Composite insulated solid-sealed pole and production method thereof

A technology of solid-sealed poles and composite insulation, which is applied in the direction of high-voltage air circuit breakers, electrical components, electric switches, etc., can solve problems such as hidden dangers of insulation breakdown of solid-sealed poles, broken ceramic layers, etc., to improve the external insulation level, Improve the cushioning effect and avoid the effect of straight line breakdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

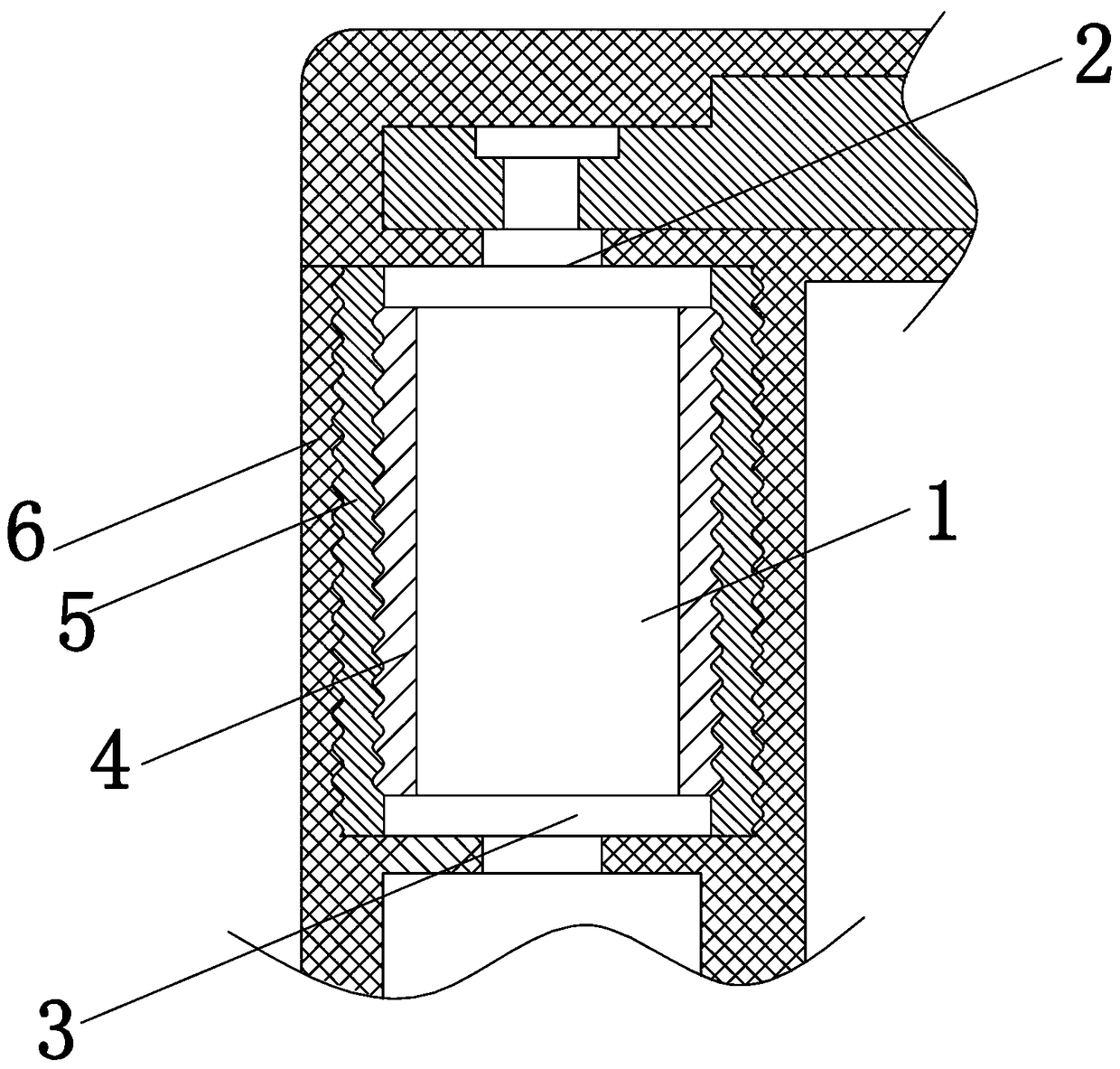

[0014] like figure 1 As shown, the composite insulated solid-sealed pole provided in this embodiment includes a vacuum interrupter 1, and a static end cover 2 and a moving end cover 3 are respectively arranged at both ends of the vacuum interrupter 1. The surface of the chamber 1 is provided with a ceramic insulating layer 4, the outside of the ceramic insulating layer 4 is coated with a silica gel layer 5, and the outside of the silica gel layer 5 is coated with an epoxy resin 6, wherein the ceramic insulating layer 4 and the silica gel layer 5 The contact interface is an annular corrugated surface, and the contact interface between the silicone layer 5 and the epoxy resin 6 is also an annular corrugated surface.

[0015] The distance between the crest and the trough of the annular corrugated surface is 3-4mm, and the distance between two crests is 10-12mm.

[0016] A production method for a composite insulating solid-sealed pole, comprising the following steps: mixing the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com