A modified ultra-high molecular weight polyethylene and its preparation method, polyethylene composite material and its preparation method

A technology of ultra-high molecular weight and polyethylene, which is applied in the field of polyethylene composite materials and its preparation, modified ultra-high molecular weight polyethylene and its preparation, and can solve the problems of inability to improve the performance of UHMWPE, uneven stretching of UHMWPE, and filler mixing Inhomogeneity and other problems, to achieve the effect of fast speed, improved performance, and uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a kind of preparation method of modified ultra-high molecular weight polyethylene, comprising the following steps:

[0029] (1) 1,3,5-trichlorobenzene is mixed with ultra-high molecular weight polyethylene and filler in turn to obtain a suspension;

[0030] (2) cooling the suspension obtained in the step (1) to room temperature to obtain a solid mixture; removing 1,3,5-trichlorobenzene in the solid mixture to obtain the modified ultra-high molecular weight polyethylene.

[0031] In the invention, 1,3,5-trichlorobenzene is sequentially mixed with ultra-high molecular weight polyethylene and filler to obtain a suspension. In the present invention, the mass ratio of the 1,3,5-trichlorobenzene to the ultra-high molecular weight polyethylene is preferably 500: 1-10, more preferably 500: 2-8; the filler and the ultra-high molecular weight polyethylene The mass ratio of ethylene is preferably 10:90 to 70:30, more preferably 20:80 to 60:40, and still mor...

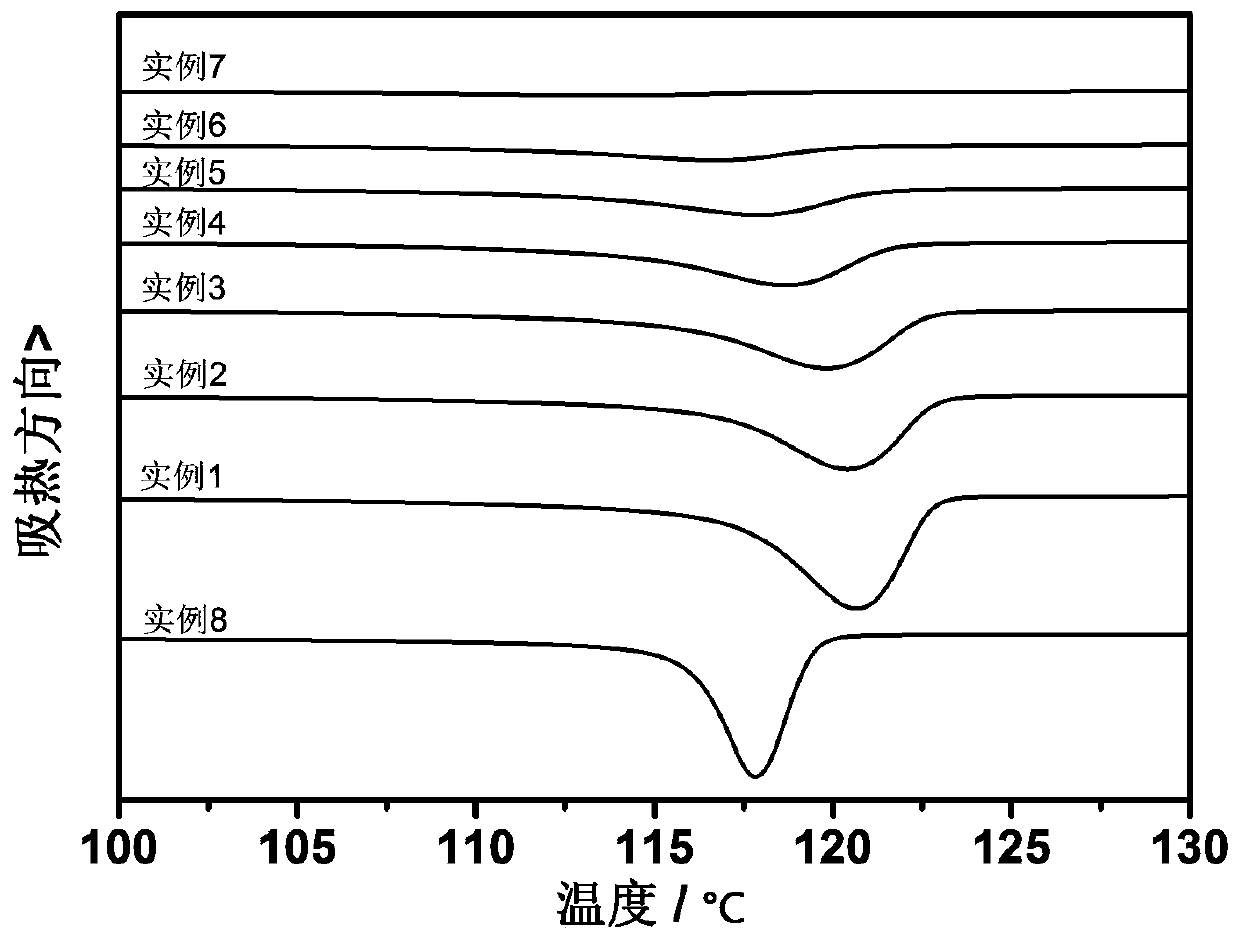

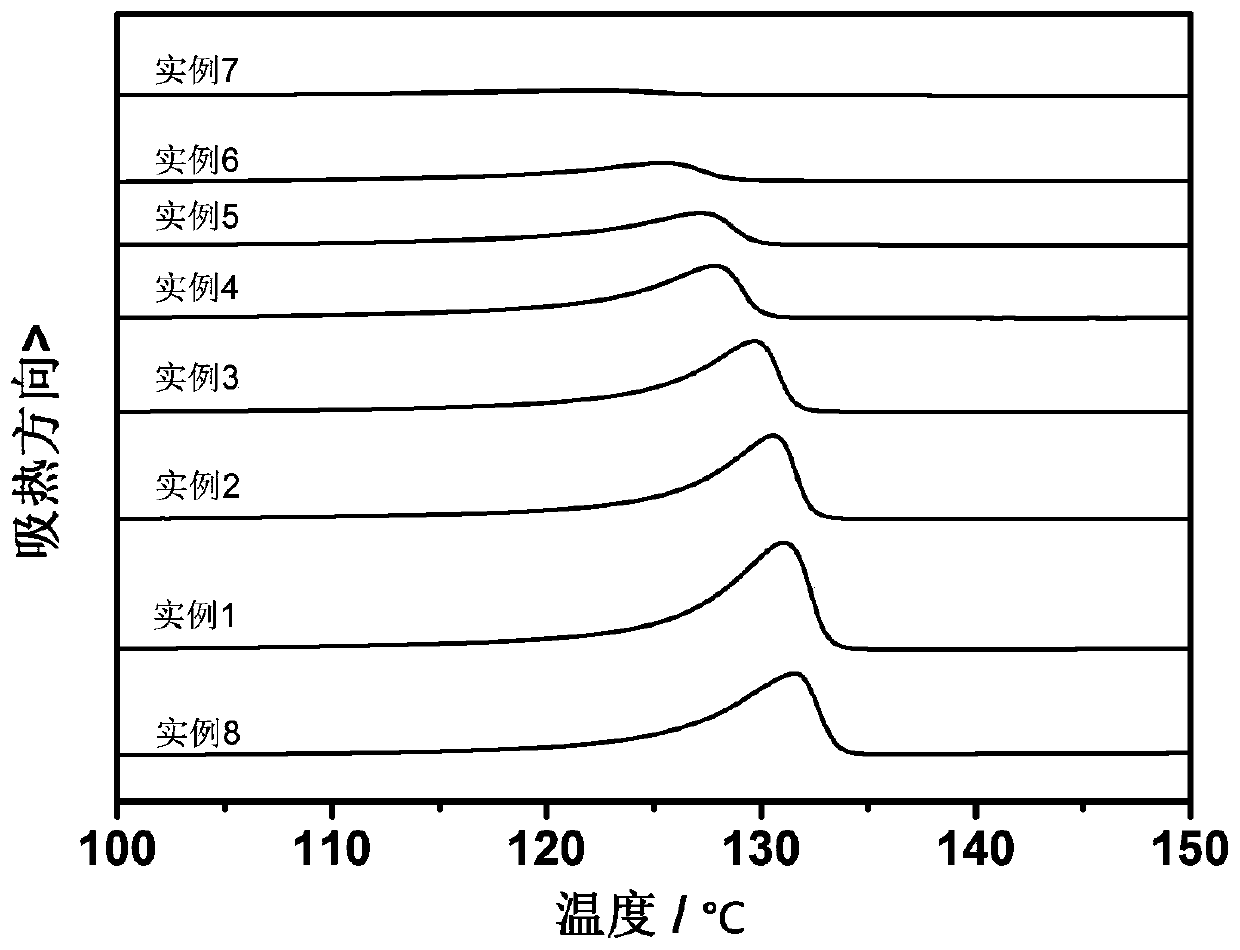

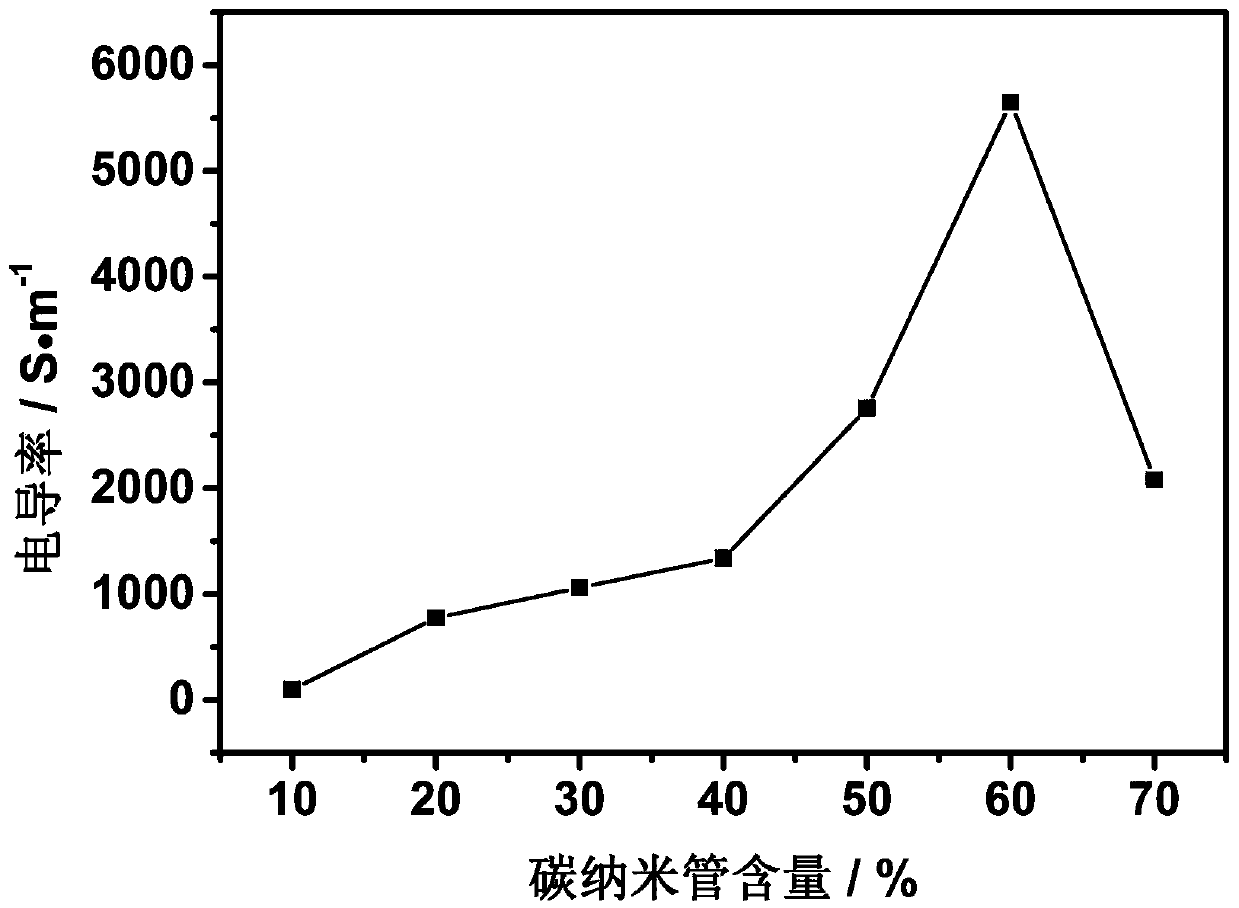

Embodiment 1

[0050] (1) Mix 9g of UHMWPE (molecular weight: 2.2 million) and 500g of 1,3,5-trichlorobenzene at room temperature for 10min, then heat to 150°C, and mix at high temperature under the condition of magnetic stirring until the solution is free of particulate matter, to obtain Ultra-high molecular weight polyethylene solution; then add 1g CNT (purchased from Nanocyl, Belgium) and carry out ultrasonic stirring for 30min to obtain a suspension;

[0051] (2) The suspension was rapidly cooled to room temperature with water to obtain a solid mixture; 2000 mL of tetrahydrofuran was added to the solid mixture, stirred at room temperature for 2 hours, suction filtered, and the solid obtained by suction filtration was repeatedly washed with tetrahydrofuran until the washing liquid was colorless, and the solid Dry naturally to obtain modified ultra-high molecular weight polyethylene.

[0052] The modified ultra-high molecular weight polyethylene obtained in this embodiment is used to prepa...

Embodiment 2

[0056] (1) Premix 8g of UHMWPE (molecular weight: 2.2 million) and 500g of 1,3,5-trichlorobenzene at room temperature for 10 minutes, heat to 150°C, and mix at high temperature under the condition of magnetic stirring. Molecular weight polyethylene solution; then add 2g CNT (purchased from Nanocyl, Belgium) and carry out ultrasonic stirring for 30min to obtain a suspension;

[0057] (2) The suspension was rapidly cooled to room temperature with water to obtain a solid mixture; 2000 mL of tetrahydrofuran was added to the solid mixture, stirred at room temperature for 2 hours, suction filtered, and the solid obtained by suction filtration was repeatedly washed with tetrahydrofuran until the washing liquid was colorless, and the solid Dry naturally to obtain modified ultra-high molecular weight polyethylene.

[0058] The modified ultra-high molecular weight polyethylene obtained in this embodiment is used to prepare a polyethylene composite material, comprising the following step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com