LED structure and manufacturing method thereof

A technology of light-emitting diodes and manufacturing methods, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of cumbersome and time-consuming, increase costs, and do not meet the commercial application of light-emitting diodes, so as to reduce the probability of total reflection, make it simple, Effect of improving light extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The detailed content and technical description of the present invention will be further described by examples, but it should be understood that these examples are for illustrative purposes only, and should not be construed as limitations on the implementation of the present invention.

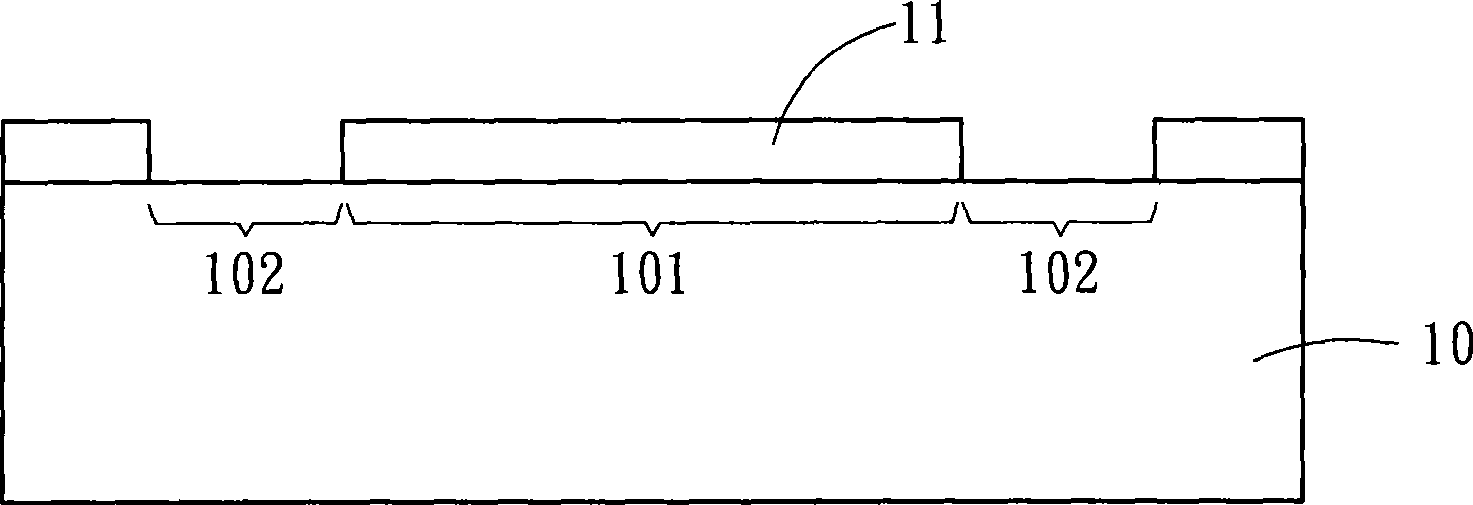

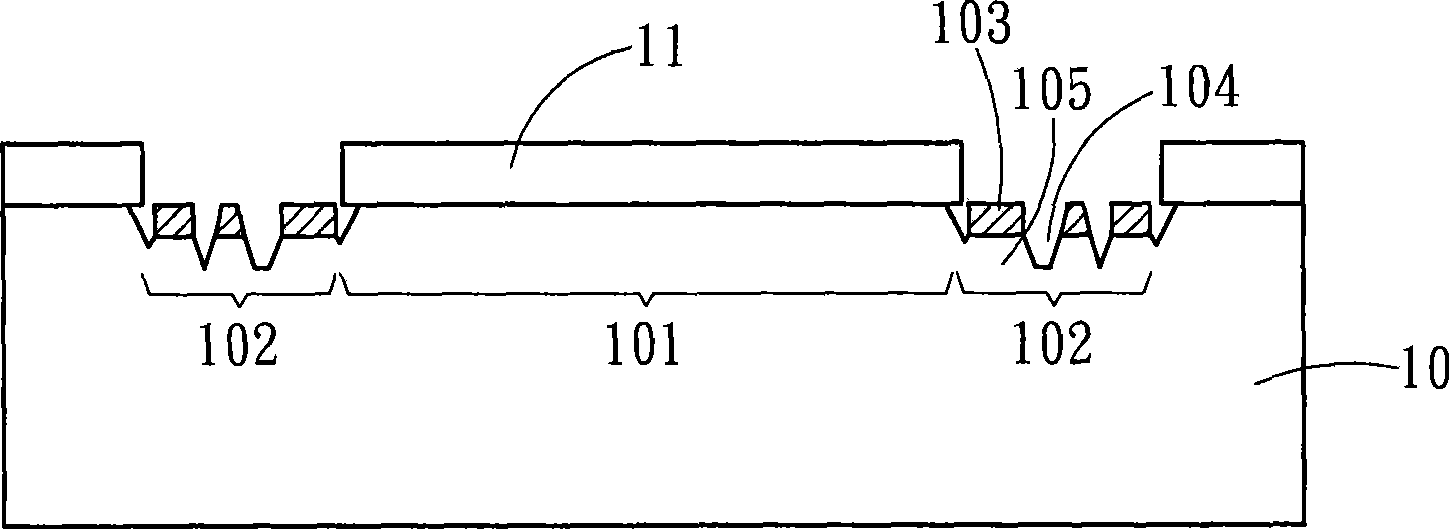

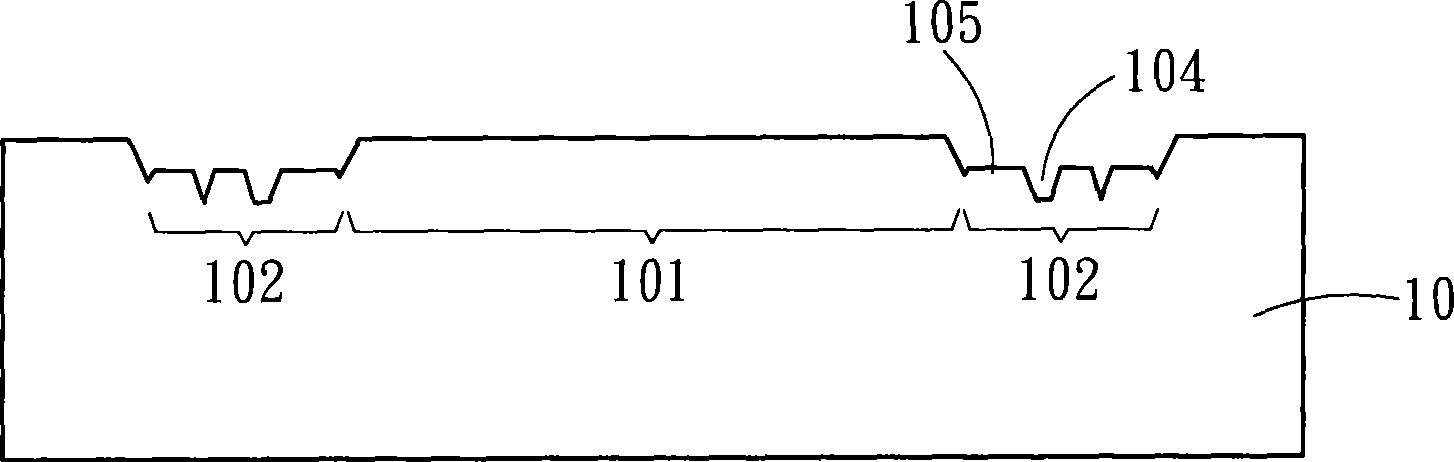

[0020] see Figure 1 to Figure 5 shown. The manufacturing method of the light-emitting diode of the present invention includes: first, providing the substrate 10, and the substrate 10 is one of sapphire, silicon carbide, silicon, gallium arsenide, aluminum nitride, and gallium nitride substrates. A passivation layer 11 is grown on the surface of the substrate 10, and the passivation layer 11 is patterned to define the element area 101 covered by the passivation layer 11 and the scribe area 102 exposed on the surface of the substrate 10 (such as figure 1 shown).

[0021] Then, the substrate 10 is placed in the first solution to react, so that the surface of the substrate 10 exposed from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com