Air cushion track leveling system based on single chip microcomputer control

A single-chip control, guide rail technology, applied in educational appliances, instruments, teaching models, etc., can solve problems such as rough balance adjustment, cumbersome steps, affecting experimental accuracy, etc., to improve measurement accuracy and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

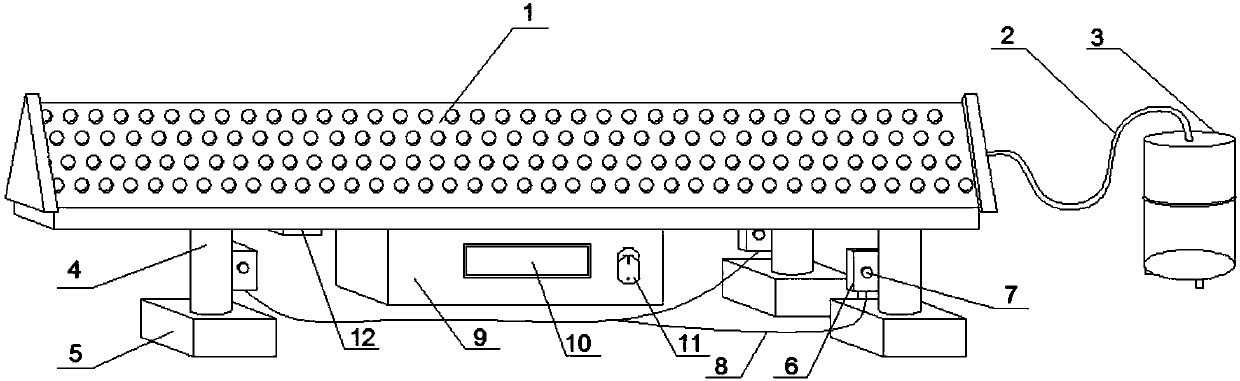

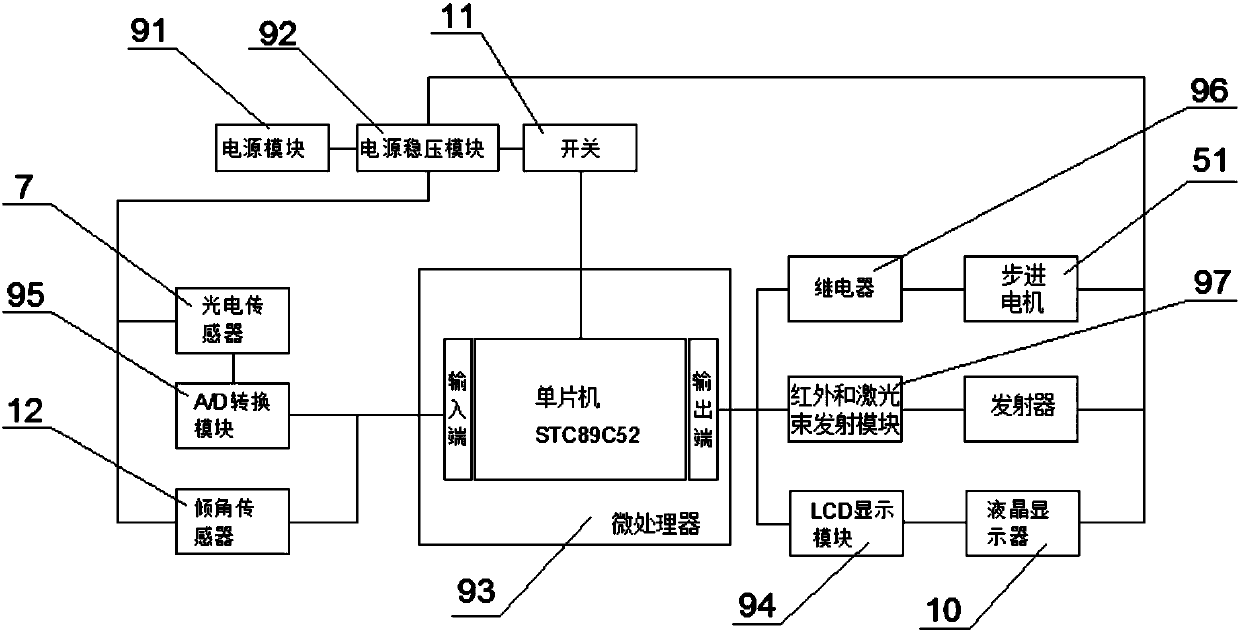

[0030] as attached figure 1 To attach Figure 7 shown

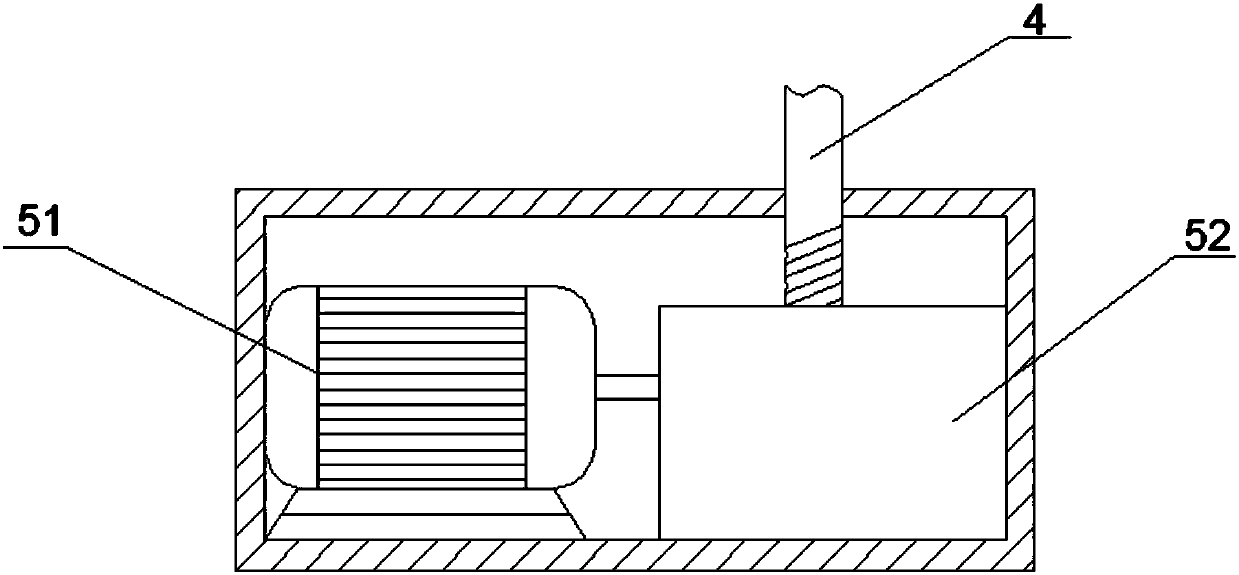

[0031]The present invention provides an air cushion guide rail leveling system based on single-chip microcomputer control, including an air cushion guide rail 1, an air supply pipe 2, an air pump 3, a foot 4, a telescopic adjustment device 5, a measuring cup 6, a photoelectric sensor 7, a liquid connector 8, and a controller 9 , a liquid crystal display 10, a switch 11 and an inclination sensor 12, wherein: one end of the air cushion guide rail 1 is connected to the air pump 3 through the air supply pipe 2, and the lower side of the air cushion guide rail 1 is fixed above the telescopic adjustment device 5 through the feet 4; the feet 4 Or three telescopic adjustment devices 5 are used in pairs, and the structure and driving principle are the same, one pair is installed on one side below the air cushion guide rail 1, and the remaining two pairs are installed on the other side below the air cushion guide rail 1; the measu...

Embodiment 2

[0039] as attached image 3 to attach Figure 9 shown

Embodiment

[0040] Embodiment: including air cushion guide rail 1, air supply pipe 2, air pump 3, adjusting foot 4, telescopic adjusting device 5, infrared emitting device 6, base point supporting foot 7, base 8, reflective target 9, inclination sensor 10, controller 11, liquid crystal display Screen 12 and switch 13, wherein: one end of the air cushion guide rail 1 is connected to the air pump 3 through the air supply pipe 2, and the lower side of the air cushion guide rail 1 is fixed above the telescopic adjustment device 5 or the base 8 through the adjustment leg 4 or the base point leg 7, the base point leg 7 A reflective target 9 is installed on the side facing the adjusting leg 4; two of the adjusting leg 4 or the telescopic adjusting device 5 are used in pairs, and the structure and driving principle are the same, and they are installed in pairs on the lower side of the air cushion guide rail 1; Two infrared emitting devices 6 are used, and they are fixed at a certain angle horizont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com