LED packager

A light-emitting diode, diode technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

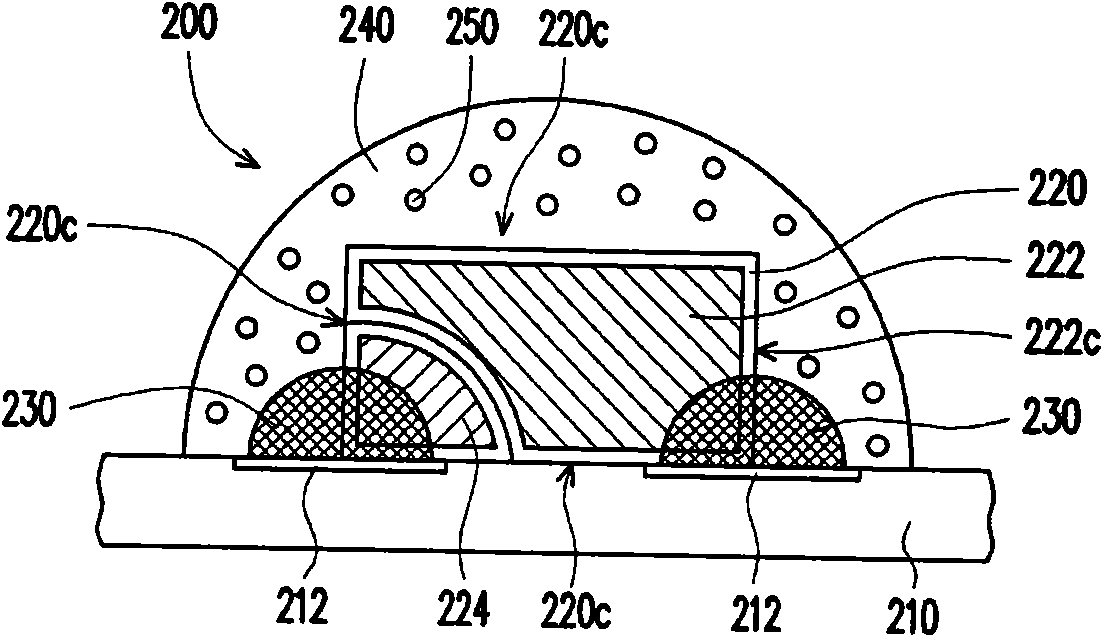

[0043] Figure 2A Is a side view of the light emitting diode package according to the first embodiment of the present invention, and Figure 2B It is a three-dimensional schematic diagram of the light emitting diode package according to the first embodiment of the present invention. Please refer to Figure 2A versus Figure 2B The light emitting diode package 200 of this embodiment includes a carrier 210, a light emitting diode chip 220, and a plurality of conductors 230. The light emitting diode chip 220 has a front surface 220a, a back surface 220b, and a plurality of side walls 220c connected between the front surface 220a and the back surface 220b, and one of the side walls 220c of the light emitting diode chip 220 faces the carrier 210 and is connected to the carrier 210 . In addition, the conductor 230 is electrically connected between the carrier 210 and the LED chip 220.

[0044] In this embodiment, the carrier 210 may be a circuit board with a plurality of pads 212, and...

no. 2 example

[0052] image 3 It is a side view of the light emitting diode package according to the second embodiment of the present invention. Please refer to image 3 The light emitting diode package 300 of this embodiment is similar to the light emitting diode package 200 of the first embodiment, but the main difference between the two lies in: the light emitting diode chip 320 and the light emitting diode chip 220 used in this embodiment. In detail, the LED chip 320 has a plurality of electrodes 322 and 324, and the electrodes 322 and 324 are respectively distributed on the front surface 320a and the back surface 320b of the LED chip 320. In addition, the electrodes 322 and 324 are electrically connected to the carrier 210 through the conductors 230 located on both sides of the LED chip 320, respectively.

no. 3 example

[0054] Figure 4 It is a side view of the light emitting diode package according to the third embodiment of the present invention. Please refer to Figure 4 The light emitting diode package 400 of this embodiment is similar to the light emitting diode package 300 of the second embodiment, but the main difference between the two is that the number of light emitting diode chips 320 used in this embodiment is multiple ( Figure 4 3 are shown in the middle). In detail, since the LED chips 320 are connected to the carrier 210 through the sidewall 320c, the distance between the LED chips 320 (the distance between the centers of the two LED chips 320) can be effectively shortened, and the The light mixing efficiency. In other words, on the carrier 210 of the same area, this embodiment can accommodate a larger number of light-emitting diode chips 320 to easily meet the requirements of high brightness output.

[0055] It is worth noting that in this embodiment, optical elements (such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com