Optical film

An optical film and light-collecting technology, applied in diffusing elements, prisms, etc., can solve the problems of light energy dispersion and light energy reduction, reduce the probability of total reflection, improve light uniformity, and improve light utilization efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

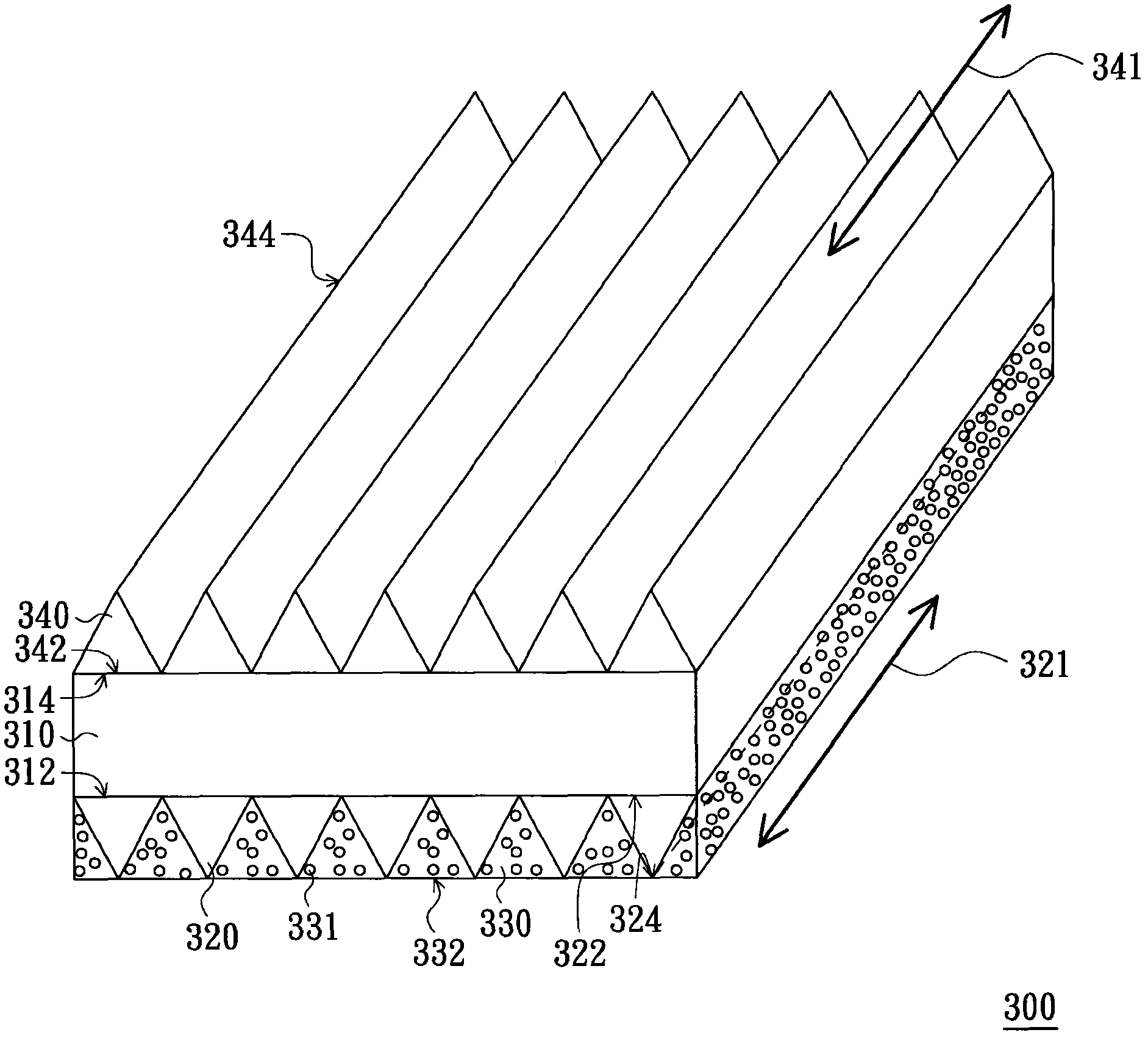

[0058] image 3 It is a three-dimensional schematic diagram of an optical film according to an embodiment of the present invention. Please refer to image 3 , the optical film 300 of this embodiment includes a substrate 310 , a plurality of first light-collecting structures 320 and a plurality of diffusion structures 330 . The substrate 310 has a light incident surface 312 and a light exit surface 314 opposite to each other, and the distance between the light incident surface 312 and the light exit surface 314 is, for example, between 30 microns and 300 microns.

[0059]The diffusion structures 330 are disposed on the light incident surface 312 , and there are gaps between two adjacent diffusion structures 330 , and the first light collection structures 320 are respectively disposed in these gaps, and the first light collection structures 320 are adjacent to the diffusion structures 330 . From another perspective, each first light collecting structure 320 has a bottom surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com