Truss robot multisection cross beam horizontal adjusting device

A truss robot and level adjustment technology, applied in the direction of manipulators, manufacturing tools, etc., can solve the problems of increased cost, uncoordinated appearance, small contact surface, etc., and achieve the effects of improving installation performance, facilitating promotion and use, and increasing contact surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

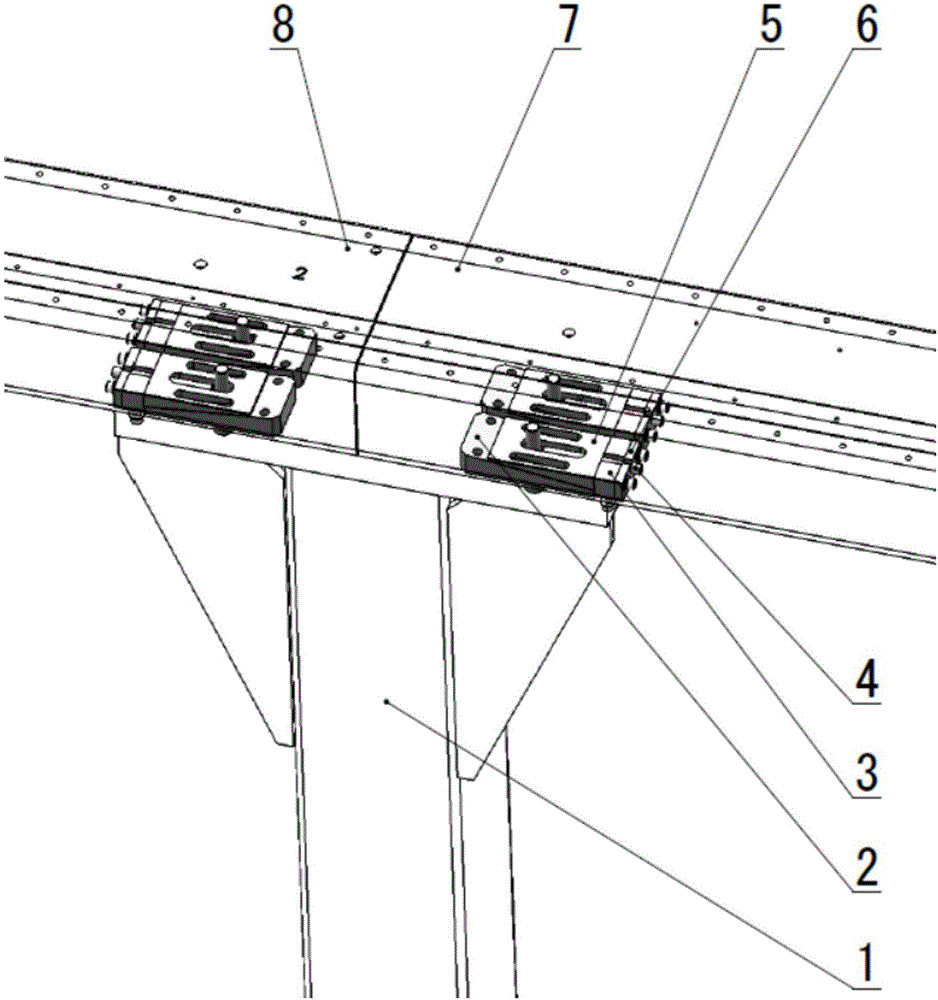

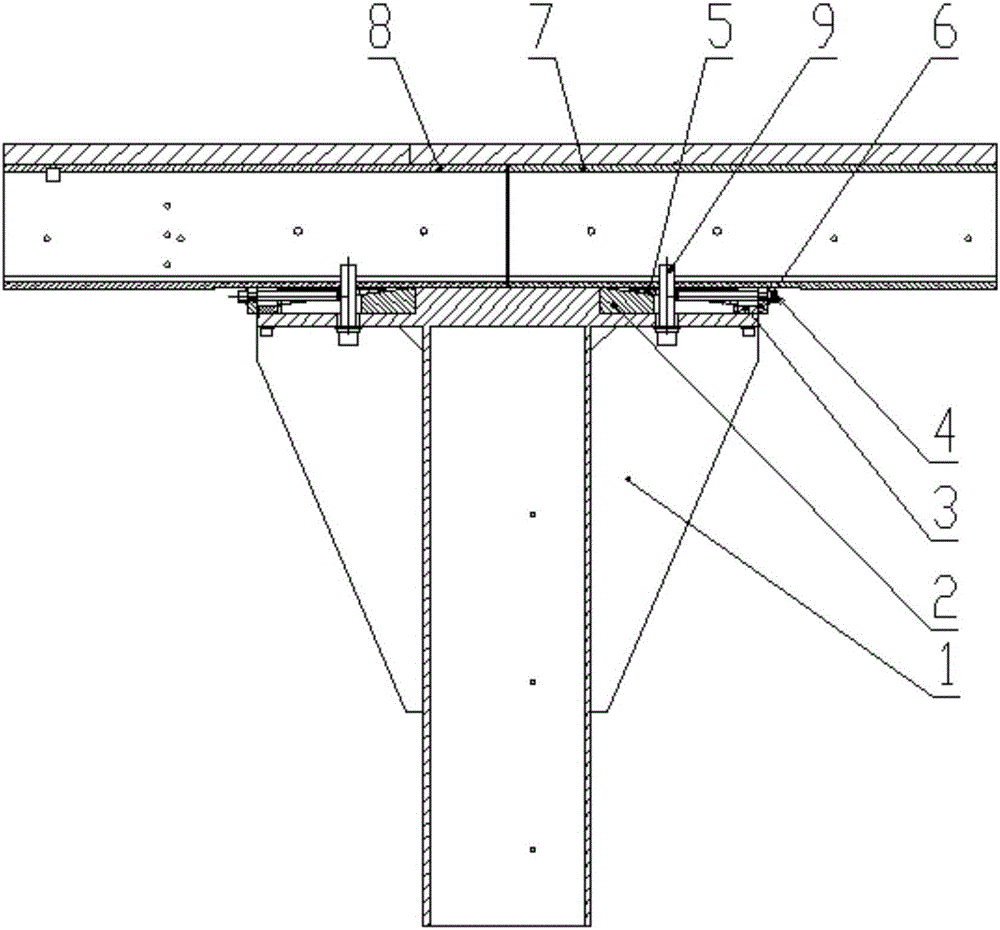

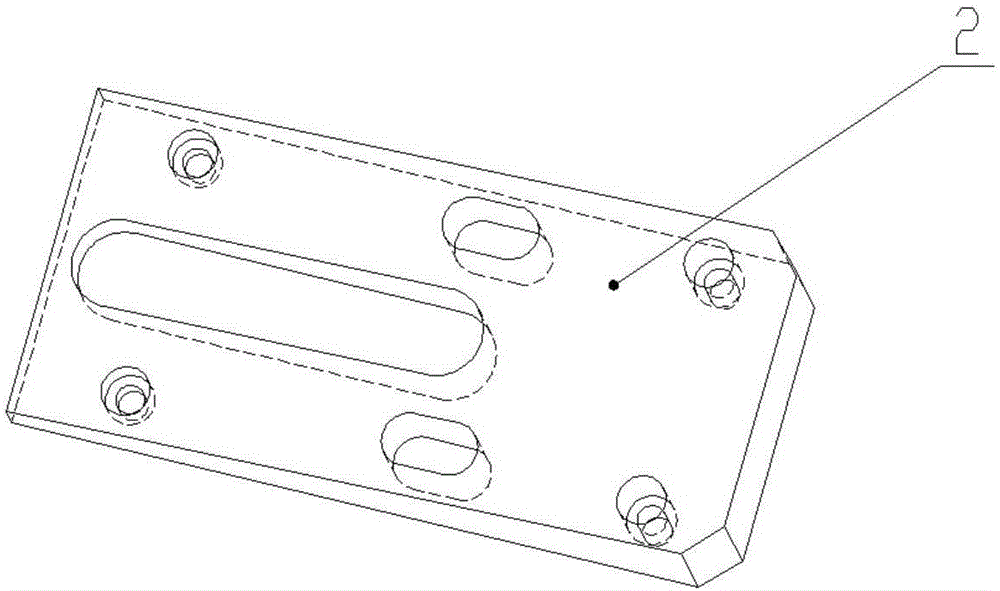

[0022] Such as Figure 1 to Figure 7 As shown, the multi-section crossbeam level adjustment device of the present invention includes a truss column 1, an inclined plane fixed block 2, a large notch fixed stop 3, an adjusting bolt 4, an inclined plane adjustment block 5, and a small notch fixed stop 6. Such as image 3 and Figure 6 As shown, the top of the inclined plane fixing block 2 of the present invention is provided with an upper inclined plane, and the bottom of the inclined plane adjusting block 5 is provided with a lower inclined plane, and the upper inclined plane is consistent with the inclination of the lower inclined plane. After the upper slope, the plane of the top of the slope adjustment block 5 is in a device parallel to the slope of the slope fixed block 2 bottoms.

[0023] Such as figure 1 , figure 2 As shown, in the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com