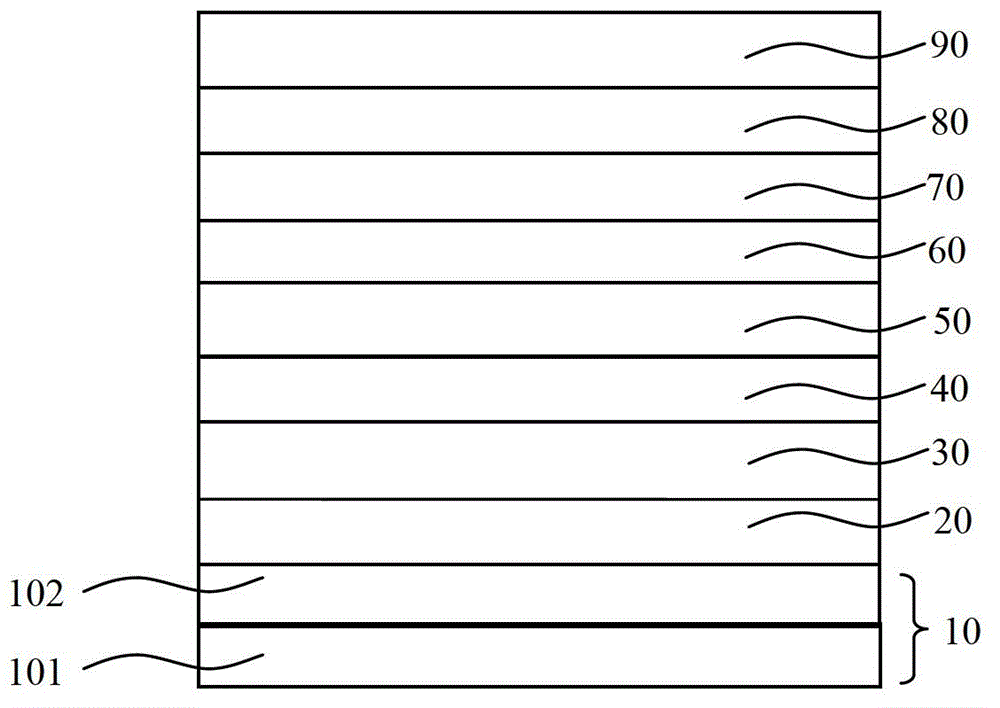

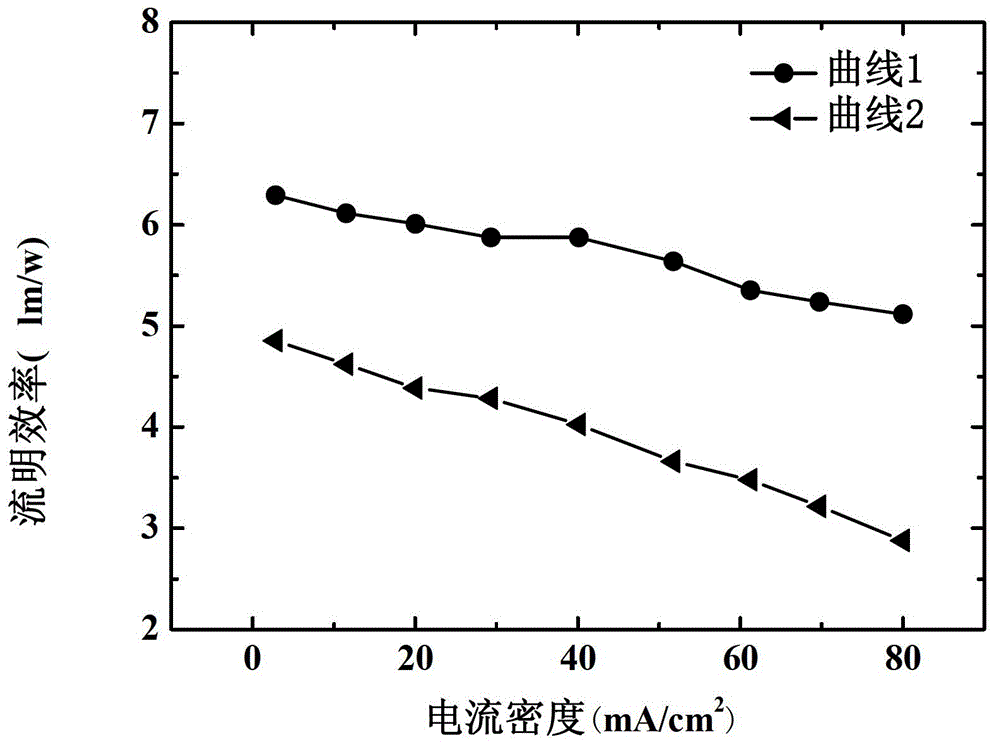

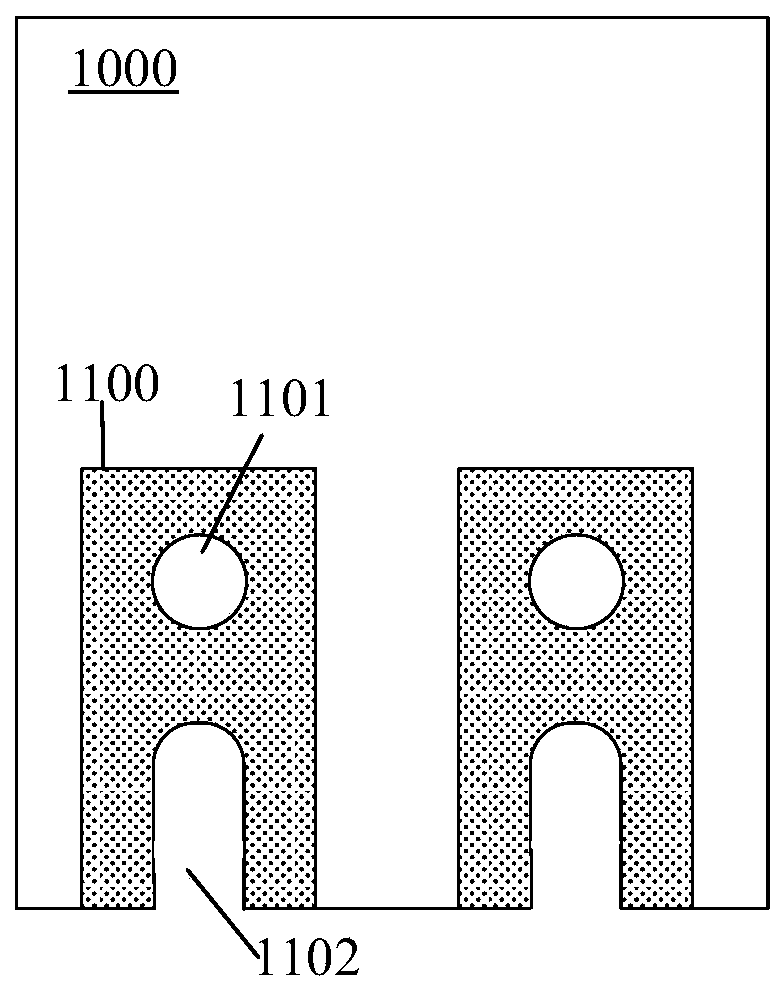

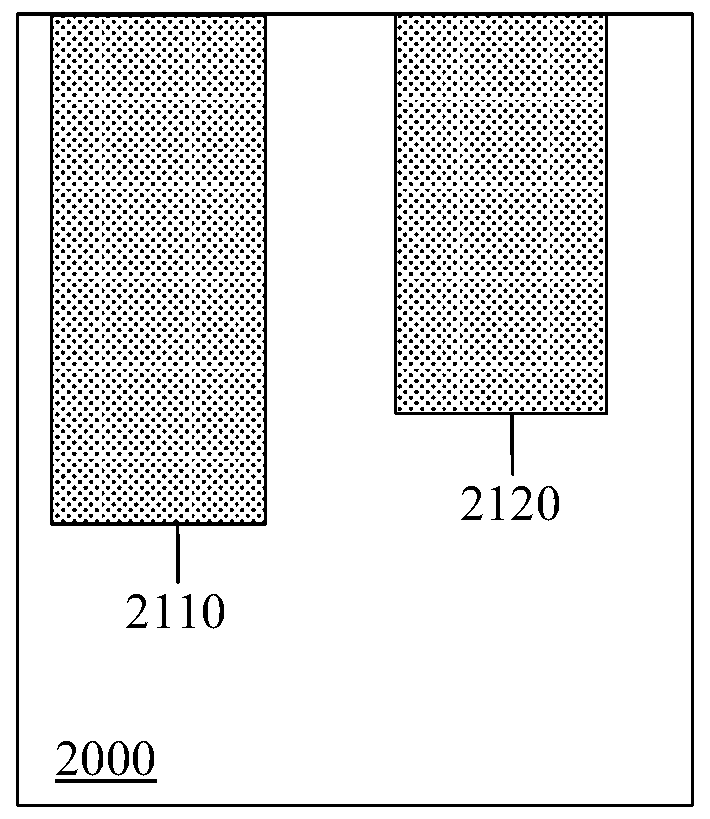

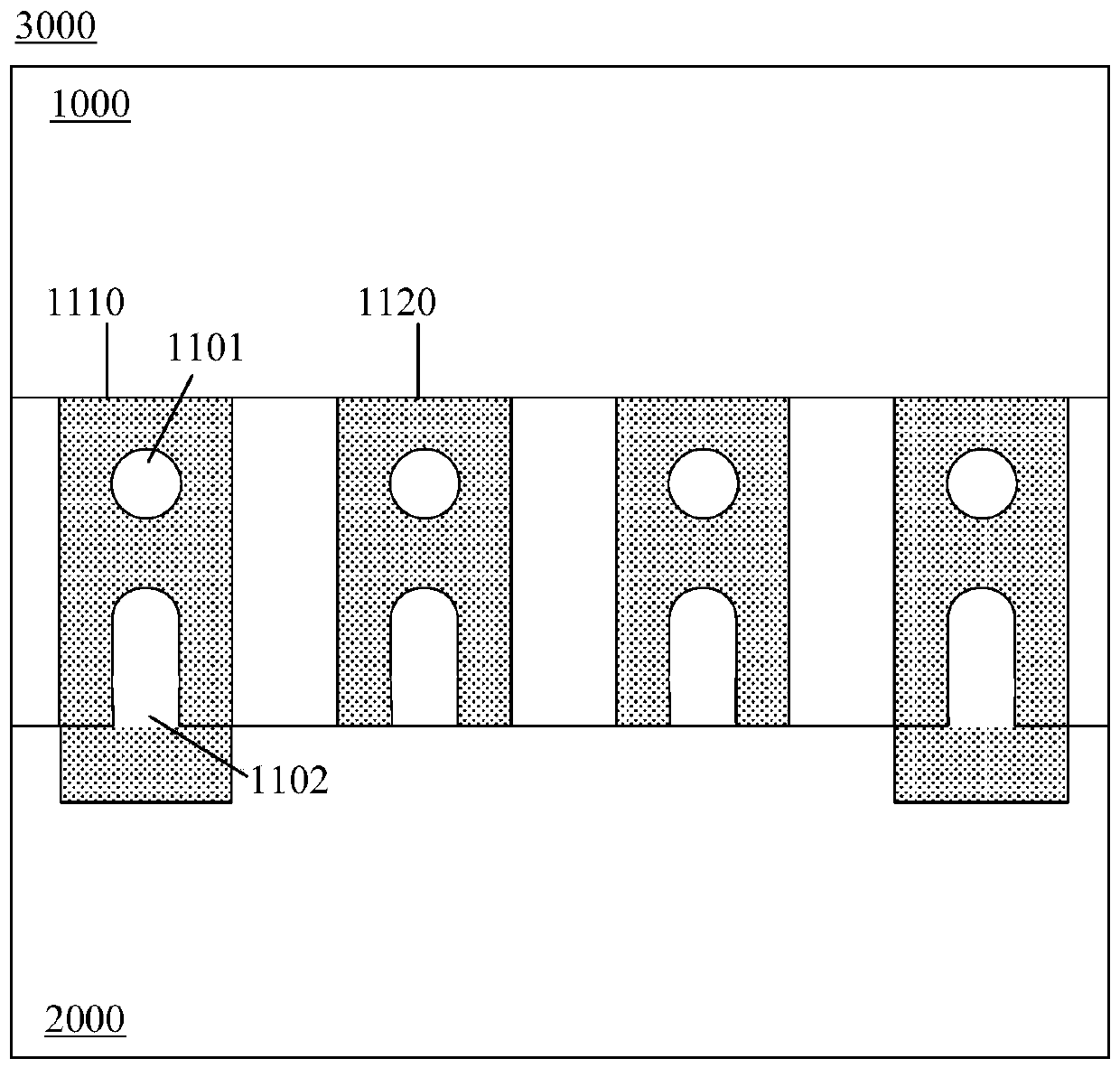

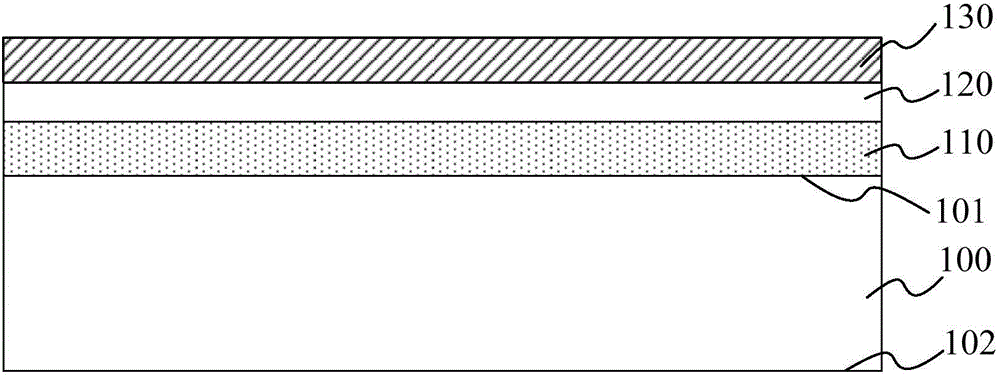

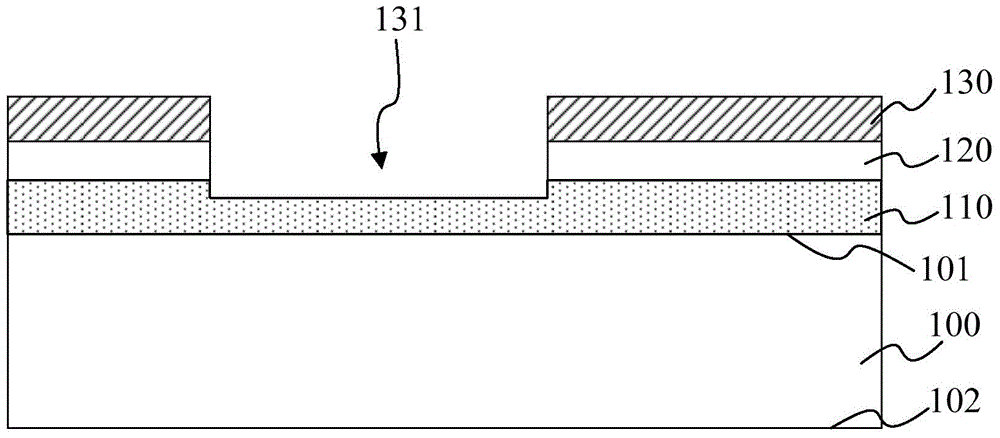

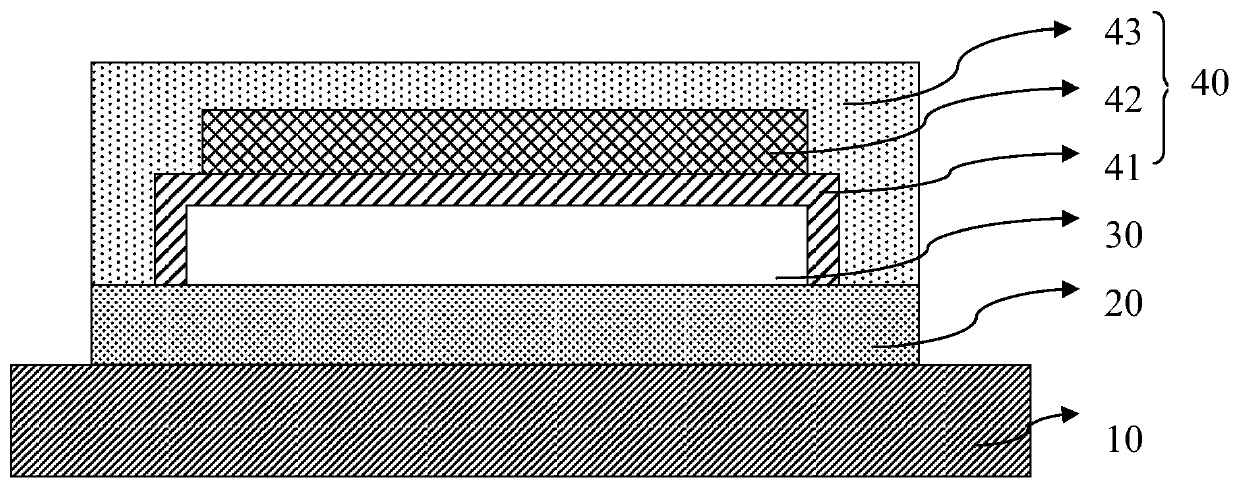

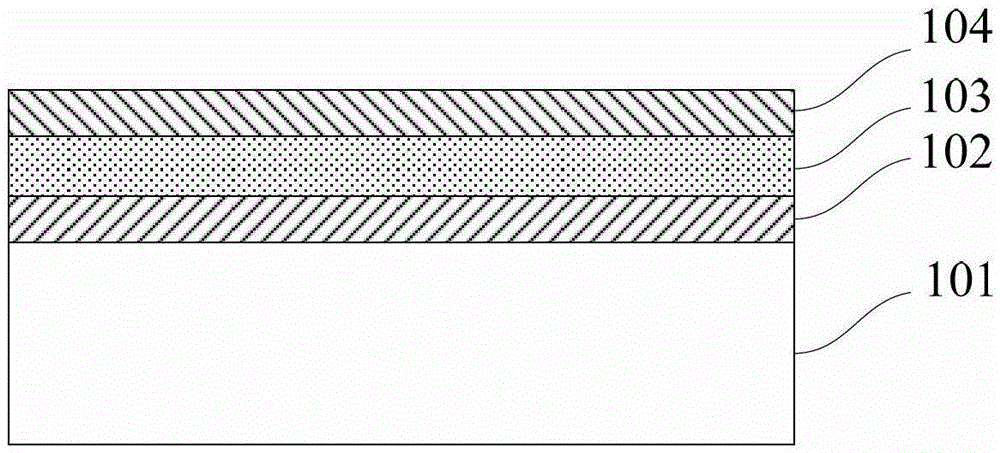

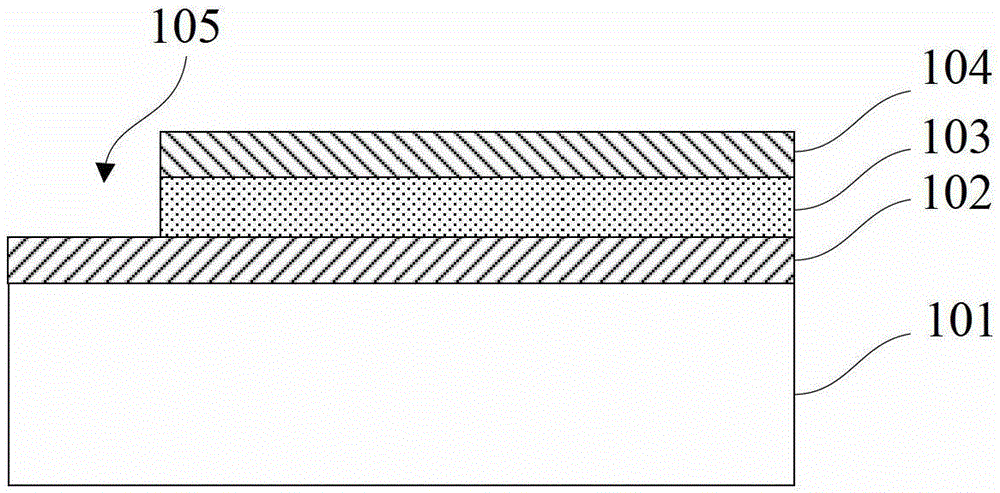

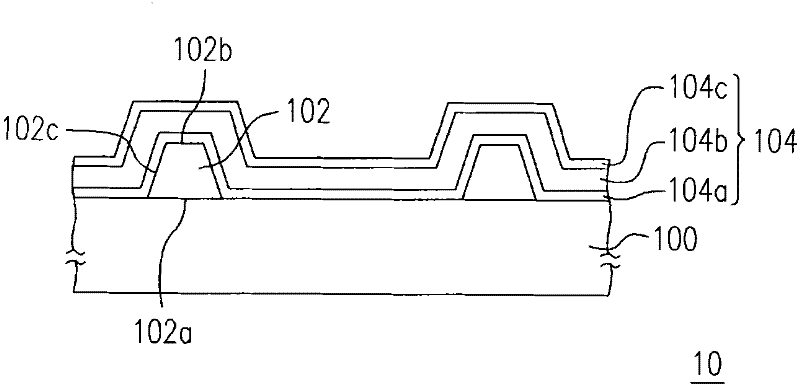

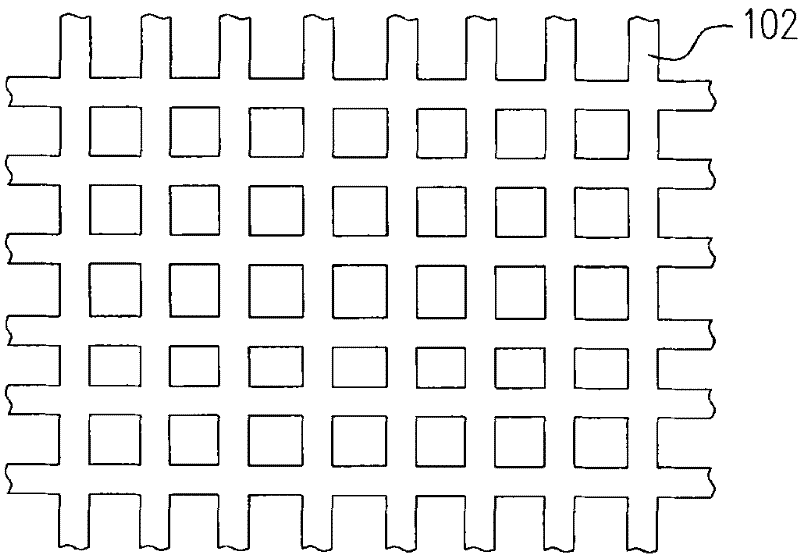

Display panel and manufacturing method thereof, and display device

ActiveCN111668384AReduce power consumptionImprove light extraction efficiencySolid-state devicesSemiconductor/solid-state device manufacturingRefractive indexDisplay device

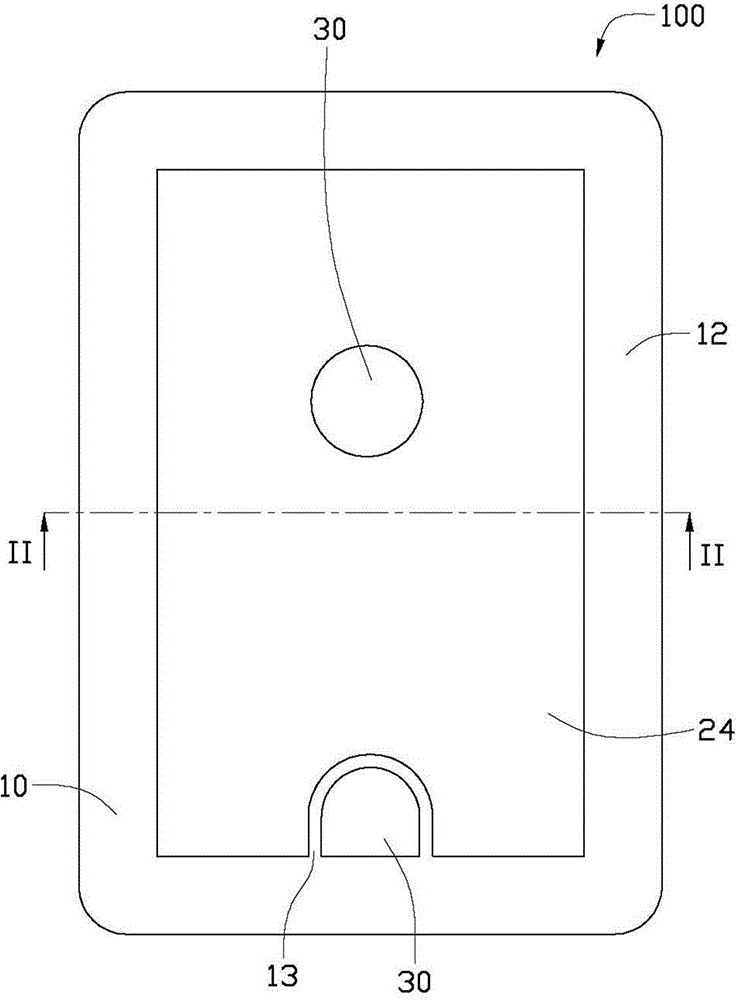

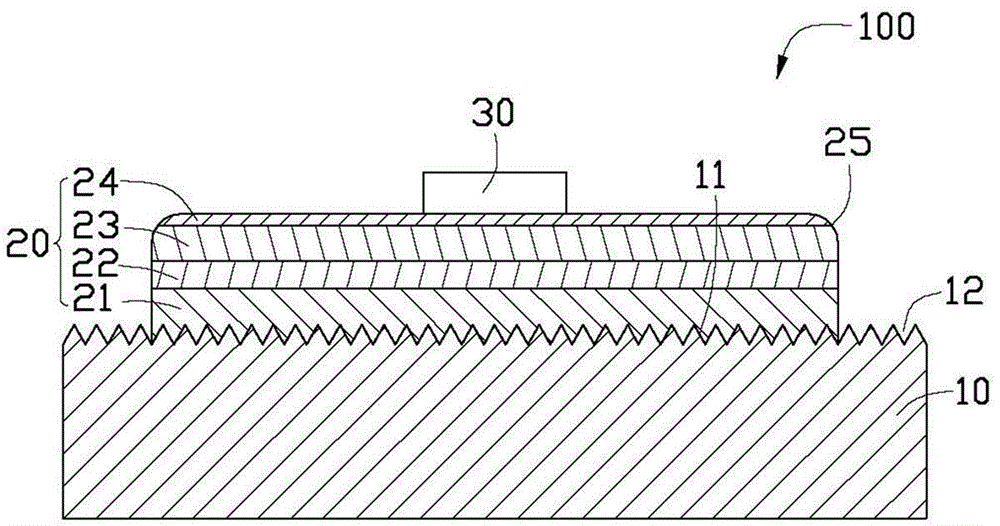

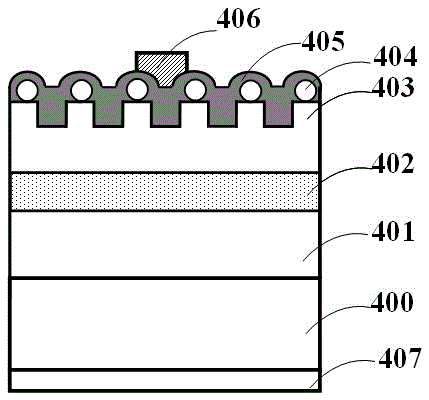

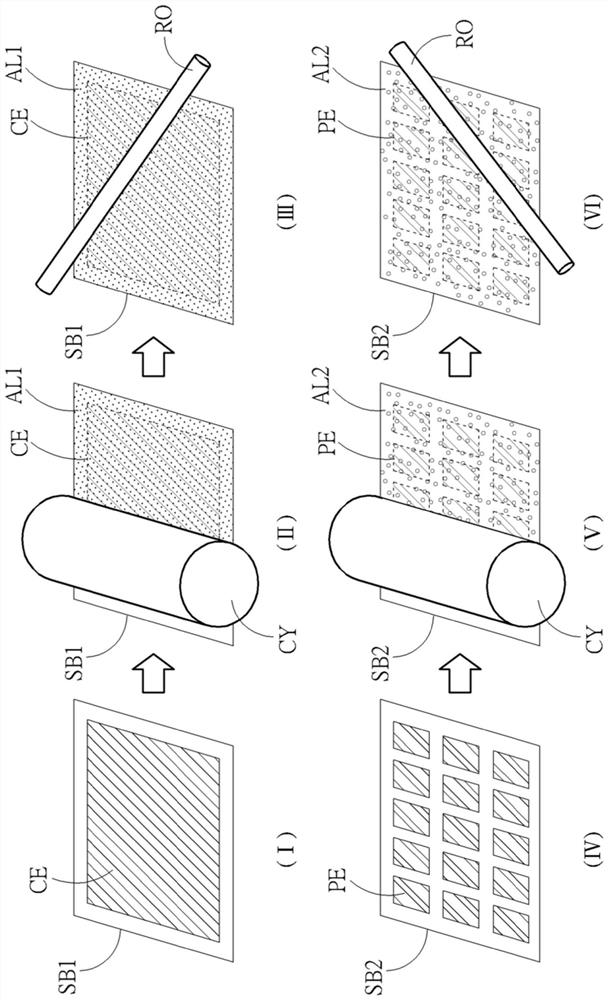

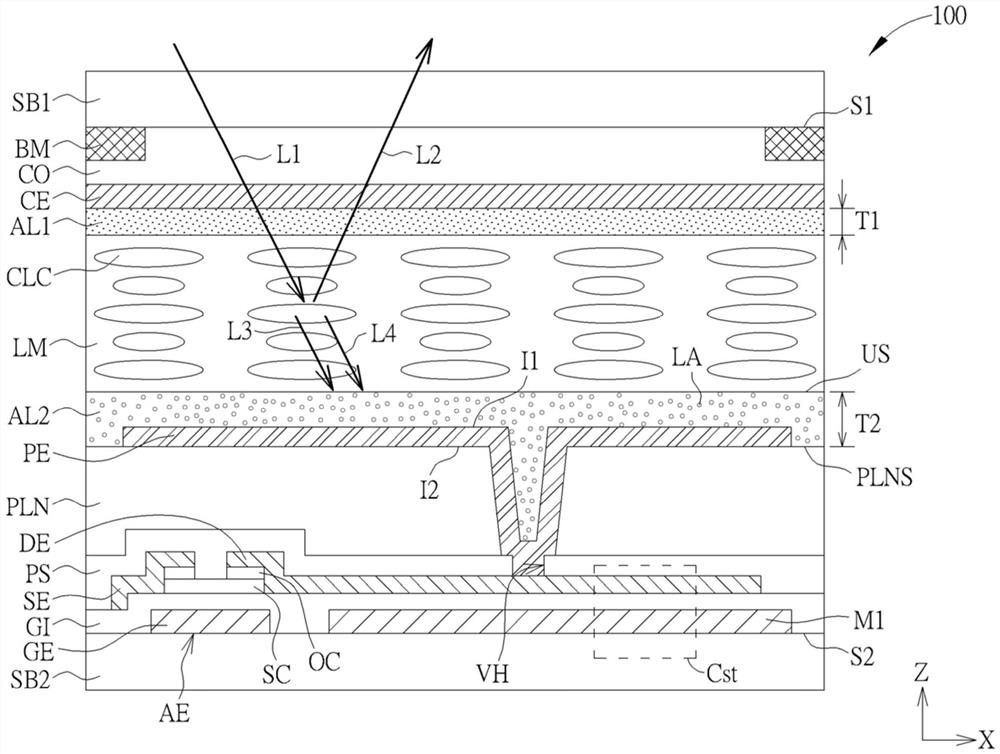

The embodiment of the invention provides a display panel and a manufacturing method thereof, and a display device. The display panel comprises a substrate, a light-emitting device layer and a light adjusting structure layer, wherein the light-emitting device layer is located on the substrate, and comprises a plurality of light-emitting devices, the light adjusting structure layer is located on theside, away from the substrate, of the light-emitting device layer, and comprises a plurality of light adjusting units and a dielectric layer covering the plurality of light adjusting units, the refractive index of the light adjusting units is smaller than that of the dielectric layer, each light adjusting unit comprises a light adjusting sub-part, each light adjusting unit comprises a through hole, the through holes penetrate through the light adjusting units in the direction perpendicular to the substrate, the through holes are overlapped with the light emitting device, and the light adjusting sub-parts are arranged around the through holes. For one light adjusting unit, the thickness of the light adjusting part is gradually increased in the direction from the through hole to the light adjusting sub-part. The probability that light rays are totally reflected in the display panel and limited in the display panel can be reduced, and the light emitting efficiency of the light emitting device is improved.

Owner:HUBEI YANGTZE IND INNOVAION CENT OF ADVANCED DISPLAY CO LTD

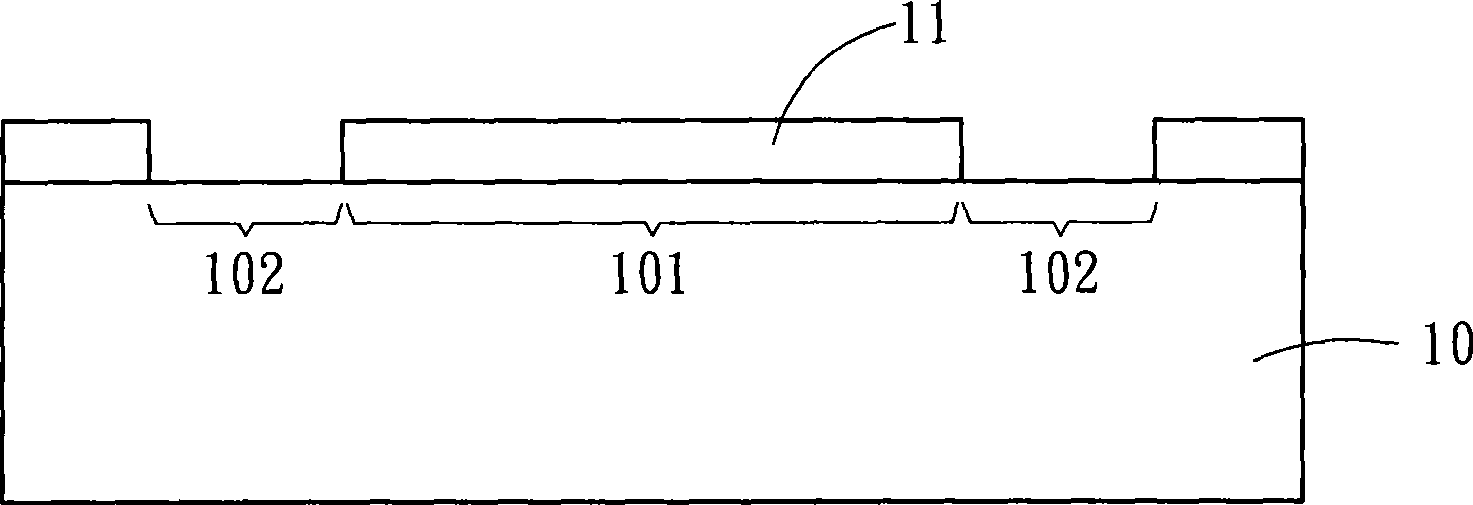

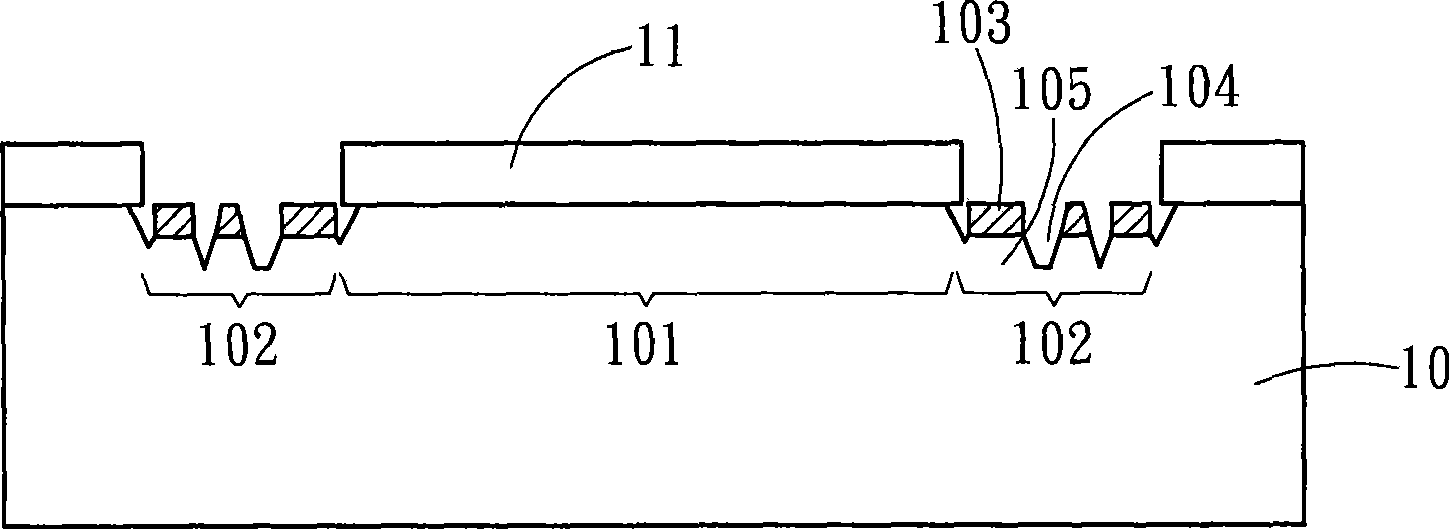

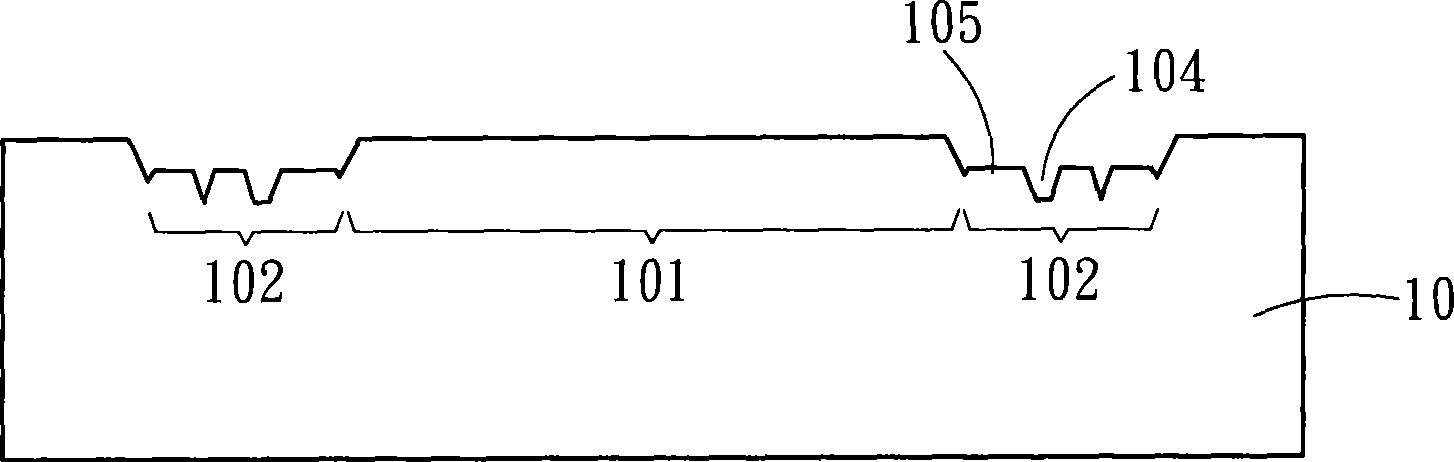

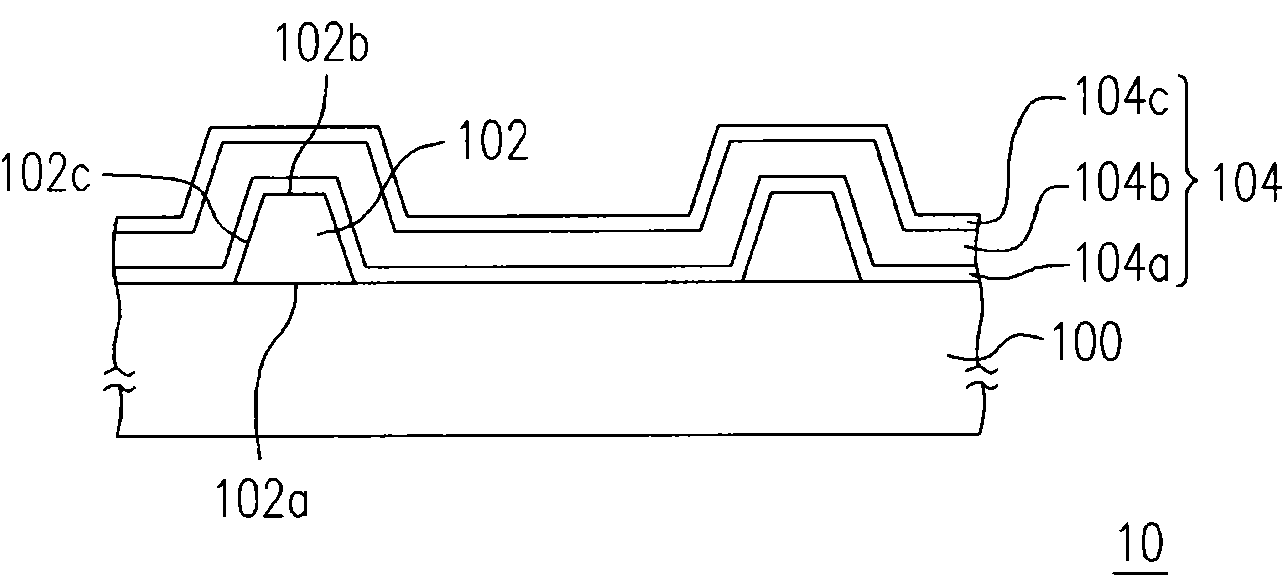

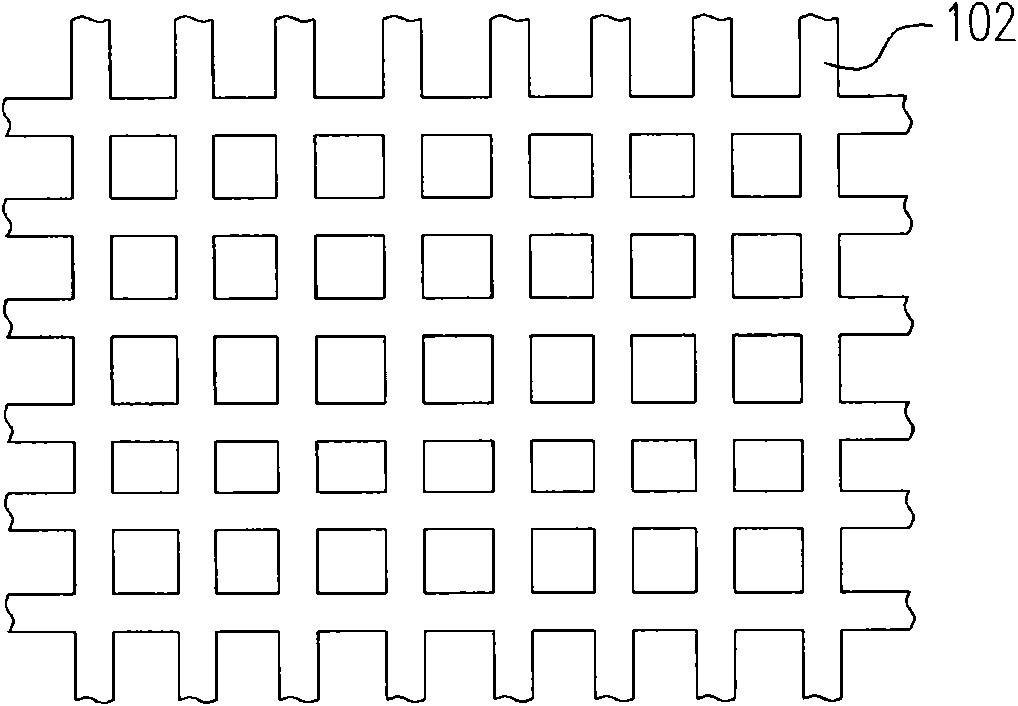

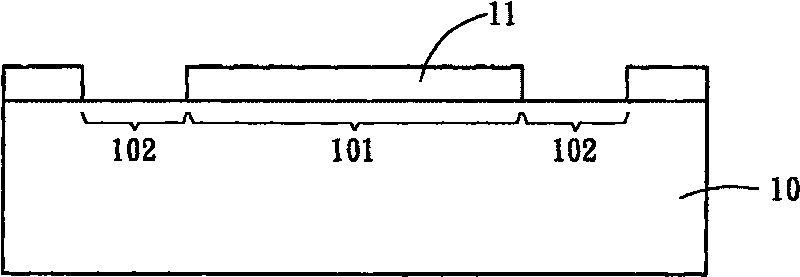

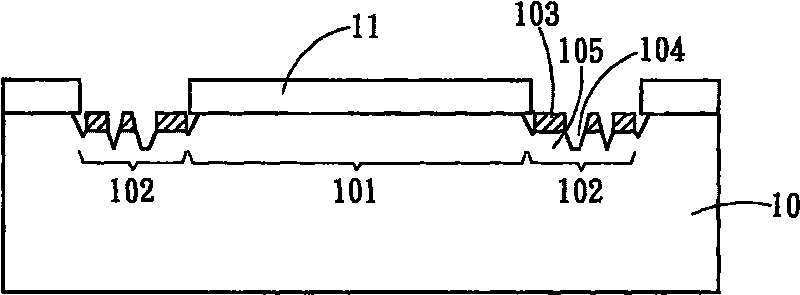

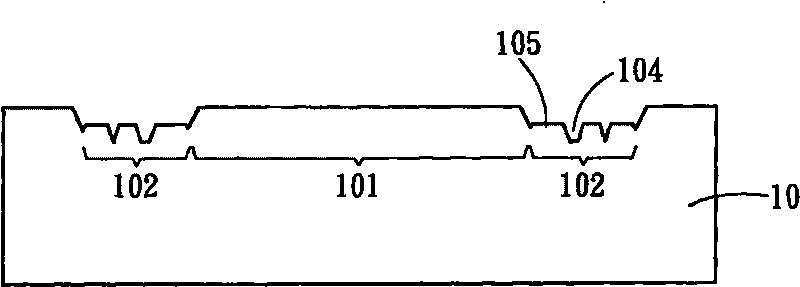

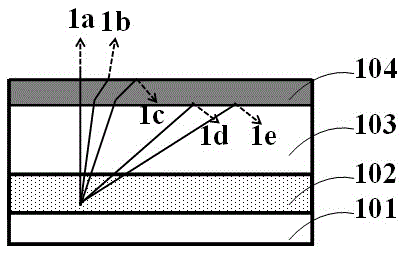

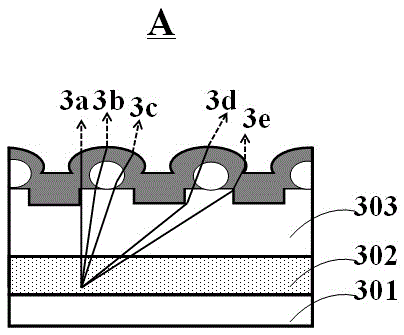

LED structure and manufacturing method thereof

InactiveCN101414653AImprove light extraction rateReduced instances of lateral spreadSemiconductor devicesChemical reactionLithography process

The invention discloses an LED structure and a fabrication method. The method comprises the following steps: placing a substrate in a solution for reaction; naturally forming a chemical reaction layer on the surface of a cutting street region of the substrate; forming a plurality of concave parts and convex parts on the surface of the cutting street region by selective etching; growing a semiconductor layer structure on a component region and the cutting street region on the surface of the substrate by an epitaxial growth technology; and then forming the LED by the semiconductor layer structure on the component region using yellow light lithography process.

Owner:TEKCORE CO LTD

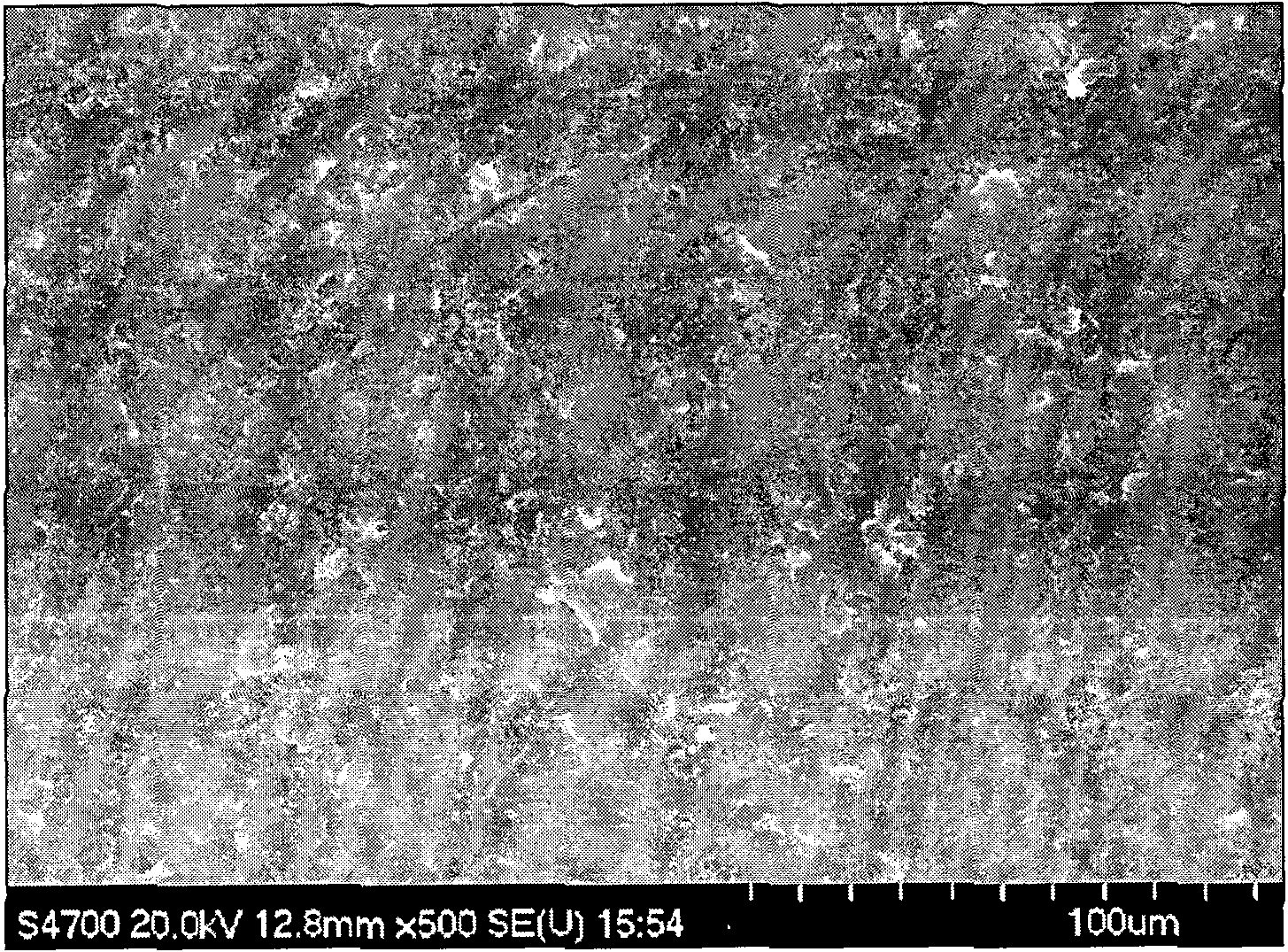

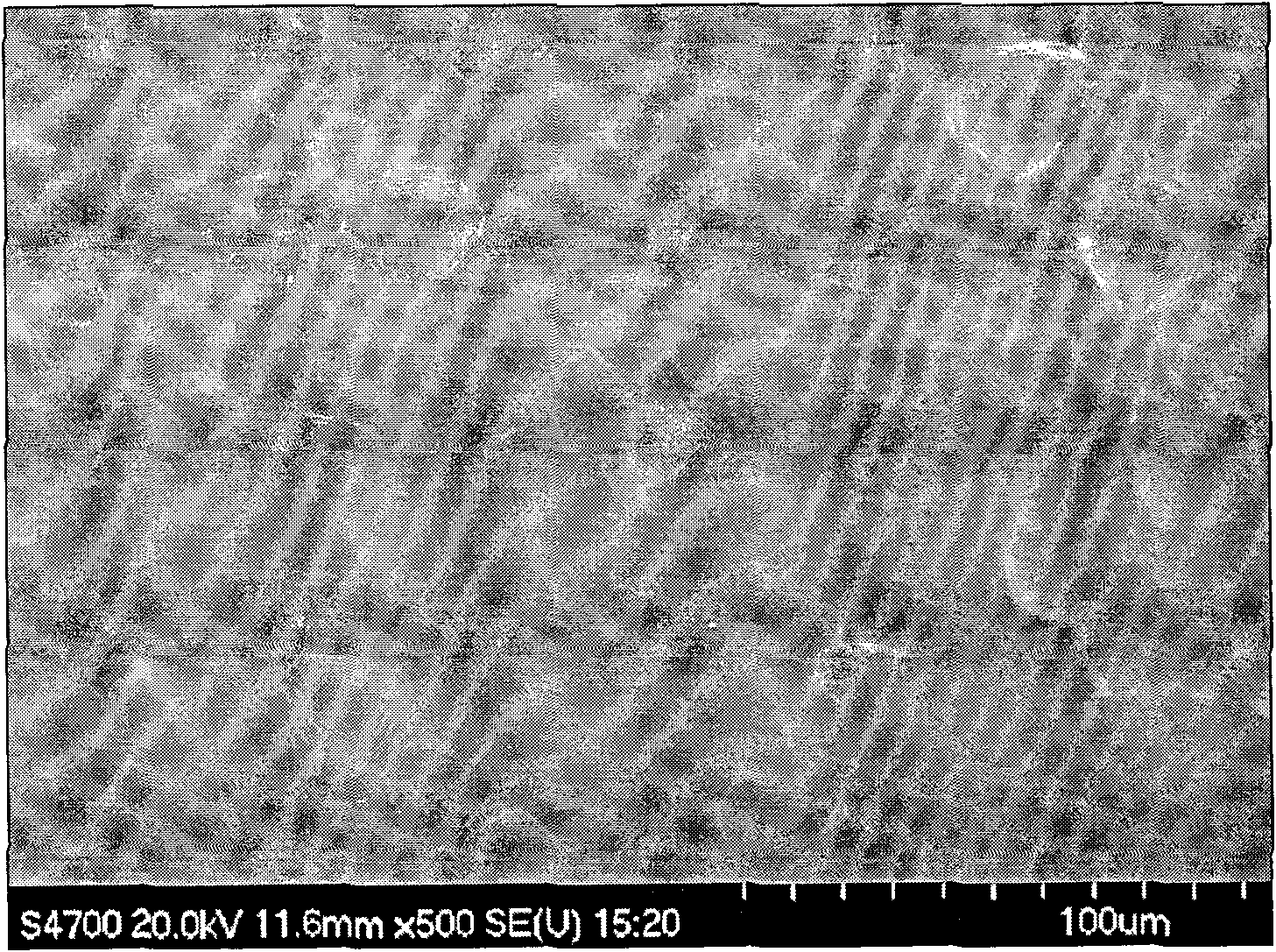

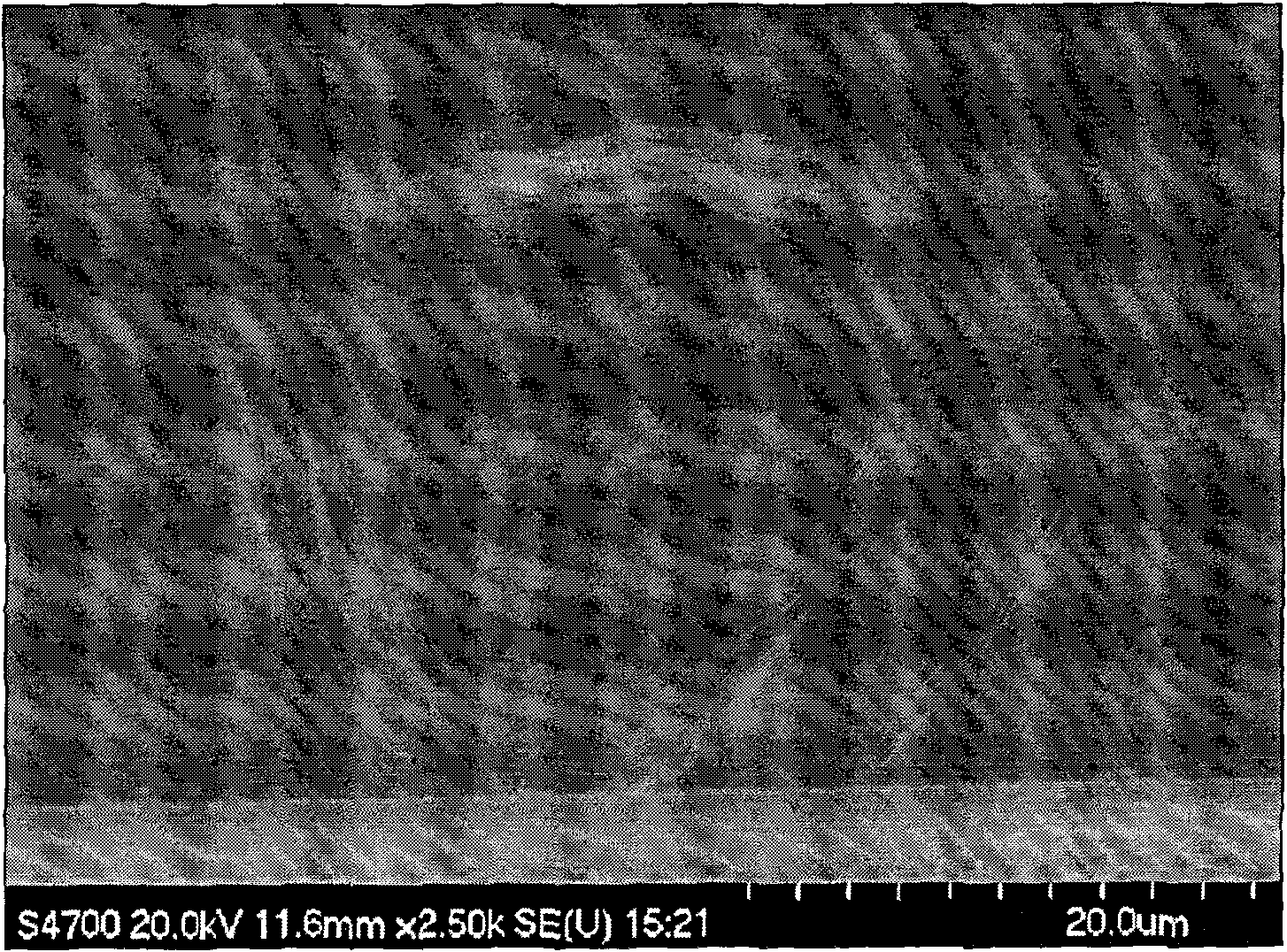

Sapphire substrate and polishing method and application thereof

ActiveCN101604666AImprove adhesionAvoid crackingSemiconductor/solid-state device detailsSolid-state devicesSemiconductor materialsProcessing cost

The invention relates to the field of semiconductor materials and discloses a sapphire substrate and a polishing method and an application thereof. The surface of the sapphire substrate is polished, and the polished surface has random sunken patterns. The surface of the sapphire substrate is partially planarized. Therefore the processing cost for the sapphire substrate is greatly reduced and the polishing efficiency is increased.

Owner:SHANGHAI XINANNA ELECTRONICS TECH

Light emitting diode crystalline grain

InactiveCN103066177AImprove luminous efficiencyReduce the angle of incidenceSemiconductor devicesElectrical conductorDiode

A light emitting diode crystalline grain comprises a substrate and an epitaxial layer which is formed on the substrate. The substrate comprises an upper surface. The epitaxial layer comprises a first semiconductor layer close to the substrate, a second semiconductor layer far away from the substrate, and an active layer arranged between the first semiconductor layer and the second semiconductor layer. The edge of the top, far away from the substrate, of the epitaxial layer is provided with an arc angle or a slant chamfer, and therefore light can be emitted from the side face of the epitaxial layer favorably, and luminous efficiency of the light emitting diode crystalline grain is improved.

Owner:ZHANJING TECH SHENZHEN +1

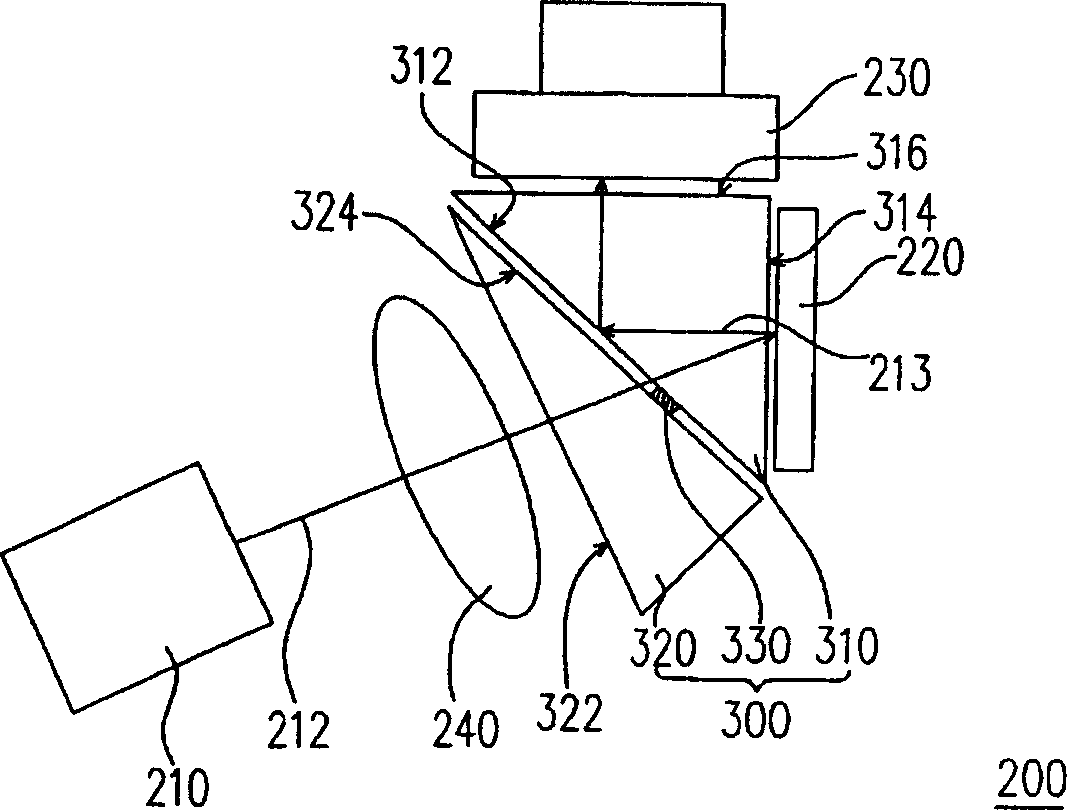

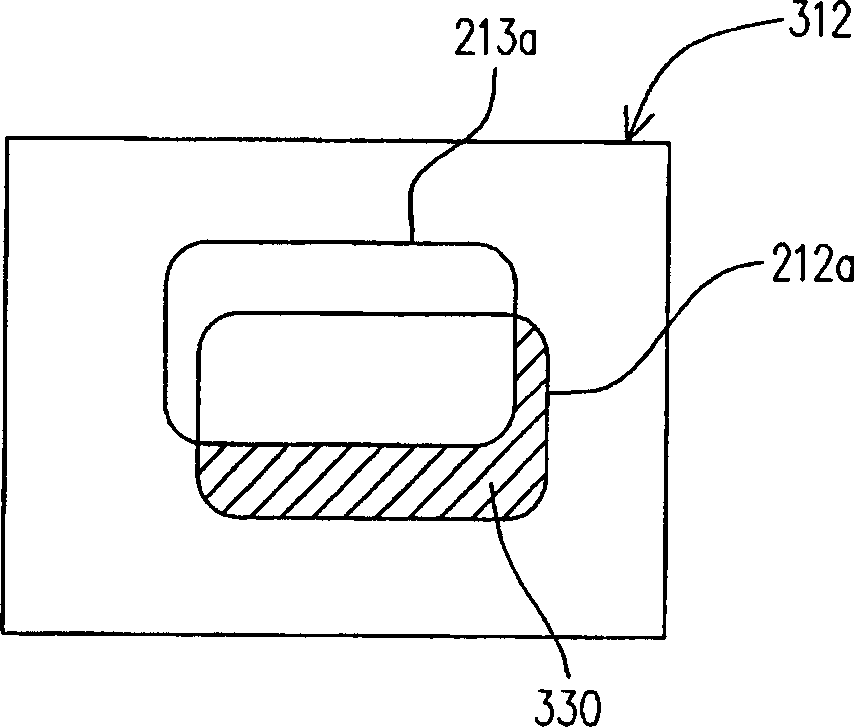

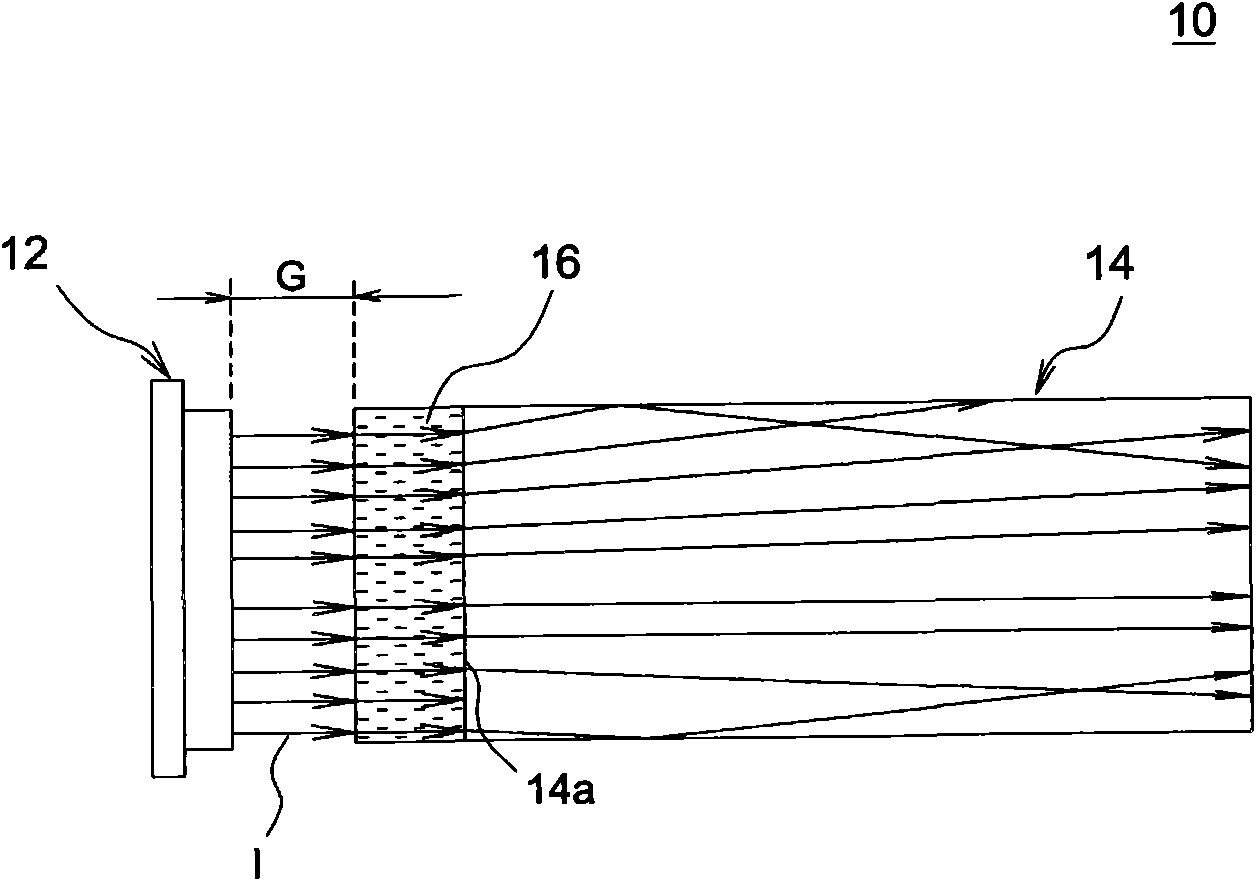

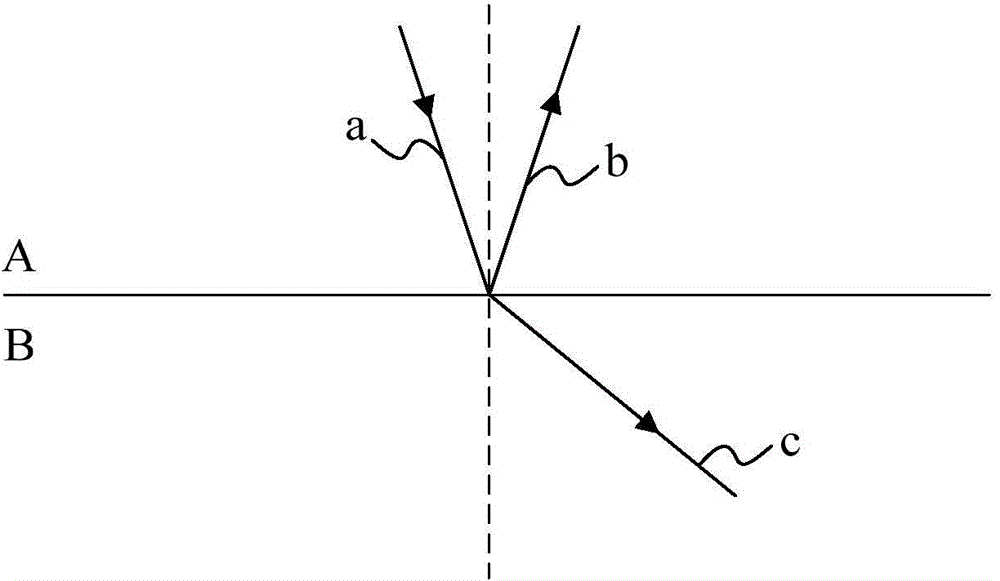

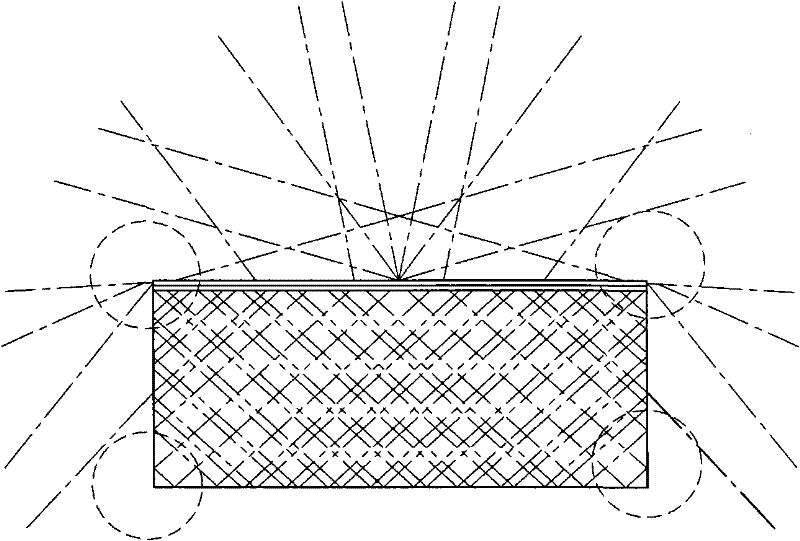

Projection device and its inner full-reflection prism

InactiveCN101169576AReduce the chance of total reflectionIncrease image brightnessPrismsProjectorsLight beamPrism

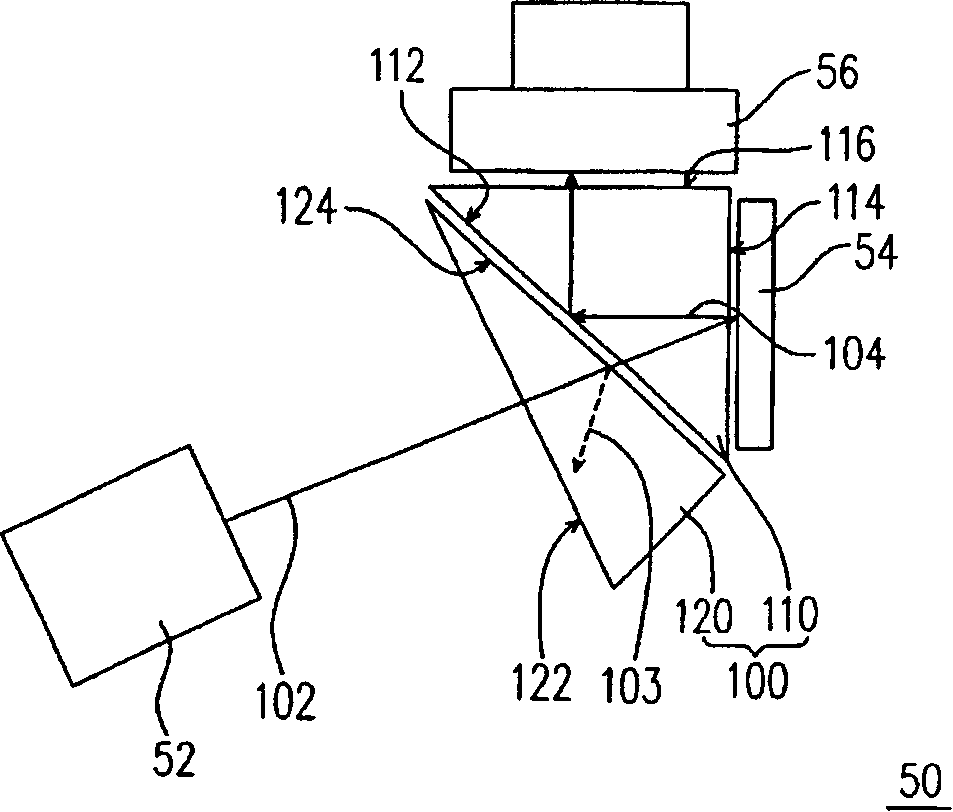

The invention relates to the inner total-reflection prism of a projecting device, and consists of a first prism, a second prism and a total-reflection resistant layer. The first prism is provided with a first surface, a second surface and a third surface, while the second prism is provided with a light-in surface and a light-out surface. The light-out surface is opposite to the first surface, anda clearance is formed between the light-out surface and the first surface. The total-reflection resistant layer is connected between the part of the light-out surface and the part of the first surface. With the total-reflection resistant layer arranged, the probability of occurrences of total reflections in the inner total-reflection prism for illuminating rays is lowered, thereby, the utilization efficiency of the illuminating rays can be improved, and then the brightness of images are enhanced.

Owner:CORETRONIC

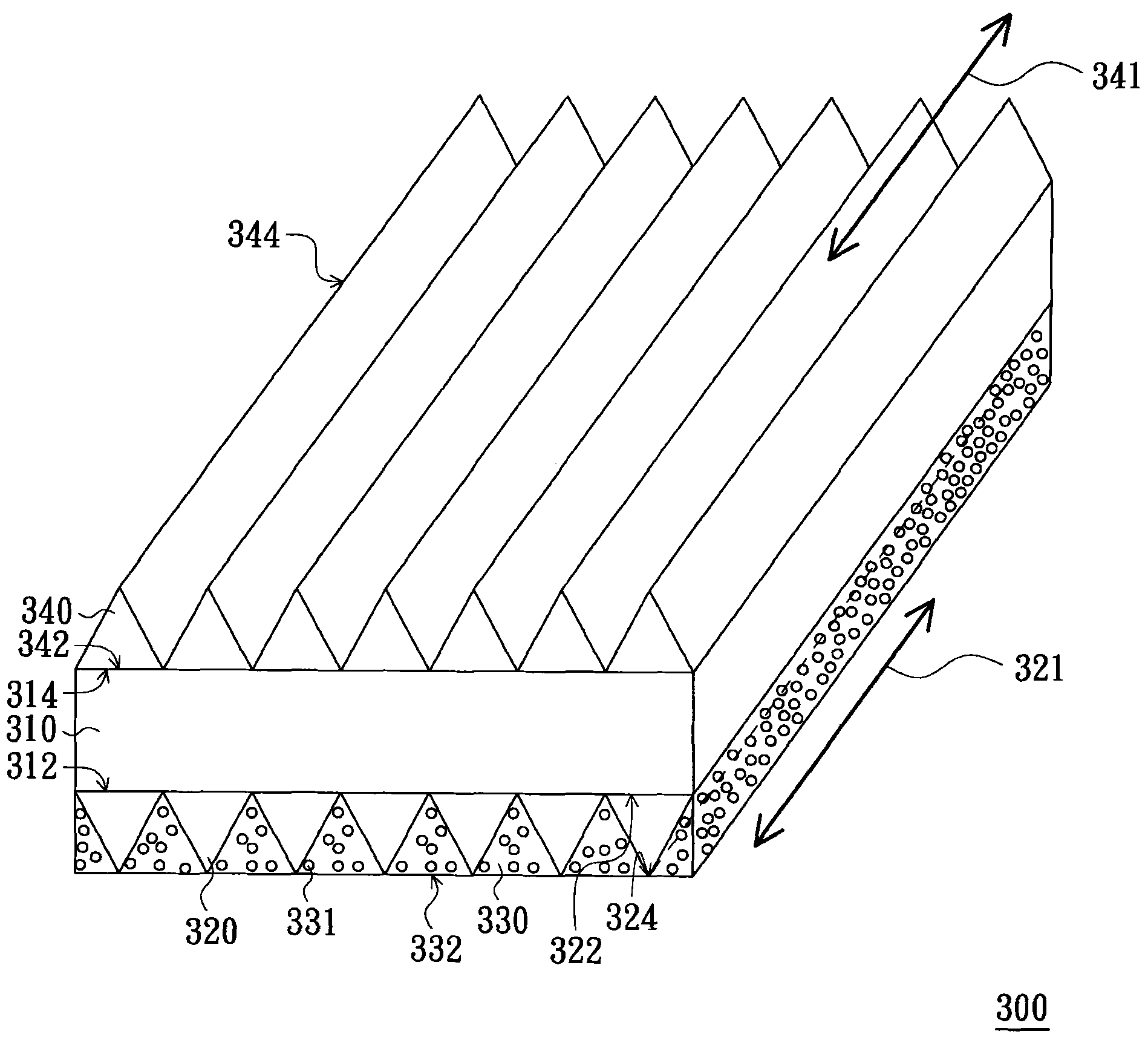

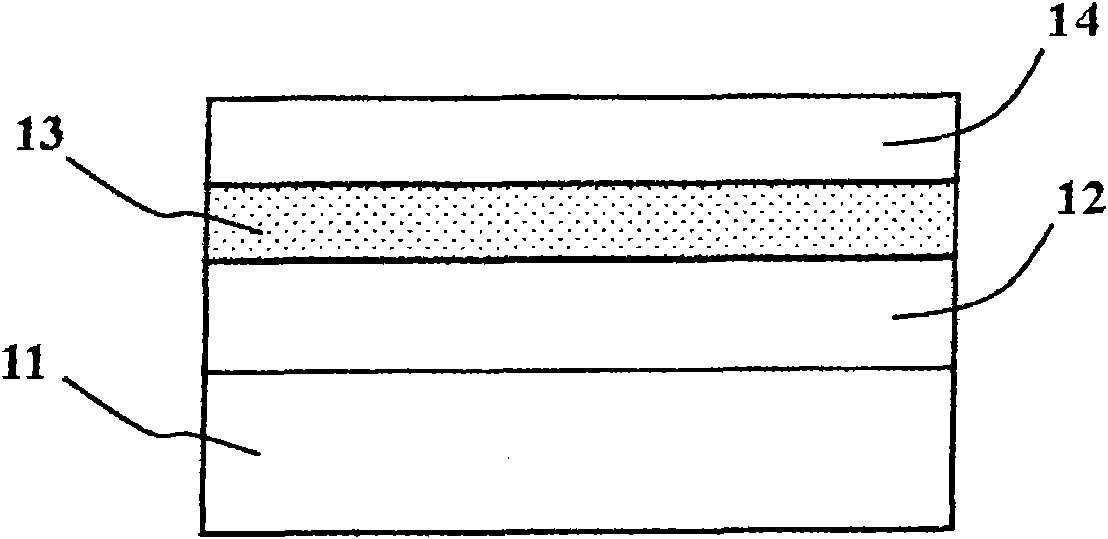

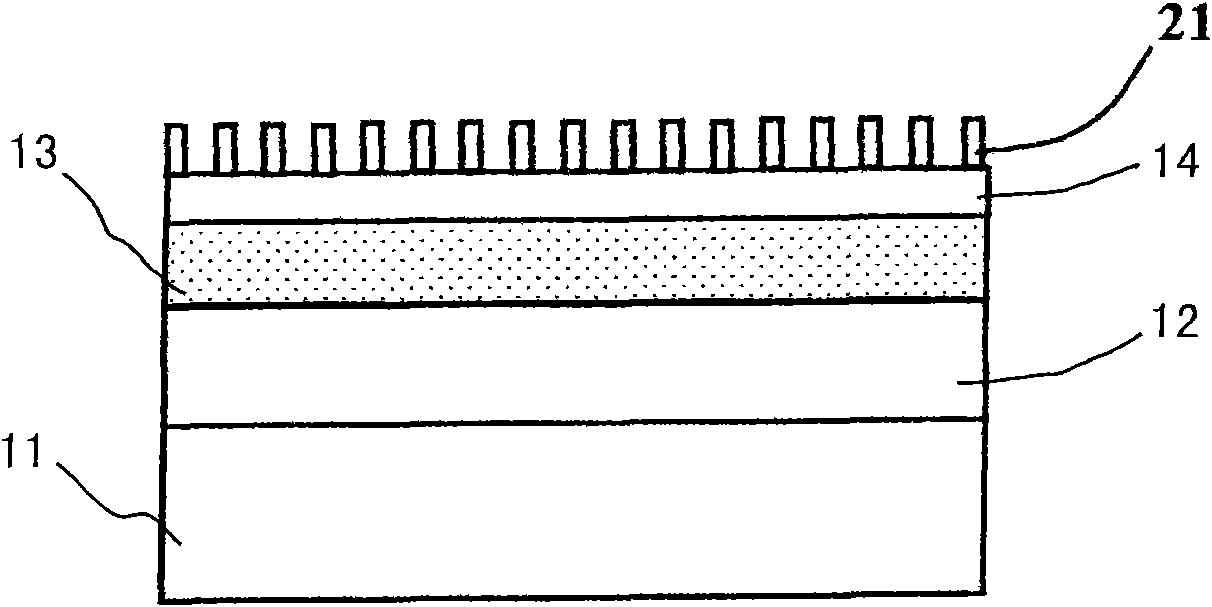

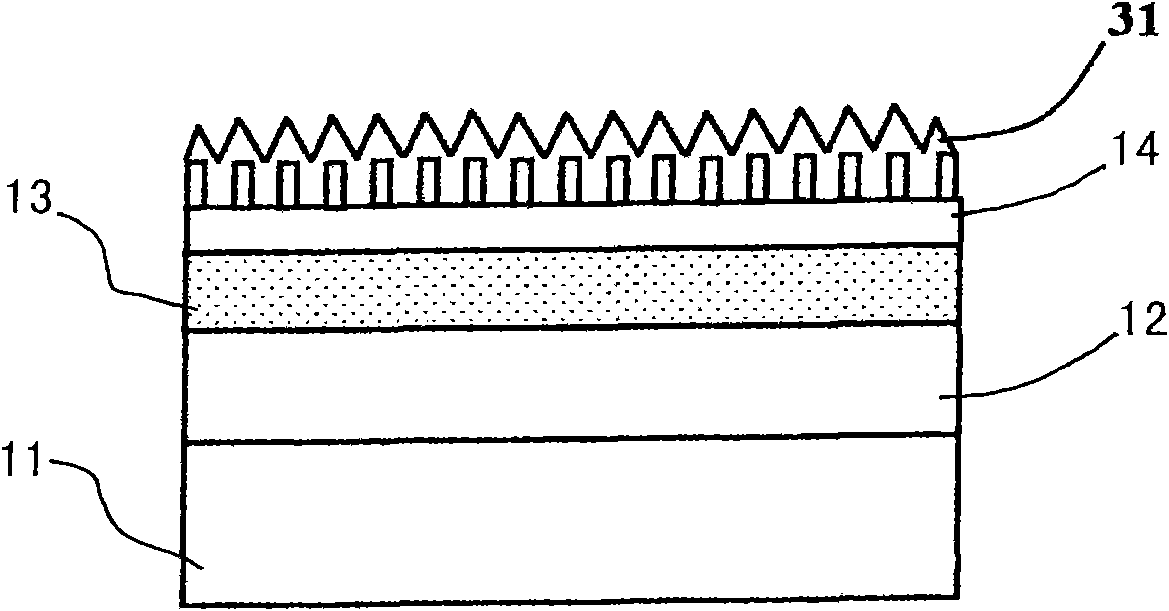

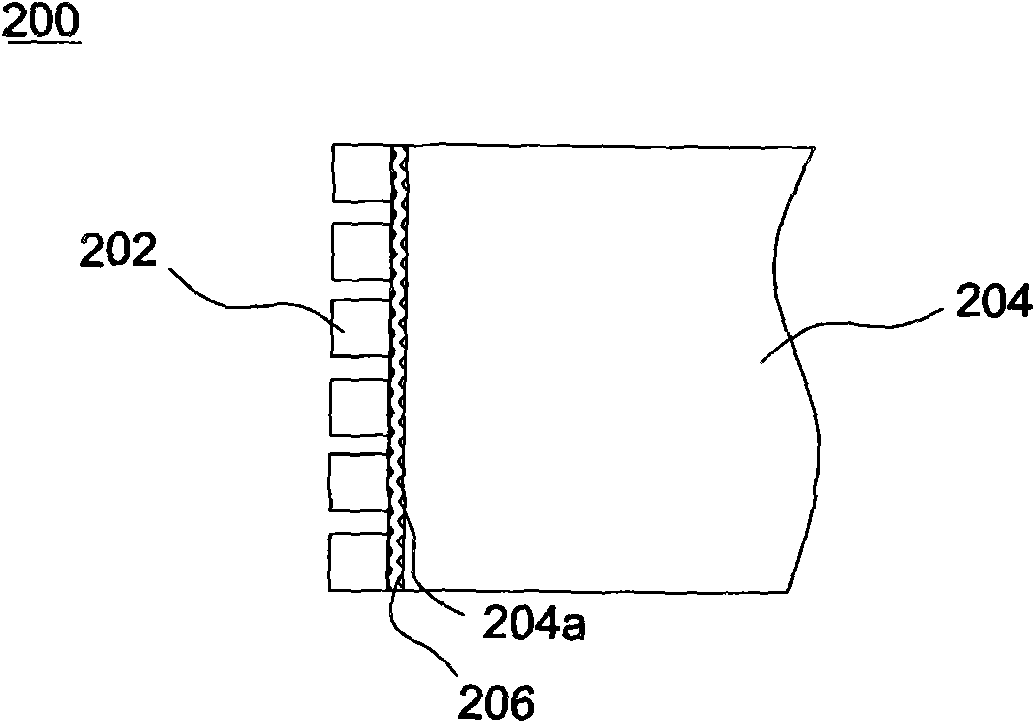

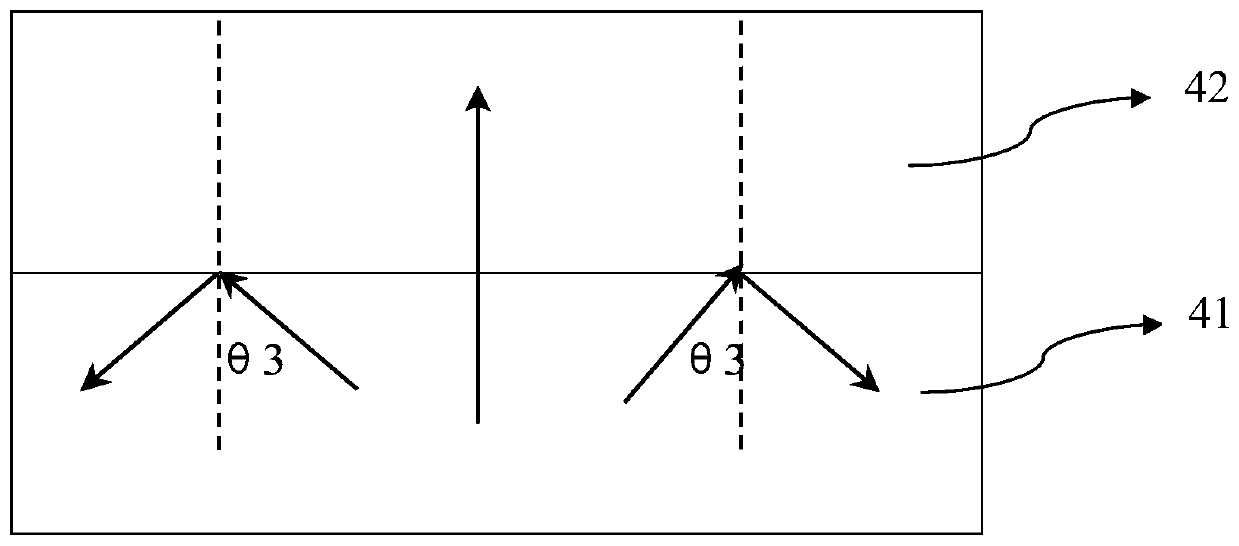

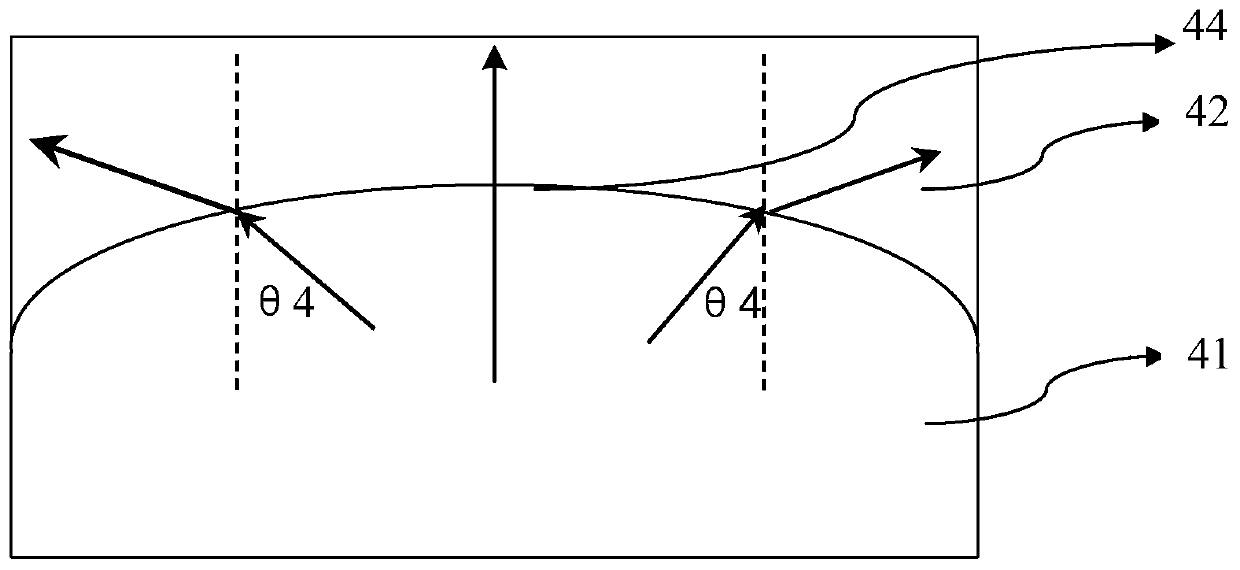

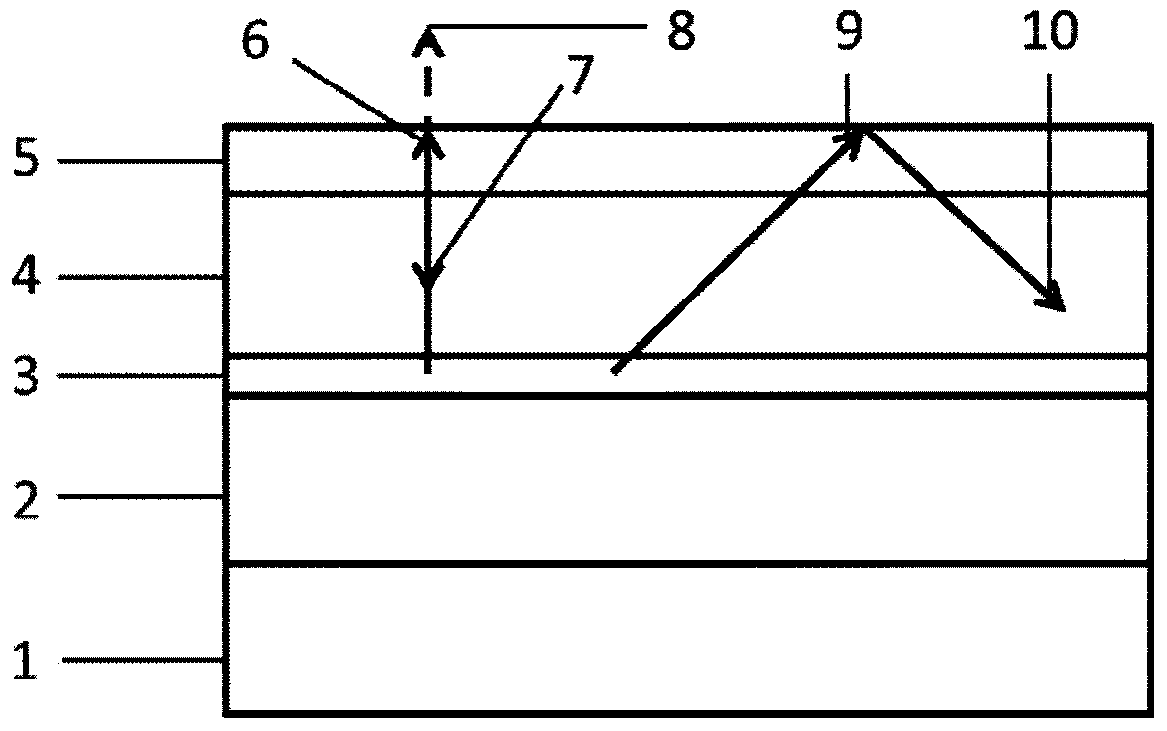

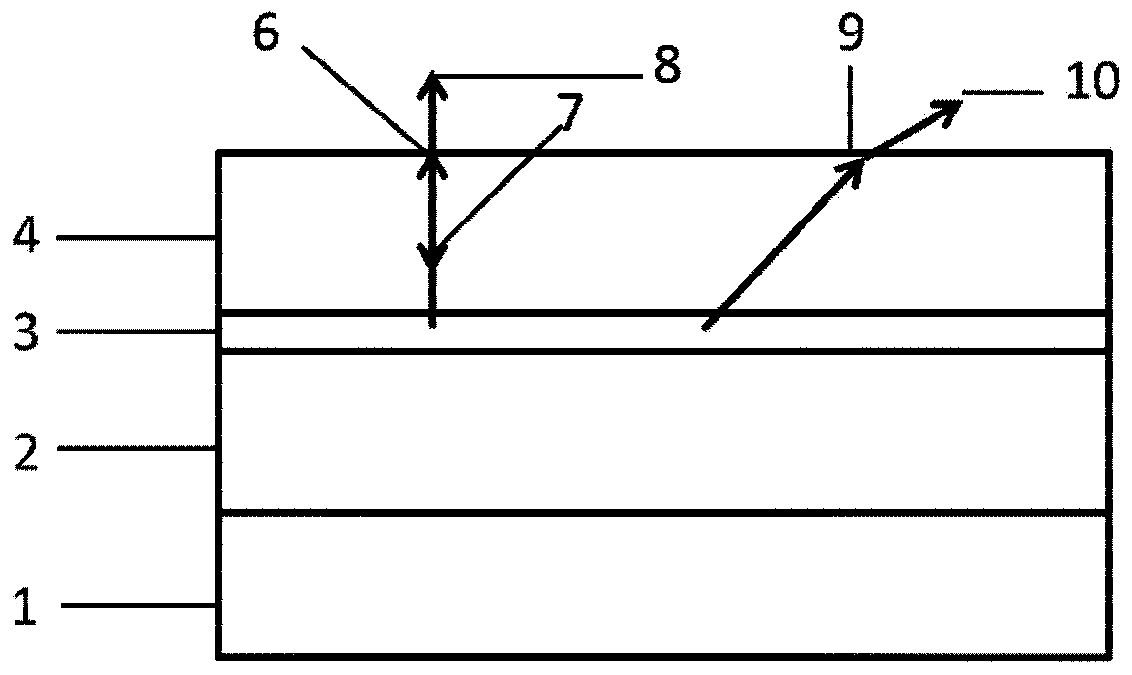

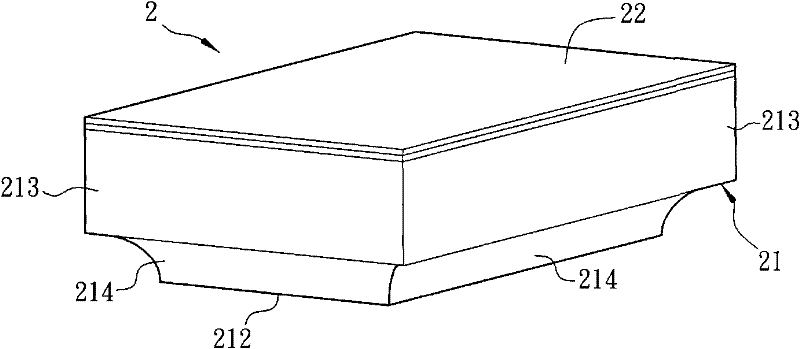

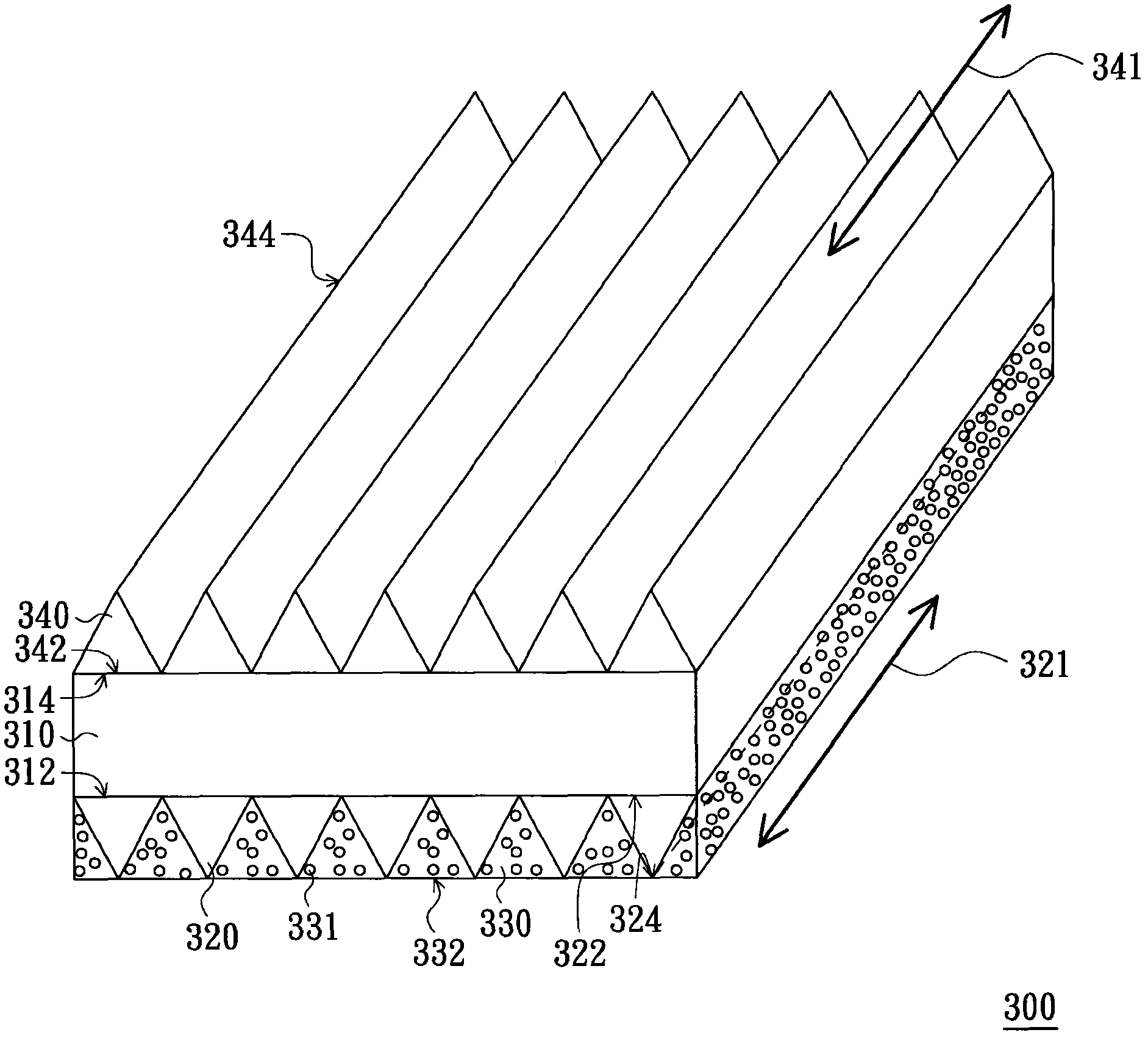

Area light source and display panel

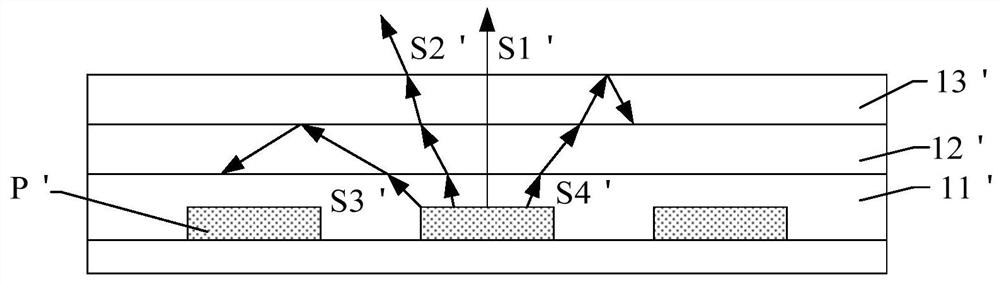

ActiveCN101834279AReduce the chance of total reflectionImprove light outputSolid-state devicesSemiconductor/solid-state device manufacturingElectroluminescenceLight source

The invention discloses an area light source, which comprises a substrate, a patterned scattering layer and an organic electro-luminescence element, wherein the patterned scattering layer is arranged on a part of the area of the substrate and is provided with a bottom face contacting the substrate, a top face opposite to the bottom face and a plurality of side walls connecting the bottom face and the top face; and the organic electro-luminescence element is at least arranged on the side walls.

Owner:AU OPTRONICS CORP

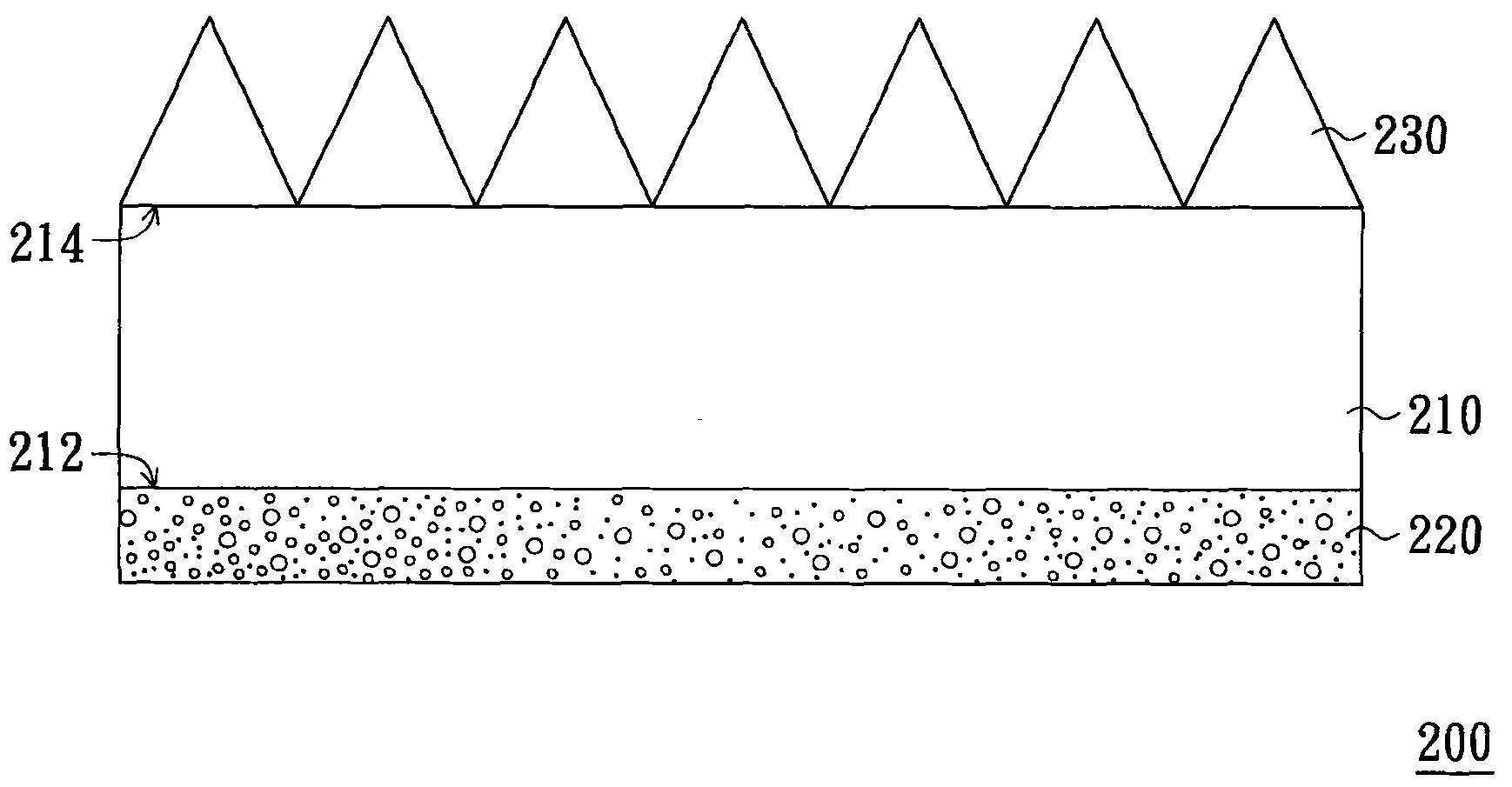

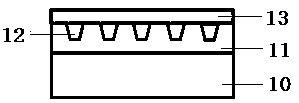

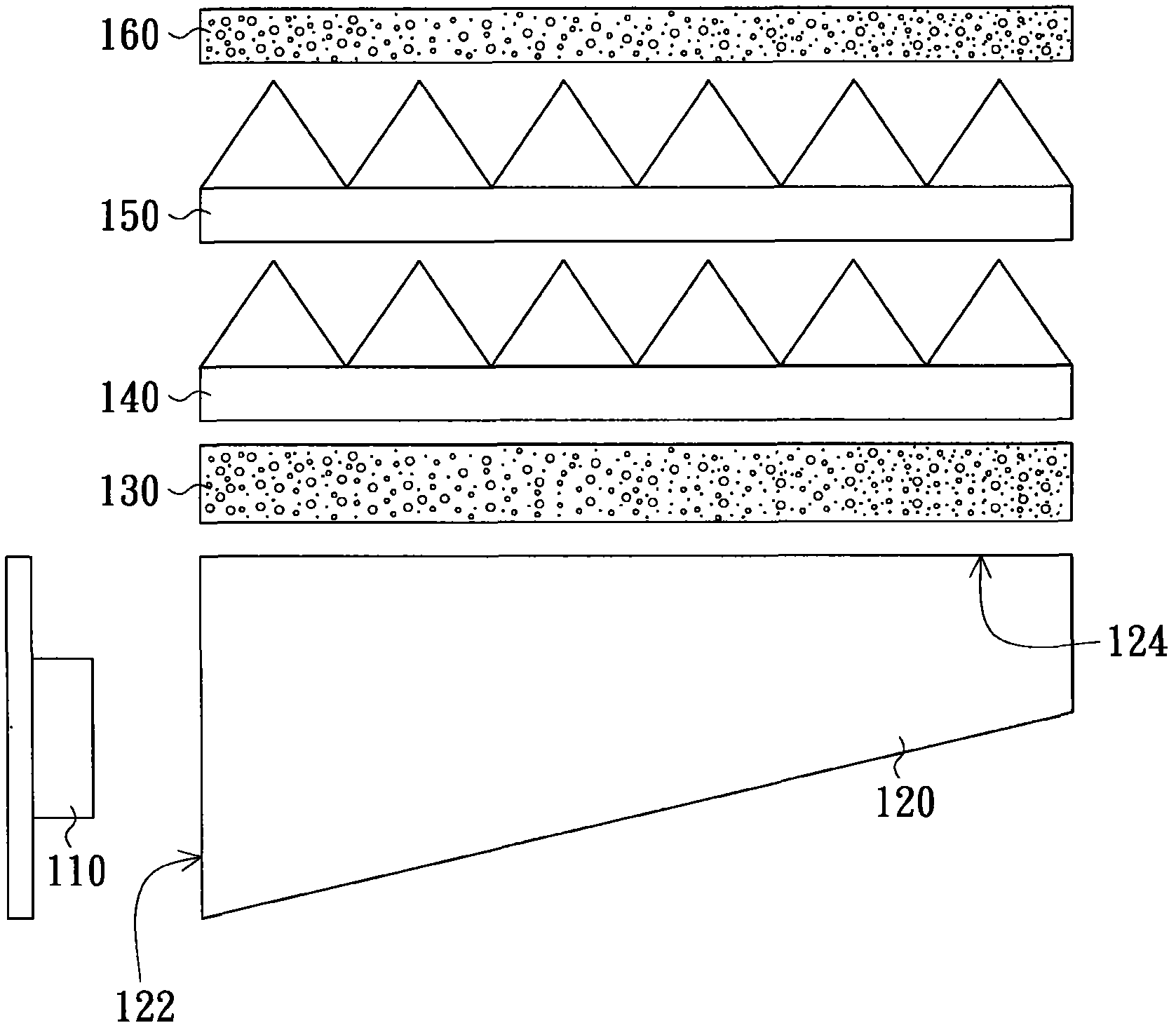

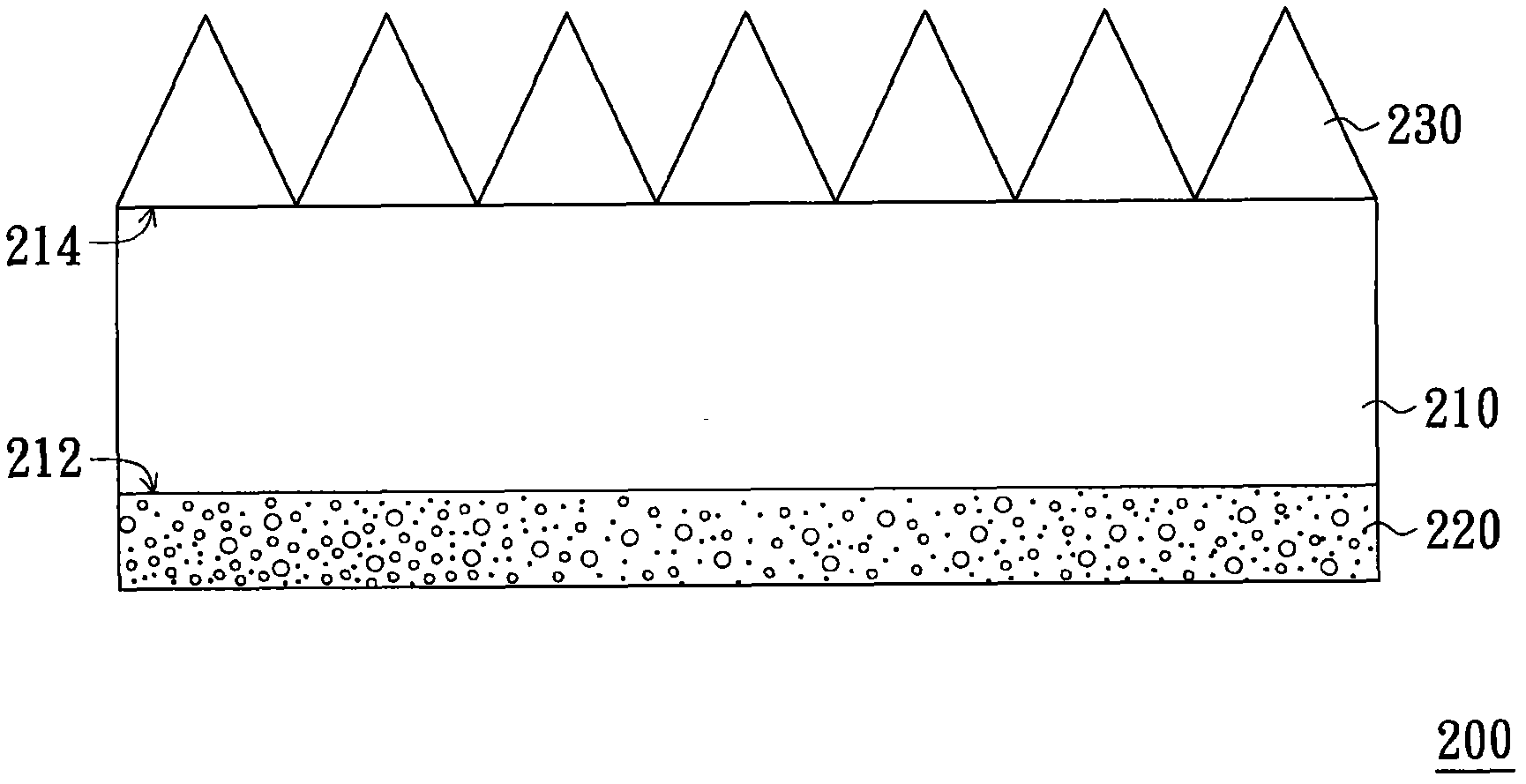

Optical film

InactiveCN102253440AImprove collection efficiencyImprove light utilization efficiencyPrismsDiffusing elementsPhysicsOptical film

The invention provides an optical film, including a substrate, a plurality of first light gathering structures and a plurality of diffusion structures. The substrate has a light inlet face and a light outlet face which are opposite. The first light gathering structures are disposed on the light inlet face. Each of first light gathering structures has opposite bottom face and top corner and the bottom face is connected with the ligth inlet face. The diffusion structures are respectively disposed in the gaps between the first light gathering structures. The diffusion structures are adjacent to the first light gathering structures and the top corner of each of the first light gathering structures and the bottom face far away from the substrate of each of the diffusion structures are in the same plane. The optical film has the good light gathering efficiency.

Owner:AU OPTRONICS CORP

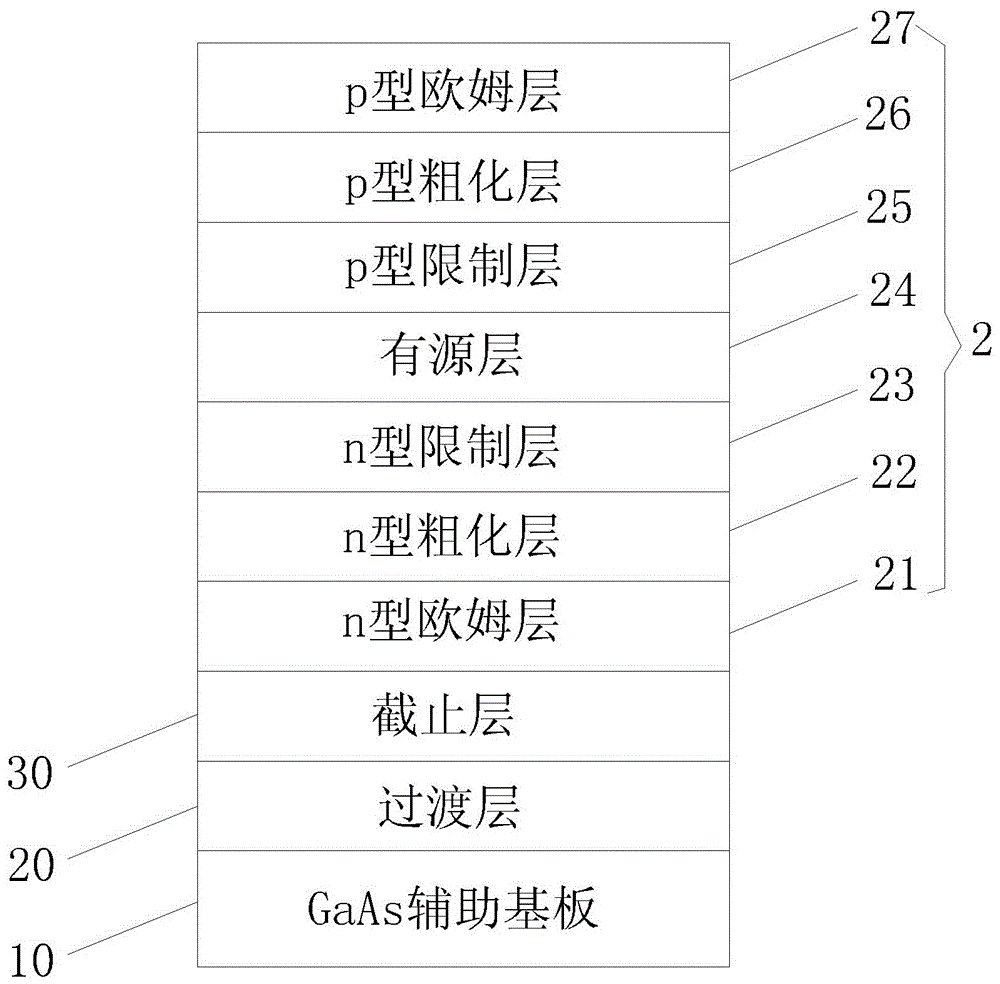

Manufacturing method for surface roughening of GaN-based optoelectronic device

InactiveCN102064258AControl roughnessReduce the chance of total reflectionFinal product manufacturePhotovoltaic energy generationNanometreNanotechnology

The invention discloses a manufacturing method for surface roughening of a GaN-based optoelectronic device, which comprises the following steps of: 1, taking a substrate; 2, epitaxially growing an n-type layer, an i-type layer and a p-type layer in turn on the substrate; 3, processing a nano column array on the p-type layer by using nano processing technology; and 4, epitaxially growing a p-type surface roughened layer on the nano column array.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

White light LED light source component and production method thereof

InactiveCN104676299ANo structural damageLow light extraction efficiencyPoint-like light sourceElectric circuit arrangementsManufacturing technologyFluorescence

The invention discloses a white light LED light source component and a production method thereof. The white light LED light source component comprises an yttrium aluminum garnet phosphor powder fluorescent glass matrix, an LED blue light chip, and a connecting circuit. The melting point of the matrix is 400-600 degrees centigrade; and the matrix comprises 45-55wt% of PbO, 20-30wt% of SiO2, 15-20wt% of ZnO, and 0.5-5wt% of yttrium aluminum garnet phosphor powder. The LED blue light chip is fixed on the surface of the matrix and the light-emitting surface of the LED blue light chip faces to the matrix. The connecting circuit is used for connecting the LED blue light chip with an external power supply. The disclosed white light LED light source component breaks the limitation of light-emitting angle of the LED single-side lamp source in the prior art by arranging the LED blue light chip and the connecting circuit on the fluorescent glass matrix which has a low melting point; therefore, a wide-angle light emission is achieved by a simple manufacturing technology. The disclosed white light LED light source component has very high light-emitting efficiency.

Owner:ELEC TECH INT CO LTD

Organic electroluminescent device and preparation method

InactiveCN104009178AEliminate reflectionsReduce the refractive index differenceSolid-state devicesSemiconductor/solid-state device manufacturingRefractive indexSilicon oxide

The invention discloses an organic electroluminescent device and its preparation method. A polymer layer is firstly prepared on a glass substrate, thus reducing refractive index difference between the glass substrate and the air. A scattering layer is prepared on the polymer layer. Then, light which reaches a polymer can be scattered, and light which is emitted to two sides can return to the middle. Thus, luminous efficiency is raised. Transmission band of silicon oxide is wide, and silicon oxide has a high anti-reflection effect. Refractive index difference between the polymer layer and the air also can be further minimized, total reflection probability is reduced, and more light is emitted to the air. The preparation method is simple and easy to control and operate, and raw materials are easily available.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Flexible circuit board, printed circuit board, rigid-flex board and manufacturing method thereof

ActiveCN110933836ALarge impedance adjustment rangeAchieve Impedance MatchingPrinted circuit assemblingPrinted circuit groundingFlexible circuitsEngineering

The embodiment of the invention discloses a flexible circuit board, a printed circuit board, a rigid-flex board and a manufacturing method of the rigid-flex board. The flexible circuit board comprises: a first bonding pad which is connected with a signal line and is provided with at least two through holes, and the at least two through holes for realizing impedance matching between the first bonding pad and the signal line.

Owner:WUHAN OPTICAL VALLEY INFORMATION OPTOELECTRONICS INNOVATION CENT CO LTD +1

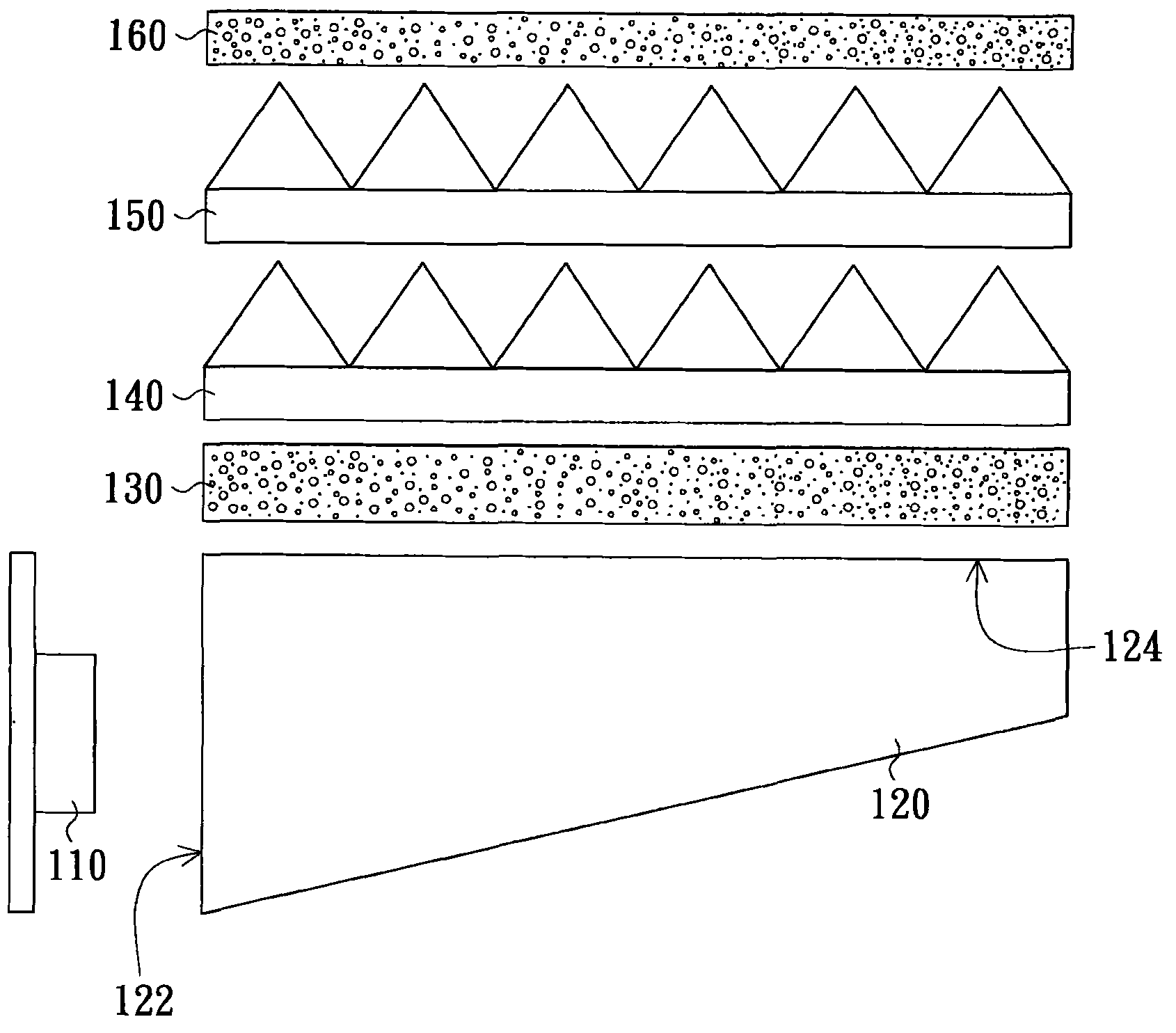

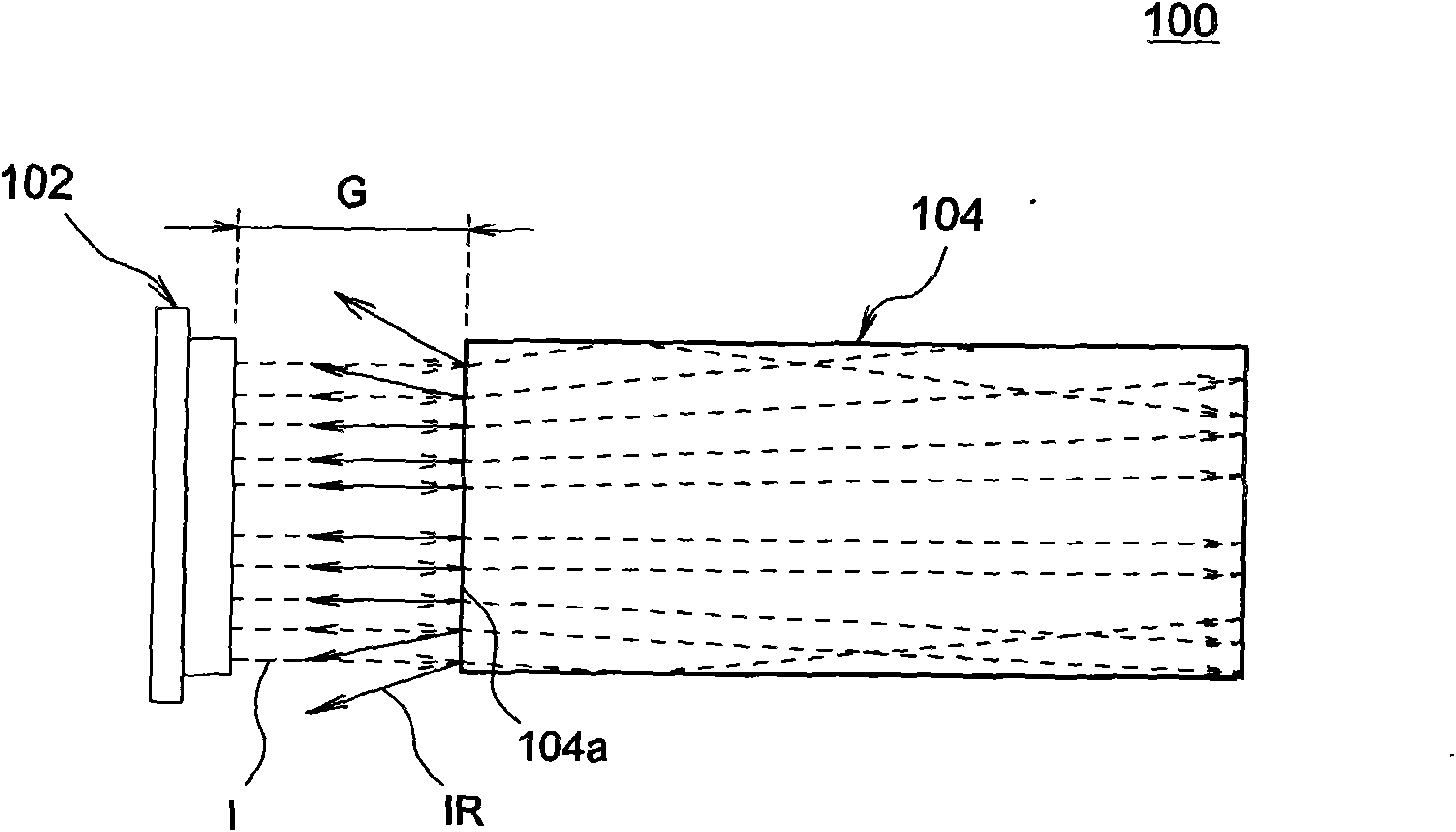

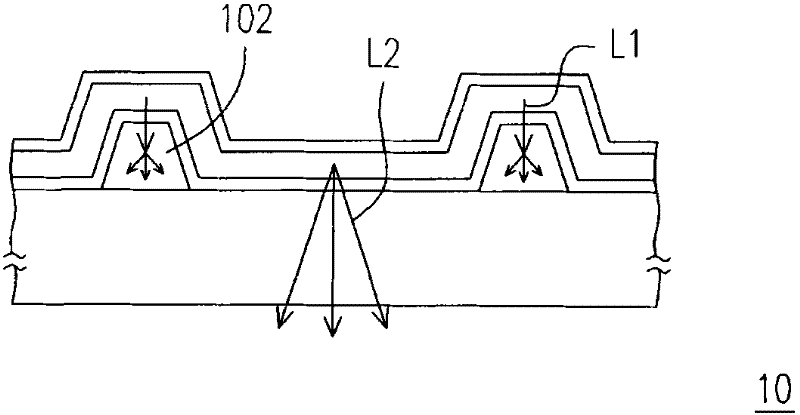

Backlight module

InactiveCN102466172AReduce the chance of total reflectionReduce lossesPoint-like light sourceLight fasteningsLight guideRefractive index

The invention discloses a backlight module. The backlight module comprises at least one light source, a light guide plate and a refractive medium. A light incidence surface of the light guide plate is adjacent to the light source, the refractive medium is adhered to the light incidence surface and an air gap is formed between the refractive medium and the light incidence surface, the refractive index of the refractive medium is smaller than the refractive index of the light guide plate, and the light beams which are emitted by the light source pass through the air gap and the refractive medium sequentially and then enter the light guide plate through the light incidence surface. The backlight module can effectively improve the light utilization rate, and can keep the air gap between the light guide plate and the light source.

Owner:CORETRONIC

LED structure and manufacturing method thereof

InactiveCN101414653BImprove light extraction rateReduced instances of lateral spreadSemiconductor devicesChemical reactionEtching

The invention discloses an LED structure and a fabrication method. The method comprises the following steps: placing a substrate in a solution for reaction; naturally forming a chemical reaction layeron the surface of a cutting street region of the substrate; forming a plurality of concave parts and convex parts on the surface of the cutting street region by selective etching; growing a semiconductor layer structure on a component region and the cutting street region on the surface of the substrate by an epitaxial growth technology; and then forming the LED by the semiconductor layer structureon the component region using yellow light lithography process.

Owner:TEKCORE CO LTD

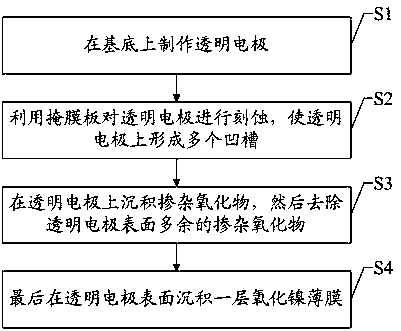

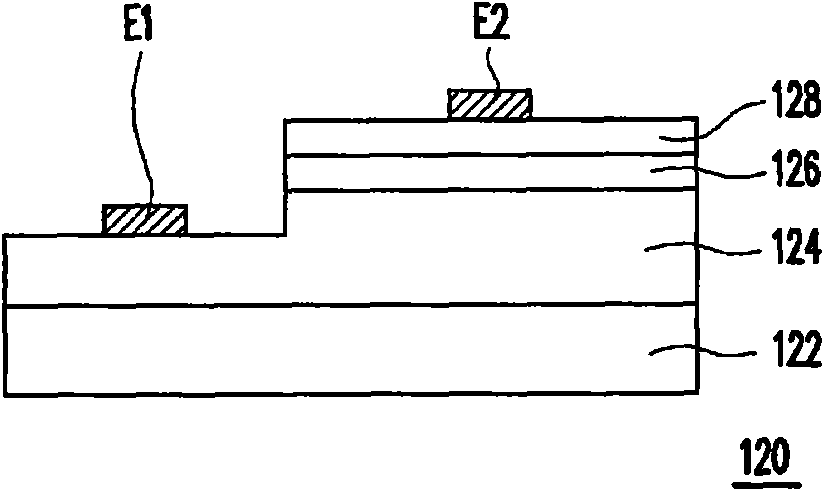

Electrode structure capable of enhancing luminous efficiency, QLED and preparation method of electrode structure capable of enhancing luminous efficiency

ActiveCN108539036AImprove light extraction efficiencyImprove hole injection efficiencySolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsDoped oxide

The invention discloses an electrode structure capable of enhancing luminous efficiency, a QLED and a preparation method of the electrode structure capable of enhancing the luminous efficiency. The electrode structure comprises a substrate, a transparent electrode which is arranged on the surface of the substrate and has multiple slots, a doped oxide filling in the slots and a nickel oxide film ora manganese oxide film which is deposited on the surface of the transparent electrode. According to the electrode structure, the doped oxide is introduced to the transparent electrode having the slots to fill in the slots and then a layer of nickel oxide film or manganese oxide film is deposited on the transparent electrode, the light emitted out of the luminous layer can be effectively constrained by introducing of the nickel oxide film or the manganese oxide film, the light can be guided into the slots of the transparent electrode to a greater extent, and the light emergent angle of the light from the transparent electrode to the glass interface can be changed by using the slots and the probability of total reflection can be reduced so that the luminous efficiency of the device can be enhanced. The barrier of the transparent electrode and the luminous functional layer can be reduced and the hole injection efficiency of the device can be enhanced.

Owner:TCL CORPORATION

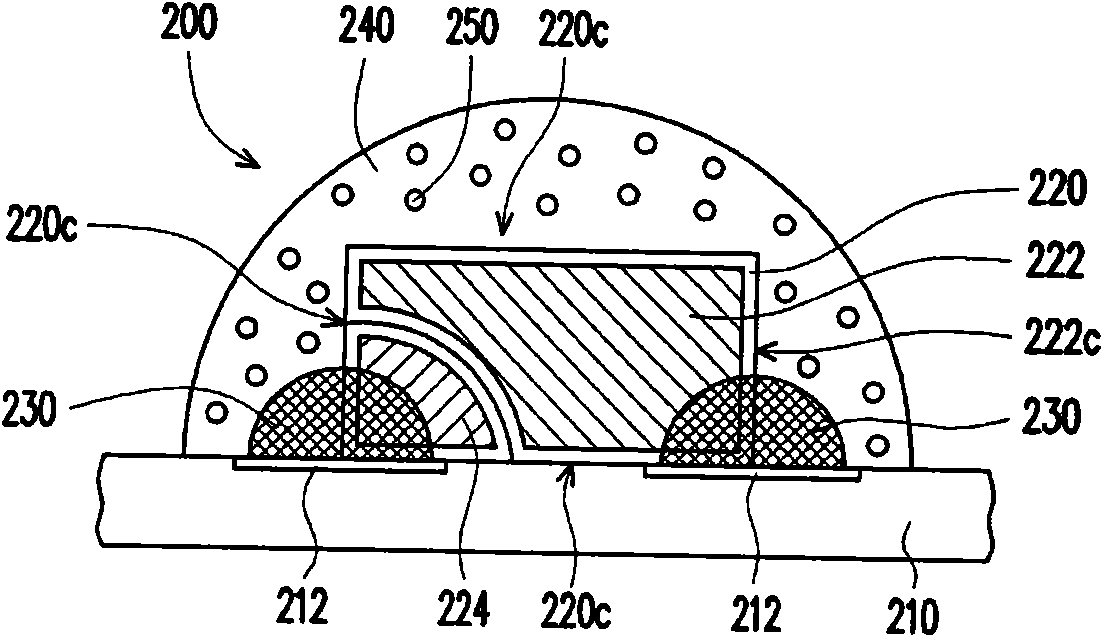

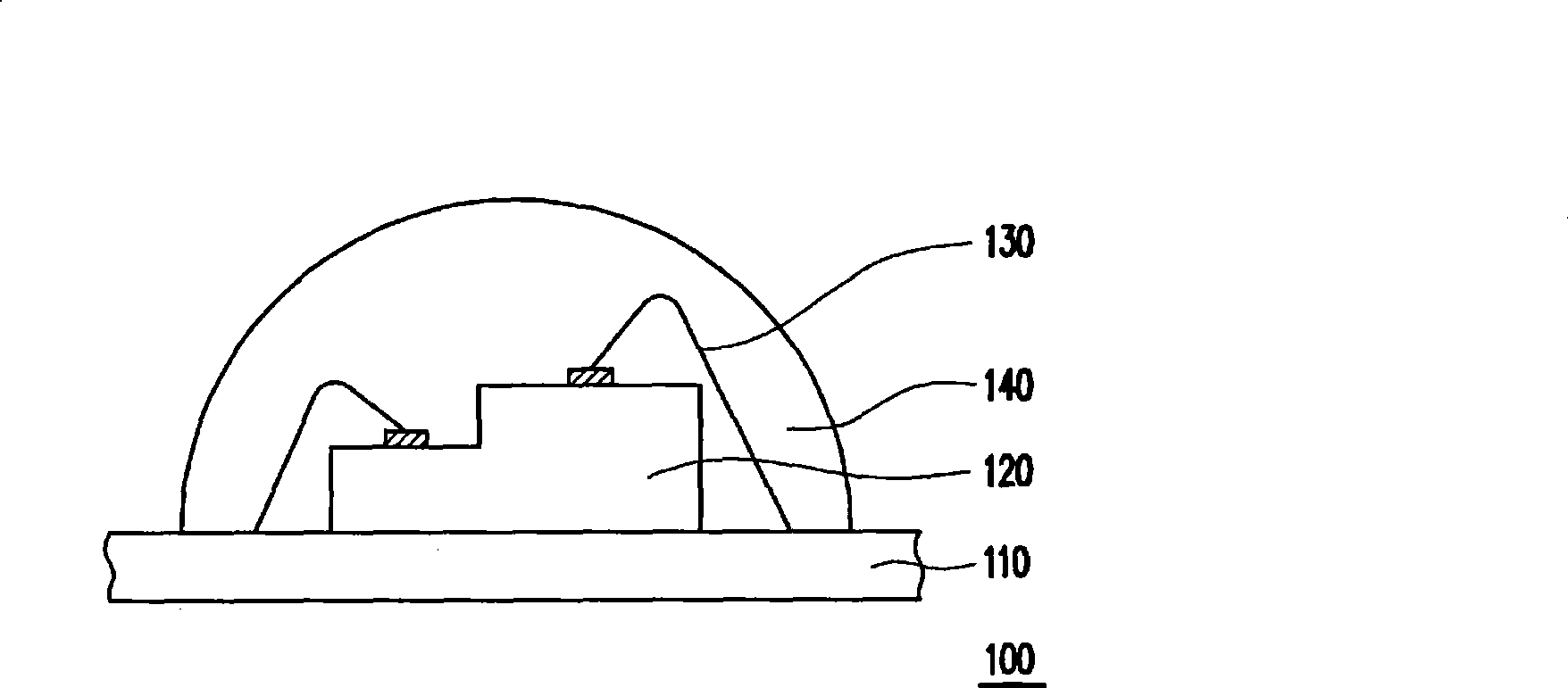

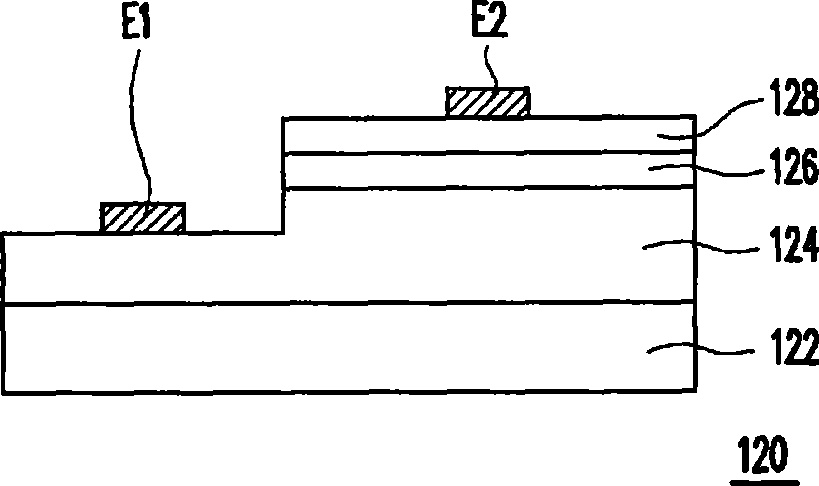

LED packager

ActiveCN101661982AImprove luminous efficiencyReduce the chance of total reflectionSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorEngineering

The invention discloses an LED packager comprising a carrier, an LED chip and a plurality of conductors, wherein the LED chip is provided with a front surface, a back surface and a plurality of side walls connected between the front surface and the back surface; one side wall of the LED chip faces the carrier and is connected with the carrier; and the conductors are electrically connected betweenthe carrier and the LED chip.

Owner:TEKNOWLEDGE DEV

LED chip structure and manufacturing method thereof

InactiveCN106159044AIncrease brightnessReduce the difference sizeSemiconductor devicesRefractive indexTransmittance

The invention provides an LED chip structure and a manufacturing method thereof. The manufacturing method comprises that a substrate including a front side and a back side is provided; an N type semiconductor layer, an active layer and a P type semiconductor layer are formed successively; an N electrode and a P electrode are formed; and a buffer layer whose reflective index is lower than that of the substrate is formed. The LED structure comprises the substrate, an N type semiconductor layer, an active layer, a P type semiconductor layer, the N electrode, the P electrode and the buffer layer, wherein the N electrode and the P electrode are electrically connected with the N type semiconductor layer and the P type semiconductor layer respectively, and the buffer layer is formed in the back side of the substrate. The LED chip structure and the manufacturing method thereof have the advantages that the buffer layer whose refractive index is lower than that of the substrate is added, the possibility that light transmitted from the substrate generates total reflection is reduced, the possibility that light generates total reflection at the surface of the substrate is reduced, the light transmissivity is improved, and further the brightness of the LED chip structure is improved.

Owner:ENRAYTEK OPTOELECTRONICS

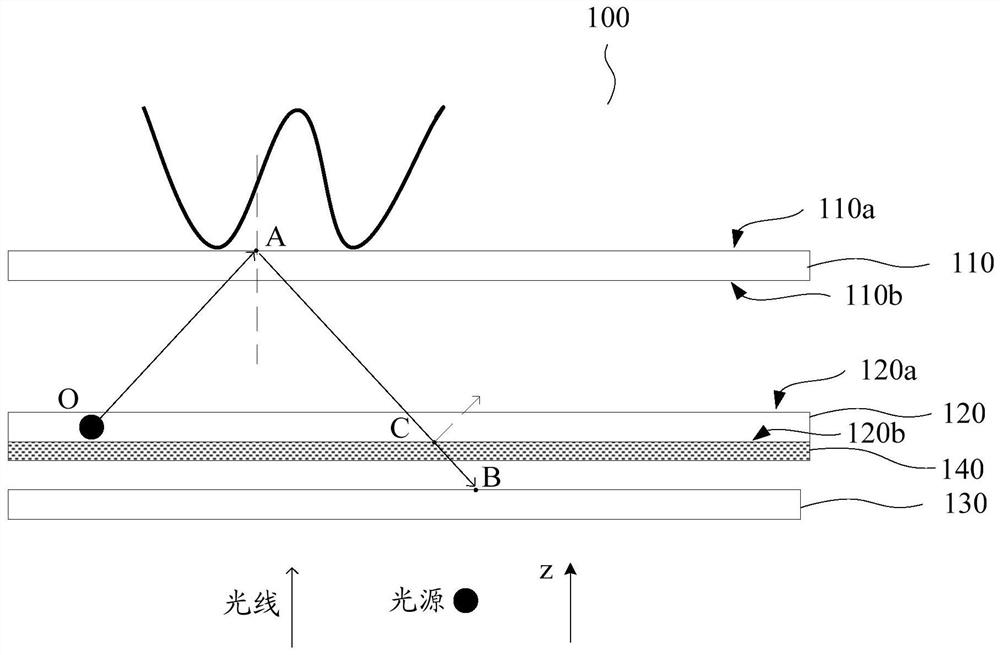

Image acquisition device

PendingCN111950322APrevent double total reflectionReduce the chance of total reflectionPrint image acquisitionEngineeringSignal light

An image acquisition device comprises a light-transmitting cover plate, the light-transmitting cover plate is provided with a first surface and a second surface which are opposite to each other alongthe thickness direction, and the first surface of the light-transmitting cover plate is suitable for being contacted with an object to be acquired; the device also comprises a light source part provided with a first surface and a second surface which are opposite to each other in the thickness direction, wherein the first surface of the light source part is arranged towards the second surface of the light-transmitting cover plate; the device further comprises a sensor part provided on a second surface of the light source part; a scattering layer coated on the second surface of the light sourcepart and is suitable for scattering incident light. Through the scheme provided by the invention, secondary total reflection can be effectively prevented, and signal light can be successfully incident to the sensor part.

Owner:SHANGHAI HARVEST INTELLIGENCE TECH CO LTD

LED packager

ActiveCN101661982BImprove luminous efficiencyReduce the chance of total reflectionSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorEngineering physics

Owner:TEKNOWLEDGE DEV

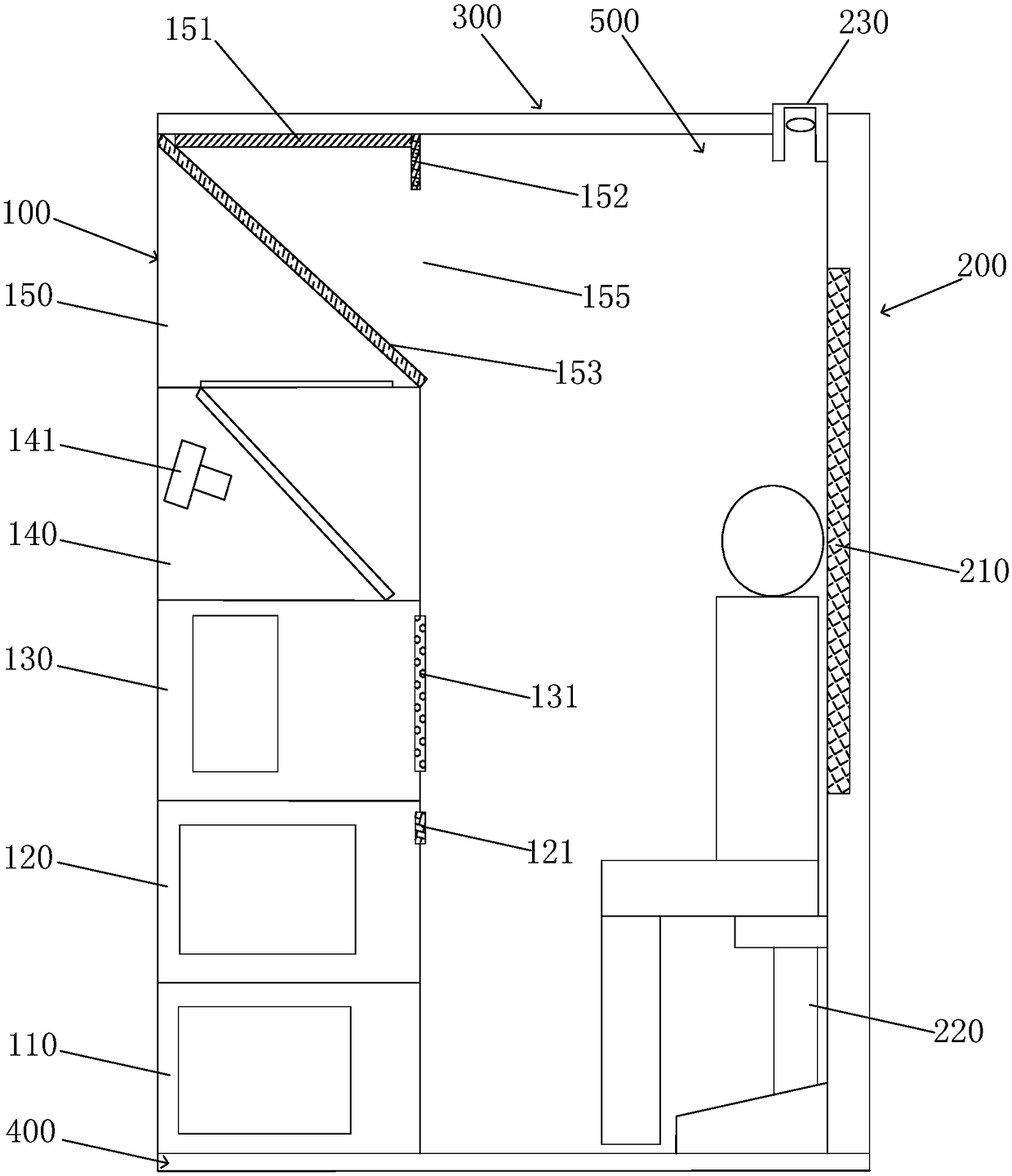

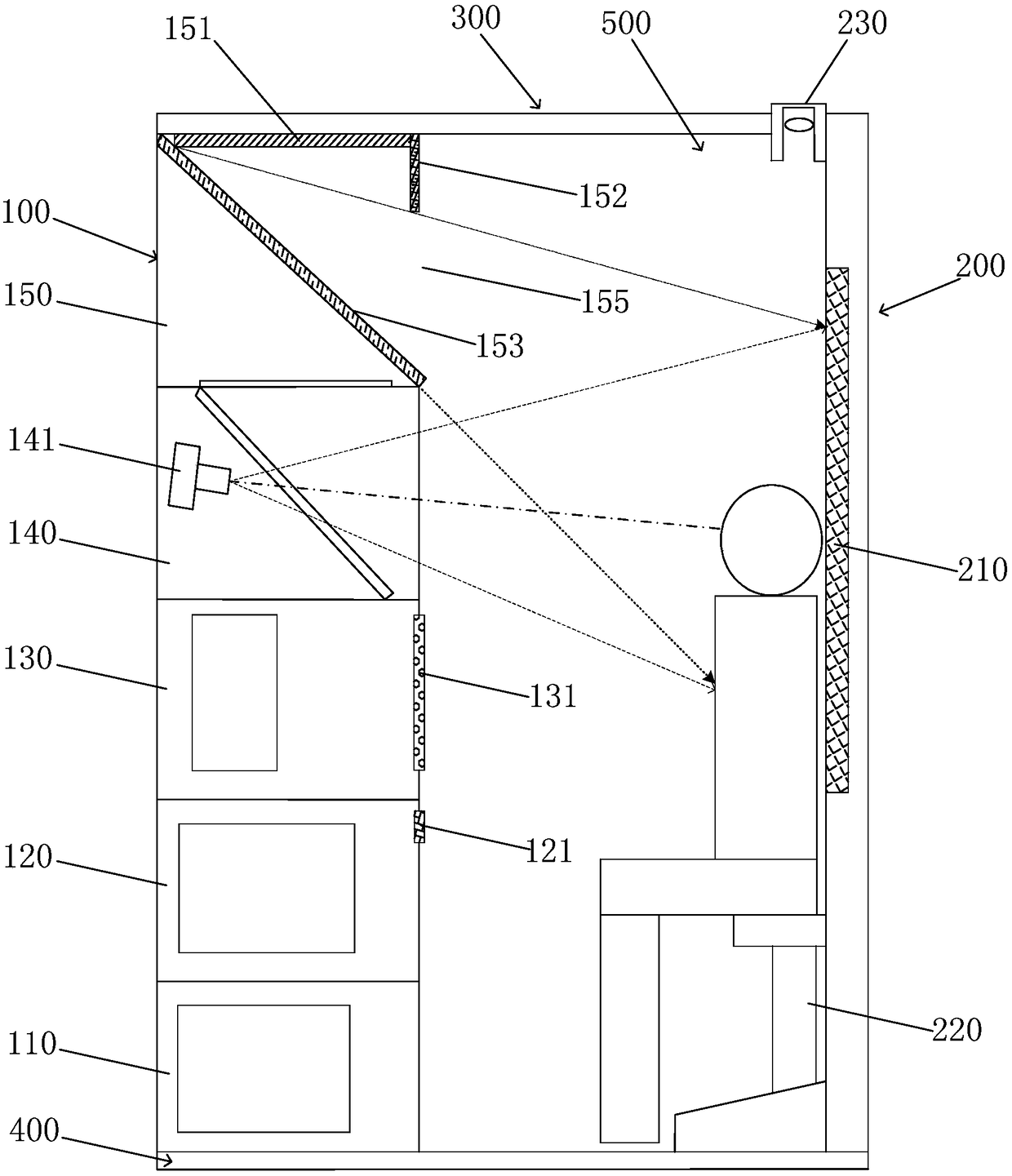

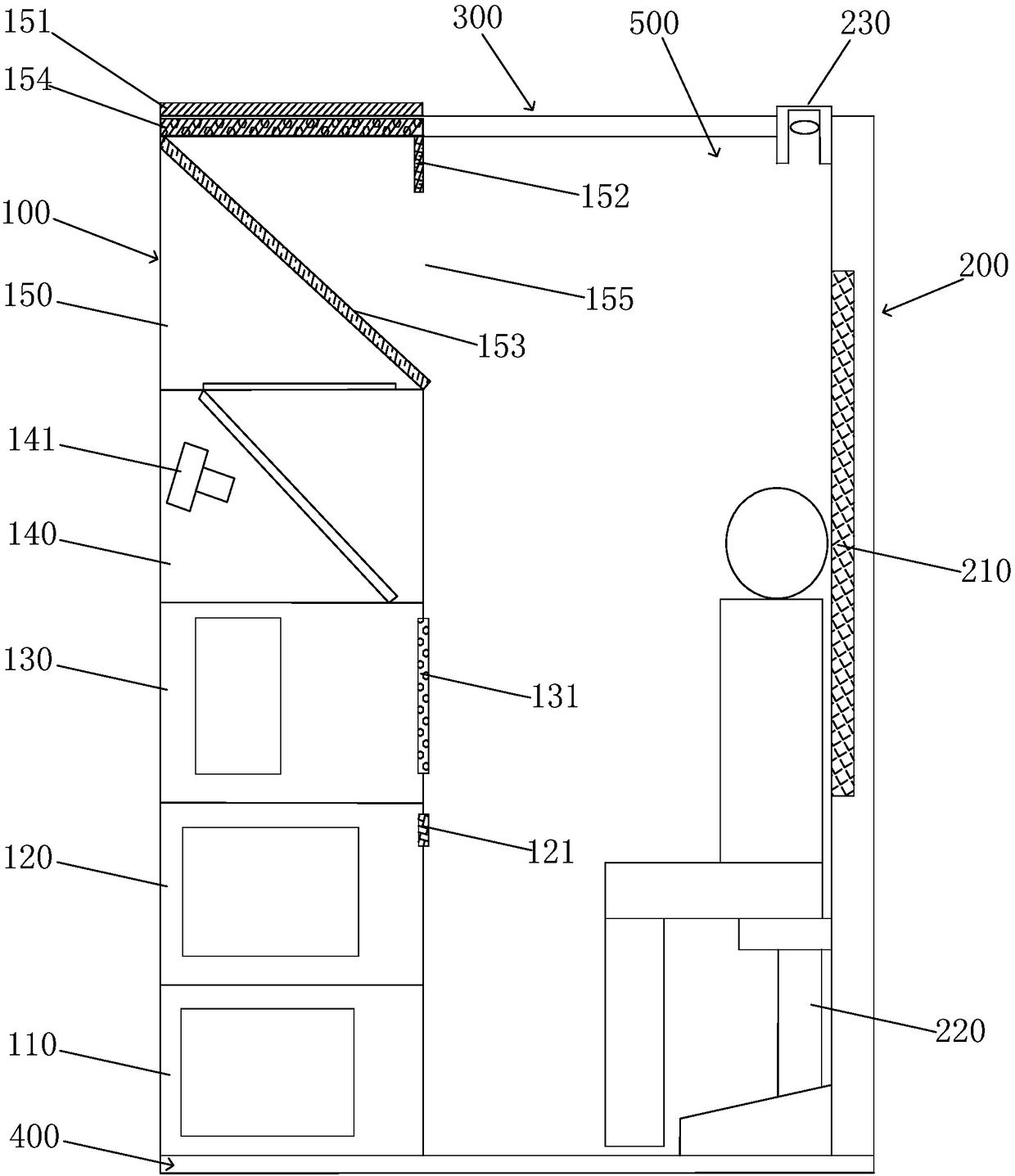

Self-service photographing device

PendingCN108171890AReduce the chance of total reflectionStrict requirementsTelevision system detailsColor television detailsLower limitSelf-service

The invention provides a self-service photographing device. A main light installation chamber is formed in a photographing cabinet body, the main light installation chamber is provided with a window close to a background cabinet body, a main illumination lamp module, an upper light barrier plate and a lower light barrier plate. Light rays emitted by the main illumination lamp module are emitted from the interior of the main light installation chamber via the window, the upper light barrier plate is used for limiting the upper limit of an illumination range of the light rays emitted by the mainillumination lamp module to the upper limit of a visual angle of a camera, and the lower light barrier plate is used for limiting the lower limit of the illumination range of the light rays emitted by the main illumination lamp module to the lower limit of the visual angle of the camera. By adopting the scheme, the average distance between the main illumination lamp module and a person is nearlydoubled, and the illumination area is increased by 50% or above, so that the light rays projected on the person are more uniform, defects such as uneven illumination and shadow are avoided, a good lighting effect in a small space is achieved, photography conditions of professional character photography are achieved, and therefore the photography effect is improved.

Owner:曾奕

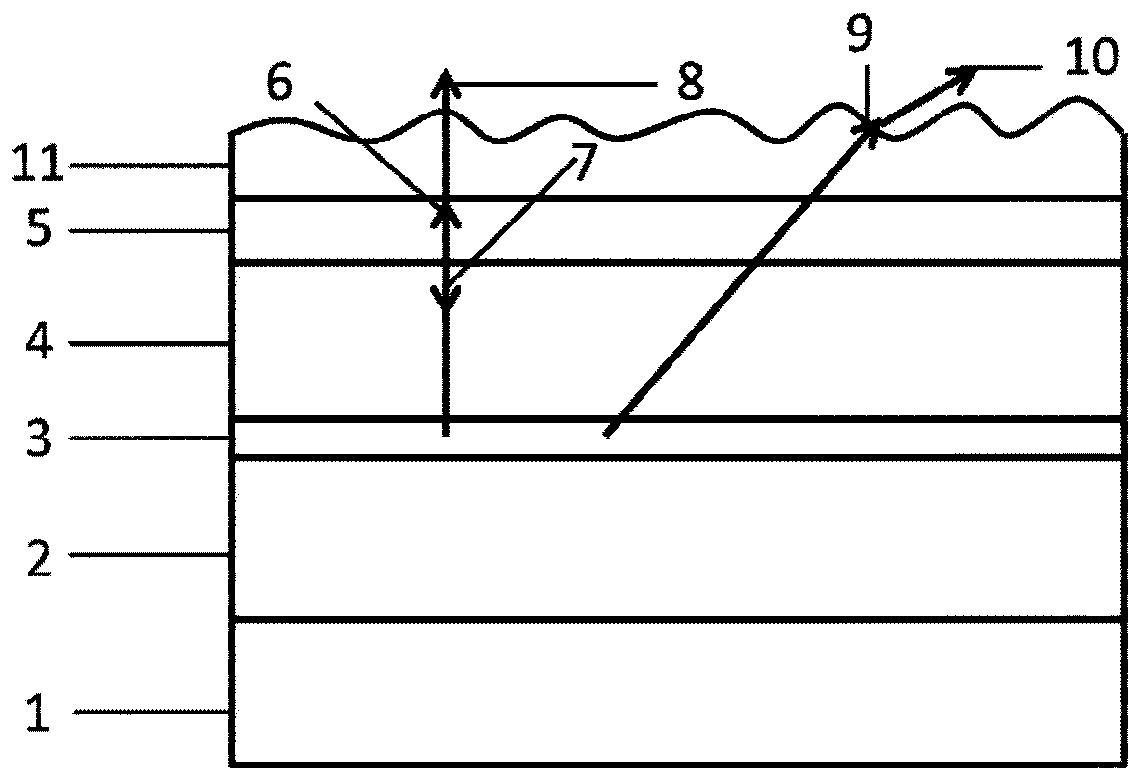

Display panel, preparation method thereof and display device

InactiveCN111584746AImprove light extraction efficiencySimple and fast operationSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceThin membrane

The embodiment of the invention discloses a display panel, a preparation method thereof and a display device. The display panel comprises a light-emitting layer and a thin film packaging layer. The light-emitting layer comprises a plurality of sub-pixel units. The thin film packaging layer comprises a first inorganic layer, a base layer and a second inorganic layer which are sequentially stacked on the light-emitting layer in the longitudinal direction. One surface, far away from the light-emitting layer, of the first inorganic layer is provided with a plurality of nano bulges; the plurality of nano bulges are arranged on one surface, far away from the light-emitting layer, of the first inorganic layer, and the incident angle of the divergent light of the light-emitting layer can be reduced through the nano bulges, so that the probability of total reflection is reduced, more light is helped to pass through the interface of the first inorganic layer and the organic layer, the light-emitting efficiency of the light-emitting layer is improved, and the display effect of the display panel is improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

A method of manufacturing a light emitting diode

InactiveCN103855255BIncrease brightnessReduce the chance of total reflectionSemiconductor devicesQuantum wellLight-emitting diode

The invention provides a manufacturing method for a light-emitting diode. The method includes the following steps: firstly, depositing a light-emitting epitaxial layer which, includes at least an N-type layer, a quantum well layer and a P-type layer, on the surface of a semiconductor substrate; then etching the P-type layer and the quantum well layer and then forming an N-electrode preparation area; then forming an ITO transparent conductive layer on the surface of the P-type layer and preparing a P-electrode on the surface of the ITO transparent conductive layer and preparing an N-electrode on the N-electrode preparation area; then placing the structure in a mixed liquid of a ZnO powder and an HCI solution and depositing a ZnO thin film on the surface of the structure; and at last, removing the P-electrode, the N-electrode and the ZnO thin film on the surface of the N-electrode preparation area so as to complete the manufacturing of the light-emitting diode. The manufacturing method for the light-emitting diode has the following beneficial effects: the ZnO thin film, which does not damage the light-emitting diode and the surface of which is roughened, on the ITO transparent conductive layer on the surface of a P-GaN surface so that reduction of a total-reflection rate of light in the light-emitting diode is facilitated and thus the brightness of the light-emitting diode is improved.

Owner:EPILIGHT TECH

A method for testing the emission wavelength of Gaas-based semiconductor laser epitaxial wafers and its application

ActiveCN105352610BIncrease the number of raysReduce the chance of total reflectionOptical measurementsPhotoluminescenceRefractive index

Owner:Shandong Huaguang Optoelectronics Co. Ltd.

LED chip and its manufacturing method

InactiveCN106057999AIncrease the chance of lightLarge specific surface areaSemiconductor devicesIsosceles trapezoidEngineering

The present invention provides an LED chip and its manufacturing method. The LED chip comprises a substrate, a semiconductor epitaxial structure on the substrate, and a P-electrode and an N-electrode on the semiconductor epitaxial structure. The substrate comprises an upper substrate and a lower substrate. The cross section of the upper substrate is an isosceles trapezoid. The two sides of the upper substrate are referred to as first symmetrical slopes. The cross-section of the lower substrate is a parallelogram. The two sides of the lower substrate are referred to second parallel slops. The two sides of the semiconductor epitaxial structure are inclined along the first slopes of the upper substrate. According to the invention, the brightness of an LED chip improves under the premise that the splitting position is not changed to change the topography of a substrate and that the splitting rate is not compromised.

Owner:FOCUS LIGHTINGS SCI & TECH

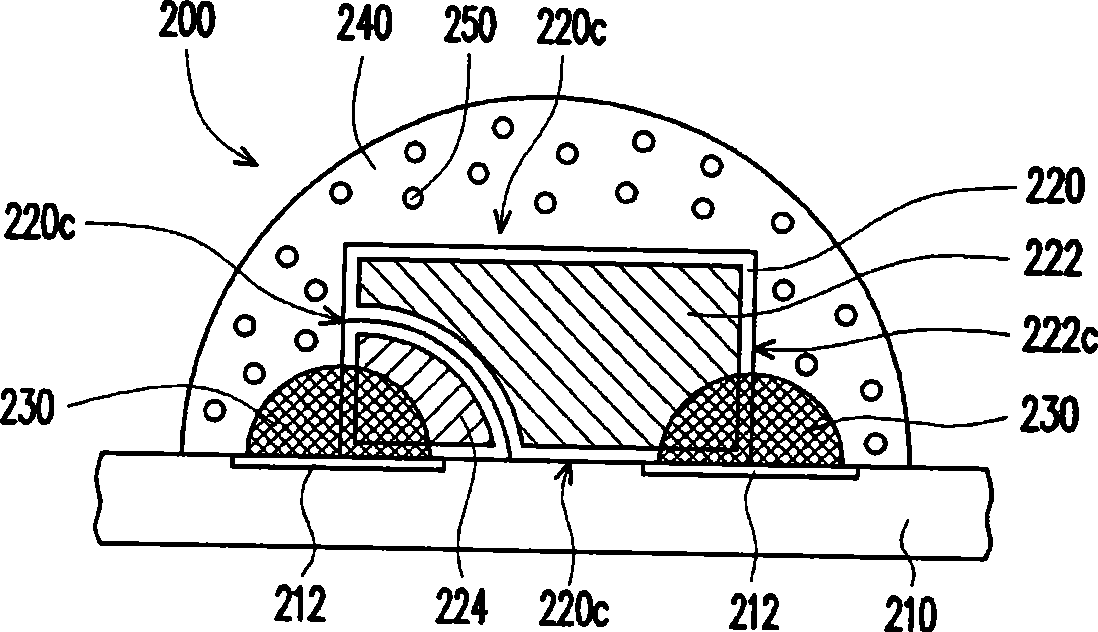

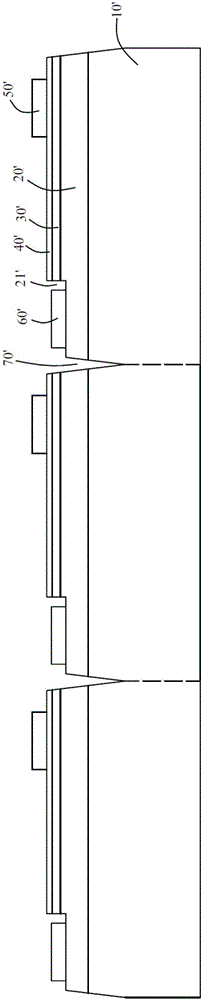

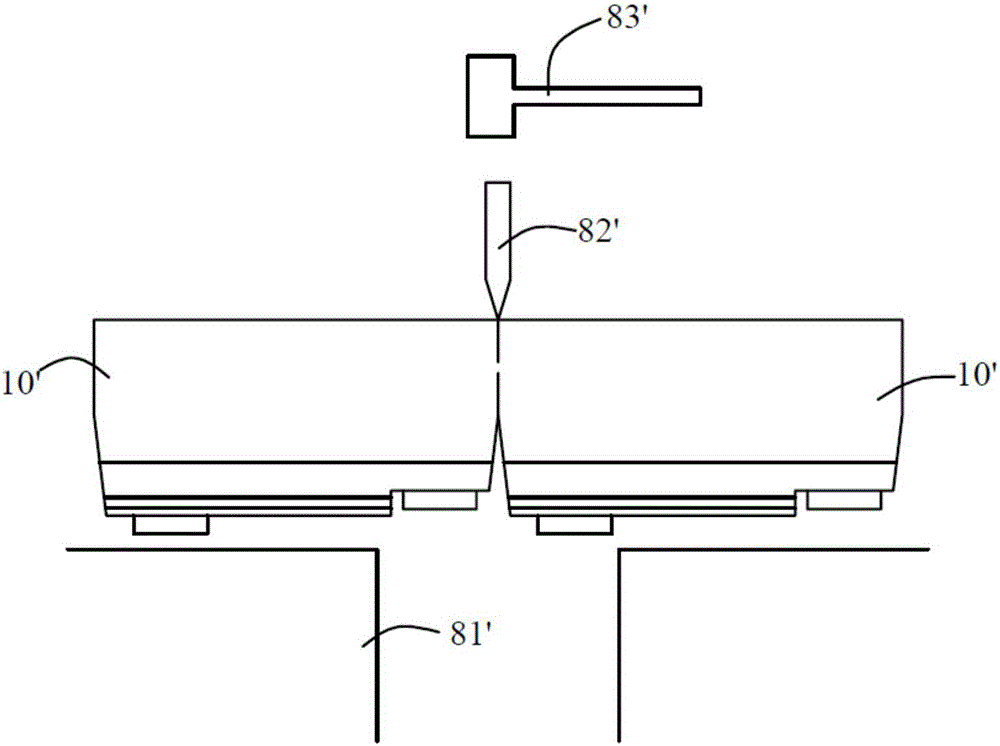

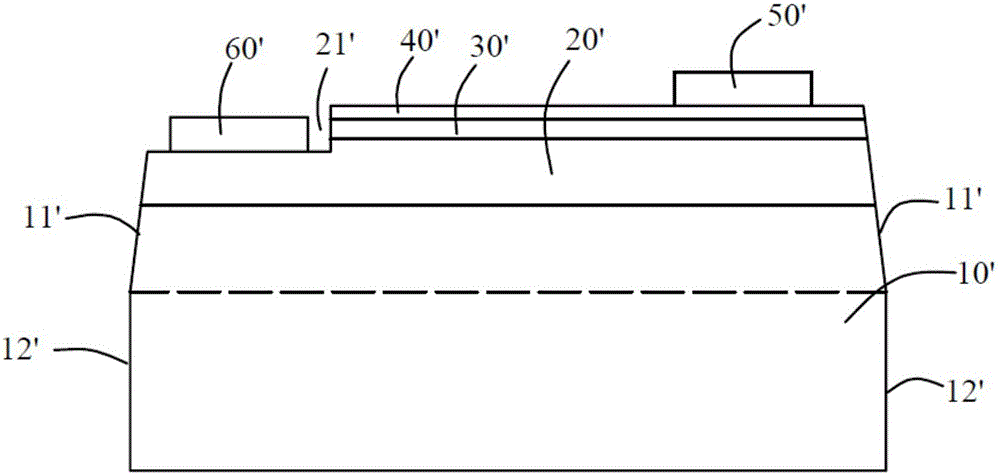

Light-emitting diode assembly

InactiveCN102347409AReduce the angle of incidenceReduce the chance of total reflectionSemiconductor devicesEngineeringLight-emitting diode

The invention discloses a light-emitting diode assembly, which comprises a substrate and an epitaxial layer, wherein the substrate is provided with a first side, a second side and an annular side, wherein the first side and the second side are opposite, and the annular side is respectively adjacent to the first side and the second side. The epitaxial layer is arranged at the first side of the substrate, and the annular side is provided with a concave structure extending to the second side from the annular side. In the light-emitting diode assembly disclosed by the invention, the concave structure extends to the first side and the epitaxial layer from the annular side. By the concave structure, the probability that total reflection is caused because light passes through the light-emitting diode assembly can be reduced, and further, the luminous efficiency is improved.

Owner:佛山市奇明光电有限公司 +1

Area light source and display panel

ActiveCN101834279BReduce the chance of total reflectionImprove light outputSolid-state devicesSemiconductor/solid-state device manufacturingElectroluminescenceLight source

The invention discloses an area light source, which comprises a substrate, a patterned scattering layer and an organic electro-luminescence element, wherein the patterned scattering layer is arranged on a part of the area of the substrate and is provided with a bottom face contacting the substrate, a top face opposite to the bottom face and a plurality of side walls connecting the bottom face andthe top face; and the organic electro-luminescence element is at least arranged on the side walls.

Owner:AU OPTRONICS CORP

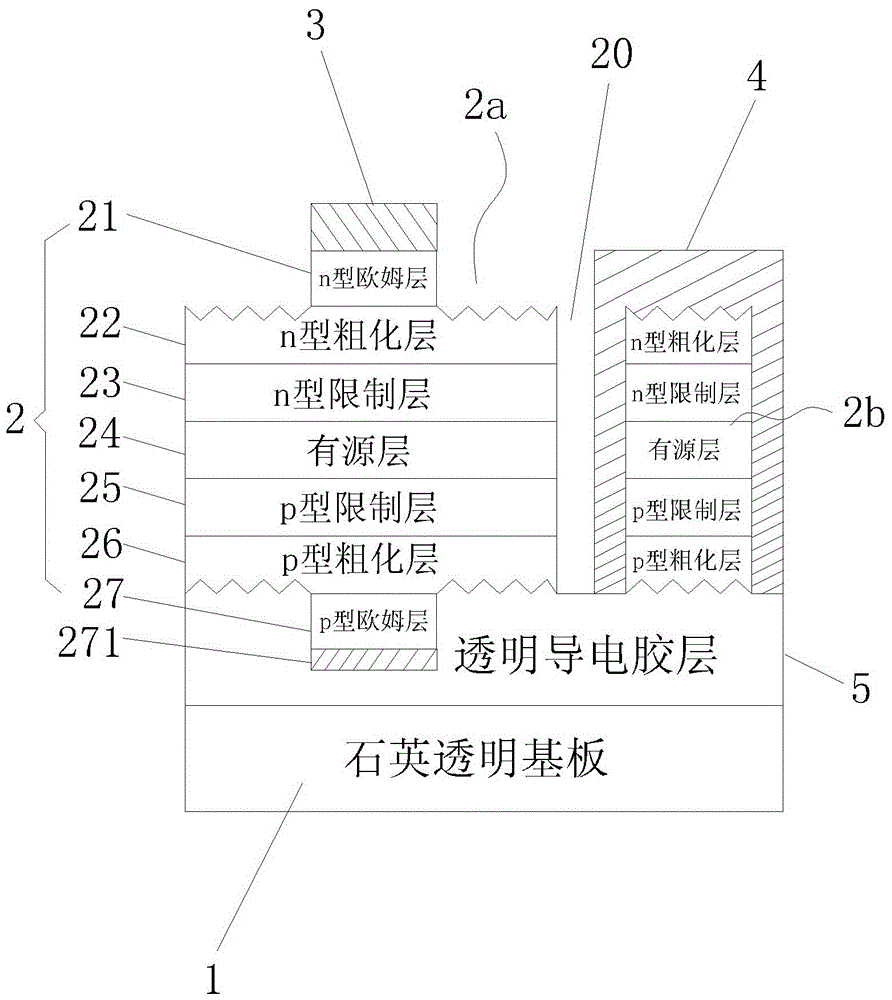

A light emitting diode and its manufacturing method

ActiveCN103715324BIncrease brightnessReduce the chance of total reflectionSemiconductor devicesEngineeringLight-emitting diode

The invention discloses a light-emitting diode of a novel structure. The light-emitting diode comprises a transparent substrate, an outwards-extending sheet, a first electrode and a second electrode. The outwards-extending sheet sequentially comprises an n type ohm layer, an n type roughening layer, an n type limiting layer, an active layer, a P type limiting layer, a p type roughening layer and a p type ohm layer. The area of the end face of the n type ohm layer is smaller than that of the end face of the n type roughening layer, the area of the end face of the p type ohm layer is smaller than that of the end face of the p type roughening layer, one side, close to the p type ohm layer and the p type roughening layer, of the outwards-extending sheet is adhered to the transparent substrate through a transparent conductive adhesive layer, the first electrode is connected to the n type ohm layer, the second electrode is connected to the transparent conductive adhesive layer, the outer surfaces of the p type roughening layer and the n type roughening layer are etched to be in the convex-concave shape through corrosive liquid, and the outer end face of the p type ohm layer is further plated with an alloy layer. The invention further discloses a manufacturing method of the light-emitting diode, the light-emitting diode of the novel structure and the manufacturing method of the light-emitting diode effectively reduce loss of emitted light generated by full reflection in the light-emitting diode and improve light-emitting efficiency.

Owner:XIAMEN CHANGELIGHT CO LTD

Optical film

InactiveCN102253440BImprove collection efficiencyImprove light utilization efficiencyPrismsDiffusing elementsPhysicsOptical film

Owner:AU OPTRONICS CORP

Light-emitting diode chip and manufacturing method thereof

ActiveCN103560189BImprove acceleration performanceImprove injection efficiencySemiconductor devicesEngineeringLight-emitting diode

The invention discloses a light-emitting diode chip and a manufacturing method thereof. The light-emitting diode chip comprises: an epitaxial layer with a concave-convex microstructure; a patterned first current spreading layer formed on the convex surface of the epitaxial layer; a second current spreading layer Layer, covering the upper surface of the patterned first current spreading layer and the uneven surface of the epitaxial layer without masking the first current spreading layer, the double current spreading layer formed in this way and the epitaxial layer with a concave-convex microstructure can not only Reducing the probability of total reflection and reducing internal reflection and absorption can also improve the expansion of the current, increase the injection efficiency of the current, and reduce the operating voltage of the device, thereby improving the luminous efficiency and brightness of the LED.

Owner:ANHUI SANAN OPTOELECTRONICS CO LTD

Reflective cholesterol liquid crystal display device

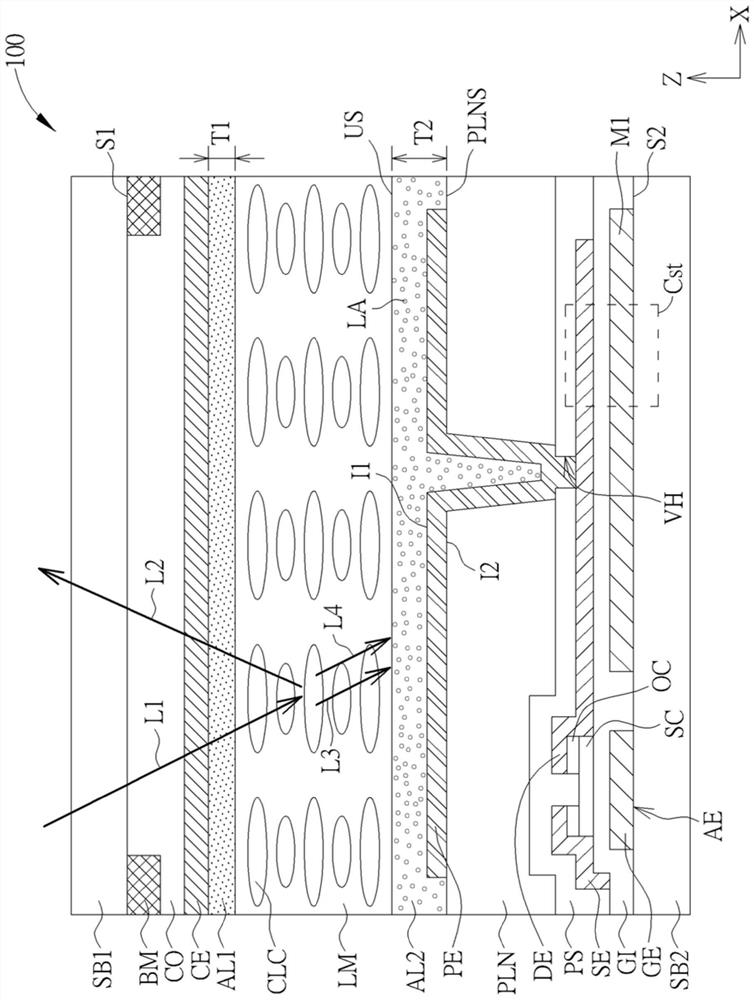

PendingCN113960838AImprove display qualityReduce the chance of total reflectionNon-linear opticsLiquid-crystal displayCholesterol

The invention discloses a reflective cholesterol liquid crystal display device which sequentially comprises an upper substrate, an upper alignment layer, a cholesterol liquid crystal layer, a lower alignment layer and a lower substrate from top to bottom, wherein an upper electrode is arranged on the surface of the upper substrate, and a lower electrode is arranged on the surface of the lower substrate. The lower alignment layer is directly adjacent to the cholesterol liquid crystal layer, and the optical density of the lower alignment layer is larger than or equal to 1.

Owner:SOLE OPTOELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com