Three-dimensional nano-structure array and preparation method and application thereof

A technology of three-dimensional nanometer and nanowire arrays, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of high cost, sensitivity to light incident angle, low conversion rate of solar cells, etc., to achieve The effect of reducing preparation cost, reducing sensitivity, and increasing absorption area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

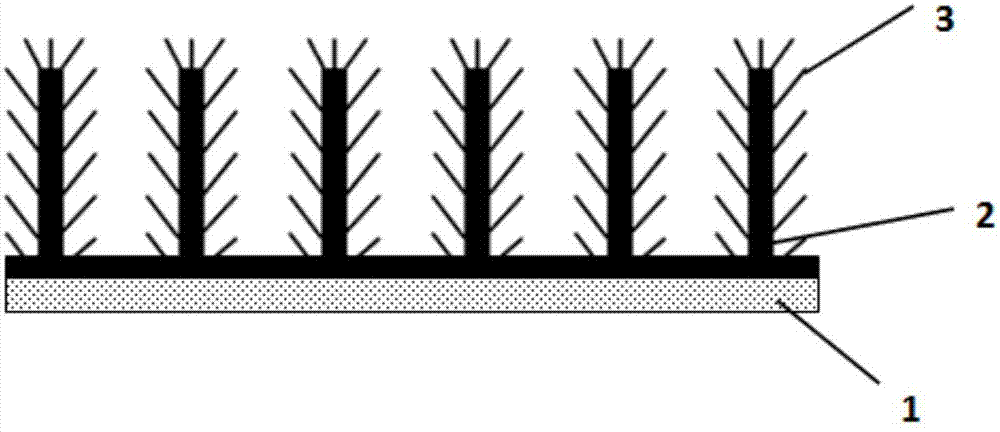

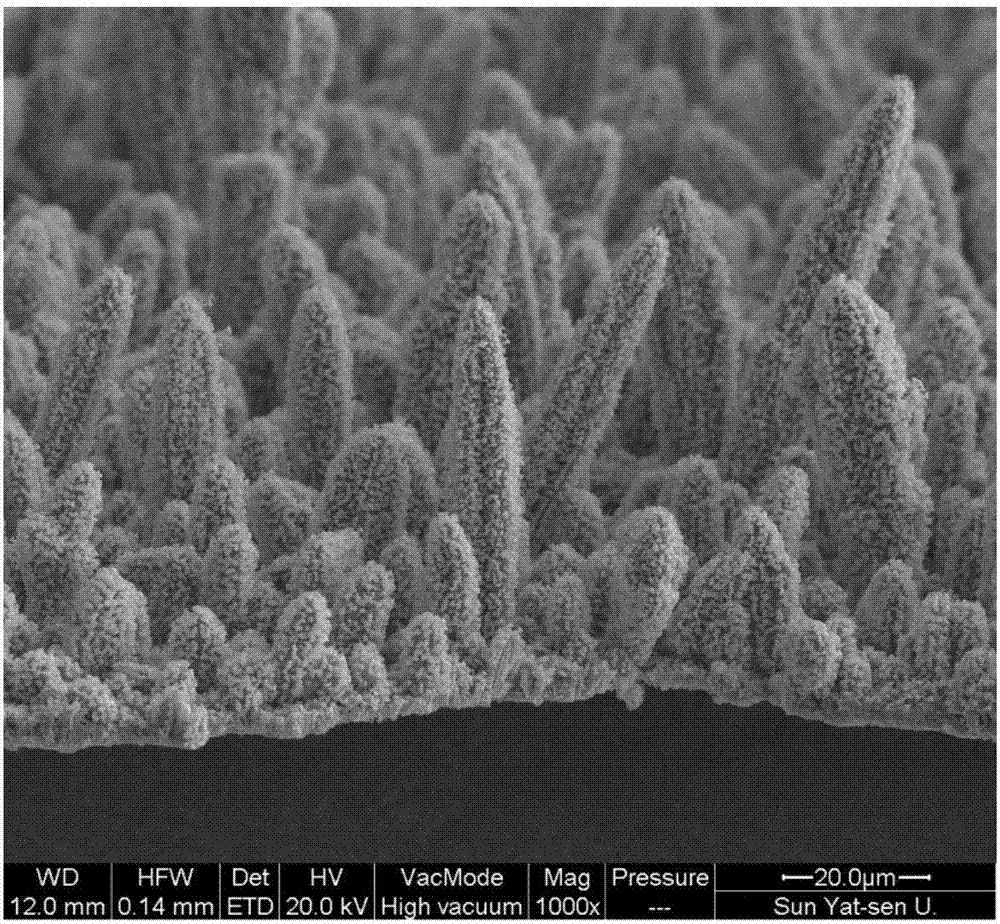

[0029] A kind of three-dimensional nanostructure array, its preparation method comprises the following steps:

[0030] (1) The glass sheet is ultrasonically cleaned with 1mol / L NaOH, 1mol / L HCl solution, absolute ethanol, and deionized water in sequence, and then a copper film is deposited on the glass sheet by a constant voltage electrochemical method, and the thickness of the copper film is 600nm ; Then put the substrate deposited with the copper film into the mixed gas of oxygen / hydrogen sulfide (volume ratio 1:2), react with gas and solid at 15°C for 20h, and the copper film is converted into a regularly arranged cuprous sulfide nanowire array;

[0031] (2) Copper particles are deposited on the surface of the cuprous sulfide nanowire array by the pulse voltage method; the size of the copper particles is 10nm;

[0032] (3) Put the cuprous sulfide nanowire array with copper particles deposited on the surface into the oxygen / hydrogen sulfide mixed gas (volume ratio 1:2), and ...

Embodiment 2

[0036] A kind of three-dimensional nanostructure array, its preparation method comprises the following steps:

[0037] (1) The glass sheet is ultrasonically cleaned with 1mol / L NaOH, 1mol / L HCl solution, absolute ethanol, and deionized water in sequence, and then a copper film is deposited on the glass sheet by a constant current electrochemical method, and the thickness of the copper film is 600nm ; Then put the substrate deposited with the copper film into the mixed gas of oxygen / hydrogen sulfide (volume ratio 1:2), react with gas-solid at 18°C for 20h, and the copper film is converted into a regularly arranged cuprous sulfide nanowire array;

[0038] (2) Copper particles are deposited on the surface of the cuprous sulfide nanowire array by magnetron sputtering; the size of the copper particles is 15nm;

[0039] (3) Put the cuprous sulfide nanowire array with copper particles deposited on the surface into the oxygen / hydrogen sulfide mixed gas (volume ratio 1:2), and react ...

Embodiment 3

[0043] A kind of three-dimensional nanostructure array, its preparation method comprises the following steps:

[0044] (1) The glass sheet is ultrasonically cleaned with 1mol / L NaOH, 1mol / L HCl solution, absolute ethanol, and deionized water successively, and then a copper film is deposited on the glass sheet by a pulse current method, and the thickness of the copper film is 600nm; then Put the substrate deposited with the copper film into the oxygen / hydrogen sulfide mixed gas (volume ratio 1:2), and react with gas-solid at 25°C for 20h, and the copper film is converted into a regularly arranged array of cuprous sulfide nanowires;

[0045] (2) Copper particles are deposited on the surface of the cuprous sulfide nanowire array by magnetron sputtering; the size of the copper particles is 18nm;

[0046] (3) Put the cuprous sulfide nanowire array with copper particles deposited on the surface into the oxygen / hydrogen sulfide mixed gas (volume ratio 1:2), and react with gas-solid a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com