Light emitting diode crystalline grain

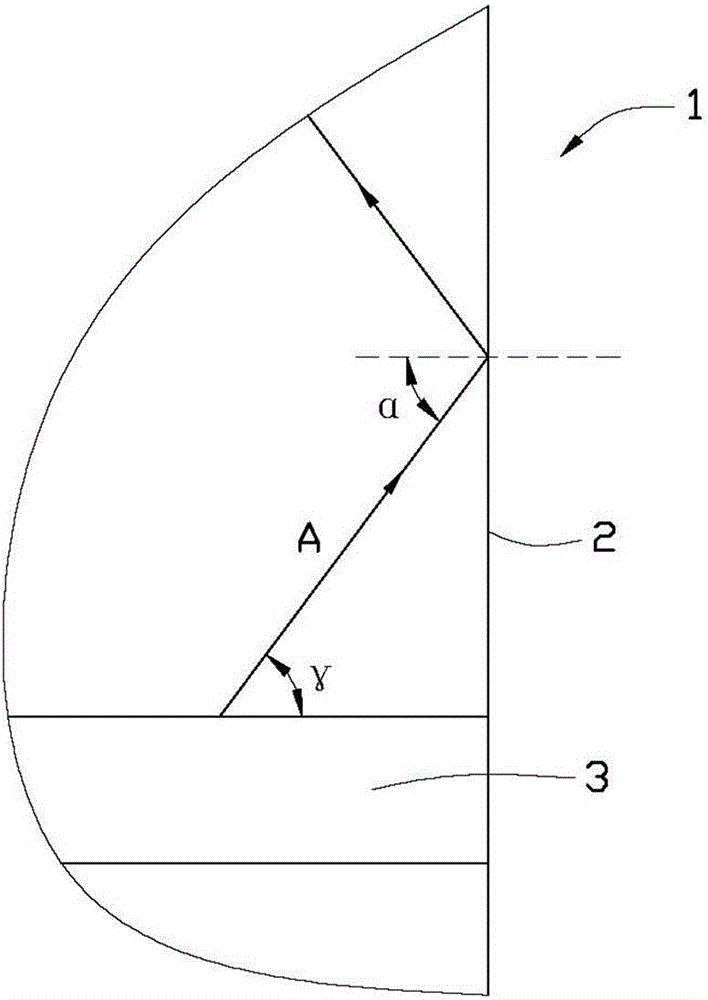

A technology for light-emitting diodes and crystal grains, which is applied to electrical components, circuits, semiconductor devices, etc., can solve the problems of affecting the light-emitting efficiency of light-emitting diode crystal grains and unfavorable epitaxial layer structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

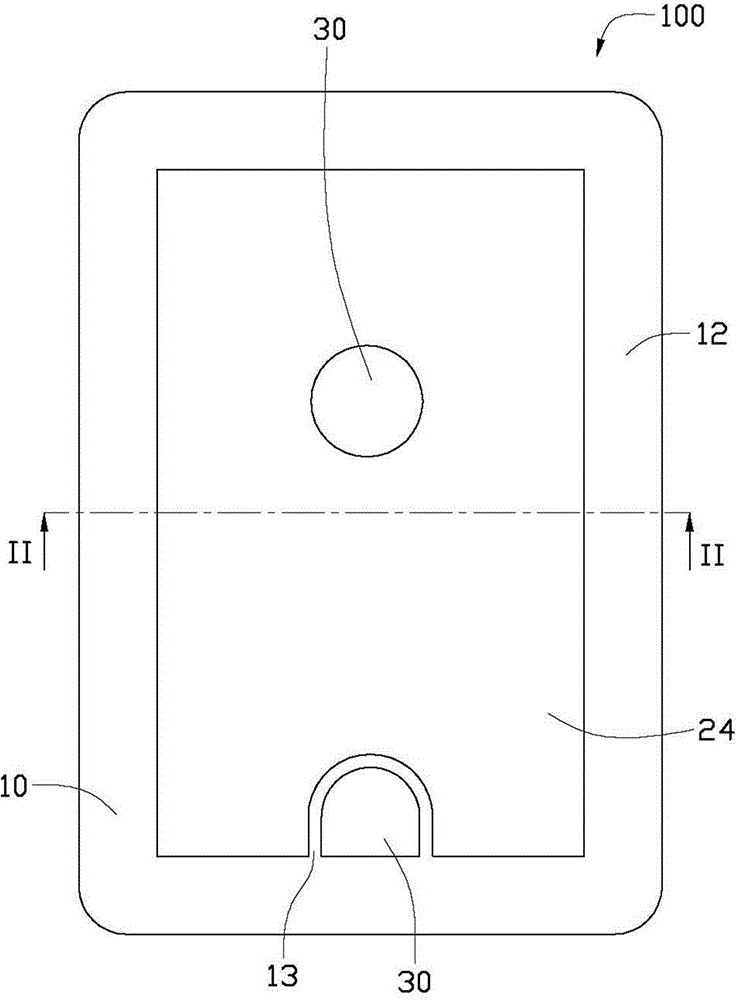

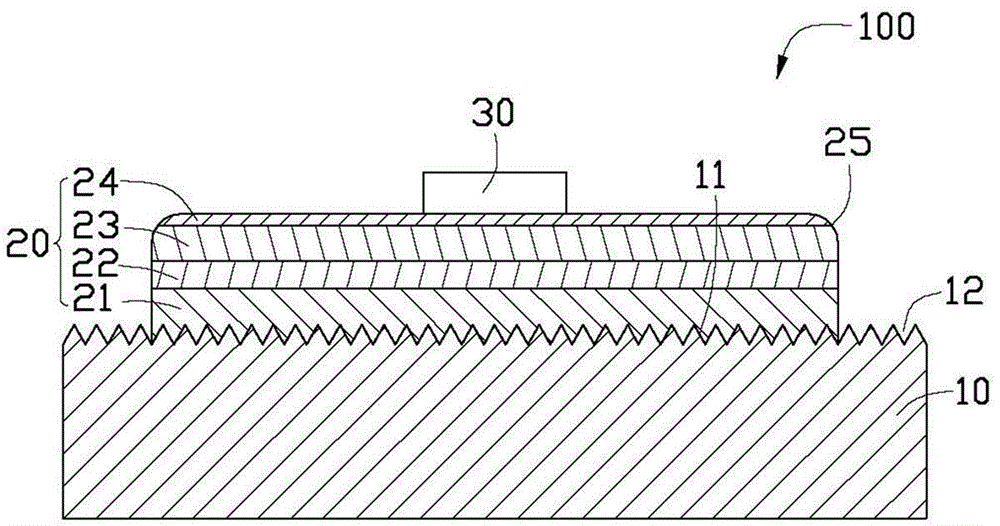

[0014] see figure 2 and image 3 The light emitting diode die 100 provided in the embodiment of the present invention includes a substrate 10 , an epitaxial layer 20 grown on the substrate 10 , and an electrode 30 .

[0015] The substrate 10 is a patterned substrate, which includes an upper surface 11 formed with microstructures. The material of the substrate 10 can be sapphire (Al 2 o 3 ), silicon carbide (SiC), silicon (Si), gallium nitride (GaN) or zinc oxide (ZnO), depending on the desired physical and optical properties and cost budget. The shape of the substrate 10 is not limited, and may be a rectangle, a circle, etc. In this embodiment, the substrate 10 is a rectangle with four sides.

[0016] The epitaxial layer 20 is formed on the upper surface 11 of the substrate 10 , and the epitaxial layer 20 covers part of the substrate 10 . Specifically, the upper surface 11 of the substrate 10 is exposed to the air and surrounds the epitaxial layer 20 to form a cutting li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com