Three-dimensional light-emitting diode (LED) light source module and lamp with LED light source module

A technology of LED light source and LED chip, applied in the direction of light source, electric light source, optical element for changing the spectral characteristics of emitted light, etc., can solve the problems of increased cost, low light extraction efficiency, low installation efficiency, etc. The effect of installation, improving the light output efficiency and saving the amount of silica gel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051]In order to make the object, technical solution, and effect of the present invention more clear, specific implementations will be used for further description below.

[0052] Embodiment 1 of LED light source module

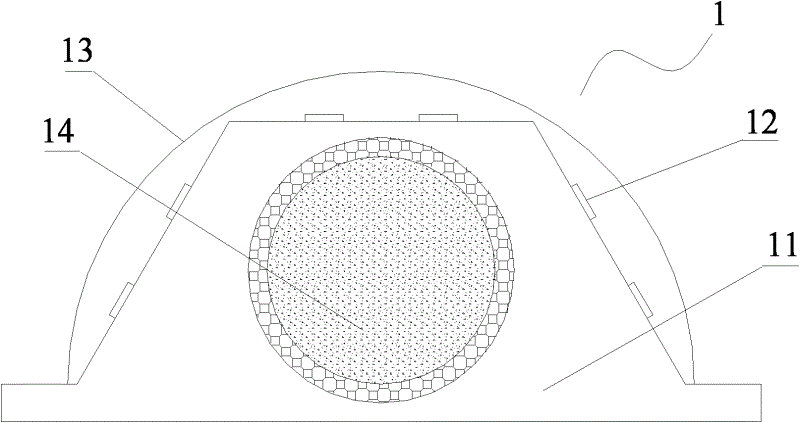

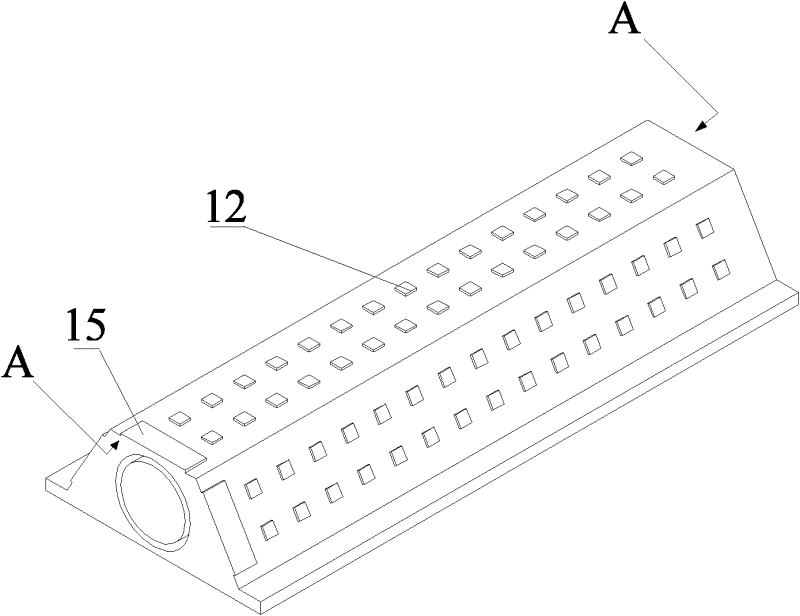

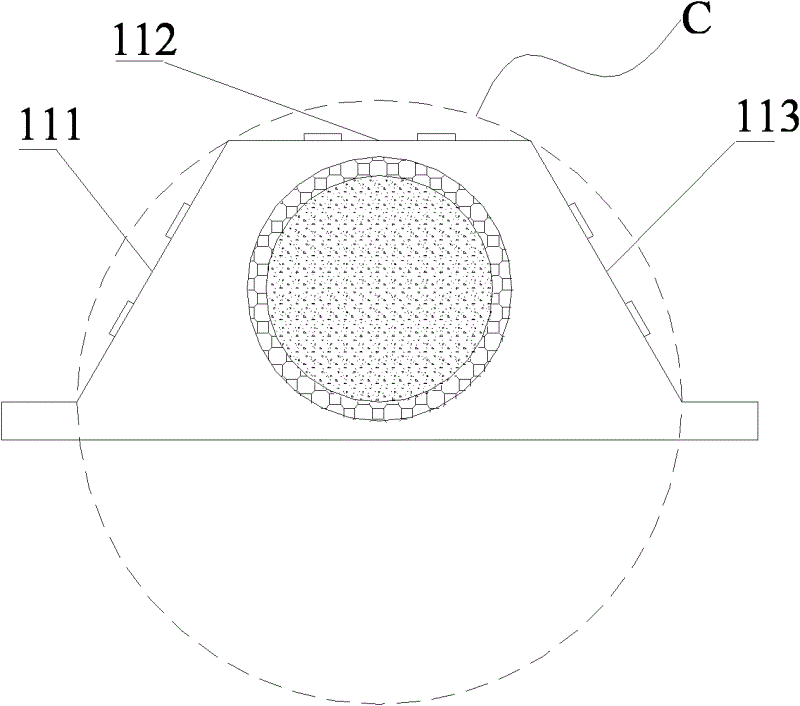

[0053] as attached figure 1 , figure 2 , image 3 , Figure 4 As shown, the three-dimensional LED light source module 1 in this embodiment includes: a base 11, an LED chip 12 mounted on the base 11, an encapsulation lens 13 covering the LED chip 12, and a corresponding lens embedded in the base 11. Variable heat transfer structure 14.

[0054] Wherein, the base 11 is strip-shaped, and the base 11 has three LED chip mounting surfaces, which are the first LED chip mounting surface 111, the second LED chip mounting surface 112 and the third LED chip mounting surface 113, and the third LED chip mounting surface 113. The two LED chip mounting surfaces are arranged along the horizontal direction, and the first LED chip mounting surface 111 and the third LED ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com