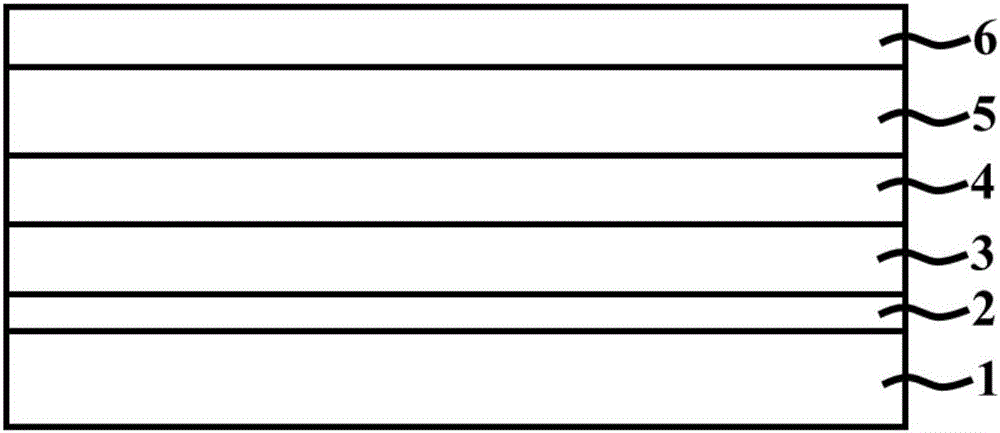

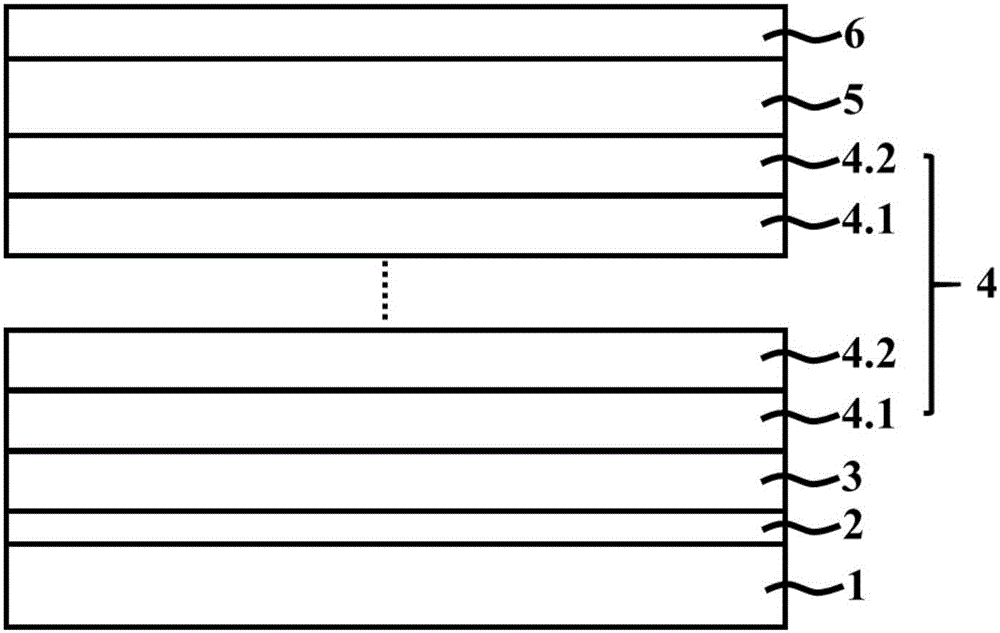

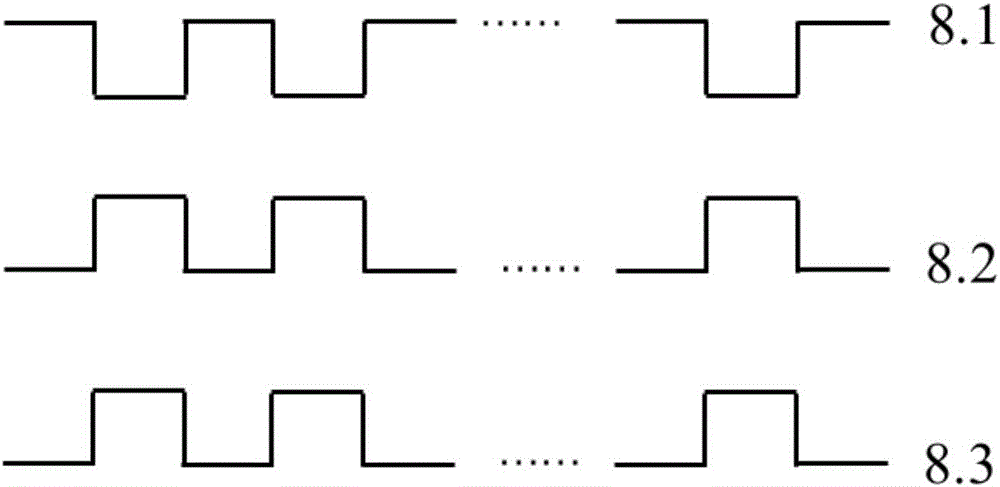

HEMT structure with modulated carbon-doped gallium nitride high-resistance layer and preparation method of structure

A high-resistance layer, gallium nitride technology, used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of deteriorating crystal quality, poor reliability and life, and high leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A method for preparing a HEMT structure with a modulated carbon-doped gallium nitride high resistance layer, the steps are as follows:

[0049] 1) Put the sapphire substrate 1 into the metal organic chemical vapor phase chemical deposition equipment (Veco K465 type), the temperature of the substrate sheet is raised to 1100°C, the pressure is 100mbar, and hydrogen gas is introduced to clean the substrate at high temperature and remove the lining. contamination of the bottom surface;

[0050] 2) The temperature of the substrate 1 is reduced to 550° C., the pressure is increased to 550 mbar, and ammonia gas, hydrogen gas and trimethylgallium are introduced, and the flow rates are 5 liters / minute, 22 liters / minute and 30 cc respectively, as described in step 1) A 30nm GaN nucleation layer 2 is grown on the substrate to provide crystal nuclei for subsequent GaN growth.

[0051] 3) Increase the temperature of the substrate with the GaN nucleation layer 2 in step 2 to 1080° C...

Embodiment 2

[0061] A method for preparing a HEMT structure with a modulated carbon-doped gallium nitride high resistance layer, the steps are as follows:

[0062] 1) Put the sapphire substrate 1 into the metal organic chemical vapor phase chemical deposition equipment (Veco K465 type), the temperature of the substrate sheet is raised to 1050°C, the pressure is 80mbar, and hydrogen gas is introduced to clean the substrate at high temperature and remove the lining. contamination of the bottom surface;

[0063] 2) The temperature of the substrate 1 is reduced to 530° C., the pressure is increased to 530 mbar, and ammonia gas, hydrogen gas and trimethylgallium are introduced, and the flow rates are 4 liters / minute, 18 liters / minute and 25 cc respectively, as described in step 1) A 25nm GaN nucleation layer 2 is grown on the substrate to provide crystal nuclei for subsequent GaN growth.

[0064] 3) Increase the temperature of the substrate with the GaN nucleation layer 2 in step 2) to 1050° C...

Embodiment 3

[0072] A method for preparing a HEMT structure with a modulated carbon-doped gallium nitride high resistance layer, the steps are as follows:

[0073] 1) Put the sapphire substrate 1 into the metal organic chemical vapor phase chemical deposition equipment (Veco K465 type), the temperature of the substrate sheet is raised to 1150°C, the pressure is 120mbar, and hydrogen gas is introduced to clean the substrate at high temperature and remove the lining. contamination of the bottom surface;

[0074] 2) The temperature of the substrate 1 is reduced to 570° C., the pressure is increased to 570 mbar, and ammonia gas, hydrogen gas and trimethylgallium are introduced, and the flow rates are 8 liters / minute, 25 liters / minute and 35 cc respectively, as described in step 1) A 35nm GaN nucleation layer 2 is grown on the substrate to provide crystal nuclei for subsequent GaN growth.

[0075] 3) Increase the temperature of the substrate with the GaN nucleation layer 2 in step 2) to 1100° C....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com