Manufacturing method for GaN-based LED (Light Emitting Diode) chip for coarsening p-GaN layer nanometer bowl-shaped surface

An LED chip and surface roughening technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problem of limited light extraction, achieve the effects of low cost, simple process, and increase the probability of extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

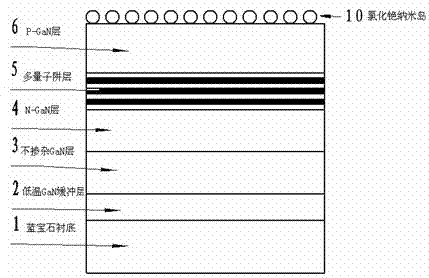

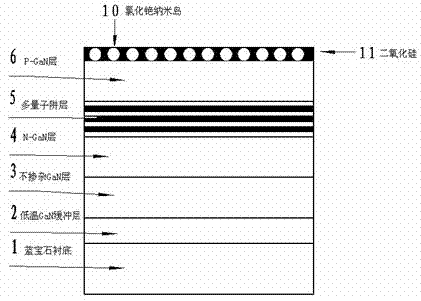

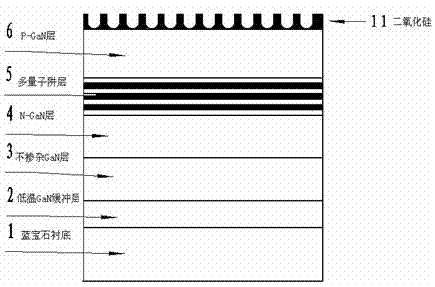

[0027] 1. Preparation of a GaN-based LED chip with p-GaN layer nano-bowl-shaped surface roughening:

[0028] Step 1: Using metal-organic chemical vapor deposition (MOCVD), sequentially grow a 1 μm low-temperature GaN buffer layer 2, a 2 μm undoped GaN layer 3, a 3 μm N-GaN layer 4, and a 200 nm multi-quantum well light-emitting layer on a semiconductor substrate 1 5 and 700nm P-GaN layer 6 to form a GaN epitaxial wafer, wherein the semiconductor substrate 1 is sapphire, silicon, silicon carbide or metal.

[0029] Step 2: put the GaN epitaxial wafer into the evaporation table, vapor-deposit cesium chloride for etching on the surface of the P-GaN layer 6, the time is 5-40min, and the film thickness is 100-800nm;

[0030] Step 3: After the evaporation is completed, fill the chamber of the evaporation table with water vapor for 5 to 20 minutes, so that the cesium chloride on the surface of the P-GaN layer 6 absorbs water and gradually grows to form a cesium chloride nano-islan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| etching power | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com