Manufacturing method for surface roughening of GaN-based optoelectronic device

A surface roughening and electronic device technology, which is applied in the field of p-type layer roughening on the surface of photoelectric conversion devices, can solve the problem of reducing the conductivity type of the p-GaN layer, increasing the contact resistance between the electrode and the p-GaN, and the roughening effect is not ideal. and other problems, to achieve the effect of less surface defects and less chance of reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

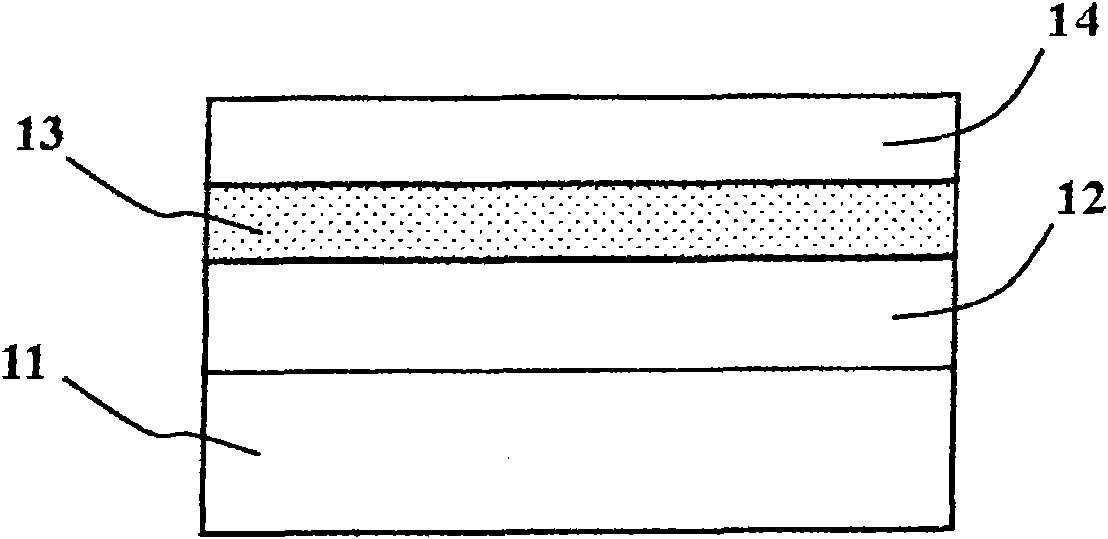

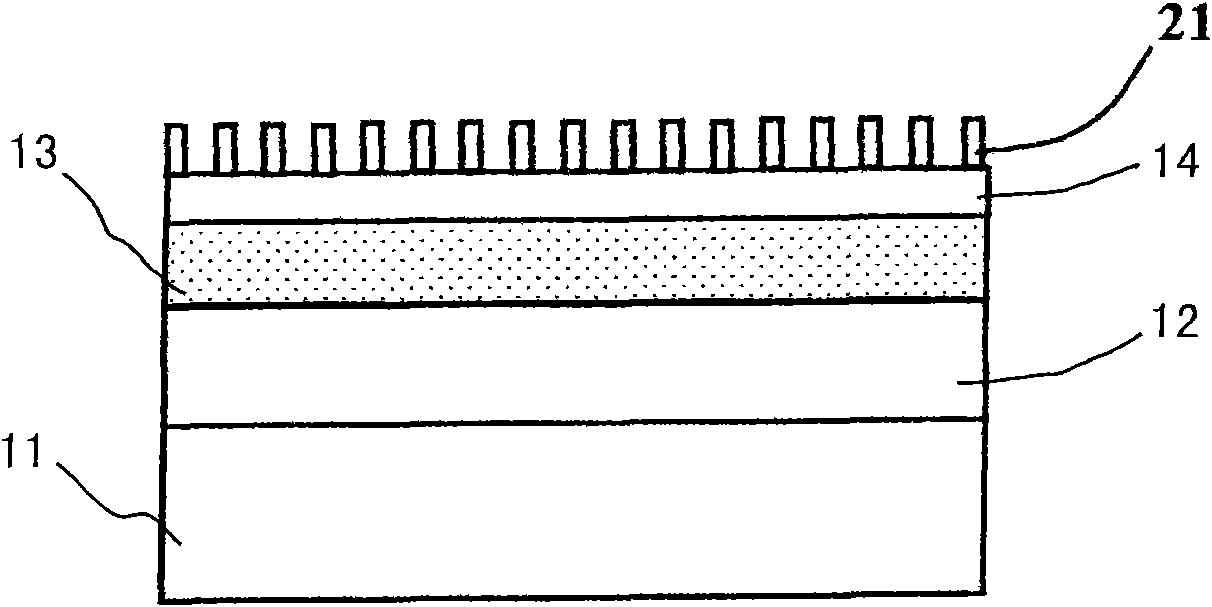

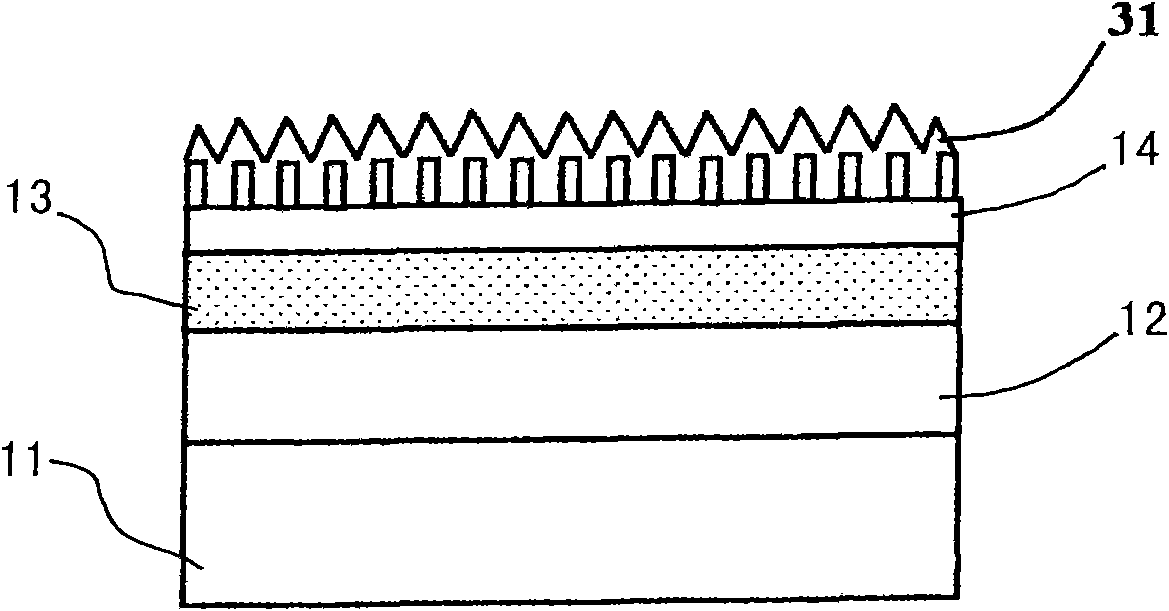

[0036] Embodiment one: see Figure 1-Figure 3 shown. Use Metal Organic Chemical Vapor Deposition (MOCVD) method to epitaxially grow n-type layer 12, i-type layer 13, p-type layer 14 sequentially on substrate 11, wherein said substrate 11 is a sapphire substrate; n-type layer 12 is The n-type GaN epitaxial layer has a thickness of 3000nm; the i-type layer 13 is In 0.1 Ga 0.9 N / GaN multi-quantum well structure with a thickness of 60nm; the p-type layer 14 is a p-type GaN material with a thickness of 150nm; then deposit 200nm thick SiO on the p-type layer 14 2 Dielectric film; then in SiO 2 A layer of metal Ni is evaporated on the dielectric film, and the metal Ni is aggregated into metal islands with a diameter of about 10-200 nanometers by means of rapid annealing. Use the metal island as a mask material to etch the p-type layer 14 with an etching depth of 100nm, thereby producing the nano-column array 21; then, grow the p-type thick p-type layer on the surface of the epita...

Embodiment 2

[0037] Embodiment two: see Figure 1-Figure 3 shown. Use metal organic chemical vapor deposition (MOCVD) method to epitaxially grow n-type layer 12, i-type layer 13, p-type layer 14 sequentially on substrate 11, wherein said substrate 11 is n-type GaN substrate material; n-type Layer 12 is an n-type GaN epitaxial layer with a thickness of 300nm; the i-type layer 13 is In 0.1 Ga 0.9 N / GaN multi-quantum well structure with a thickness of 60nm; the p-type layer 14 is a p-type GaN material with a thickness of 150nm; then deposit 200nm thick SiO on the p-type layer 14 2 Dielectric film; then in SiO 2 A layer of metal Ni is evaporated on the dielectric film, and the metal Ni is aggregated into metal islands with a diameter of about 10-200 nanometers by means of rapid annealing. Use the metal island as a mask material to etch the p-type layer 14 with an etching depth of 100nm, thereby producing the nano-column array 21; then, grow the p-type thick p-type layer on the surface of t...

Embodiment 3

[0038] Embodiment three: see Figure 1-Figure 3 shown. Use Metal Organic Chemical Vapor Deposition (MOCVD) method to epitaxially grow n-type layer 12, i-type layer 13, p-type layer 14 sequentially on substrate 11, wherein said substrate 11 is a sapphire substrate; n-type layer 12 is The n-type GaN epitaxial layer has a thickness of 3000nm; the i-type layer 13 is intrinsic In 0.2 Ga 0.8 N layer with a thickness of 200nm; the p-type layer 14 is a p-type GaN material with a thickness of 150nm; then deposit 200nm thick SiO on the p-type layer 14 2 Dielectric film; then in SiO 2 A layer of metal Ni is evaporated on the dielectric film, and the metal Ni is aggregated into metal islands with a diameter of about 10-200 nanometers by means of rapid annealing. Use the metal island as a mask material to etch the p-type layer 14 with an etching depth of 100nm, thereby producing the nano-column array 21; then, grow the p-type thick p-type layer on the surface of the epitaxial wafer wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com