LED UV-cured black ink, preparation method and application thereof

A technology of black ink and photocurable resin, which is applied in the field of ink, can solve the problems of affecting the health of employees, large VOC emissions, and low production efficiency, and achieve the effects of low power consumption, reduced VOC emissions, and improved utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] According to another aspect of the present invention, also provide a kind of preparation method of the black ink of LED UV curing, comprise the following steps:

[0032] While stirring, add self-extinction photocurable resin, acrylic modified rosin resin, UV monofunctional monomer, UV multifunctional monomer and mix evenly, add photoinitiator and stir until completely dissolved, then add inorganic black pigment and carbon black and stir Homogenize, disperse, obtain a mixture;

[0033] Grind the mixture to a fineness of ≤5 μm, add light guide powder, photochromic pigment, leveling agent and defoamer to the mixture in turn while stirring, mix evenly, and disperse to obtain LED UV-curable black ink.

[0034] The preparation method of LED UV-cured black ink of the present invention creatively adopts LED UV curing technology, combined with photochromic and light-guiding technology, and grinds the mixture to a fineness of ≤5 μm, so that the particle size of each component is ...

Embodiment 1

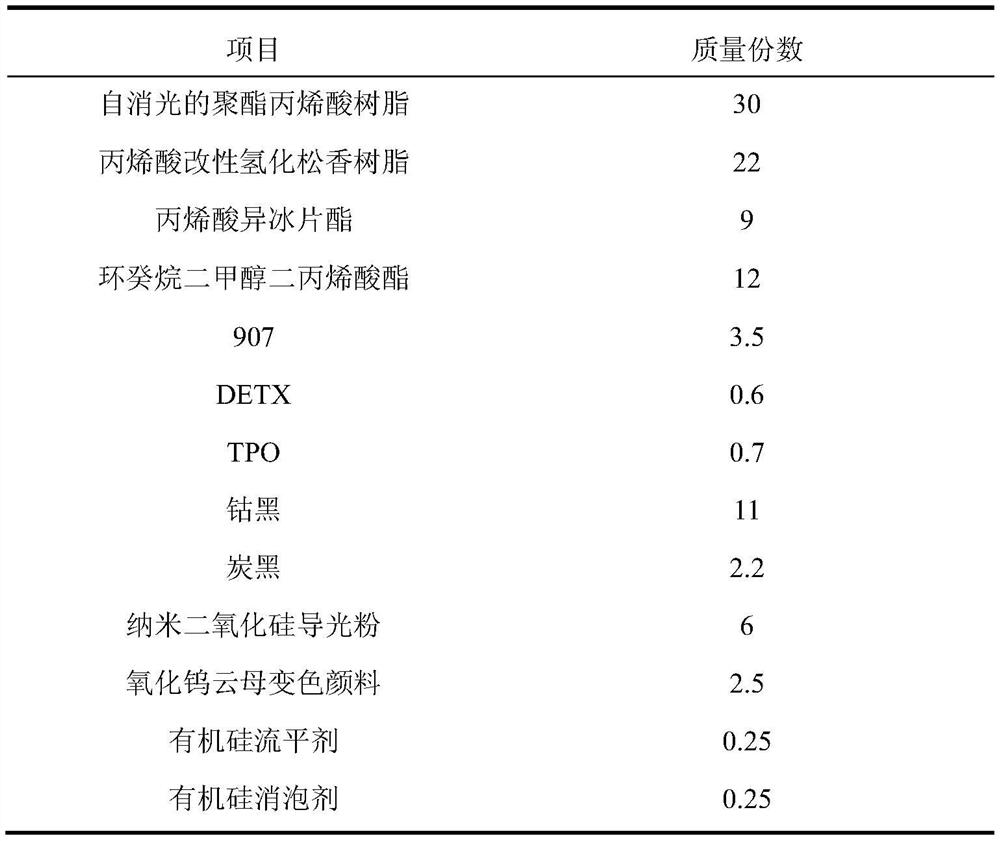

[0041] The addition amount of each component of LED UV-cured black ink is shown in Table 1:

[0042] Table 1 Addition amount of each component of black ink cured by LED UV

[0043]

[0044] The rotation speed is 1000 rpm, while stirring, add self-dulling polyester acrylic resin, acrylic modified hydrogenated rosin resin, isobornyl acrylate, cyclodecane dimethanol diacrylate, and disperse evenly. Add 907, DETX, TPO Stir until completely dissolved, then add cobalt black and carbon black and stir evenly, then disperse at a speed of 2000 rpm for 15 minutes to obtain a mixture, grind the mixture on a three-roller machine to a fineness of ≤5 μm, and stir at a speed of 1000 rpm While adding nano-silica light guide powder, tungsten oxide mica color-changing pigment, silicone leveling agent, and silicone defoamer in sequence, mix evenly. After mixing evenly, disperse at 2000 rpm for 25 minutes to obtain LED UV curing. black ink.

[0045] Use 350-mesh screen and 80° squeegee to scr...

Embodiment 2

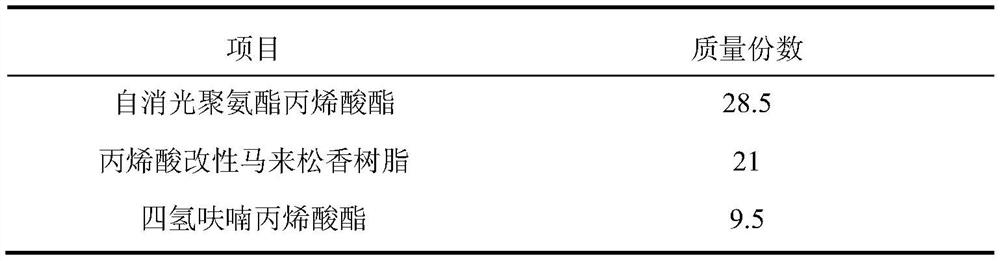

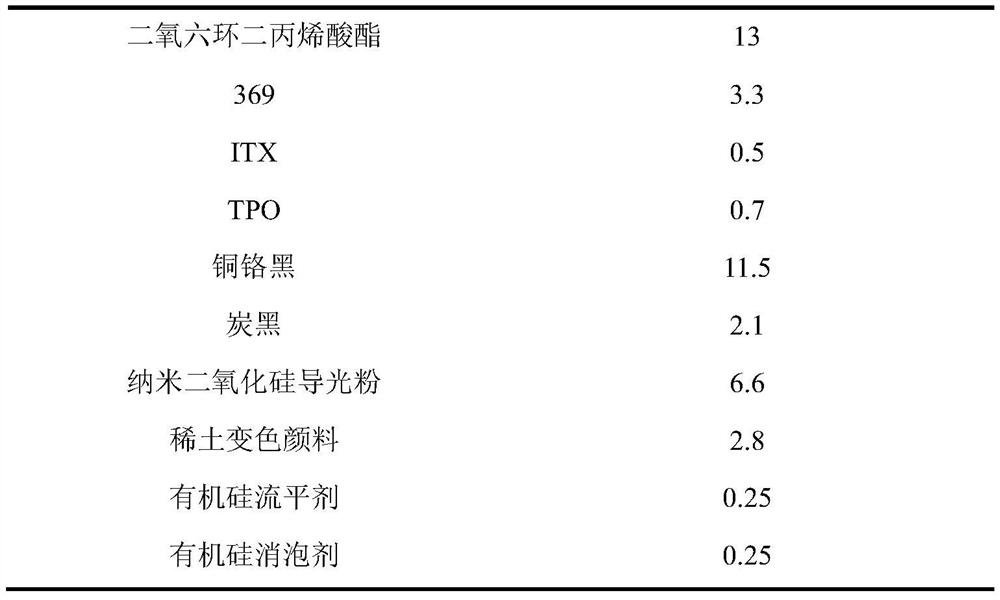

[0047] The addition amount of each component of LED UV-cured black ink is shown in Table 2:

[0048] Table 2 Addition amount of each component of black ink cured by LED UV

[0049]

[0050]

[0051] The rotation speed is 1000 rpm, and while stirring, add self-dull polyurethane acrylate, acrylic modified maleic rosin resin, tetrahydrofuran acrylate, and dioxane diacrylate in sequence, and disperse evenly. Add 369, ITX, TPO, and stir until Dissolve completely, then add copper chromium black and carbon black and stir evenly, then disperse at 2000 rpm for 15 minutes to obtain a mixture, grind the mixture on a three-roller machine to a fineness ≤ 5 μm, and stir at a speed of 1000 rpm Add nano-silica light guide powder, rare earth color-changing pigment, silicone leveling agent, and silicone defoamer in sequence and mix evenly. After mixing evenly, disperse at a speed of 2000 rpm for 25 minutes to obtain LED UV-cured black ink .

[0052] Use 350-mesh screen and 80° squeegee ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com