Reducer shell polishing equipment with robot

A reducer and robot technology, which is applied in the direction of grinding/polishing equipment, metal processing equipment, grinding machine parts, etc., can solve the harsh environment of workers' processing, cannot meet the needs of production and processing, and cannot achieve the follow-up of strength Multi-angle and other issues, to achieve the effect of improving grinding accuracy and finished product quality, reducing labor costs and error rates, and improving grinding efficiency and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

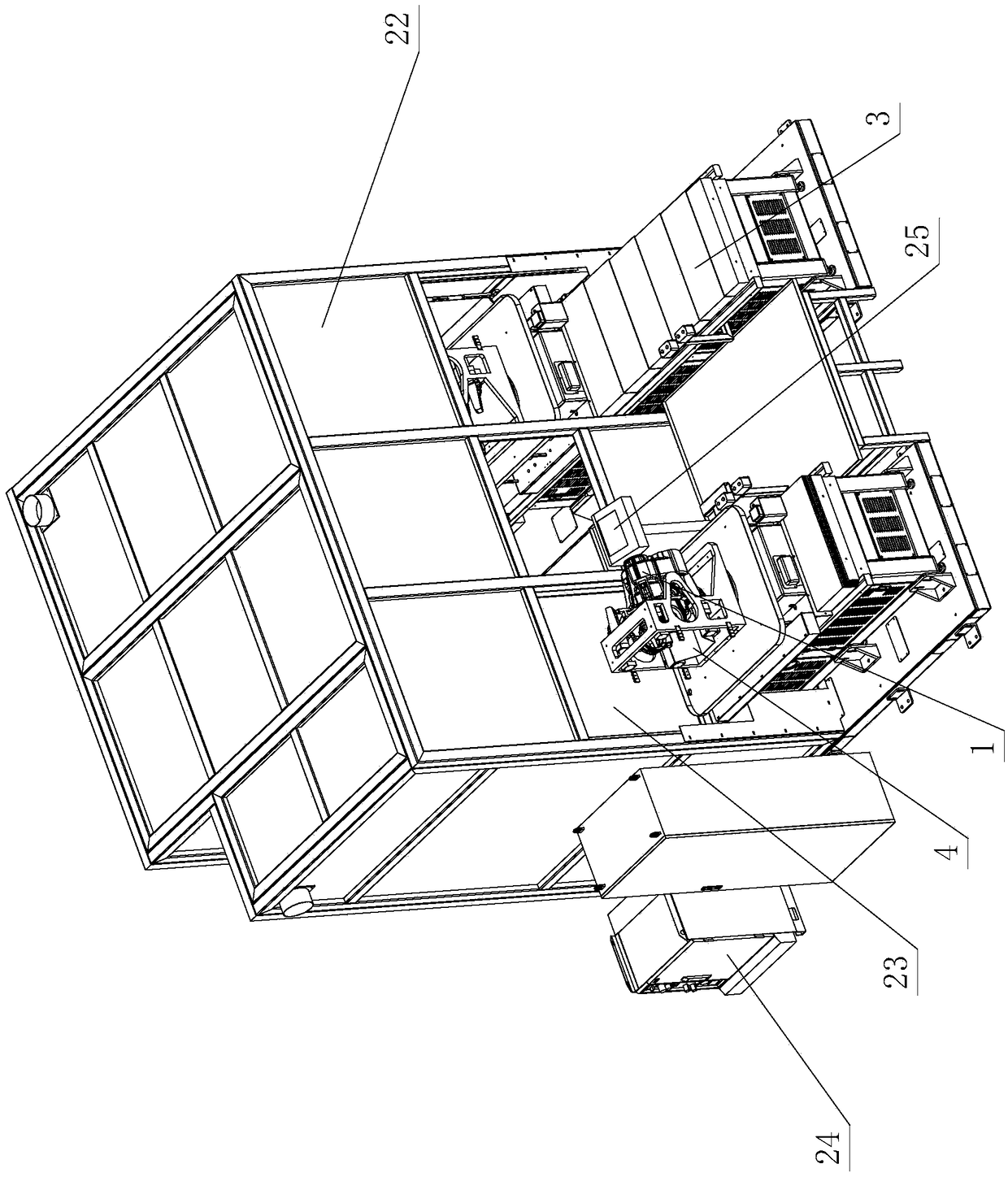

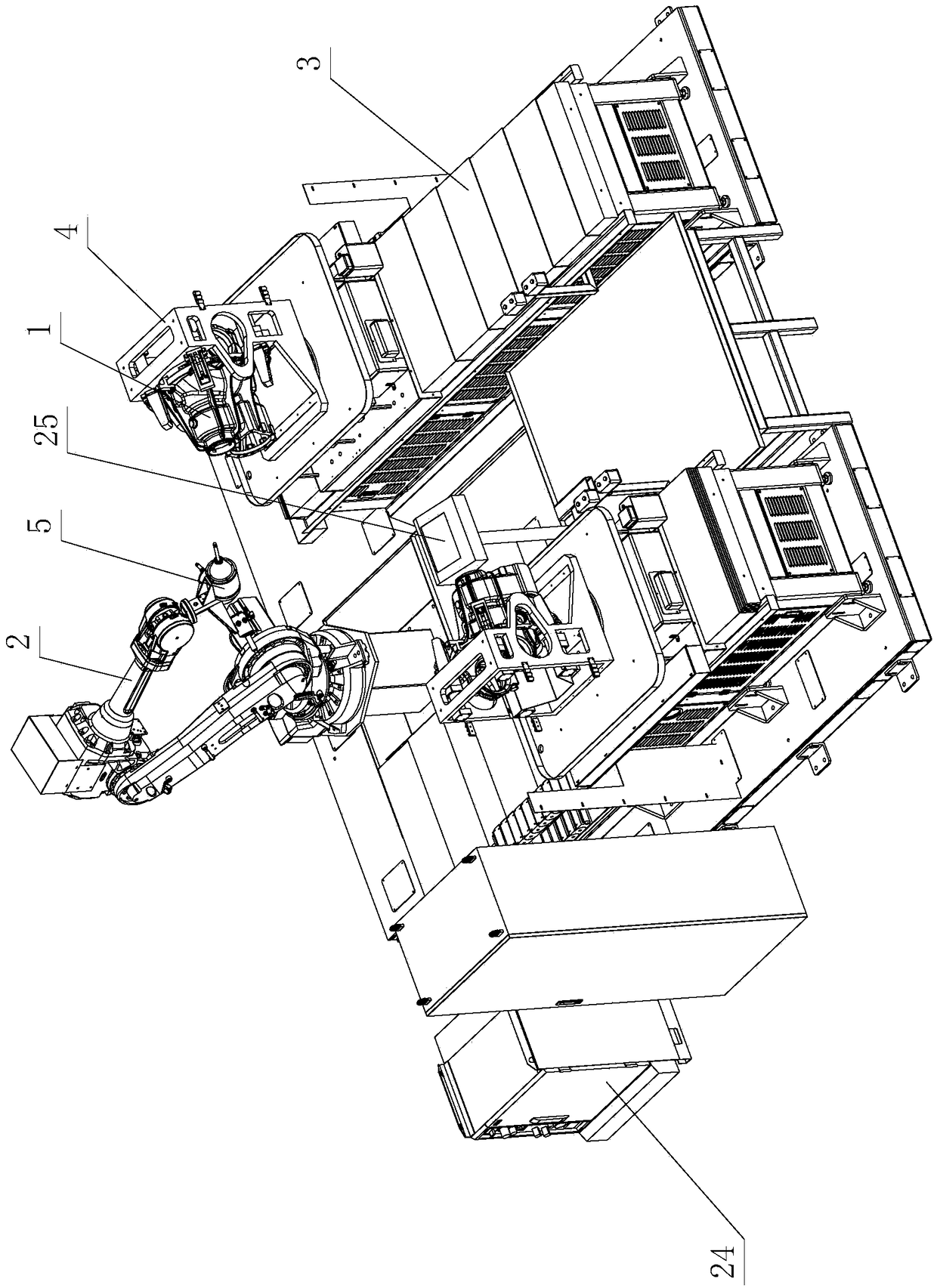

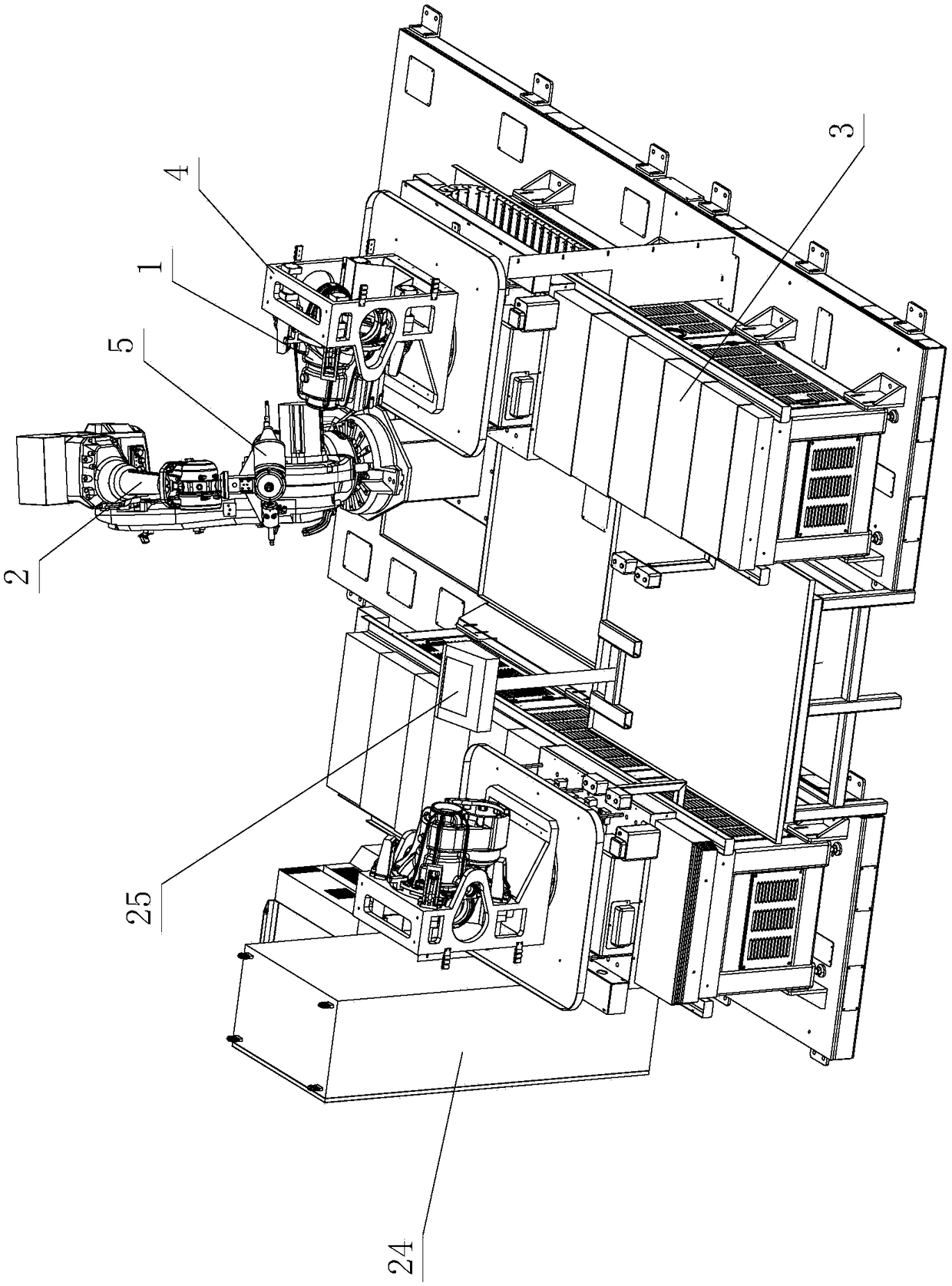

[0026] see figure 1 - Figure 7 , the reducer shell grinding equipment with a robot, including a workpiece to be polished 1, a six-axis robot 2 and a loading and unloading delivery platform 3, is characterized in that: there are two loading and unloading delivery platforms 3, and the two loading and unloading delivery platforms 3 A clamp assembly 4 is respectively provided, and the clamp assembly 4 slides back and forth on the loading and unloading conveying platform 3, and forms a loading and unloading station and a grinding station; the six-axis robot 2 is arranged between two loading and unloading conveying platforms 3, And there are three rotating and floating grinding assemblies 5 arranged on it; the workpiece 1 to be polished is fed to the clamp assembly 4 through the loading and unloading station, and slides to the grinding station through the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com