Preparation method of mussel byssus antiskid rubber sole

A technology of anti-slip rubber and foot silk, which is applied in the field of shoe sole materials, can solve the problems of environmental pollution, underutilization of waste foot silk, waste of resources, etc., achieve excellent anti-slip performance, improve dynamic anti-slip coefficient, and increase overall intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

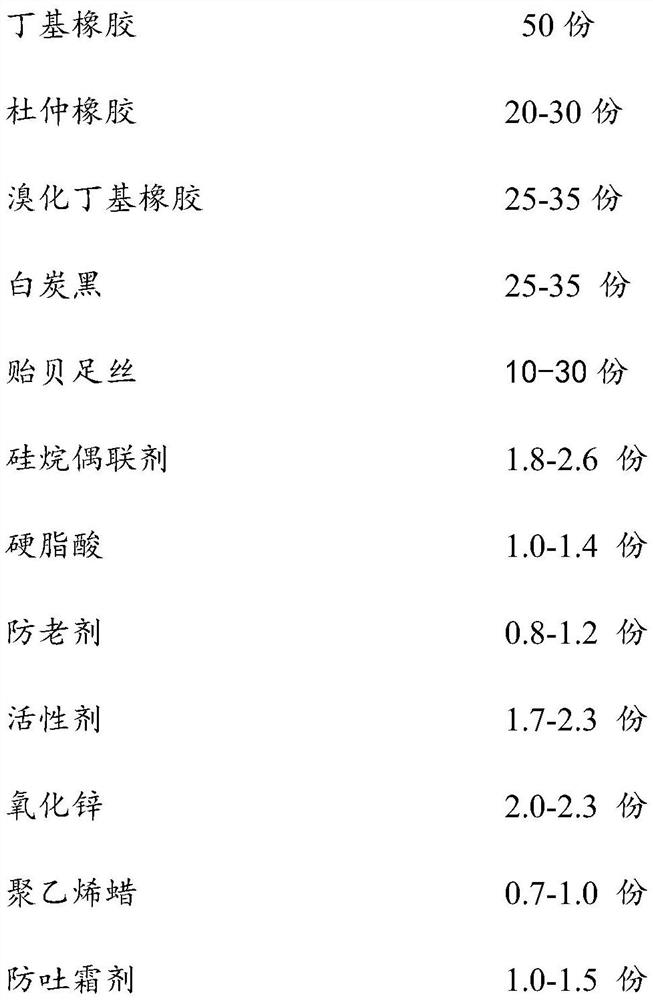

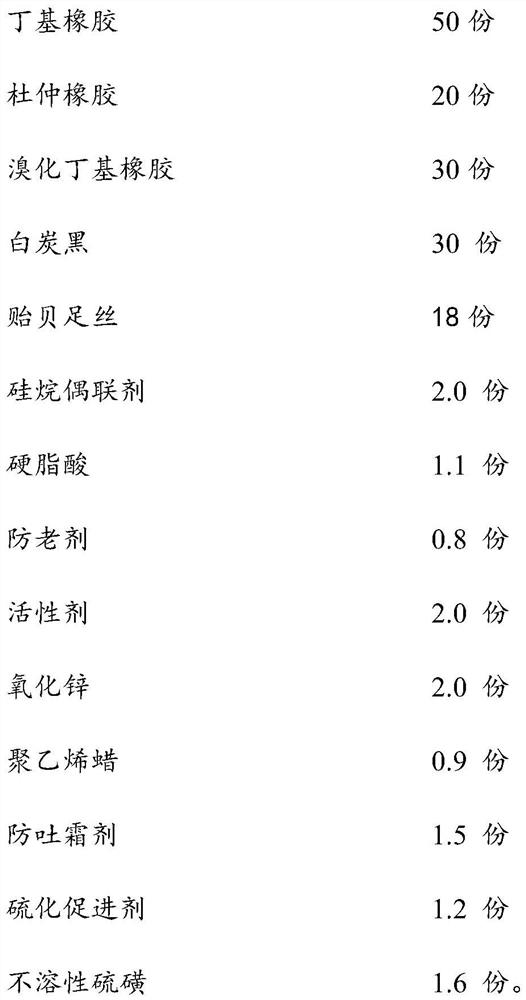

[0025] A kind of mussel silk non-slip rubber sole of the present embodiment is made up of following components:

[0026]

[0027] The three-dimensional support structure, in the process, directly collect the whole silk of fresh thick-shelled mussels, including the stem, thread and root; among them, the cuticle of the stem increases the contact area, and the rigid and elastic thread parts are respectively The construction of straight line and curly mesh structure is carried out, and the plaque at the root acts as an anchor, which can ensure the dispersion of the silk in the shoe material and ensure the compounding with the shoe material.

[0028] The preparation method of the present embodiment comprises the steps:

[0029] The present invention also provides the preparation method of above-mentioned a kind of mussel silk non-slip rubber sole, comprising the following steps:

[0030] Step (1) Raw material processing: take mussel foot silk; disperse and disperse through ca...

Embodiment 2

[0035] A preparation method for mussel silk non-slip rubber soles, comprising the steps of:

[0036] Step (1) raw material processing: get the complete silk, especially the stem and root;

[0037] Step (2) Internal mixing: first put 50 parts of butyl rubber 402 and 25 parts of Eucommia rubber into an internal mixer for mixing at a temperature of 80°C for 90 seconds; then put in 17 parts of white carbon black, silane coupling agent KH- Mix 1.0 parts of 560 at 90°C for 120 seconds; add 8 parts of white carbon black, 35 parts of brominated butyl rubber 2030, 10 parts of mussel silk, 1.0 parts of stearic acid 1804, and 1.0 parts of antioxidant BHT , 1.0 parts of polyethylene glycol PEG-4000, 0.7 parts of diethylene glycol, 2.0 parts of zinc oxide, 0.7 parts of polyethylene wax, 1.0 parts of anti-emetic cream agent OH3 to the internal mixer at a temperature of 110 ° C for 110 seconds; clean once, Continue mixing, temperature 115°C, time 90 seconds; discharge temperature 120°C, imm...

Embodiment 3

[0041] A preparation method for mussel silk non-slip rubber soles, comprising the steps of:

[0042] Step (1) Raw material processing: take the complete foot silk after washing and high-temperature cooking, especially the stem and root;

[0043]Step (2) Internal mixing: first put 50 parts of butyl rubber 301 and 30 parts of eucommia rubber into an internal mixer for mixing at a temperature of 80°C for 110 seconds; then put 23 parts of white carbon black and silane coupling agent KH- Mix 2.6 parts of 550 at 90°C for 130 seconds; add 12 parts of white carbon black, 25 parts of brominated butyl rubber 2030, 30 parts of mussel silk, 1.4 parts of stearic acid 1804, and 0.6 parts of antioxidant RD , 0.6 parts of anti-aging agent MB, 1.3 parts of polyethylene glycol PEG-4000, 1.0 parts of diethylene glycol, 2.3 parts of zinc oxide, 1.0 parts of polyethylene wax, 1.2 parts of anti-vomiting cream agent OH until the temperature of the internal mixer is 115 ° C, the time 130 seconds; cl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com