High trans-1,4-polyisoprene modified by oil-extended high vinyl polybutadiene rubber by molybdenum catalyst system

A high-vinyl polybutadiene and polyisoprene technology, applied in the field of rubber processing, can solve the problems of poor TPI processing performance, poor wet skid resistance, poor cold resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] raw material

[0013] High trans-1,4-polyisoprene (TPI)

[0014] It is prepared by catalyzing the polymerization of isoprene with a supported titanium catalyst, etc., and the content of trans-1,4-structure is ≥98%.

[0015] Oil-filled molybdenum-based high-vinyl polybutadiene rubber, using molybdenum-based catalysts to synthesize high Mooney base rubber, vinyl content = 82 ML 1+4 100℃=89, high aromatic oil oil extension is 37.5 parts, oil-extended rubber ML 1+4 100°C=47.

[0016] Other processing aids are common commercial products.

[0017] And glue preparation process

[0018] First plasticize TPI on the open mill, and then add oil-extended HVBR after TPI is fully plasticized. After the rubber is mixed evenly, add zinc oxide, stearic acid, anti-aging agent, carbon black, process oil, sulfur and accelerator in turn, and then release the film after 4-6 times of thinning.

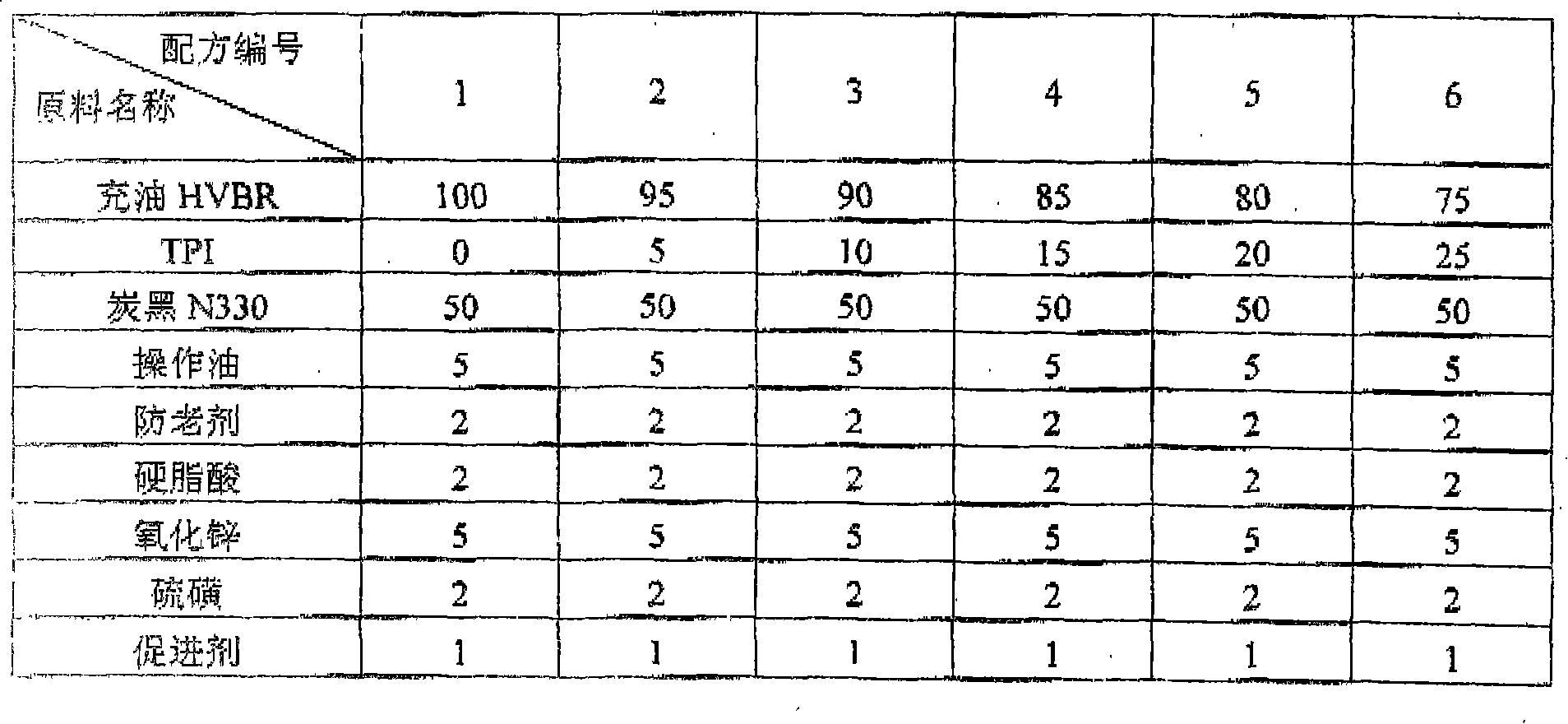

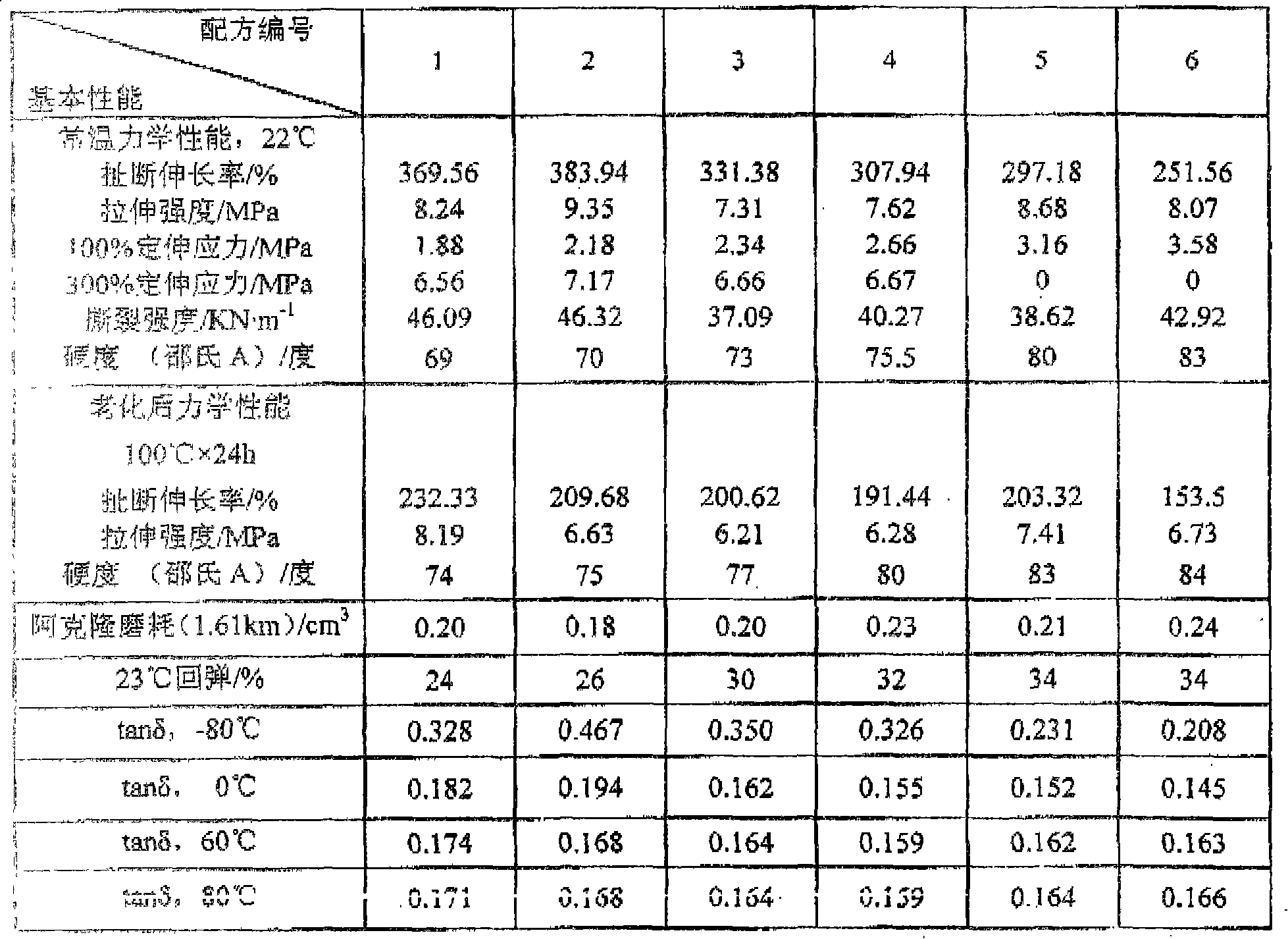

[0019] Table 1 below shows the formulas of 6 examples of the present invention, and Ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com