White light LED light source component and production method thereof

A technology of LED light source and production method, which is applied in the direction of light source, electric light source, point light source, etc., which can solve the problems of low light output efficiency of LED lamps and wide-angle lighting of LED lamps, and achieve simple manufacturing process and high light output efficiency , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

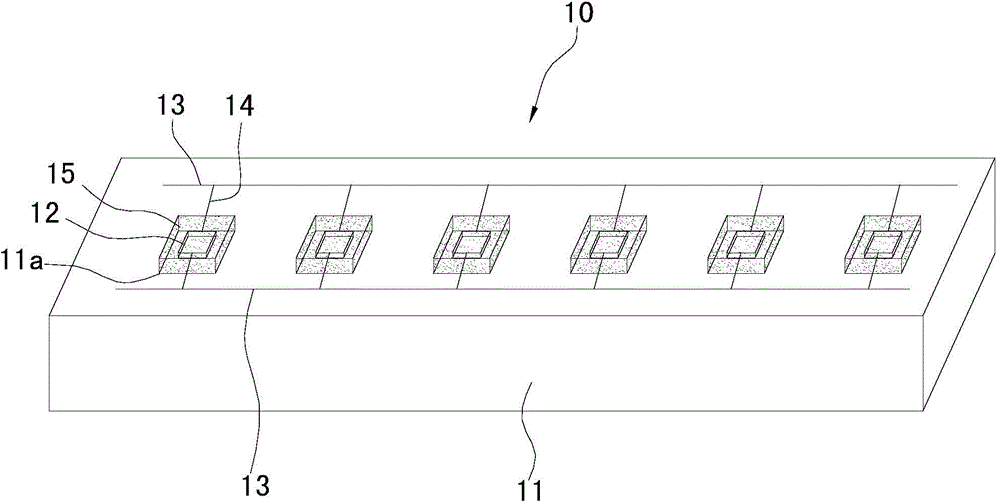

[0037] The production method of the above-mentioned white LED light source assembly 10 includes the following steps:

[0038] Step S101, uniformly mixing low melting point glass powder and yttrium aluminum garnet fluorescent powder to prepare initial raw materials, the weight percentage of each component of the initial raw materials is: 49.5% PbO, 30% SiO 2 , 20% ZnO and 0.5% yttrium aluminum garnet phosphor.

[0039] Step S102, calcining the above-mentioned initial raw materials in a furnace at 400° C., and then forming the matrix 11 by hot pressing with a hot pressing die;

[0040] Step S103 , on the base 11 , an encapsulation cavity 11 a is formed by extruding a cofferdam of phosphor silica gel, and 5 wt % of yttrium aluminum garnet phosphor is mixed in the phosphor silica gel;

[0041] Step S104, screen printing silver paste on the substrate 11 to form two main lines;

[0042]Step S105, bonding the LED blue light chip 12 in the packaging cavity 11a through phosphor silic...

Embodiment 2

[0046] The production method of the white LED light source assembly 10 in this embodiment includes the following steps:

[0047] Step S201, uniformly mixing low melting point glass powder and yttrium aluminum garnet fluorescent powder to prepare initial raw materials, the weight percentage of each component of the initial raw materials is: 55% PbO, 25% SiO 2 , 15% ZnO and 5% yttrium aluminum garnet phosphor.

[0048] Step S202, calcining the above-mentioned initial raw materials in a furnace at 400°C, and then forming the base body 11 by hot pressing with a hot pressing die, and the base body 11 is hot pressing molded with an encapsulation cavity 11a;

[0049] Step S203, screen printing silver paste on the substrate 11 to form two main lines;

[0050] Step S204, bonding the LED blue light chip 12 in the packaging cavity 11a through phosphor silica gel, where 10 wt% of yttrium aluminum garnet phosphor is mixed in the phosphor silica gel;

[0051] Step S205, welding one end of...

Embodiment 3

[0055] The production method of the white LED light source assembly 10 in this embodiment includes the following steps:

[0056] Step S301, uniformly mixing low melting point glass powder and yttrium aluminum garnet fluorescent powder to prepare initial raw materials, the weight percentage of each component of the initial raw materials is: 45% PbO, 30% SiO 2 , 20% ZnO and 5% yttrium aluminum garnet phosphor.

[0057] Step S302, calcining the above-mentioned initial raw materials in a furnace at 600°C, and then forming the base body 11 by hot pressing with a hot pressing die, and the base body 11 is hot pressing molded with an encapsulation cavity 11a;

[0058] Step S303, screen printing silver paste on the substrate 11 to form two main lines;

[0059] Step S304, bonding the LED blue light chip 12 in the packaging cavity 11a through phosphor silica gel, where 8wt% of yttrium aluminum garnet phosphor is mixed in the phosphor silica gel;

[0060] Step S305, welding one end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com