III group nitride semiconductor LED based on plane structure and its preparing process

A technology for nitride semiconductors and light-emitting diodes, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of high manufacturing cost, difficulty in making diodes with large light-emitting area, and increased process cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

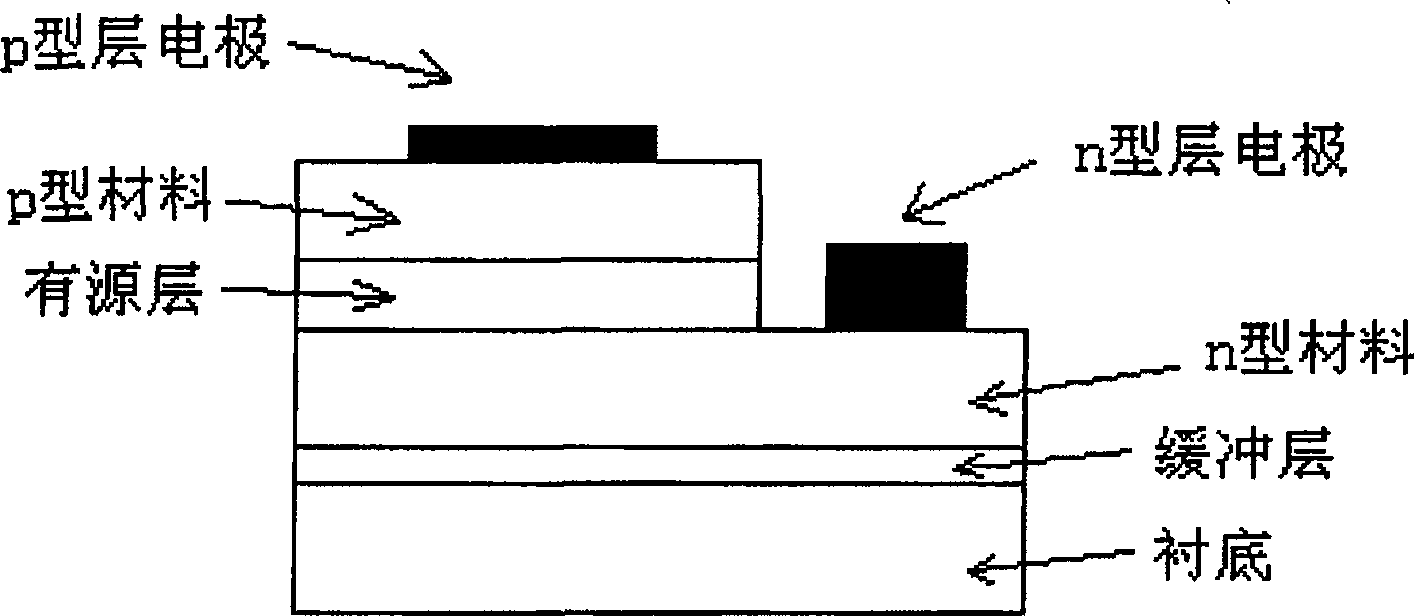

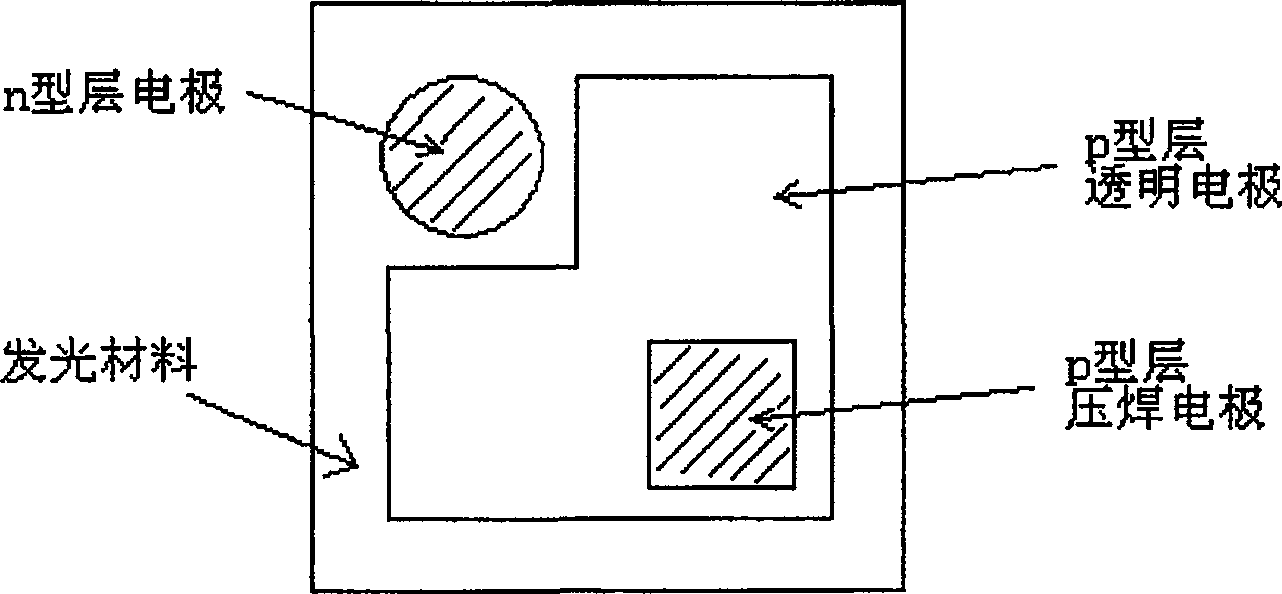

[0028] To further illustrate the content of the present invention, the present invention will be described in detail below in conjunction with the embodiments and accompanying drawings. Among them: see figure 1 and figure 2 As shown, the fabrication process of the usual vertical structure Group III nitride semiconductor light-emitting diode is:

[0029] 1) growing buffer layers, active light-emitting layers and contact layers based on group III nitride semiconductor materials on sapphire or silicon substrates by chemical vapor deposition;

[0030] 2) Expose the electrical contact area on the other side of the active area of the light-emitting diode by etching. figure 1 , figure 2 The middle finger engraves the electrical contact area of n-type material;

[0031] 3) Fabricate n-type layer and p-type layer electrodes in the electrical contact region for n-type and p-type materials respectively by using semiconductor process technology.

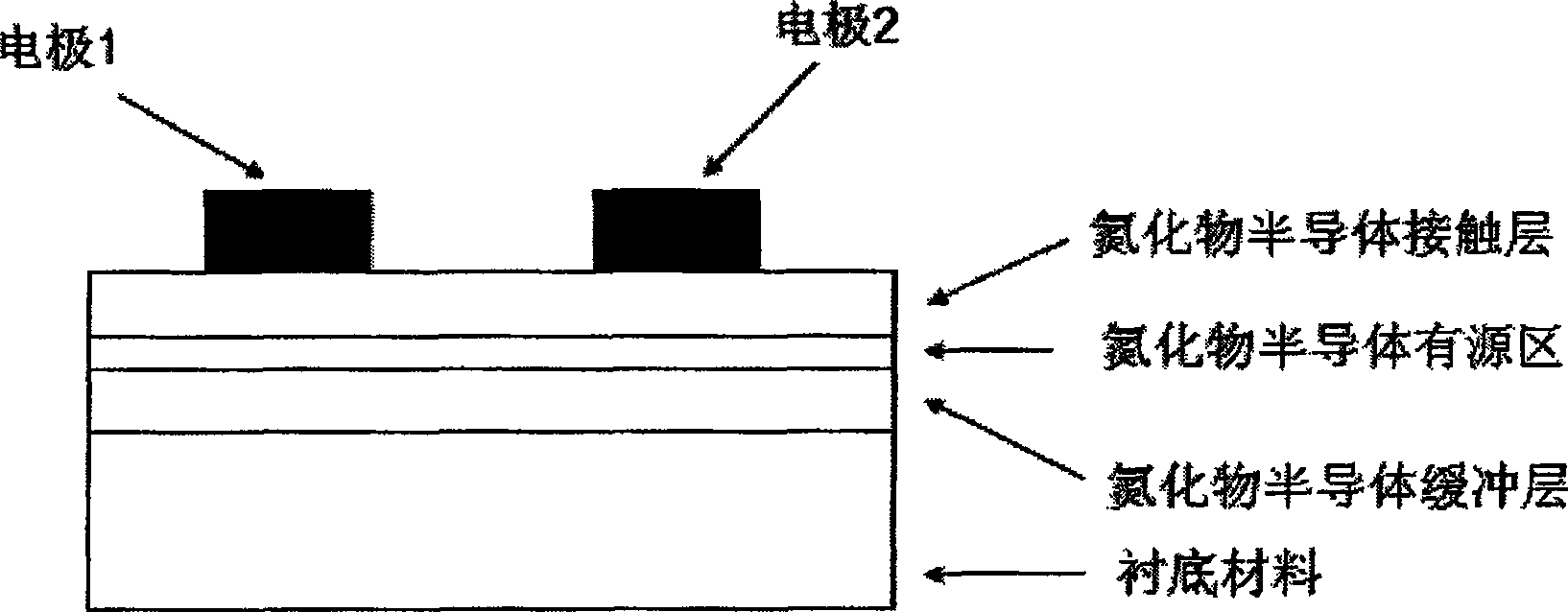

[0032] see image 3 and Fig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com