A sensor installation adjustment device

An installation adjustment, sensor technology, applied in the direction of measuring devices, instruments, etc., to achieve the effect of precise horizontal adjustment, improved installation accuracy, and efficient horizontal installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

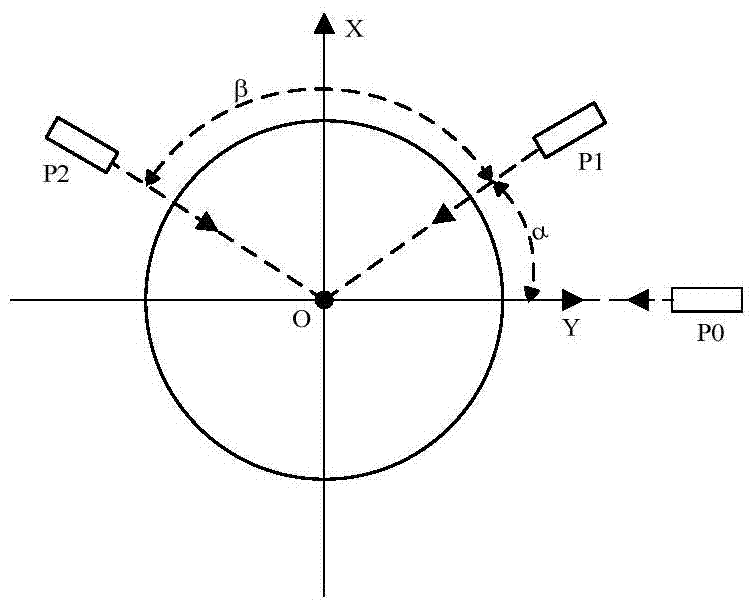

[0019] The principle of three-point method error separation technology is as follows: figure 1 shown. The three sensors P0, P1, and P2 are installed at different positions on the circumference of the workpiece, and the angles between the three sensors are α and β respectively. It is required that the installation axes of the three sensors intersect at the center of the circle O, which is also the origin and origin of the coordinate system XOY. Rotate the center of the table. When measuring, the sensor is fixed, and the workpiece to be measured is driven by the rotary table to make a rotary motion. According to the output equation of the measurement results and the error separation equation of the three-point method, the roundness error of the workpiece and the rotation error of the rotary axis can be separated by using appropriate paramete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com