Adjustable veneer hanging component combination

A veneer, adjustable technology, applied in covering/lining, construction, building structure, etc., can solve the problems of affecting the construction progress, small unevenness, brittleness, etc., to improve construction efficiency, relax installation accuracy, ensure The effect of flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

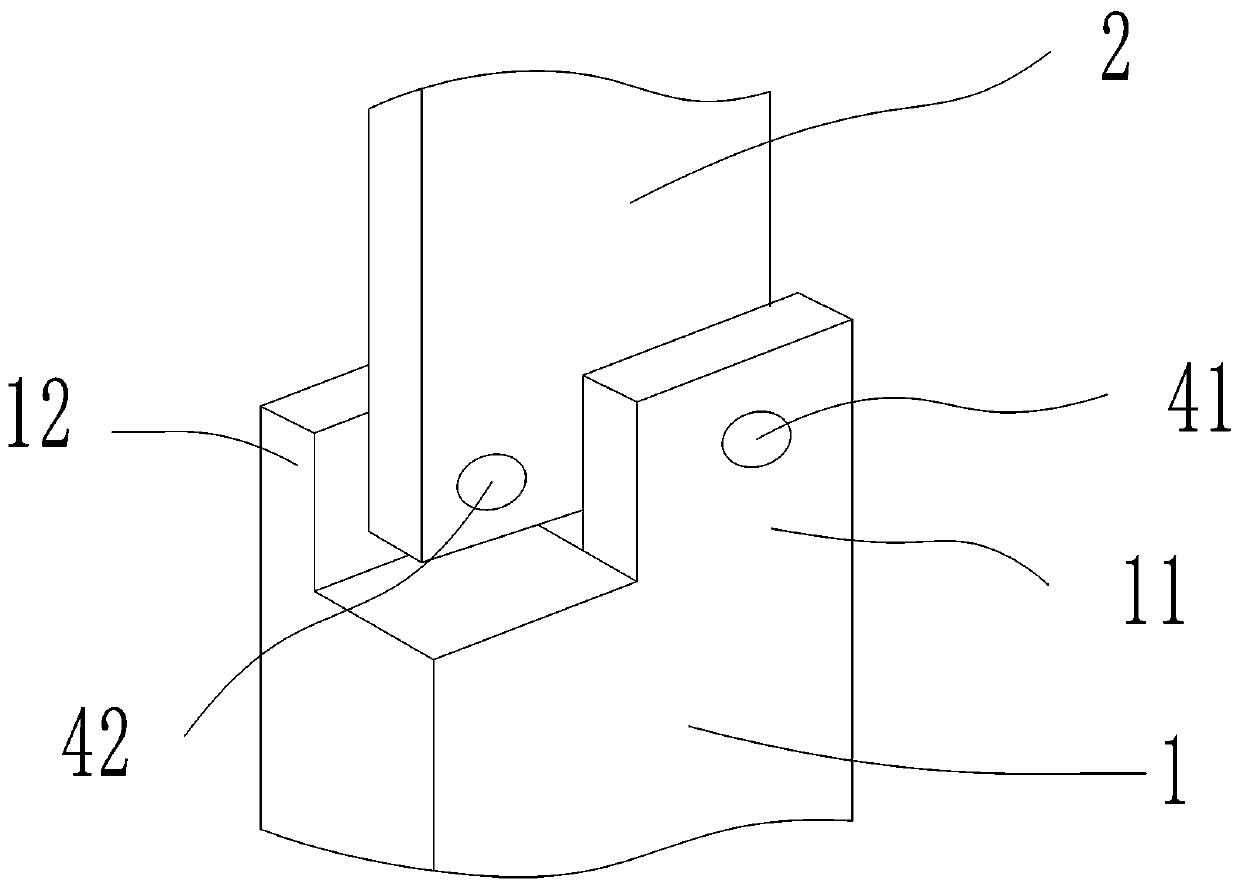

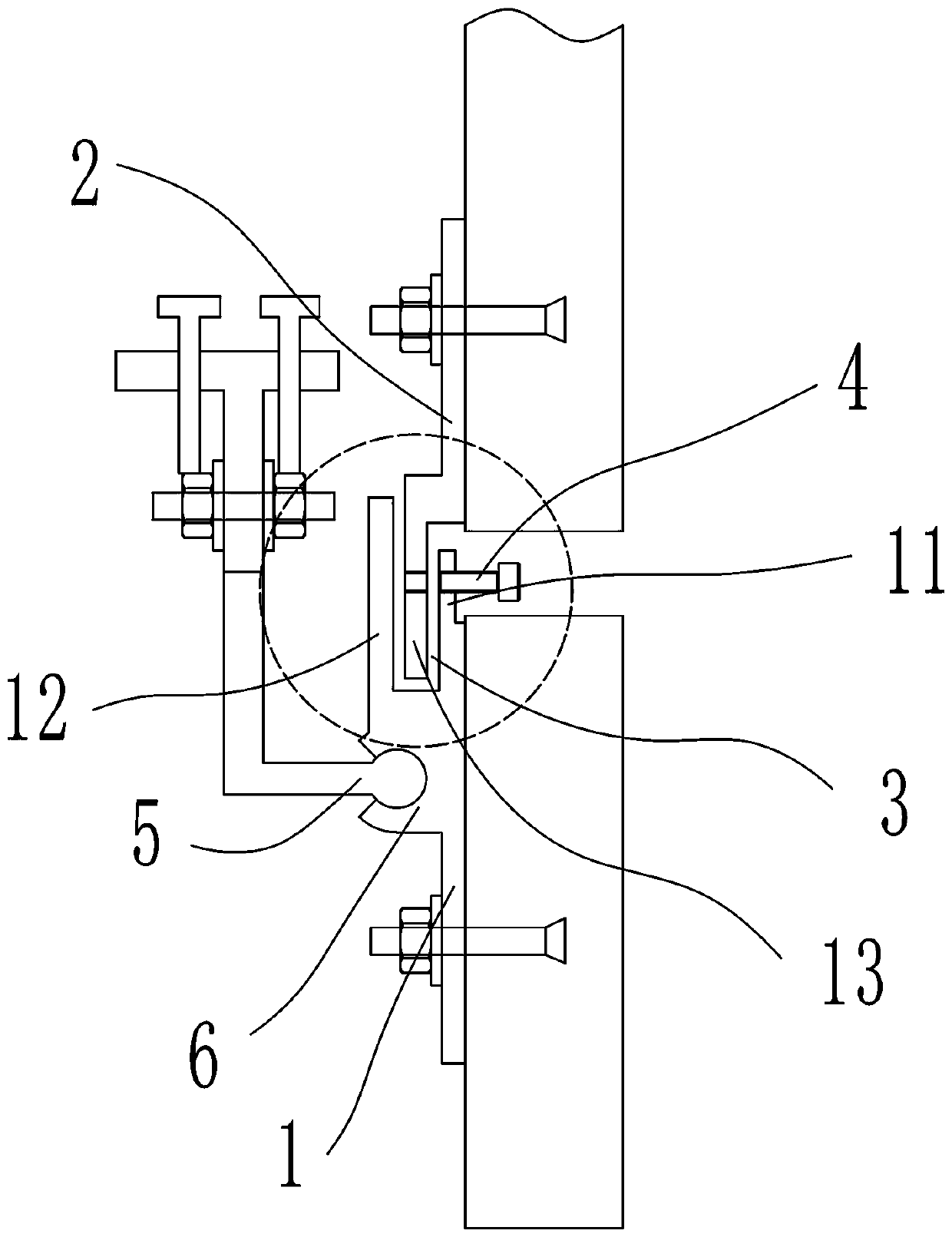

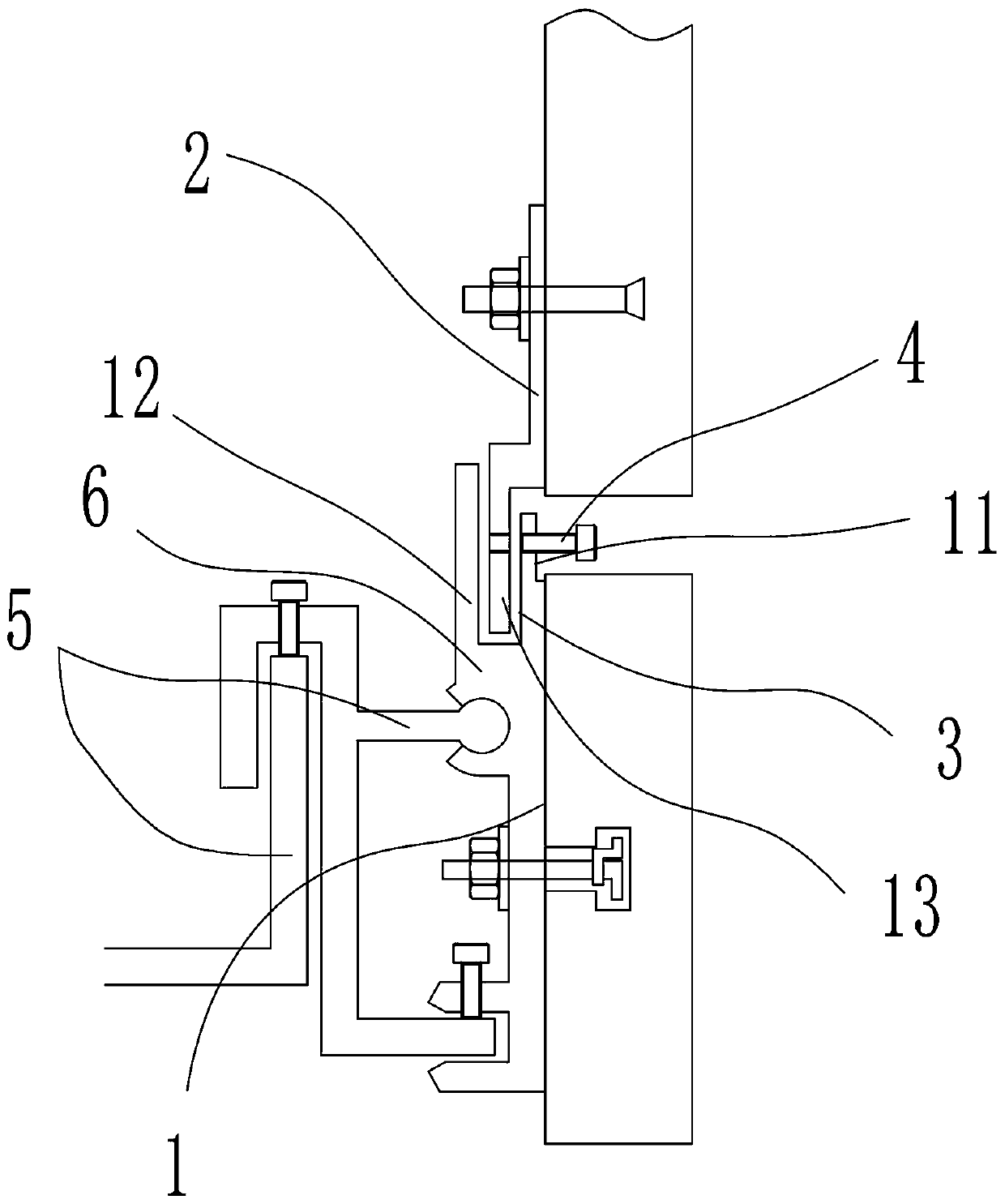

[0047] Embodiment one, such as figure 1 , 2 , 3, 4, 5, 6, 7 and 8, an adjustable veneer pendant combination, including an upper pendant 1 installed above the veneer and a lower pendant 2 installed below the veneer, the upper pendant It is male-female connected with the lower pendant, the top of the upper pendant 1 or the lower pendant 2 is provided with a front catch 11, a rear catch 12 or a positioning plug 13, when the upper hanger 1 is provided with the front catch 11 and When the rear block 12 is used, the lower hanger 2 is provided with the positioning plug 13; when the lower hanger 2 is provided with the front block 11 and the rear block 12, the upper hanger 1 is provided with There is the positioning plug 13, the adjustment area 3 is formed between the front block 11 and the rear block 12, the positioning plug 13 is arranged in the adjustment area 3, and the bolt 4 is arranged on the positioning plug , the bolt 4 controls the positioning plug 13 to move back and forth...

Embodiment 2

[0055] Embodiment 2, the upper hanging part 1 and the lower hanging part 2 are connected to the decorative panel through a back bolt structure or a common bolt structure or a T-shaped structure, and the upper hanging part 1 is detachably connected to the decorative panel. The lower hanging part 2 is detachably connected to the veneer, the upper hanging part 1 and the support point 5 are provided with a hooking part 6, and the hooking part 6 and the upper hanging part 1 are connected by a steering shaft connection. The connection of the steering shaft will achieve relative rotation, which can realize the rotation adjustment of the pendant relative to the installation place. The connection of the steering shaft may not be the connection of concentric shafts or concentric circles, as long as the relative rotation adjustment can be achieved. After the adjustment position is locked, the joint of the steering shaft can be locked by screws, so as to avoid swing failures in the later s...

Embodiment 3

[0056] Embodiment 3, the upper hanger 1 and the lower hanger 2 are connected to the decorative panel through a back bolt structure or a common bolt structure or a T-shaped structure, and it is specially reminded that the back bolt connecting the upper hanger 1 and the decorative panel is a new type of positioning back bolt , a hooking portion 6 is provided between the upper hanging part 1 and the support point 5, and the hanging part 6 and the upper hanging part 1 are provided with two connection points, one of which is connected by a steering shaft connection, and the steering The shaft connection will achieve relative rotation, and the rotation adjustment of the pendant relative to the installation place can be realized. The connection of the steering shaft may not be the connection of concentric shafts or concentric circles, as long as the relative rotation adjustment can be achieved. The other The connection point is a plug-in connection, after two connection points are con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com