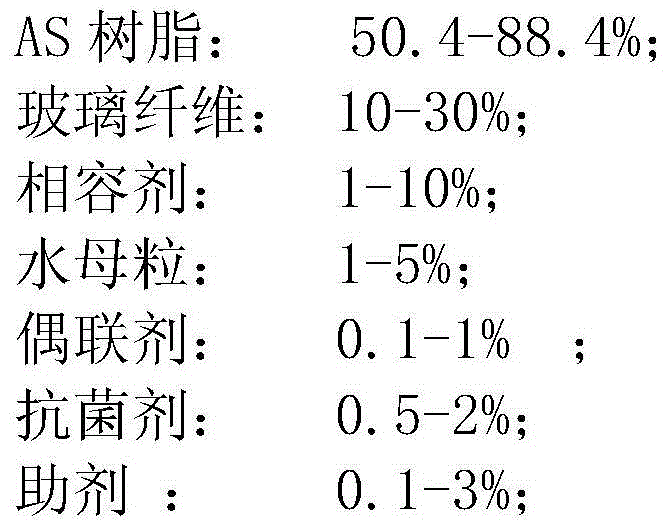

Low-odor antibacterial glass-fiber-reinforced AS (acrylonitrile-styrene) composition and preparation method thereof

A low-odor and composition technology, applied in the field of modified plastics, can solve the problems of poor composite material strength, toughness, heat resistance and other properties, increase glass fiber impregnation treatment steps, increase manufacturing costs and other problems, achieve excellent antibacterial effect, The effect of improving mechanical properties and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

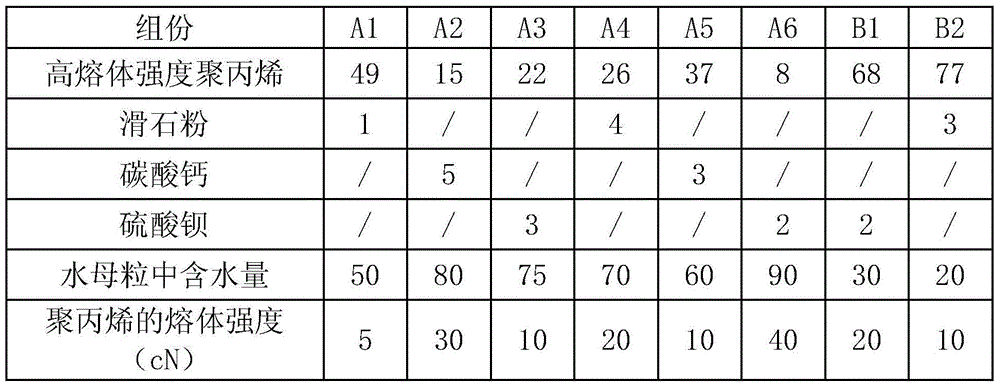

[0053] The present invention provides embodiment 1-6 and comparative example 1-6, and the preparation method of embodiment and comparative example is identical, and concrete steps are as follows:

[0054] S1, the preparation method of jellyfish grain, comprises the steps:

[0055] (1) The weight percentages listed in the following table 1 are weighed respectively, high melt strength polypropylene, talcum powder, calcium carbonate and barium sulfate; high melt strength polypropylene and mineral filler are fully mixed according to the proportioning, Extrude the strip mixture in the extruder, then chop the strip mixture into pre-expanded particles;

[0056] (2) Using water as a foaming agent, foaming the pre-expanded particles to prepare expanded polypropylene with high melt strength;

[0057] (3) Mix high-melt-strength foamed polypropylene and water in a high-speed mixer for 5-10 minutes to prepare jellyfish particles with the water content shown in Table 1, and release them fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com