LED chip structure and manufacturing method thereof

A technology of LED chips and manufacturing methods, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve problems such as unsatisfactory luminous efficiency, reduce the probability of total reflection, reduce the probability of total reflection problems, and increase transmittance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] When the flip-chip LED chip structure in the prior art is in operation, the light emitted by it will be transmitted through the substrate.

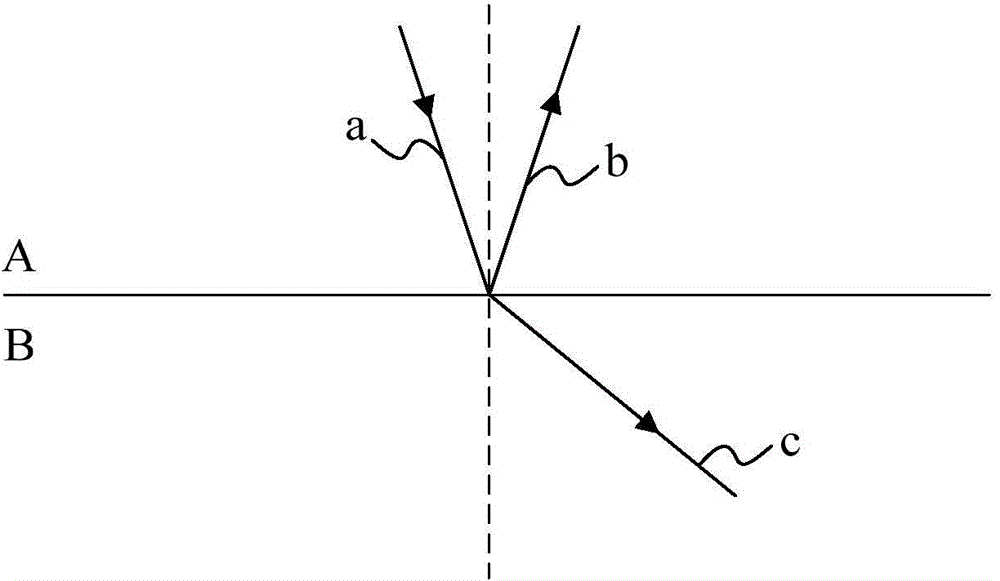

[0049] However, the refractive index of the substrate used in the LED chip structure in the prior art is quite different from that of air, please refer to figure 1 , wherein A medium represents the substrate of the LED chip structure in the prior art, medium B represents the air, and the light a generated by the LED chip structure is transmitted from the substrate to the air, but the light is transmitted from the solid substrate as an optically dense When the medium enters an optically sparse medium with a refractive index close to 1, refraction will occur (please refer to light c). When the refractive index of the substrate is greatly different from that of the air, it is easy to cause total reflection of the light that should have entered the air ( Please refer to ray b) re-entering the substrate.

[0050] This will affect the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com