Nitrogen polar surface GaN material and homoepitaxial growth method

A nitrogen polar, epitaxial layer technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problem of increasing the background doping concentration of nitrogen polar GaN materials, hindering the migration ability and diffusion length of metal atoms, and increasing the growth process. Control difficulty and parasitic contamination to enhance migration capability and diffusion length, avoid short pauses and gaps, and reduce surface pit-like defect density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

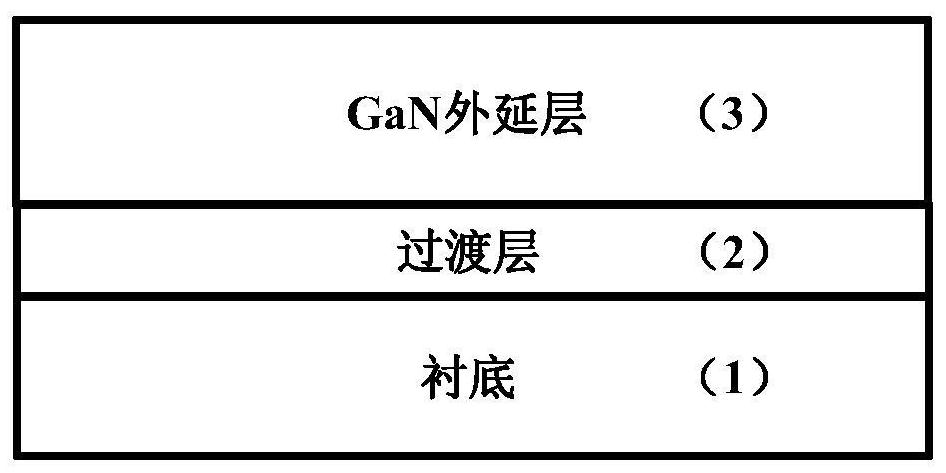

[0031] Example 1, the substrate is a non-beveled gallium nitride single crystal with a nitrogen polar surface, and the transition layer is In with a thickness of 10 nm. 0.17 Al 0.83 N, the epitaxial layer is a GaN material with a nitrogen polar surface of GaN.

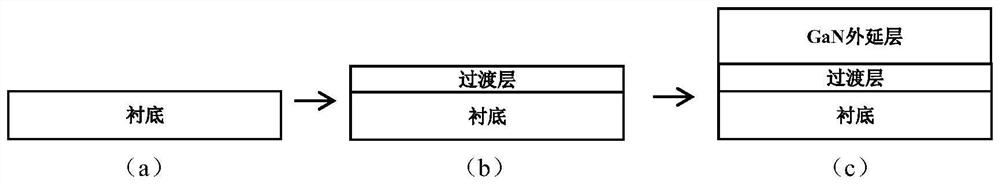

[0032] In step 1, a gallium nitride single crystal with a non-bevelled nitrogen polar surface is selected as the substrate, such as image 3 (a).

[0033] Step 2, epitaxy In 0.17 Al 0.83 N transition layers, such as image 3 (b).

[0034] Epitaxy of In with a thickness of 10 nm on a GaN single crystal substrate with a nitrogen polar surface using molecular beam epitaxy 0.17 Al 0.83 N transition layer.

[0035] Epitaxial In 0.17 Al 0.83 The process conditions used for the N transition layer are as follows: the temperature is 670°C, the flow rate of nitrogen gas is 2.3 sccm, and the equilibrium vapor pressure of the indium beam is 1.5×10 -7 Torr, the equilibrium vapor pressure of an aluminum beam is 2.3×10 -7...

Embodiment 2

[0039] Example 2, the substrate is a non-beveled gallium nitride single crystal with a nitrogen polar surface, and the transition layer is Sc with a thickness of 5 nm. 0.18 Al 0.82 N, the epitaxial layer is a GaN material with a nitrogen polar surface of GaN.

[0040] In step 1, a gallium nitride single crystal with a non-bevelled nitrogen polar surface is selected as the substrate, such as image 3 (a).

[0041] Step 2, using molecular beam epitaxy to deposit Sc 0.18 Al 0.82 N transition layers, such as image 3 (b).

[0042] The set temperature is 690°C, the nitrogen flow rate is 2.3 sccm, and the scandium beam equilibrium vapor pressure is 1.3×10 -8 Torr, the equilibrium vapor pressure of an aluminum beam is 2.0×10 -7 Torr, the process condition of nitrogen RF source power is 375W, using molecular beam epitaxy technology, depositing Sc with a thickness of 5nm on the nitrogen polar surface gallium nitride single crystal substrate 0.18 Al 0.82 N transition layer.

...

Embodiment 3

[0045] Example 3, the substrate is a non-beveled gallium nitride single crystal with a nitrogen polar surface, and the transition layer is a Y layer with a thickness of 1 nm. 0.11 Al 0.89 N, the epitaxial layer is a GaN material with a nitrogen polar surface of GaN.

[0046] In step A, a gallium nitride single crystal with a non-bevelled nitrogen polar surface is selected as the substrate, such as image 3 (a).

[0047] Step B, grow Y 0.11 Al 0.89 N transition layers, such as image 3 (b).

[0048] Using molecular beam epitaxy technology, at a temperature of 720°C, a nitrogen flow rate of 2.3 sccm, and an yttrium beam equilibrium vapor pressure of 1.0×10 -8 Torr, the equilibrium vapor pressure of an aluminum beam is 2.6×10 -7 Torr, under the process conditions of nitrogen RF source power of 375W, Y with a thickness of 1nm was grown on a non-beveled nitrogen polar GaN single crystal substrate 0.11 Al 0.89 N transition layer.

[0049] Step C, growing a GaN epitaxial la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com