Large-angle lens and large-angle light-emergent LED (Light Emitting Diode) light source module

An LED light source and large-angle technology, which is applied in the field of LED packaging, can solve the problems of unsatisfactory distribution and utilization, and achieve the effects of reducing labor installation costs and product costs, increasing the irradiation surface, and increasing the luminous angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0042] Embodiment 1 of large-angle lens

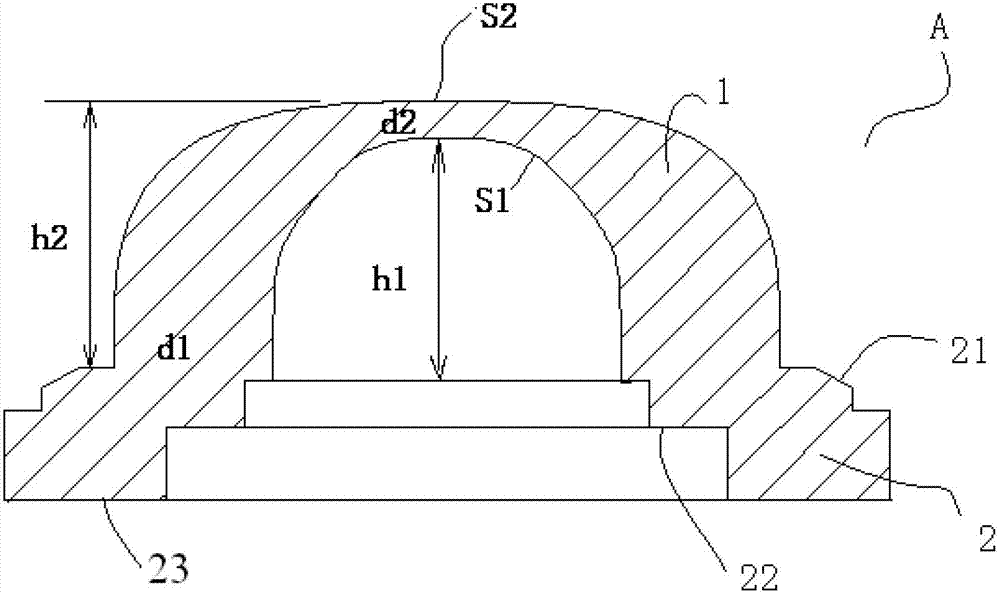

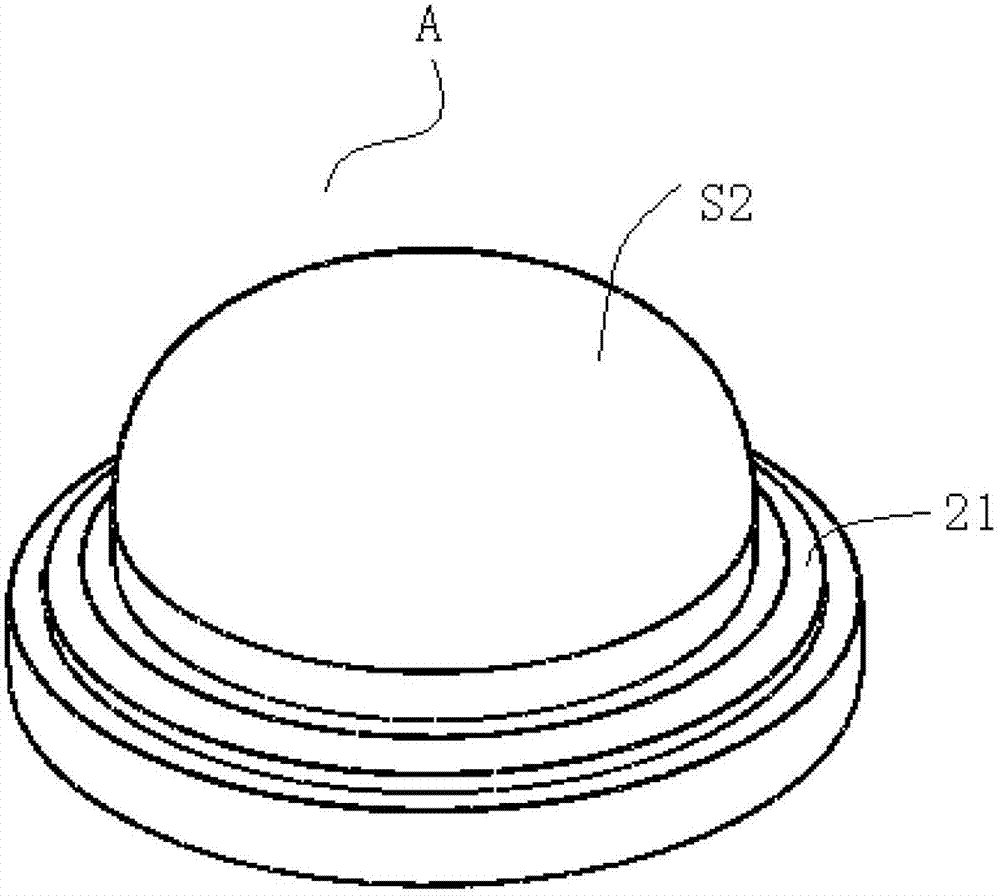

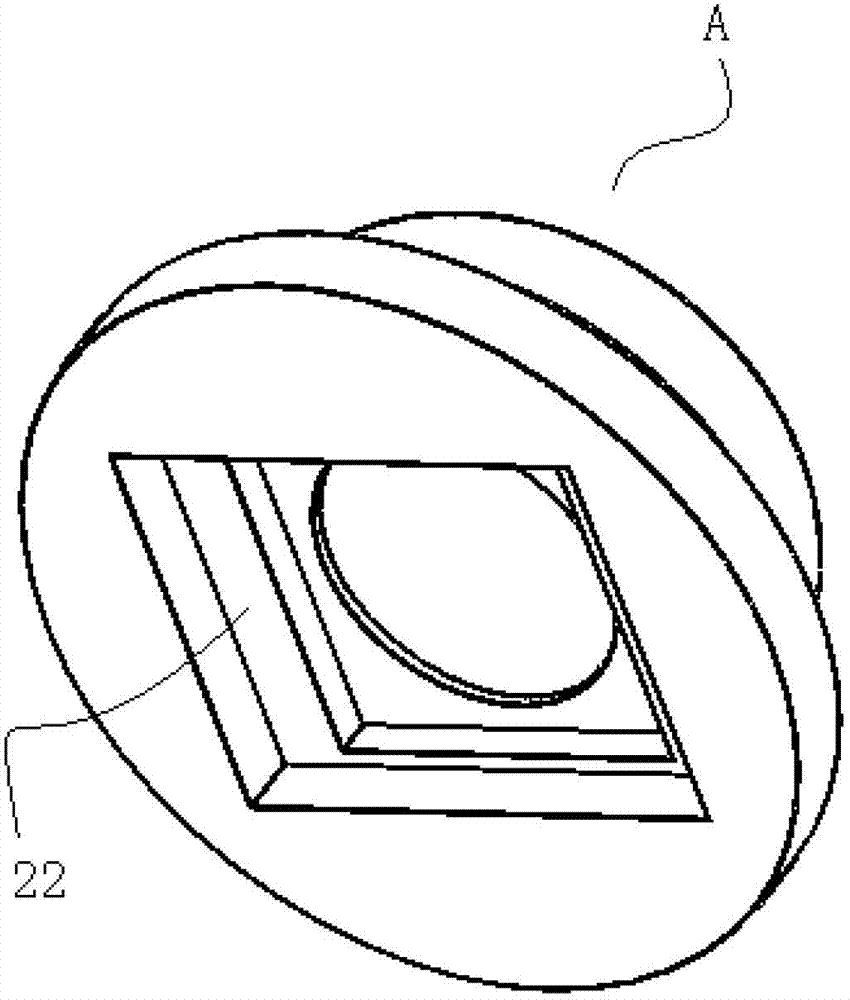

[0043] see figure 1 , figure 2 , image 3, the large-angle lens A of this embodiment includes a shell-shaped main body 1 with an open lower end, and a mounting part 2 integrally formed with the main body is provided below the main body 1; wherein, the main body has an incident surface S1 and an outgoing surface S2, and the incident surface S1 and the exit surface S2 are both arranged rotationally symmetrically with respect to the central axis. The material used for the large-angle lens in this embodiment is a light-transmitting material.

[0044] Wherein, the incident surface S1 is a light-transmitting concave surface, and the light-transmitting concave surface gradually chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com