A light emitting diode and its manufacturing method

A technology of light-emitting diodes and electrodes, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of limited improvement of LED chip external quantum efficiency, increase of manufacturing cost, increase of process complexity, etc., to improve light extraction efficiency and broad application space , the effect of reducing the probability of total reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032]The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

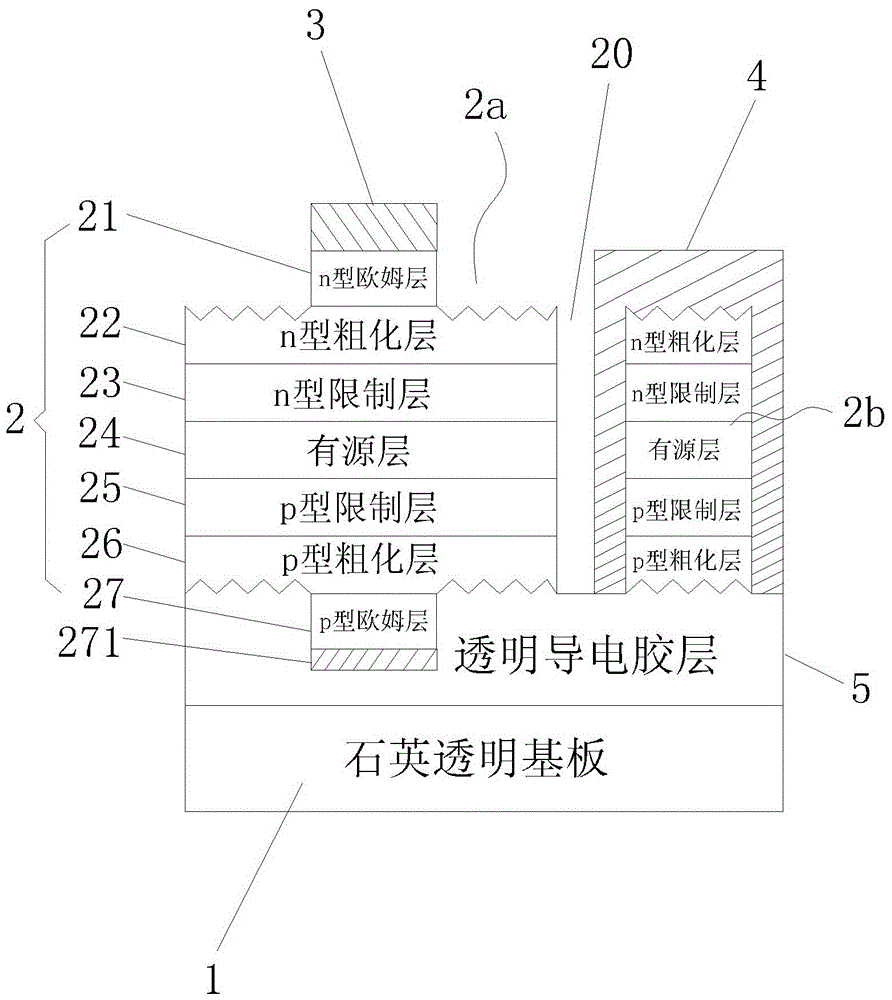

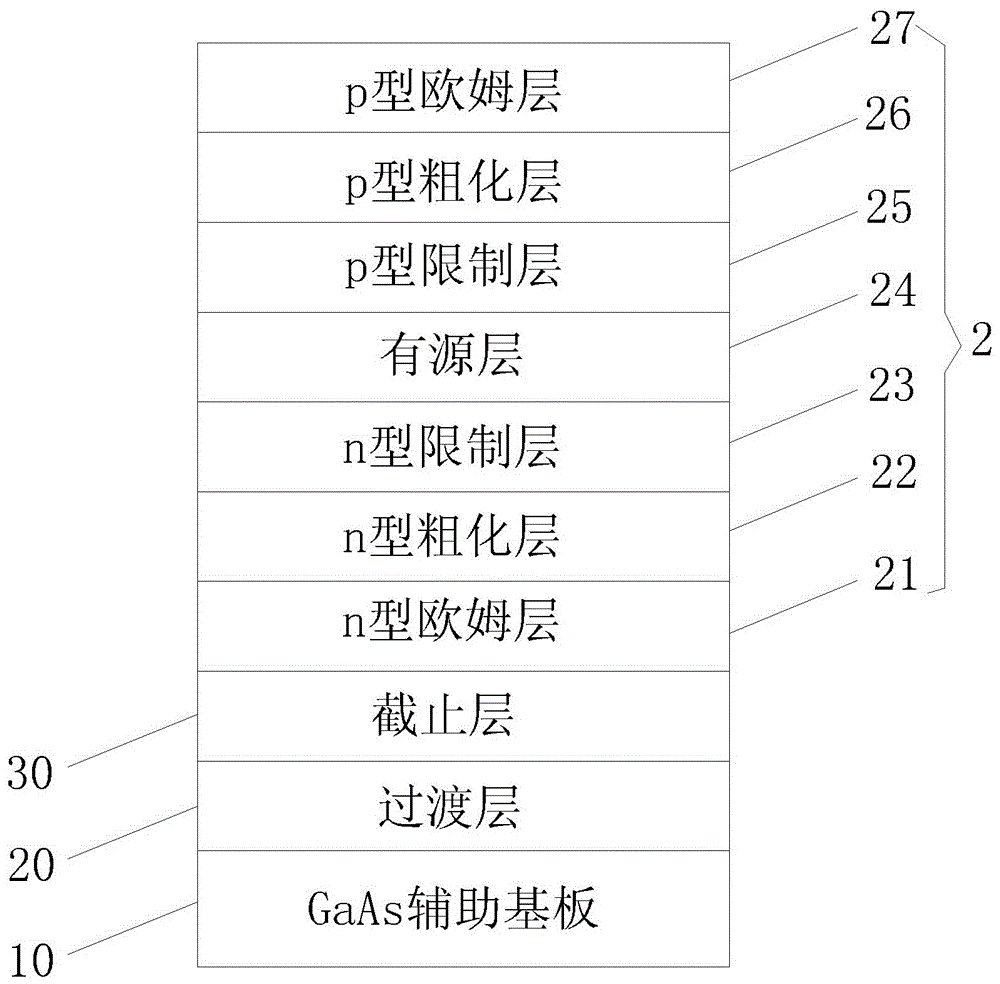

[0033] figure 1 As shown, a light emitting diode includes a transparent substrate 1 made of quartz, an epitaxial wafer 2, a first electrode 3 and a second electrode 4, and the epitaxial wafer 2 sequentially includes an n-type ohmic layer 21, an n-type roughening layer 22. N-type confinement layer 23, active layer 24, p-type confinement layer 25, p-type rough layer 26, p-type ohmic layer 27, the area of the end face of the n-type ohmic layer 21 is smaller than the end face of the n-type rough layer 22 The area of the end face of the p-type ohmic layer 27 is smaller than the area of the end face of the p-type roughened layer 26, the outer end face of the p-type ohmic layer 27 is also plated with an alloy layer 271, and the epitaxial wafer 2 rests on the p-type roughened layer 26 and one side of the p-type ohmic layer 27 are bonded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com