Light-emitting diode assembly

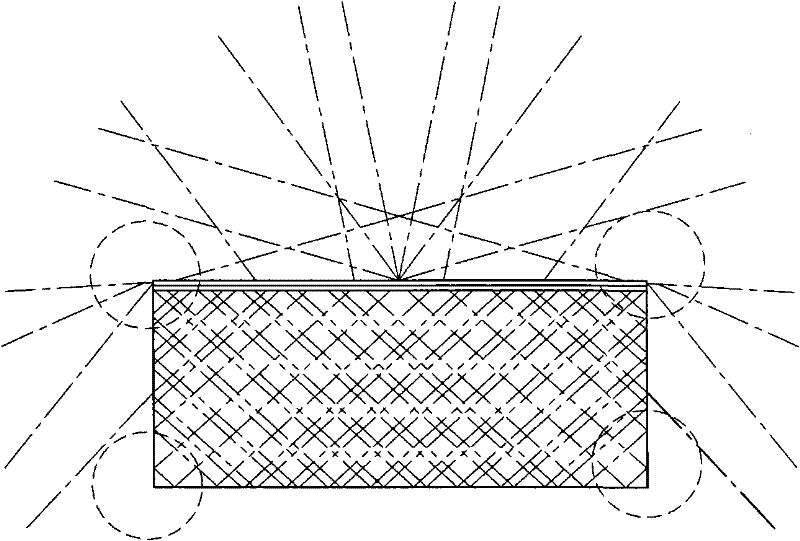

A technology of light-emitting diodes and components, applied in the direction of electrical components, semiconductor devices, circuits, etc., can solve the problems of reducing light output efficiency, achieve the effects of improving luminous efficiency, reducing the incidence angle, and reducing the probability of total reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] A light emitting diode assembly according to a preferred embodiment of the present invention will be described below with reference to related drawings, wherein the same components will be described with the same component symbols.

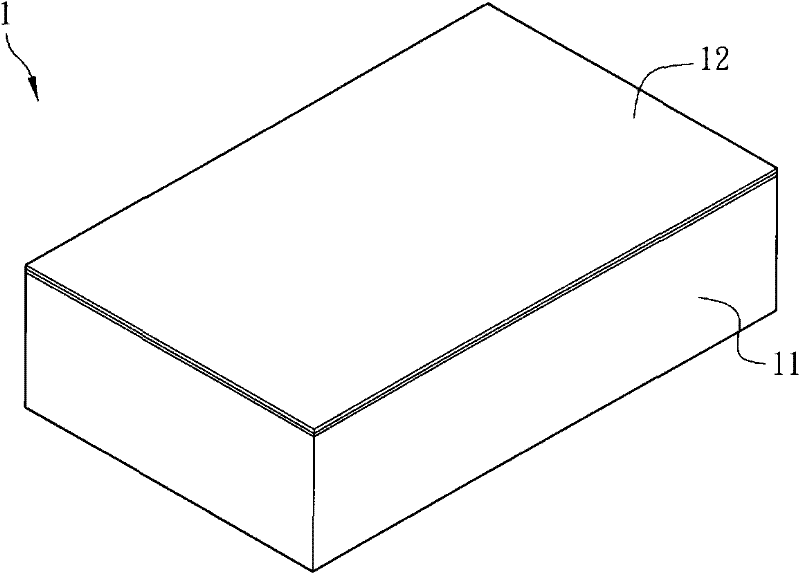

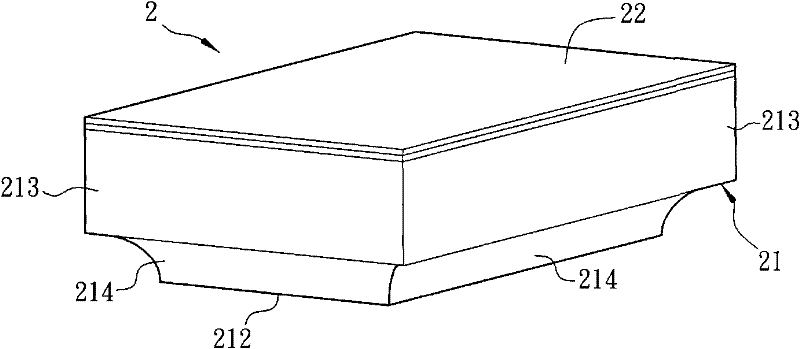

[0036] image 3 It is a three-dimensional schematic diagram of a light emitting diode assembly 2 in a preferred embodiment of the present invention, Figure 4 is a schematic side view of the light emitting diode assembly 2 . Please refer to image 3 and Figure 4 As shown, a light emitting diode assembly 2 according to a preferred embodiment of the present invention includes a substrate 21 and an epitaxial layer 22 . The epitaxial layer 22 is provided on the substrate 21 .

[0037] The material of the substrate 21 may include, for example, sapphire, silicon carbide (SiC), gallium phosphide (GaP) or silicon (Si). Here, sapphire is taken as an example. The substrate 21 has a first side 211 , a second side 212 and an annular side 213 . T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com