Conductive polypropylene material and preparation method thereof

A polypropylene material and polypropylene technology are applied in the field of conductive polypropylene materials and their preparation, and achieve the effects of avoiding vacuum opening, reducing elongation at break, and increasing external lubricity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

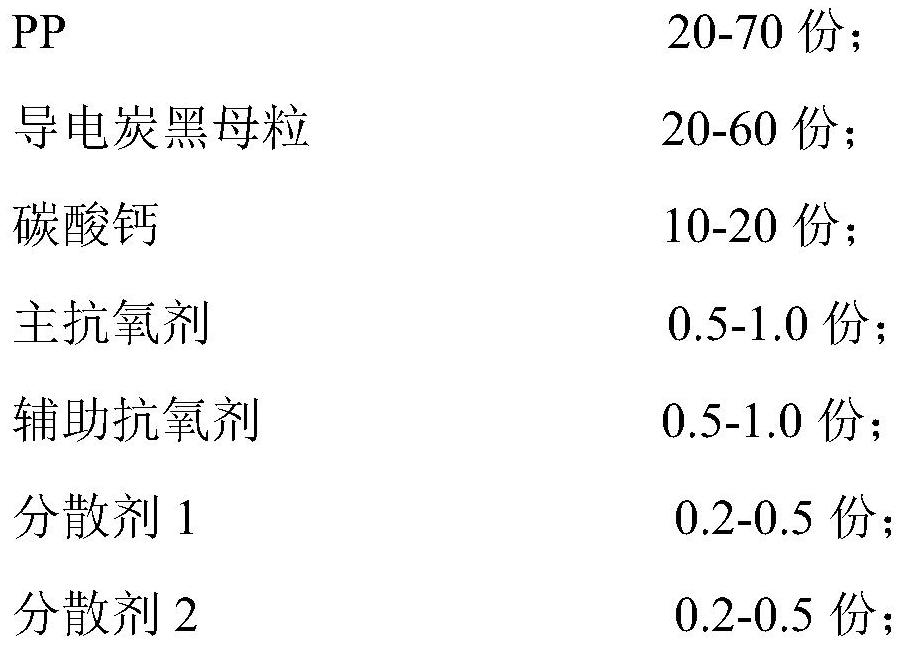

Method used

Image

Examples

Embodiment 1

[0036] (1) Put 0.2 parts of white oil and 10 parts of calcium carbonate into the high-mixer, and mix at 80-90℃ for 3 minutes;

[0037] (2) Cool the high-mixer to room temperature, add 70 parts of PP, 20 parts of conductive carbon black masterbatch, 0.5 parts of antioxidant 1010, 0.5 parts of antioxidant 168, and 0.2 parts of erucamide; continue mixing for 3 minutes;

[0038] (3) The mixture is added to a twin-screw extruder with a temperature of 180-220°C in each zone for extrusion and granulation to obtain a conductive polypropylene material.

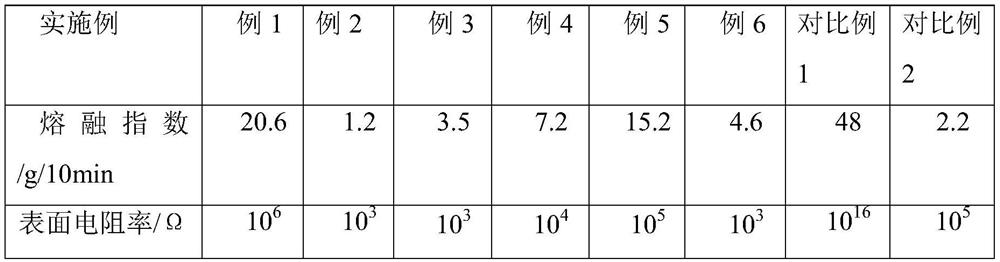

[0039] The performance test results are shown in Table 1.

Embodiment 2

[0041] (1) Put 0.35 parts of polyethylene wax and 20 parts of calcium carbonate into the high-mixer, and mix at 80-90°C for 8 minutes;

[0042] (2) Cool the high-mixer to room temperature, add 20 parts of PP, 60 parts of conductive carbon black masterbatch, 1.0 part of antioxidant 1010, 1.0 part of antioxidant 168, and 0.5 part of silicone powder; continue mixing for 8 minutes;

[0043] (3) Add the mixture into a twin-screw extruder with a temperature of 180-220°C in each zone for extrusion granulation to obtain conductive polypropylene material.

[0044] The performance test results are shown in Table 1.

Embodiment 3

[0046] (1) Put 0.5 part of white oil and 30 parts of calcium carbonate into the high mixer, and mix at 80-90℃ for 5min;

[0047] (2) Cool the high-mixer to room temperature, add 20 parts of PP, 50 parts of conductive carbon black masterbatch, 10100.7 parts of antioxidant, 168 0.7 parts of antioxidant, and 0.4 parts of erucamide; continue mixing for 6 minutes;

[0048] (3) The mixture is added to a twin-screw extruder with a temperature of 180-220°C in each zone for extrusion and granulation to obtain a conductive polypropylene material.

[0049] The performance test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com