Flip-chip LED chip structure and manufacturing method thereof

A LED chip, flip-chip welding technology, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of reduced emission area, epitaxial layer structure damage, serious light loss, etc., to buffer the change of lateral stress and reduce Effects of intensifying lattice defects and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

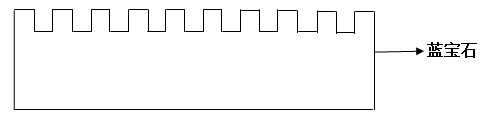

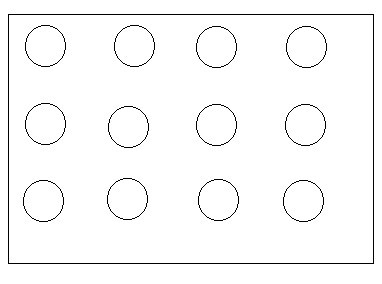

[0062] Example 1: see figure 1 with figure 2 , a flip-chip LED chip structure, including the epitaxial layer on the sapphire substrate and the SiO 2 / Si is the electrode layer of the substrate; the front of the sapphire substrate is etched with a periodic structure of circular hole-like hole 1 structure, the radius of the circular hole is 3 μm, the depth is 1 μm, and the period interval is 2.5 μm, the sapphire substrate The backside is etched with a random pattern;

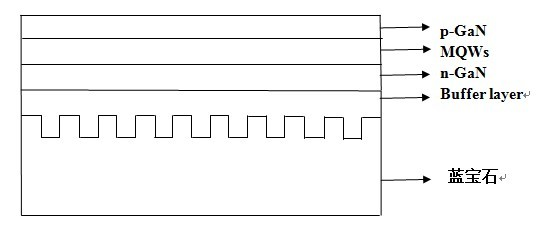

[0063] see image 3 , an epitaxial layer consisting of buffer layer buffer layer, n-type GaN layer n-GaN, multi-quantum well layer MQWs and p-type GaN layer p-GaN is grown on the front side of the sapphire substrate etched with round holes;

[0064] see Figure 4 with Figure 5 , taking the center line of the p-GaN p-GaN layer as the symmetry line, the two ends of the p-GaN layer p-GaN are symmetrically etched with cathode electrode grooves, and the etched epitaxial layer surface is divided into three part...

Embodiment 2

[0075] Example 2: see Figure 9 , the difference from Implementation 1 is that the periodic structural holes (1) etched on the front side of the sapphire substrate of the flip-chip LED chip structure are octagonal, and the side length of the octagon is 2 μm; the depth is 1 μm, and the period The pitch is 2.5 μm; the backside of the sapphire substrate is etched with a random pattern.

[0076] The manufacturing method of embodiment 2 is different from implementation 1 in that:

[0077] Step 1: On the polished sapphire substrate, use a laser to etch an octagon with a periodic structure, wherein the side length of the octagon is 2 μm; the depth is 1 μm, and the period interval is 2.5 μm. All the other steps are the same as in Example 1, omitted here.

Embodiment 3

[0078] Example 3: see figure 1 with figure 2 , a flip-chip LED chip structure, including the epitaxial layer on the sapphire substrate and the SiO 2 / Si is the electrode layer of the substrate; the front of the sapphire substrate is etched with a periodic structure of circular hole-like hole 1 structure, the radius of the circular hole is 3 μm, the depth is 1 μm, and the period interval is 2.5 μm, the sapphire substrate The backside is etched with a random pattern;

[0079] see image 3 , an epitaxial layer consisting of buffer layer buffer layer, n-type GaN layer n-GaN, multi-quantum well layer MQWs and p-type GaN layer p-GaN is grown on the front side of the sapphire substrate etched with round holes;

[0080] see Figure 10 with Figure 11, with the center line of the p-GaN layer p-GaN as the symmetry line, four cathode electrode grooves are etched symmetrically at the four corners of the p-type GaN layer p-GaN, and the etched epitaxial layer surface is divided into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com