A kind of preparation method of efficient porous composite photocatalytic material

A composite photocatalytic and high-efficiency technology, applied in the field of photocatalysis, can solve the problems of large photocatalytic contact area, large specific surface area, and fast electron-hole recombination speed, and achieve large contact area, large specific surface area, and recyclability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

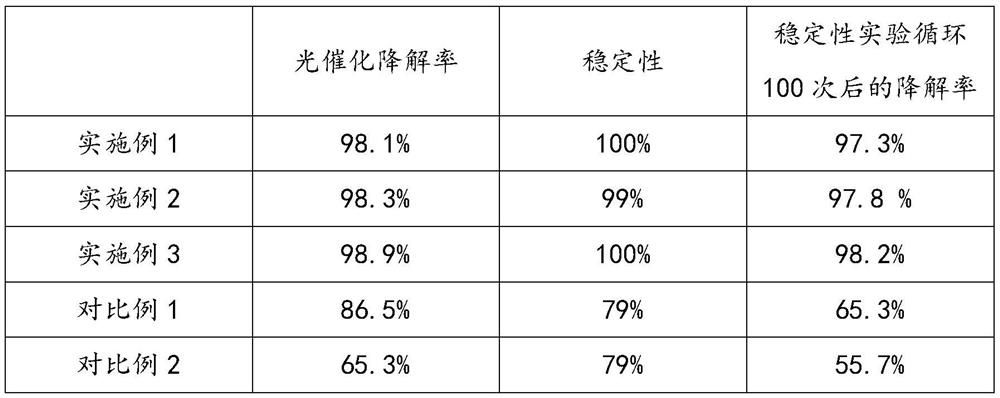

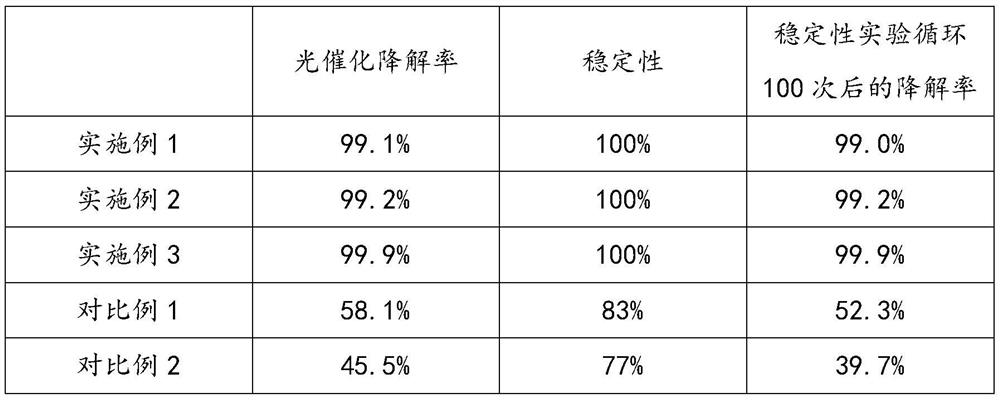

Embodiment 1

[0032]Method for preparing high efficiency porous composite photocatalytic materials, including steps:

[0033]Step 1, mix the electrical stone powder and polyvinylpyrrolidone to form a mixed solid, then anhydrous ethanol is added, and the stiff is formed.

[0034]Step 2, place the viscies into the mold to warm the pressurized reaction for 2 h, and obtain the substrate after removal;

[0035]Step 3, put the substrate into anhydrous ethanol soaked for 10 min, and then dried to obtain a porous substrate;

[0036]Step 4, the zinc acetate and ethylcellulose were added to anhydrous ethanol to be stirred to completely dissolve, and the organic zinc solution was obtained, and then the organic zinc solution was evenly applied to the surface of the porous substrate, dried into the ultraviolet light. 20min to get a primary coating substrate;

[0037]Step 5, spray the titanate n-butyl ethanol solution on the surface of the primary coating substrate, and then put it in a high humidity environment for 10 min, ...

Embodiment 2

[0048]Method for preparing high efficiency porous composite photocatalytic materials, including steps:

[0049]Step 1, mix the electrical stone powder and polyvinylpyrrolidone to form a mixed solid, then anhydrous ethanol is added, and the stiff is formed.

[0050]Step 2, place the viscies into the mold to warm the pressurized reaction for 4 h, after removing the substrate;

[0051]Step 3, put the substrate into anhydrous ethanol for 20 min, and then dry the porous substrate after removal;

[0052]Step 4, the zinc acetate and ethylcellulose were added to anhydrous ethanol to be stirred to completely dissolve, and the organic zinc solution was obtained, and then the organic zinc solution was evenly applied to the surface of the porous substrate, dried into the ultraviolet light. 50min to get a primary coating substrate;

[0053]Step 5, spray the titanate n-butyl ethanol solution on the surface of the primary coating substrate, and then put it in a high humidity environment for 30 min, and then drie...

Embodiment 3

[0064]Method for preparing high efficiency porous composite photocatalytic materials, including steps:

[0065]Step 1, mix the electrical stone powder and polyvinylpyrrolidone to form a mixed solid, then anhydrous ethanol is added, and the stiff is formed.

[0066]Step 2, place the viscies into the mold to warm the pressurized reaction for 3 h, and obtain the substrate after removal;

[0067]Step 3, place the substrate into anhydrous ethanol for 15 min, and then dry after the porous substrate is obtained.

[0068]Step 4, the zinc acetate and ethylcellulose were added to anhydrous ethanol to be stirred to completely dissolve, and the organic zinc solution was obtained, and then the organic zinc solution was evenly applied to the surface of the porous substrate, dried into the ultraviolet light. 40min to get a first-order coating substrate;

[0069]Step 5, spray the titanate n-butyl ethanol solution on the surface of the primary coating substrate, and then put it in a high humidity environment for 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com