High-luminance chip of luminescent tube in GaN base, and preparation method

A light-emitting tube and high-brightness technology, which is applied in the field of optoelectronics, can solve problems such as process sensitivity, and achieve the effects of increasing output efficiency, improving thermal characteristics, and improving electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The technical scheme of embodiment one:

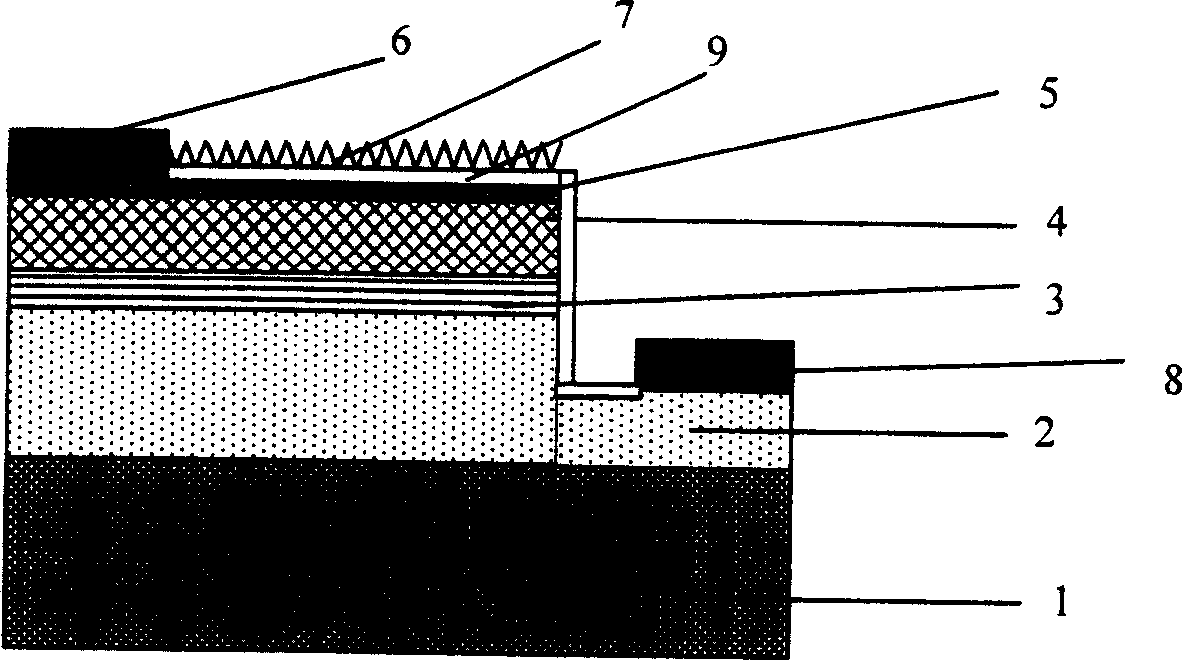

[0023] Figure 2a-2d It is a flow chart of the manufacturing process of the GaN-based light-emitting diode die with a surface microstructure; the manufacturing process and chip structure of Embodiment 1 will be described in detail below with reference to FIG. 2 .

[0024] 1) Prepare an LED chip with a conventional structure, the specific steps are as follows:

[0025] a) A mesa is first etched on the GaN-based LED epitaxial wafer grown on the sapphire substrate 1, and the mesa is etched through the active region 3 to the N-type GaN material 2;

[0026] b) Deposit Ni / Au (5nm / 5nm) P-type ohmic contact layer 5 on the P-type GaN material 4 on the mesa, and after alloying at 500° C. for 2-10 minutes in an oxygen atmosphere, rinse off the surface NiO with oxalic acid aqueous solution.

[0027] c) Prepare an N-type ohmic contact layer 8 on the N-type GaN material 2 under the mesa, which is composed of Ti / Al (5nm / 20-200nm), and then d...

Embodiment 2

[0032] The technical scheme of embodiment two:

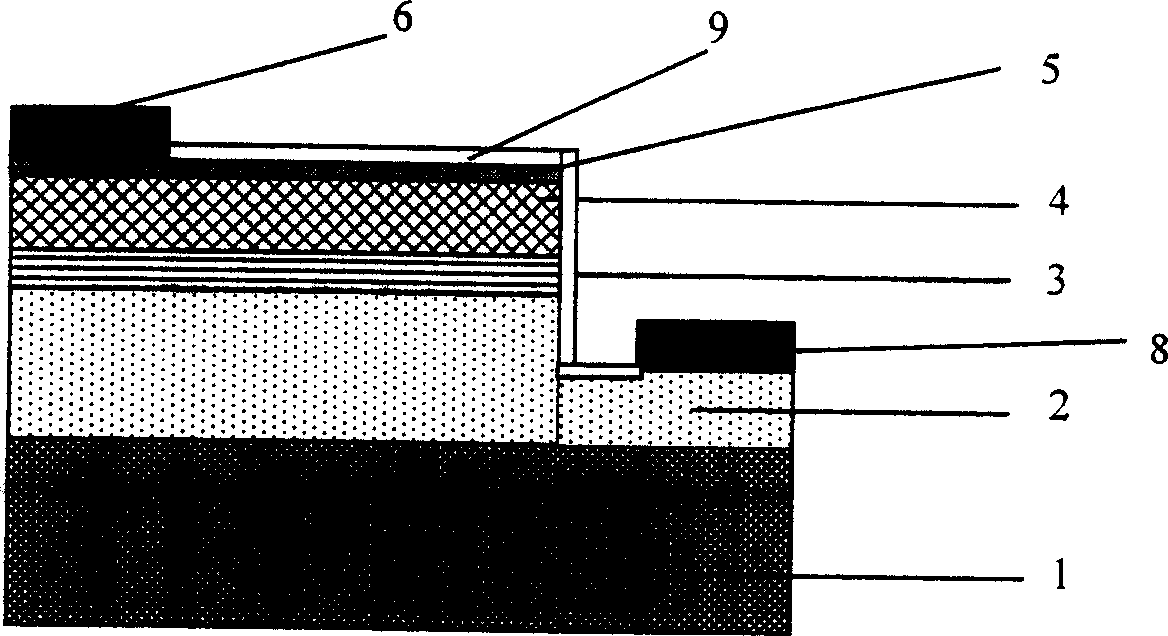

[0033] Figure 3a ~ 3f It is a flow chart of the manufacturing process of the GaN-based light-emitting diode tube core with a surface microstructure; the preparation process and chip structure of the second embodiment will be described below with reference to FIG. 3 .

[0034] 1) Prepare the LED chip with the vertical structure of the upper and lower electrodes, the specific steps are as follows:

[0035] a) On the P-type GaN material 4 on the GaN-based LED epitaxial wafer of the sapphire substrate, the transparent electrode Ni / Au (5nm / 5nm) 5 is evaporated on a large area, and then alloyed at 500° C. for 2-10 minutes under an oxygen atmosphere, and used Aqueous oxalic acid rinses off the surface NiO. Evaporate a multi-layer reflective film 13 on the transparent electrode, consisting of Ni / Ag / Ti / Au (10nm / 200nm / 20nm / 200nm), wherein Ag is a reflective layer, and Au is a metal barrier layer, such as Figure 3a .

[0036] b) On t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com