Structure for improving Schottky performance of grid electrode of gallium nitride based transistor in high electron mobility

A high electron mobility, gallium nitride-based technology, applied in the semiconductor field, can solve the problems of reducing the quality of the gate and gate Schottky junction of AlGaN/GaN HEMT devices and affecting the performance of AlGaN/GaN HEMT devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] Examples (see Figure 2-Figure 7 ):

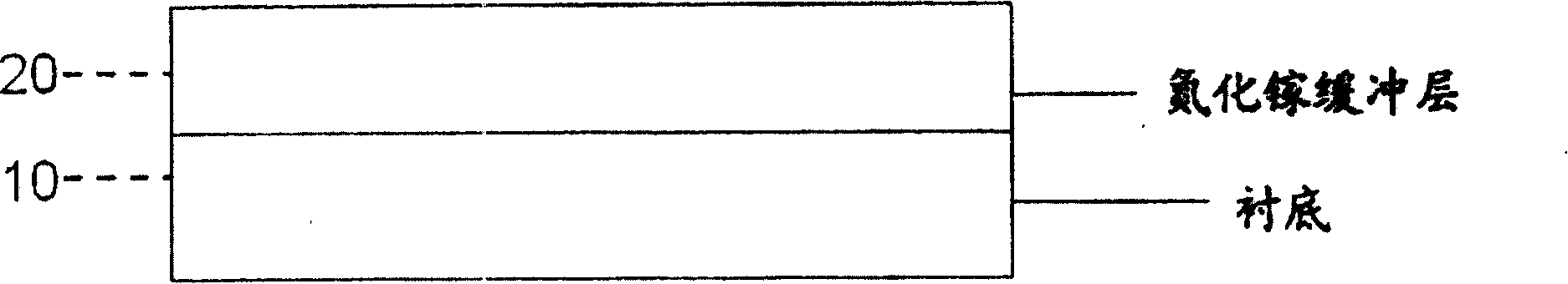

[0031] (1) First, a thicker high-resistance (semi-insulating) gallium nitride buffer layer 20 is grown on the (0001) crystal surface of the substrate sapphire 10 by molecular beam epitaxy technology, the growth temperature is 1050° C., and the growth thickness is 1.5-5 μm. ( figure 2 ) The high-resistance (semi-insulating) gallium nitride buffer layer 20 can be generated by methods such as ion implantation, doping, compensation, etc., and the main purpose is to reduce the leakage of the buffer layer of the current when the device is in operation, thus preventing the device from operating temperature rise. Performance deterioration improves device stability.

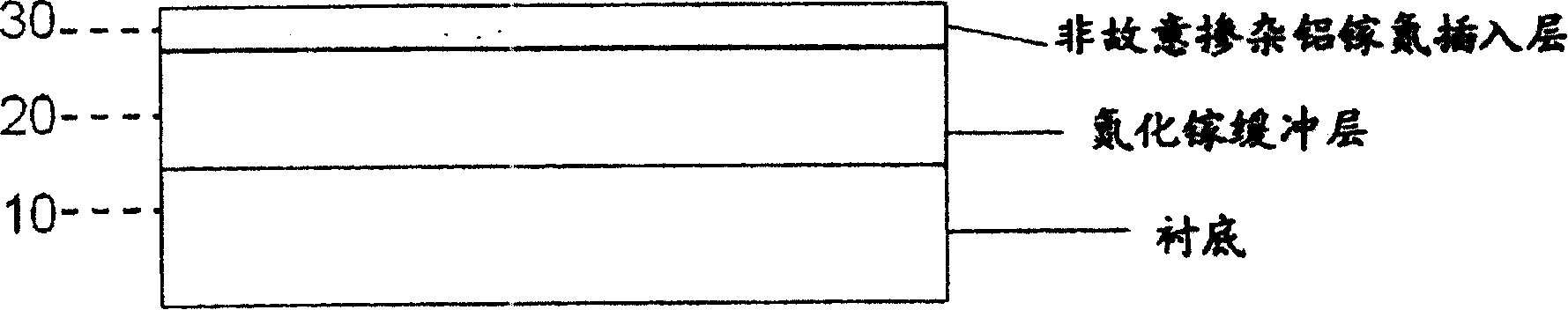

[0032] (2) Second, grow a thin layer of non-intentionally doped AlGaN (Al x Ga 1-x N, 0≤x≤1) the insertion layer 30 has a thickness of 1-10 nm, ( image 3 ) According to needs, the Al composition x of the unintentionally doped AlGaN insertion layer 30 can be changed betwe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com