Electrode structure capable of enhancing luminous efficiency, QLED and preparation method of electrode structure capable of enhancing luminous efficiency

A technology of electrode structure and light extraction efficiency, applied in circuits, electrical components, electric solid devices, etc., can solve the problem of inability to improve the light extraction efficiency of QLED devices, and achieve the goal of reducing the probability of total reflection, improving hole injection efficiency, and improving light extraction efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

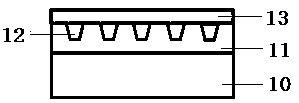

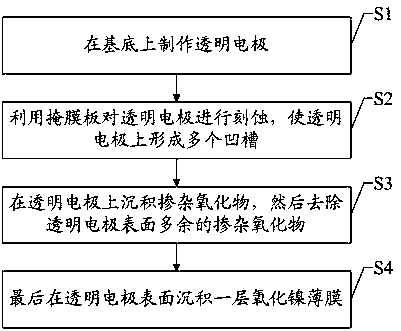

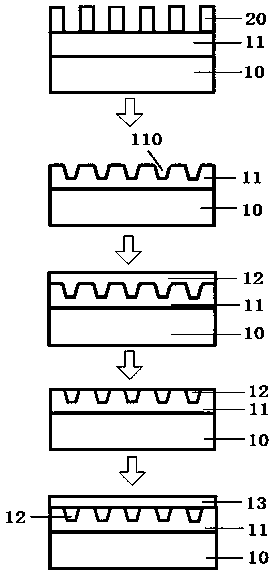

[0048] Clean the substrate, deposit a 250nm ITO film on the substrate by magnetron sputtering, deposit a layer of positive photoresist on the ITO film, and use it as a mask after exposure and development to control the aperture of the circular hole on the mask The total area of the circular holes accounts for 15% of the total surface area of the mask. The ITO thin film was etched by wet method, and the etching depth was controlled to be 100nm. Expose to remove the mask, and then use the magnetron sputtering method to deposit a 200nm AZO film on the ITO film, and then use chemical mechanical polishing to remove the AZO film on the surface of the ITO film, leaving only a 200nm ITO film on the substrate. At this time, about 50 nm of AZO was filled into the grooves of the ITO film. Finally, a 7.5nm NiO film was deposited on the surface of the ITO film by magnetron sputtering. A hole injection layer, a hole transport layer, a quantum dot light-emitting layer, an electron tran...

Embodiment 2

[0050] The substrate was cleaned, and a 300nm ITO film was deposited on the substrate by magnetron sputtering, and a plurality of circular grooves were etched by laser (the groove diameter was 5 μm, and the total area of the grooves accounted for 20% of the total surface area of the mask. %), control the etching depth to 50nm. A 200nm FTO film was deposited on the ITO film by magnetron sputtering, and then chemical mechanical polishing was used to remove the FTO film on the surface of the ITO film, leaving only a 200nm ITO film on the substrate. At this time, about 50 nm of FTO was filled in the grooves of the ITO film. Finally, a 10nm MnO film was deposited on the surface by magnetron sputtering. A hole injection layer, a hole transport layer, a quantum dot light-emitting layer, an electron transport layer, an electron injection layer, and a cathode are sequentially deposited on the MnO thin film to obtain a QLED device.

Embodiment 3

[0052] Clean the substrate, deposit a 275nm ITO film on the substrate by magnetron sputtering, deposit a layer of positive photoresist on the ITO film, and use it as a mask after exposure and development to control the aperture of the circular hole on the mask The total area of the circular holes accounts for 30% of the total surface area of the mask. The ITO thin film was etched by wet method, and the etching depth was controlled to be 75nm. The mask was removed by exposure, and a 200nm ATO film was deposited on the ITO film by magnetron sputtering, and then chemical mechanical polishing was used to remove the ATO on the surface of the ITO film, leaving only a 200nm ITO film on the substrate. At this time, about 50 nm of ATO was filled in the grooves of the ITO thin film. Finally, a 5nm NiO film was deposited on the surface by magnetron sputtering. A hole injection layer, a hole transport layer, a quantum dot light-emitting layer, an electron transport layer, an electro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com