Highly-active soldering flux suitable for stepped brazing of magnesium-aluminum alloy and preparation method of highly-active soldering flux

A magnesium-aluminum alloy, high-activity technology, applied in the direction of welding equipment, metal processing equipment, welding medium, etc., can solve the problems of unguaranteed brazing quality and loss of activity, etc., and achieve the effect of precise composition of finished products, simple process and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with embodiment the present invention is described in further detail.

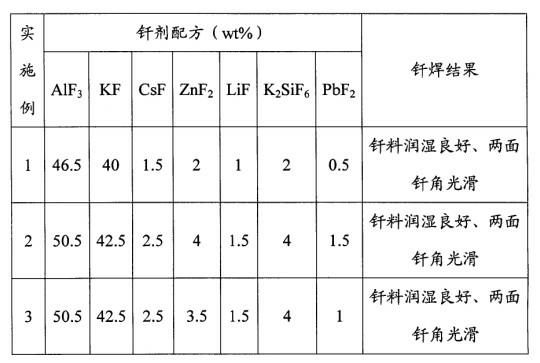

[0017] The brazing flux of the present invention takes analytically pure aluminum fluoride, potassium fluoride, cesium fluoride, zinc fluoride, lithium fluoride, potassium fluorosilicate and fluorine respectively at the mass percentages described in Examples 1-3 in Table 1. Lead powder, weighed with an electronic balance and mixed evenly, added to a plastic beaker and made into a paste with distilled water, the weight ratio of distilled water to powder was 3:4, heated in a water bath at 50°C, and used a magnetic stirrer Stir for 2 hours. After the stirring is completed, pour it into a tray covered with aluminum foil, put it into a heating furnace at 250°C and dry it for 2 hours, and grind the dried brazing flux into a white powder in a mortar, which is the brazing flux of the present invention. With HL400 aluminum-silicon-copper filler metal, the 6063 aluminum alloy was brazed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com