Organic electroluminescent device and preparation method

An electroluminescence device and luminescence technology, which is applied in the direction of electric solid-state devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of poor refractive index, loss of light output, low light output performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

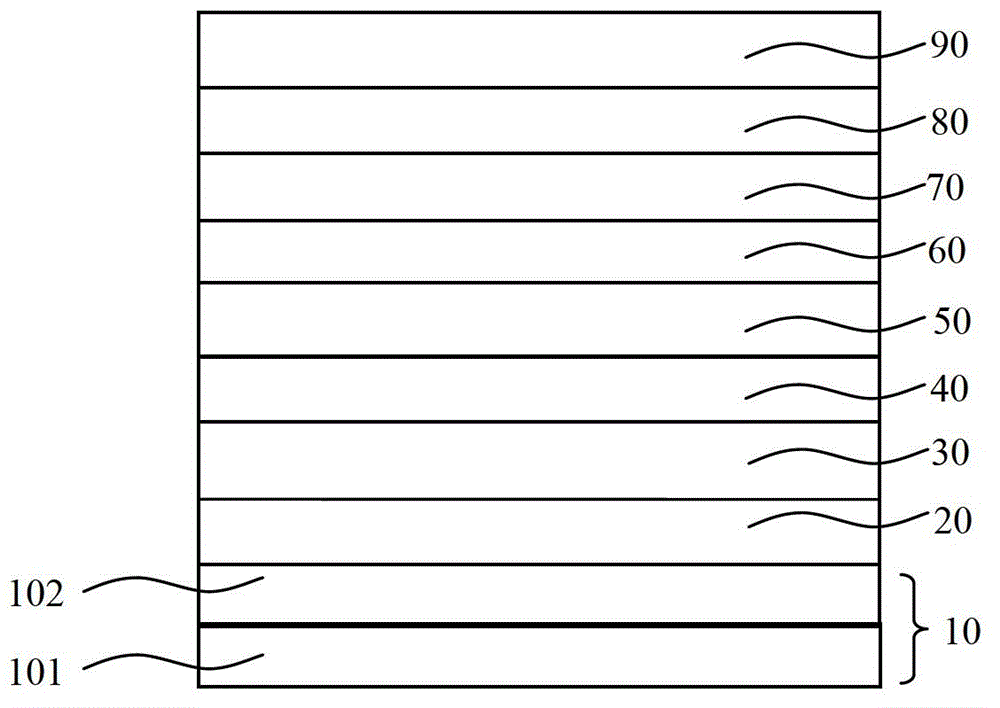

[0100] A method for preparing an organic electroluminescent device, comprising the following steps:

[0101] (1) After rinsing the N-LASF44 glass with distilled water and ethanol, soak it in isopropanol for one night to obtain a clean glass substrate;

[0102] (2) In a high-vacuum coating system (Shenyang Scientific Instrument Development Center Co., Ltd.), spin-coat PEDOT:PSS aqueous solution at a speed of 4000rpm for 15s on a clean glass substrate, and then dry it at 100°C for 15min to obtain the thickness Be the polymer layer of 50nm, wherein, the massfraction of PEDOT in PEDOT:PSS aqueous solution is 3.5%, the weight ratio of PEDOT and PSS is 3:1;

[0103] HfO 2 :SiO2 2 The mixture was deposited on the polymer layer by electron beam evaporation to obtain a scattering layer with a thickness of 200 nm, where HfO 2 :SiO2 2 The mixture is HfO 2 According to the mass fraction of 40% doped to SiO 2 The mixture formed in , the condition of electron beam evaporation is energ...

Embodiment 2

[0112] A method for preparing an organic electroluminescent device, comprising the following steps:

[0113] (1) After rinsing the N-LAF36 glass with distilled water and ethanol, soak it in isopropanol for one night to obtain a clean glass substrate;

[0114] (2) In a high-vacuum coating system (Shenyang Scientific Instrument Development Center Co., Ltd.), spin-coat PEDOT:PSS aqueous solution at a speed of 6000rpm for 30s on a clean glass substrate, and then dry it at 200°C for 10min to obtain the thickness Be the polymer layer of 20nm, wherein, the massfraction of PEDOT in PEDOT:PSS aqueous solution is 1%, the weight ratio of PEDOT and PSS is 2:1;

[0115] Will Nb 2 o 5 : The SiO mixture is deposited on the polymer layer by electron beam evaporation to obtain a scattering layer with a thickness of 50nm, where Nb 2 o 5 : SiO mixture as Nb 2 o 5 According to the mixture formed by doping SiO with 50% mass fraction, the condition of electron beam evaporation is energy densi...

Embodiment 3

[0121] A method for preparing an organic electroluminescent device, comprising the following steps:

[0122] (1) After rinsing the N-LASF31A glass with distilled water and ethanol, soak it in isopropanol for one night to obtain a clean glass substrate;

[0123] (2) In a high vacuum coating system (Shenyang Scientific Instrument Development Center Co., Ltd.), spin-coat PEDOT:PSS aqueous solution at a speed of 2000rpm for 10s on a clean glass substrate, and then dry it at 50°C for 30min to obtain the thickness Be the polymer layer of 80nm, wherein, the massfraction of PEDOT in PEDOT:PSS aqueous solution is 10%, the weight ratio of PEDOT and PSS is 6:1;

[0124] Will Ta 2 o 5 : The SiO mixture is deposited on the polymer layer by electron beam evaporation to obtain a scattering layer with a thickness of 500nm, where Ta 2 o 5 :SiO mixture is Ta 2 o 5 According to the mixture formed by doping SiO with 10% mass fraction, the condition of electron beam evaporation is energy den...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com