Method for preparing nanometer imaging substrate of LED (light emitting diode) chip epitaxial growth

An LED chip and nano-pattern technology, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as the inability to meet the light extraction efficiency of LED devices, and achieve the effect of good periodicity and uniform pattern

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

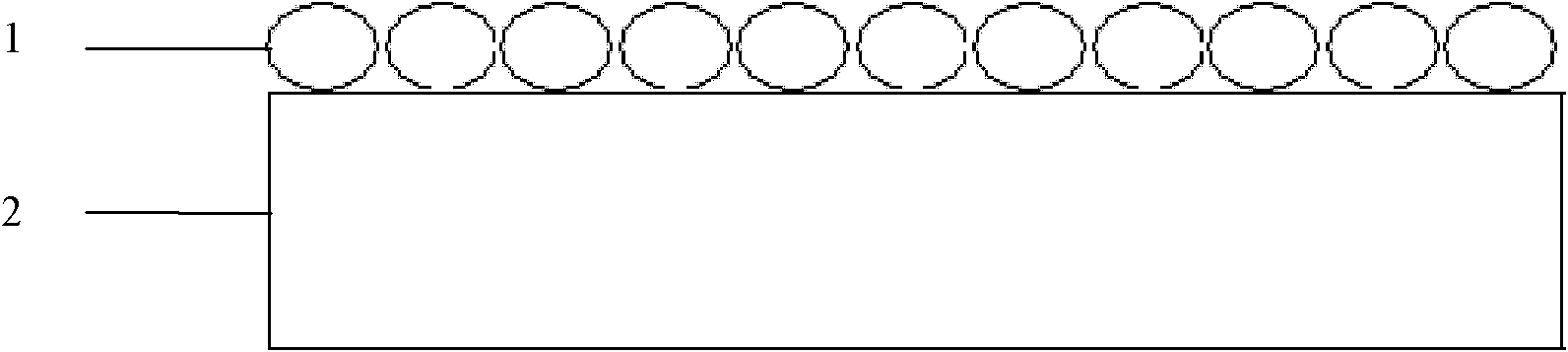

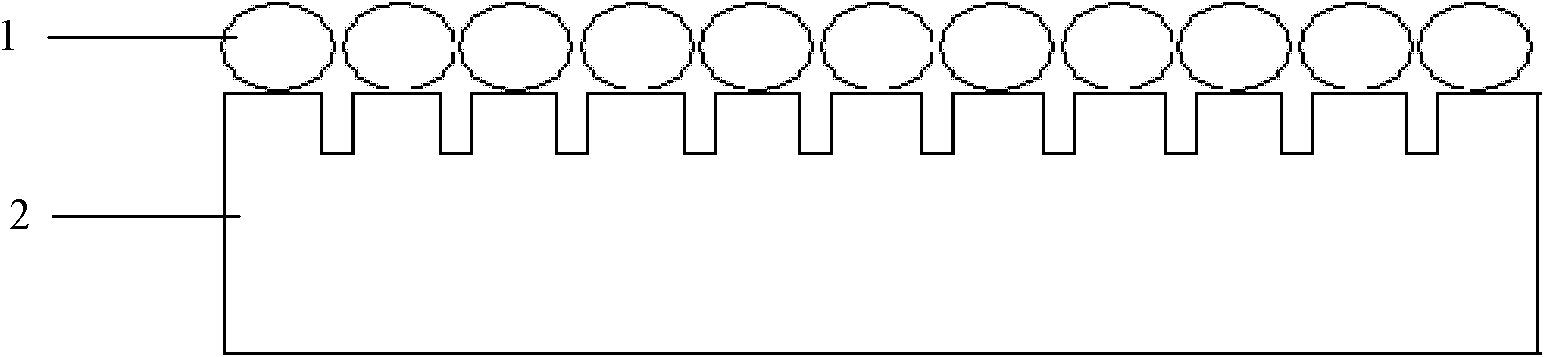

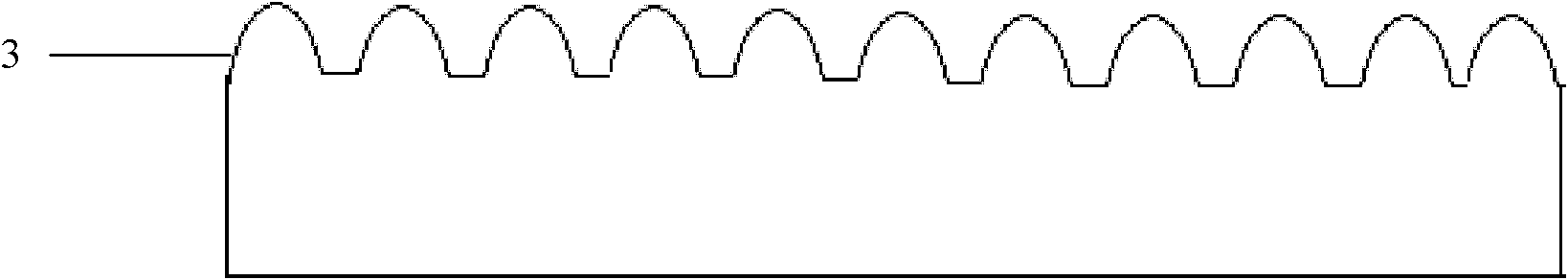

Image

Examples

Embodiment Construction

[0022] In order to further illustrate content of the present invention, below in conjunction with embodiment and accompanying drawing, the present invention is described in detail:

[0023] A method for preparing a nano-patterned substrate for LED chip epitaxial growth, the specific method is as follows:

[0024] 1. The sapphire substrate is firstly cleaned in a mixed solution of sulfuric acid:hydrogen peroxide=4:1, and rotated for 4 minutes. Then in HF:H 2 Sonicate for 2 min in a mixed solution of O=1:1. Finally, rinse with deionized water, N 2 Clean the surface and dry it in a drying oven (80°C).

[0025] 2. After adding 2ml of deionized water and 6ml of ammonia water to 50ml of absolute ethanol solution, slowly drop in 4ml of tetraethyl orthosilicate (TEOS) at a rate of about 200 microliters every two minutes, and react for 18-24 hours. During this period, the magnetic stirrer kept stirring at a constant speed, and the rotating speed was 300 rpm. After the reaction is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com