A foreship arrangement for a vessel of the deplacement type

A technology for ships and bows, applied in the new design field, which can solve problems such as negative impact on work ability, increase the risk of accidents and injuries, reduce the quality of rest time, etc., to improve safety, reduce energy requirements and fuel consumption, simple and the effect of a solid structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In the following descriptions and claims, unless otherwise specified, all descriptions about directions are explained on the basis that the ship is in a three-dimensional coordinate system, where the length direction, width direction and height direction of the ship correspond to the coordinate system The x-axis, y-axis and z-axis, where the x-axis and y-axis lie in the horizontal plane, and the z-axis lies in the vertical plane. Furthermore, the forward direction of the ship corresponds to the positive x direction.

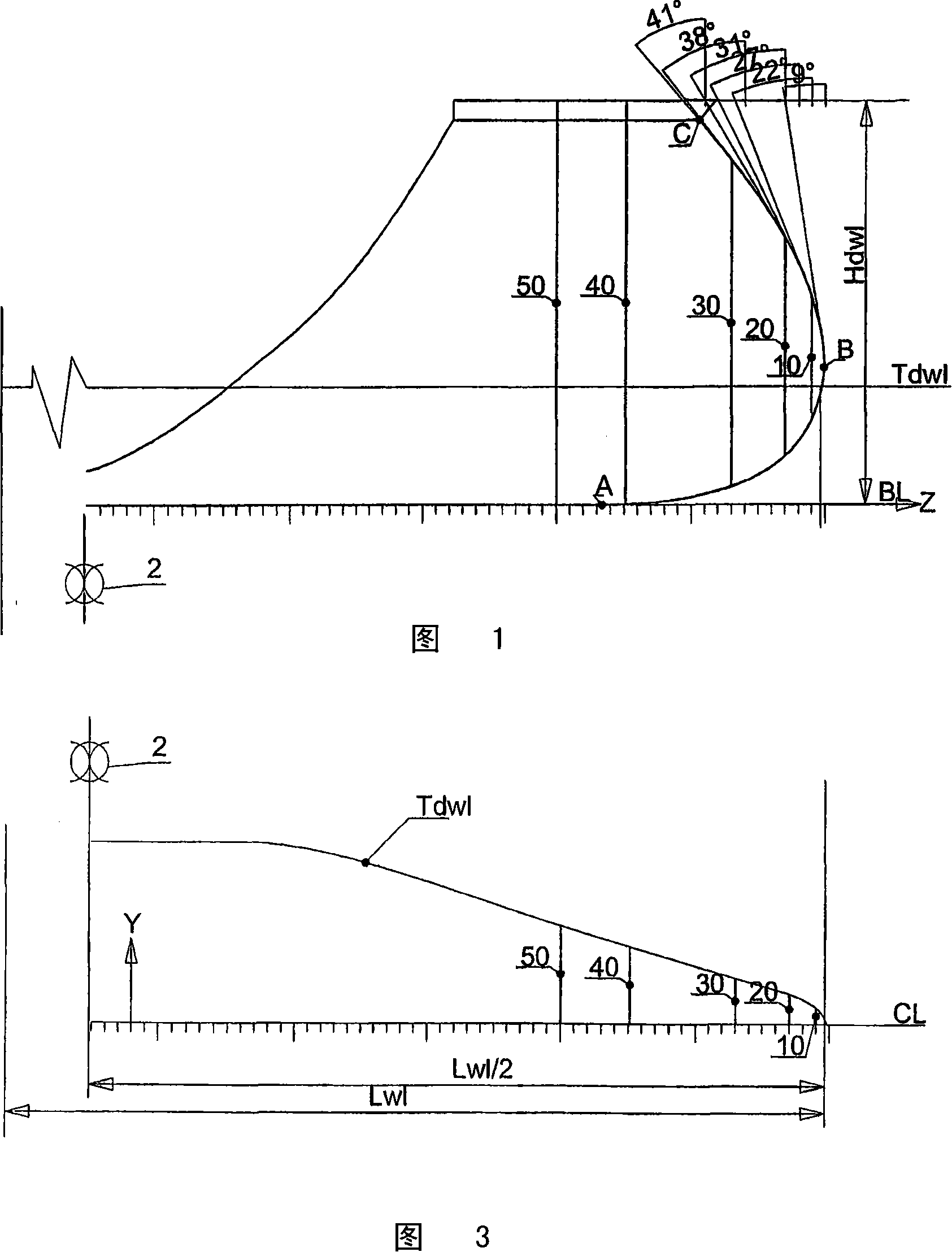

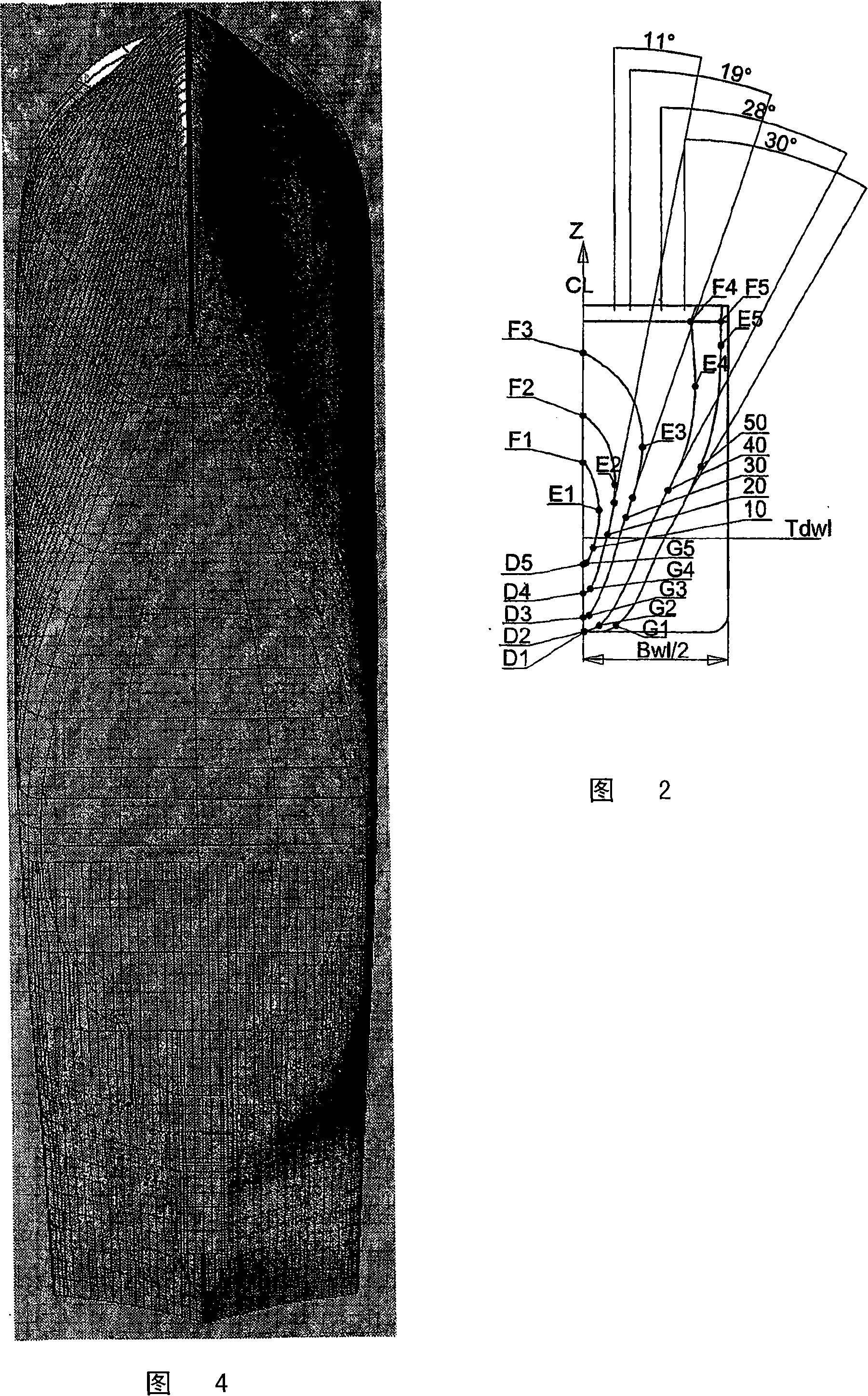

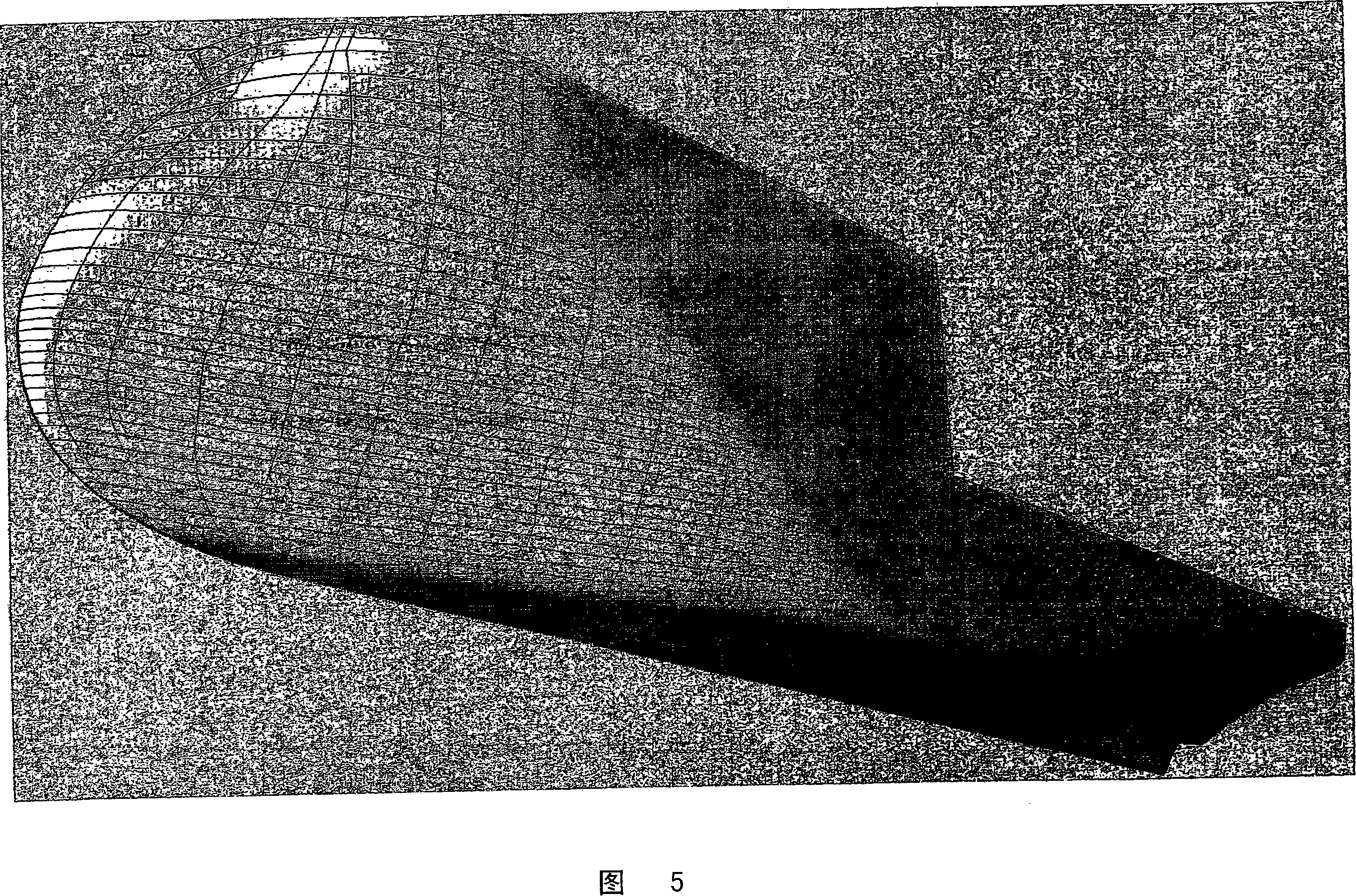

[0039] This new bow, shown starting from the midship mark 2 of the ship, has an elongated and distinctive bow shape. Figure 1 shows the bow shape 1 of the ship, starting at point A on the baseline 3, and rising with increasing curvature while being drawn forward in the length direction (x direction) to slightly at the design waterline Point B above Tdwl. From point B, the bowline 1 rises further, but with a gradually decreasing curvature and backwards (i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com