Pier head height control method for automatic drilling and riveting machine

An automatic drilling and riveting machine, a highly controlled technology, applied in the field of mechanical drilling and riveting, can solve the problems of poor working environment for workers, unstable product quality, low production efficiency, etc., to improve the processing environment, enhance stability, and reduce labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to describe the present invention more specifically, the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

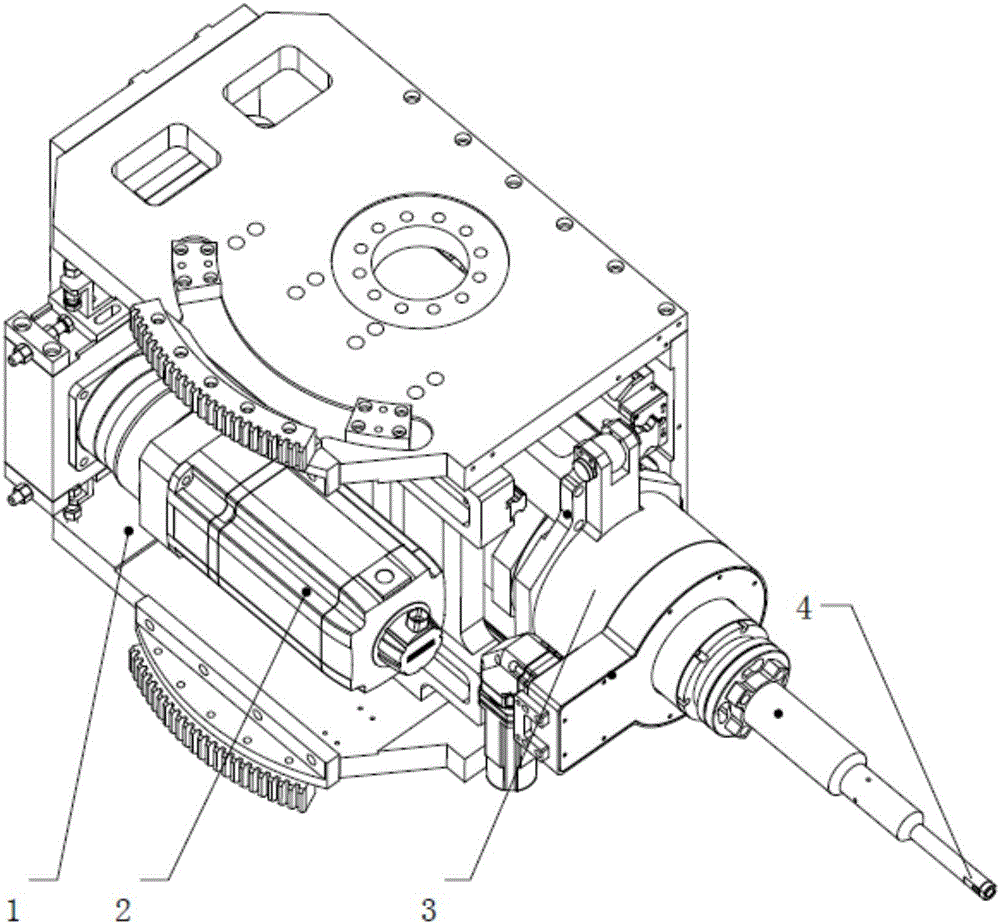

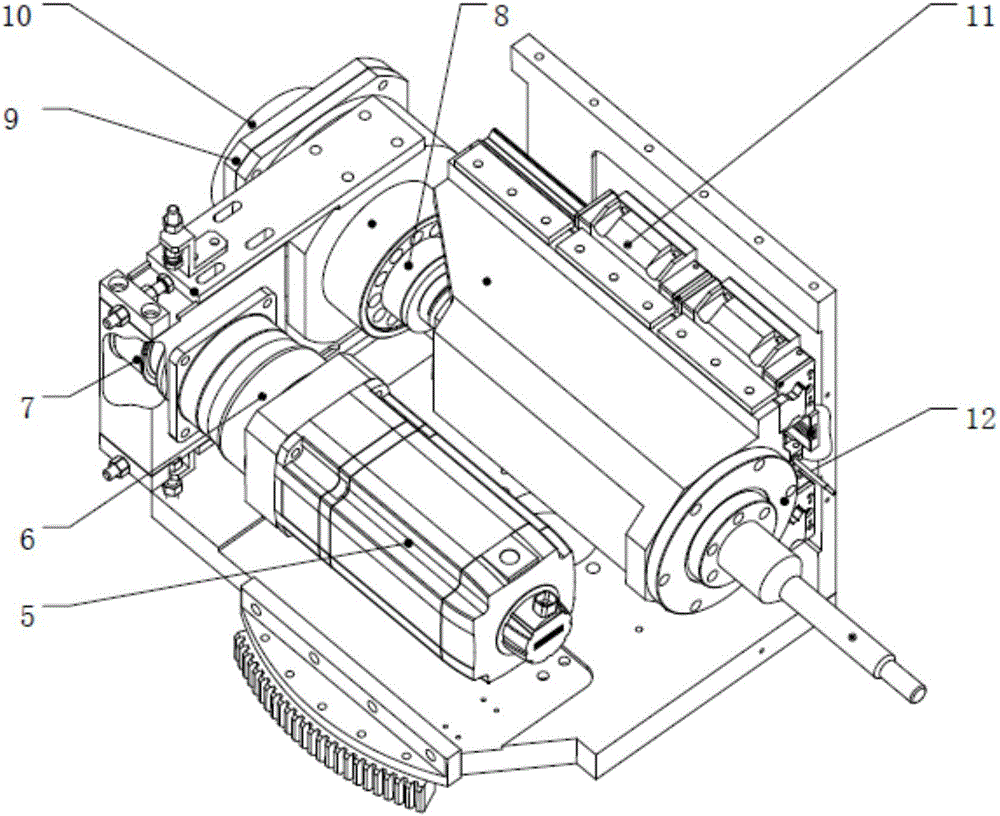

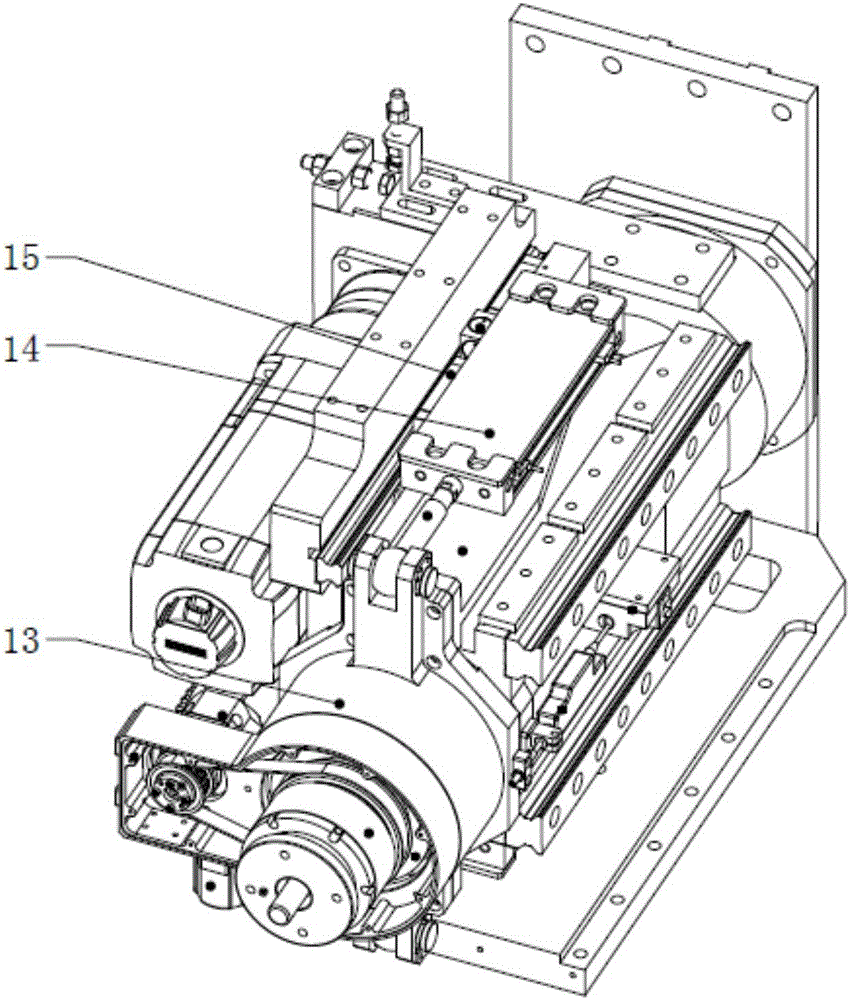

[0028] Such as Figure 1~4 As shown, the system mainly includes four components of a base (1), a pier tightening drive module (2), a bush pressing module (3) and a riveting head (4). The tightening drive module (2) is mainly composed of the tightening drive motor (5), the tightening reducer (6), the synchronous belt pulley pair (7), the tightening ball screw nut pair (8), and the tightening force sensor mounting plate (9), pier tightening force sensor (10), pier tight guide rail slider pair (11) and length gauge (12); the bush pressing module (3) is mainly composed of bush base (13), cylinder (14) , bushing guide rail slide block pair (15) and bushing (16) are formed; Pressure riveting head (4) is mainly made up of pressure riveting ejector pin (17) and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com