Overall wet chemical preparation method for nanoscale patterning sapphire substrate

A patterned sapphire and sapphire substrate technology, applied in chemical instruments and methods, nanotechnology, crystal growth, etc., can solve the problems of high cost of graphics production, expensive sub-micron masks, high cost, etc., to improve light extraction efficiency, The effect of improving crystal quality and increasing the probability of ejection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1. The all-wet chemical preparation method of nanoscale patterned sapphire substrate and its effect verification

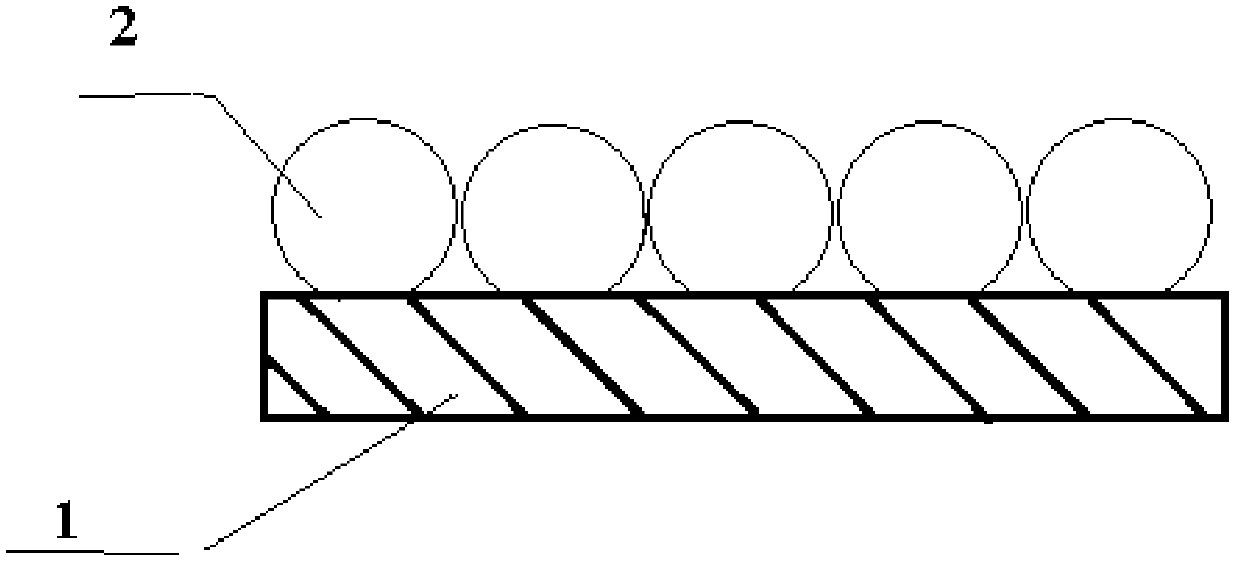

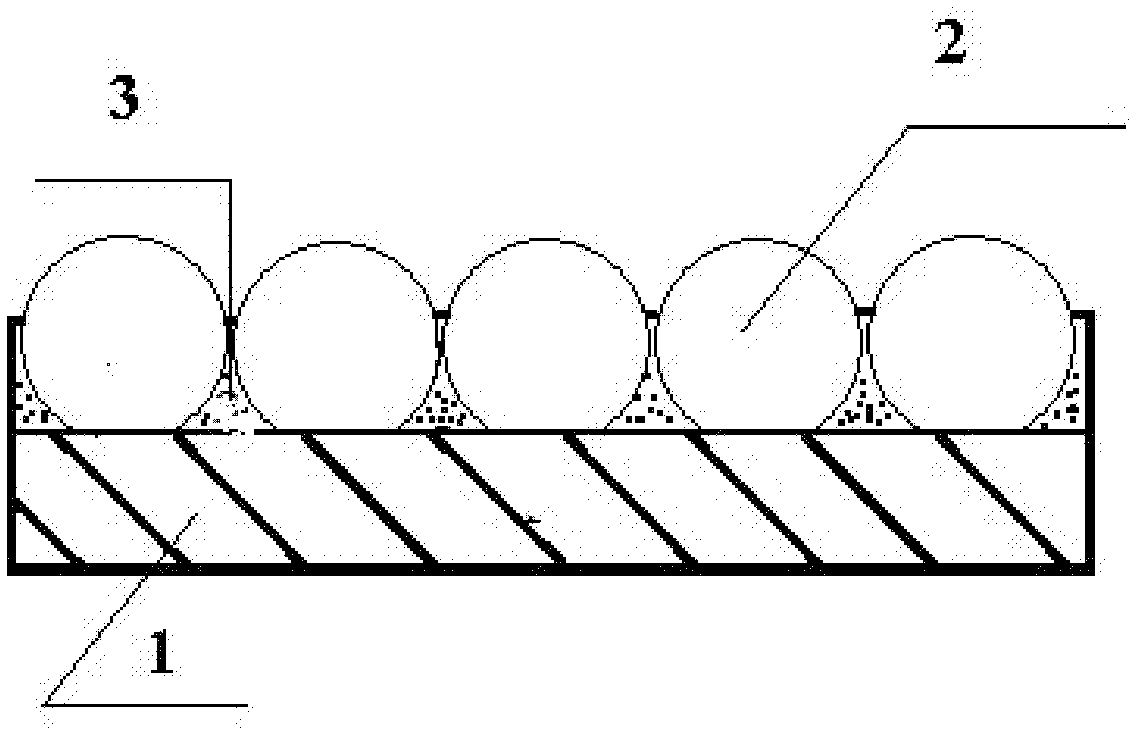

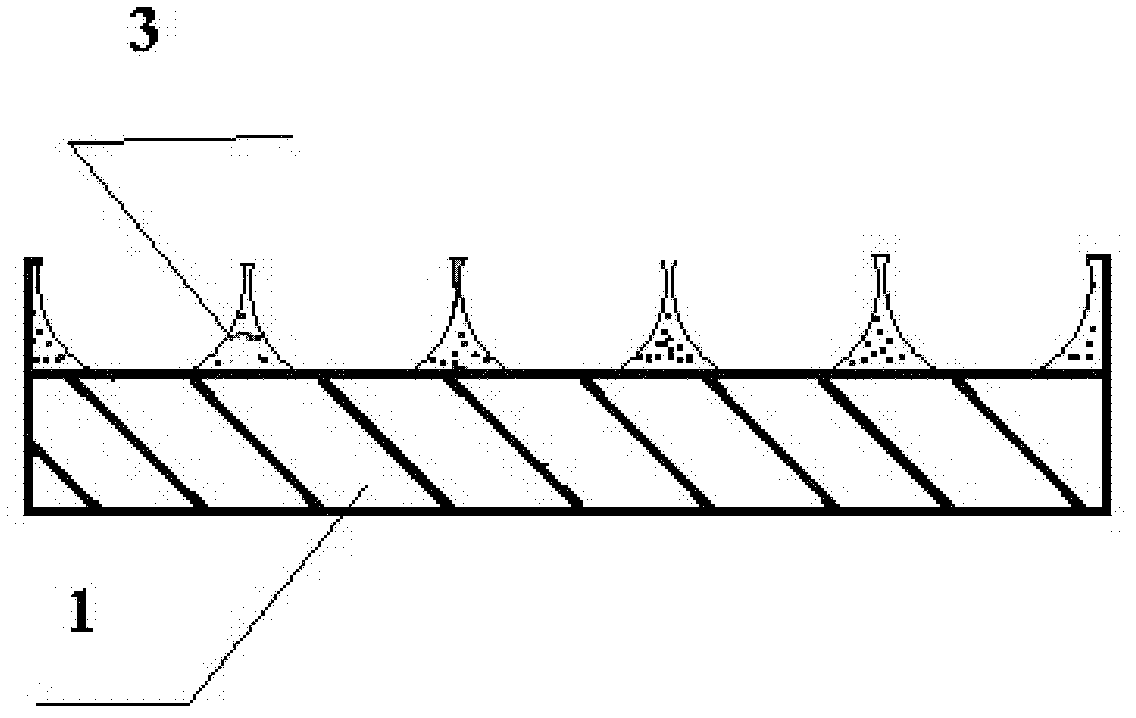

[0033] 1. Preparation of nanoscale patterned sapphire substrate by all-wet chemical preparation method

[0034] The specific steps of the all-wet chemical preparation method of nanoscale patterned sapphire substrate are as follows:

[0035] 1. Preparation of the colloidal microsphere mixture: under nitrogen protection, with 250ml deionized water as the dispersion medium, add 25ml styrene monomer and 0.125g potassium persulfate initiator into a 500ml tank equipped with a mechanical stirrer and a reflux condenser In a three-necked flask, polystyrene colloids were synthesized by conventional soap-free emulsion polymerization in a water bath at 60°C, with a mechanical stirring speed of 350r / min. After 24 hours of reaction, the obtained particle size was 650nm, and the standard deviation of the particle size was 3%. Milky white emulsion of polystyrene c...

Embodiment 2

[0041] Example 2, the all-wet chemical preparation method of nanoscale patterned sapphire substrate and its effect verification

[0042] 1. Preparation of nanoscale patterned sapphire substrate by all-wet chemical preparation method

[0043] The specific steps of the all-wet chemical preparation method of nanoscale patterned sapphire substrate are as follows:

[0044] 1. Preparation of colloidal microsphere mixture: under nitrogen protection, with 250ml deionized water as the dispersion medium, 20ml methyl acrylate monomer and 0.125g potassium persulfate initiator were added to a tank equipped with a mechanical stirrer and a reflux condenser In a 500ml three-necked flask, the methyl acrylate colloid was synthesized by conventional soap-free emulsion polymerization in a water bath at 60°C. The mechanical stirring speed was 350r / min. After 24 hours of reaction, the obtained particle size was 480nm, and the standard deviation of the particle size was 3%. milky white emulsion of ...

Embodiment 3

[0050] Example 3, the all-wet chemical preparation method of nanoscale patterned sapphire substrate and its effect verification

[0051] 1. Preparation of nanoscale patterned sapphire substrate by all-wet chemical preparation method

[0052] The specific steps of the all-wet chemical preparation method of nanoscale patterned sapphire substrate are as follows:

[0053] 1. Preparation of colloidal microsphere mixed solution: under nitrogen protection, with 250ml deionized water as the dispersion medium, 25ml methyl methacrylate monomer and 0.125g benzoyl peroxide initiator were added to a machine equipped with a mechanical stirrer and In a 500ml three-necked flask with a reflux condenser, the methyl methacrylate colloid was synthesized by conventional soap-free emulsion polymerization in a water bath at 60°C, with a mechanical stirring speed of 350r / min. After 24 hours of reaction, the obtained particle size was 520nm. Milky white emulsion of polymethyl methacrylate colloidal m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com