Fine mask plate and manufacturing method thereof

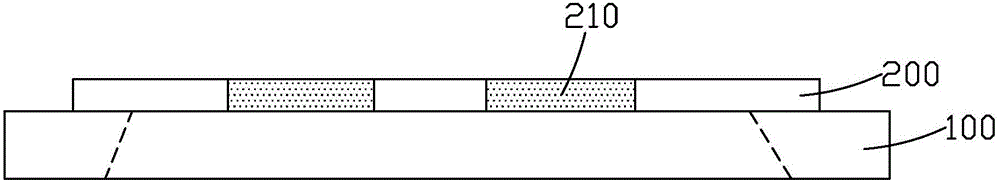

A technology of a fine mask plate and a manufacturing method, which is applied in the field of manufacturing organic light-emitting diode displays, can solve the problems of reducing the resolution of display devices, etc., and achieve the effects of reducing the shadow area of coating, improving the resolution, and simple manufacturing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

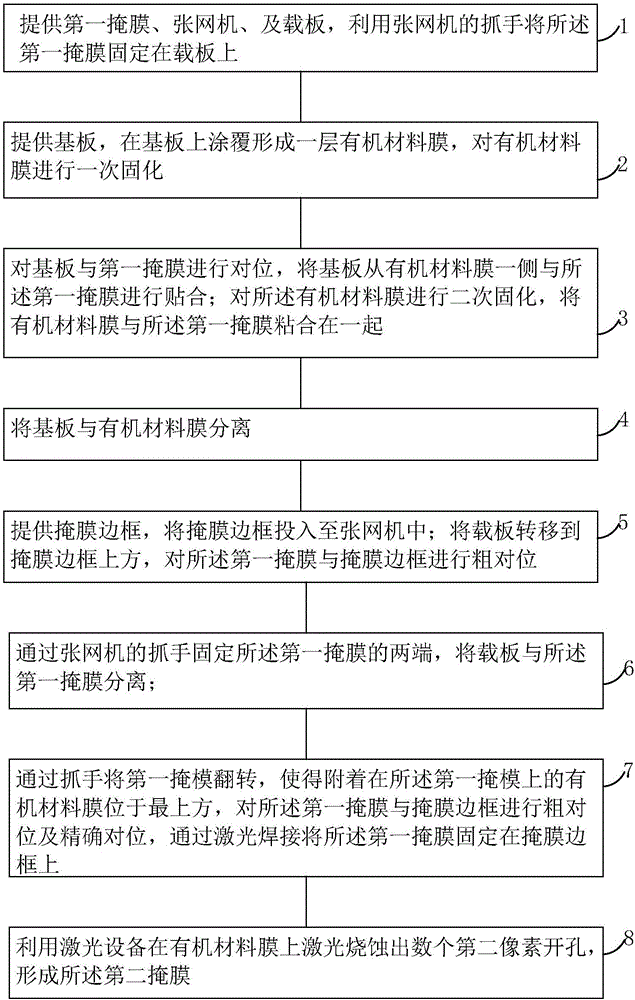

[0064] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

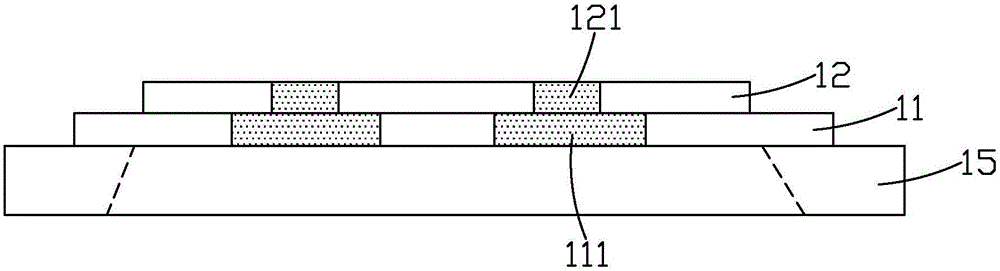

[0065] see figure 2 , the present invention provides a fine mask plate, including a mask frame 15, a first mask 11 fixed on the mask frame 15, and a second mask 12 arranged on the first mask 11 ;

[0066] The first mask 11 is provided with several first pixel openings 111;

[0067] More than one second pixel opening 121 is provided in the area corresponding to each first pixel opening 111 on the second mask 12 ;

[0068] The first mask 11 is a metal mask, and the second mask 12 is an organic material mask.

[0069] Specifically, the material of the second mask 12 is polyimide or polyamide, the thickness of the second mask 12 is less than 50 μm, preferably 20 μm or thinner, and the second pixel on it has holes 121 can be formed by laser ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com